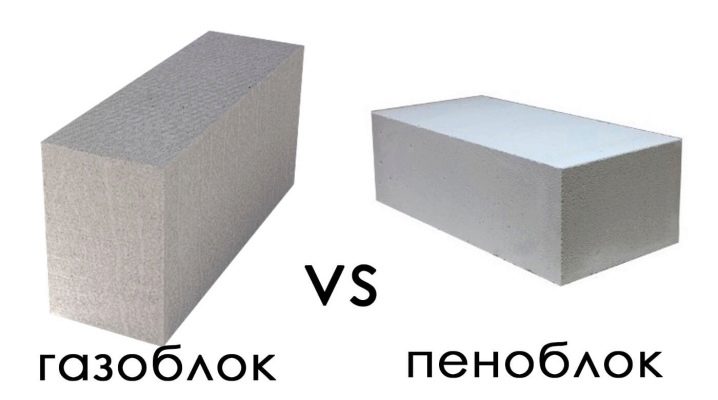

Gas-block or foam-block: what is the difference and what is better?

The modern market has literally enslaved such building materials as foam block and gas block. Many consumers are sure that the indicated names belong to the same product with its own pros and cons. But in fact, these are different building materials, which have quite a lot of differences. Today we will figure out what makes them differ from each other and determine which is better - a gas block or a foam block.

Characteristic

Foam concrete, aerated concrete and foam concrete blocks today are in great demand. Houses built from them are very common. The demand for such building materials due to their affordable cost and good performance.In addition, it should be noted that from the listed blocks it is possible to build not only residential buildings, but also various outbuildings.

To answer the main question, what kind of material is better - foam block or gas block, you need to familiarize yourself with their characteristics, advantages and disadvantages.

Foam concrete

Foam block is a very popular material that enjoys an enviable demand from modern consumers. It produces quite stable and durable buildings, which can be managed in the shortest possible time. It is easy to work with foam concrete block - it is not at all necessary to have a special education or extensive experience in construction.

Most people who want to build a house or an outhouse, choose foam concrete blocks because of their low cost. Moreover, some users make this material with their own hands - the recipe for making foam blocks is very simple and straightforward, you just need to adhere to the correct proportions.

There are many advantages of foam concrete blocks, as well as disadvantages.

For a start, let's look at how good these building materials are:

- Foam block is distinguished by low thermal conductivity.Thanks to them, this building material produces very warm and cozy houses, which, at times, do not need additional warming.

- Such materials are lightweight, so working with them is not time consuming. Moreover, the master can cope with many processes alone, without attracting assistants.

- One more important advantage follows from the above advantages of foam blocks: due to their low weight, foam block erections do not impose significant loads on the foundation structure.

- Construction of the foam block can boast a good sound insulation qualities.

- The foam block is a material with a large volume; therefore, various kinds of buildings are made of it quickly.

- Another significant advantage of foam blocks is that they are inexpensive. Most consumers can afford the purchase of these building materials.

- Not to mention that the foam blocks - a very malleable material. If required, they can be sawed or cut with a hacksaw.

- As a rule, foam blocks are environmental friendly. They do not cause any harm to the health of the household.Of course, during the manufacture of these materials, synthetic components are used, but their content is too small to harm a person.

- Foam block is a material that boasts a long service life. Moreover, over the years, foam block buildings do not lose their positive qualities.

- This building material is not afraid of fire. He does not support the flame, and he does not ignite.

- Many users mistakenly believe that only simple and uniform constructions can be made from foam blocks. In fact, it is not. If the owners have such a desire, the foam block house can be made quite original and fashionable.

- By itself, the foam block does not require a decorative decoration. Of course, it will be more protected if it is covered with plaster or any other suitable material, but this is not the first priority.

As you can see, the positive qualities of the modern foam block and its varieties abound. That is why today many users choose it for the construction of houses (and not only).

However, not everything is so rosy - the given building material has significant drawbacks,with which you also need to read:

- The foam block is a material that has a porous structure. Due to this fact, similar products become more fragile, especially at the edges. For this reason, it is necessary to transport and transport foam blocks very carefully, so as not to accidentally damage them.

- As mentioned above, it is not necessary to finish the foam block constructions, but it is better to do it. Firstly, this way you protect the material from aggressive external influences, and secondly, the construction will look much more attractive. But here you can face one common problem - to finish foam blocks, you need to select special paints / plasters, which are designed for foam concrete foundations.

- Foam blocks are required reinforcement. Usually fittings are installed at the joints of materials. If you do not supplement the structure with a reliable seismic belt, then you will not be able to build high-quality overlappings and install the same strong truss structure.

- One of the main drawbacks of using foam blocks is that the modern market is literally overflowing with low-quality counterfeit materials manufactured in underground conditions.Such materials are often made with a violation of proportions, which leads to their increased fragility.

- If you want to make a dwelling house out of foam concrete elements, then you need to take into account the fact that it is permissible to start similar works only after scrupulous carrying out a number of calculations. For example, you will need to determine the thickness of the walls of the erection, taking into account all the loads.

- For foam concrete buildings, it is required to construct special foundations of the forming type.

- Some subtypes of foam blocks do not differ in the correct geometry. Often, during construction works, they have to be long and meticulously polished and trimmed so that the same floors or walls are even and neat.

There are a number of subtypes of modern foam concrete blocks.

They are divided by purpose:

- Constructional. Instances of this type are designed for heavy loads. Often they are addressed for the construction of multi-storey buildings. Large-sized buildings of foam blocks are often warmed, because this material is characterized by considerable thermal conductivity.

- Heat insulation. These types of foam concrete blocks are very different from the construction options.They are non-thermal, so the dwellings built from them are very warm. But the insulation blocks can not be called high strength. Usually they are used only as an additional layer in the construction of residential buildings.

- Constructional and heat-insulating. These subtypes of foam blocks are considered universal. They gathered in themselves excellent strength properties, as well as good thermal insulation properties. Such materials are perfect for the construction of load-bearing walls or conventional partitions. Very often, baths or small houses are built from such blocks.

These materials differ in the method of manufacture:

- Molded (cassette). The name of such foam blocks speaks for itself. During their manufacture, special forms are used, closed with partitions. This method of production is considered to be the most economical. However, the molded parts have one drawback - the dimensions of the finished foam concrete blocks are inaccurate and poorly adjusted.

- Sliced. The above foam blocks are made from a finished solution, which is cut into individual parts using a special steel string.These materials can boast of correct and neat corners. In addition, they are geometrically verified.

Foam concrete blocks make different designs.

Depending on the specific purpose, apply one or another option from the following:

- Wall. These foam blocks are more common. They are often addressed in suburban construction. This can be not only the construction of a private residential house, but also any backyard structure.

- Partitioning. The second in demand are partitioning foam blocks. They are thin enough - 100-150 mm. They build strong and wear-resistant partitions in the inner part of the building. Due to its thickness, the partitioning blocks are seamlessly cut if required. Thanks to this distinctive feature, experienced craftsmen produce beautiful arched structures from such blocks.

- Special purpose. In the manufacture of special trays, foam concrete blocks are usually used. The fittings are usually installed in these elements.

- Reinforced. Such foam blocks are parts of foam concrete, reinforced with a steel frame.Most often, reinforced blocks are used as lintels instead of standard reinforced concrete elements.

- Non-standard. There are also special non-standard foam blocks. They are made specifically for customer orders.

Foam blocks are available with different dimensional parameters.

Materials intended for laying with glue are made with the following dimensions:

- length: 188 mm width: 300 (mm), height: 588 (mm);

- 188 mm x 250 mm x 588 mm;

- 288 mm x 200 mm x 588 mm;

- 188 mm x 200 mm x 388 mm;

- 288 mm x 250 mm x 488 mm;

- 144 mm x 300 mm x 588 mm;

- 119 mm x 250 mm x 588 mm;

- 88 mm x 300 mm x 588 mm;

- 88 mm x 250 mm x 588 mm;

- 88 mm x 200 mm x 388 mm.

As for the foam concrete blocks intended for laying on cement, their dimensions can be as follows:

- length 198 mm, width: 295 mm, height: 598 mm;

- 198 mm x 245 mm x 598 mm;

- 298 mm x 195 mm x 598 mm;

- 198 mm x 195 mm x 398 mm;

- 298 mm x 245 mm x 298 mm;

- 98 mm x 295 mm x 598 mm;

- 98 mm x 245 mm x 598 mm;

- 98 mm x 195 mm x 398 mm.

Aerated concrete

The main "competitor" of foam concrete is such a building material as aerated concrete. He is also approached by many consumers who want to build a house or any outbuilding on the plot. This popular product, like foam block, has its strengths and weaknesses.

Let's start with the good - consider the advantages of aerated concrete blocks:

- This building material is distinguished by a high density, which can range from 400 to 1200 kg / m3. If you use high-quality wall material with a small specific mass, then you can spend on the construction of a particular design quite a bit of time.

- Aerated concrete blocks are moisture resistant. Even in conditions of air humidity of 60%, the rate of gas blocks will be about 5%. If the level of air humidity reaches 96%, then it can reach up to 8%.

- Another significant advantage of aerated concrete is its fire safety, as is the case with foam blocks. This material can withstand even extremely high temperatures without any obstacles. In addition, the gas block does not support combustion.

- Not afraid of aerated concrete blocks and very low temperature values. Due to this quality, access to such materials is permissible even in harsh climatic conditions.

- Not afraid of this building material and biological effects. Aerated concrete does not need to be further treated with protective compounds or antiseptic agents, such as wood.

- This building material is distinguished by durability. Erections made of aerated concrete can last for 100 or more years.

- Aerated concrete is environmentally friendly. In its composition there are no dangerous toxins that have a negative impact on human health. With aerated concrete blocks on the environment can only be wood.

- Like foam concrete, aerated concrete has quite good noise insulation qualities. Having built a wall of this material with a thickness of 40 cm, you can not worry about the noise coming from the street.

- Another advantage of aerated concrete is that it has good thermal insulation qualities. Houses made of similar material, in many cases, do not need additional insulation. At the same time inside a similar dwelling a comfortable microclimate is always maintained.

- The undoubted advantage of aerated concrete is its level of strength. If it is properly reinforced, then you can build a large house with three floors.

- Differs this building material and ease of processing. It can be cut or sawed, if required. The block can be easily attached to certain sizes and shapes.However, it is worth considering one nuance: dowels are very poorly supported in aerated concrete walls, therefore it is recommended to use other fasteners - self-tapping screws.

- The production of aerated concrete takes a bit of cement.

- This building material is inexpensive, because its production uses raw materials of natural origin - quartz sand, cement, lime.

- Aerated concrete has a low weight, so working with it is not too time consuming. Its structure is also cellular; therefore, such blocks can be moved easily without resorting to the help of a crane.

- Aerated concrete is a versatile material that is used not only in the construction of houses or outbuildings, but also in the manufacture of fireplaces, steps or fences. This advantage is due to the ductility of this material - it is possible to give it almost any shape.

- This material also has excellent vapor and breathability characteristics. The coefficient of these qualities in foam concrete is almost the same as that of wood. According to experts, the air circulation and the level of humidity in the house from such a material will be regulated naturally, forming a comfortable microclimate.

- Currently, aerated concrete blocks are manufactured in factories, where at each stage of production strict quality control of products is carried out.

Aerated concrete blocks are not ideal, as are foam concrete options.

They have their own disadvantages:

- This material is characterized by high hygroscopicity.

- If the foundation of the building was erected with any violations, then gas-block buildings can produce noticeable cracks. Moreover, these defects arise not only along the masonry lines, but also on the gas blocks themselves. Microscopic cracks appear on this building material in just 2-4 years.

- Yes, aerated concrete blocks are responsible for the formation of an ideal level of humidity in the room, but over time, these materials begin to accumulate excess moisture in their structure. This leads to dampening and delamination of blocks.

- Aerated concrete is not the highest price, but it is higher than the cost of foam blocks.

- Aerocrete can not boast of sufficient thermal insulation characteristics, especially when compared with foam blocks.

There are several varieties of aerated concrete.

Each species has its own labeling.

- D350. This brand is considered one of the most rare. This is due to the fact that such blocks are fragile. They are permissible to install only as seals. The strength level of D350 is 0.7-1.0 MPa.

- D400. This kind of aerated concrete is more durable and strong. This property of this material can be from 1 to 1.5 MPa. Apply similar materials in the role of insulation, and in the role of openings in high-rise erections.

- D500. The strength level of this building material is 2-3 MPa. Typically, such blocks are addressed in the construction of monolithic buildings. They are suitable for low-rise construction.

- D600. This marking are high-strength aerated concrete blocks. The level of their strength can be 2.4-4.5 MPa. Due to its performance characteristics, D600 aerated concrete can be used for the construction of buildings with ventilated facades.

It is impossible to say exactly which of the listed options for aerated concrete blocks is the best, since in each category there are both disadvantages and advantages.

The brand of aerated concrete affects its final cost.

Aerated concrete blocks also differ in their forms:

- rectangular elements are used to construct partitions and load-bearing walls;

- reinforced parts are usually bought for the manufacture of ceilings;

- T-shaped blocks are designed for floors;

- Aerated concrete blocks are used for openings;

- There are also arc-like variants of aerated concrete blocks.

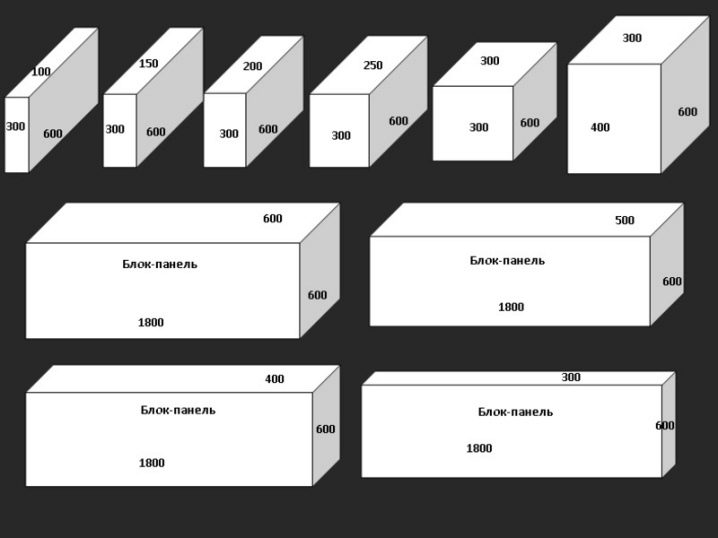

Gas-blocks, as well as foam-blocks, happen heat-insulating, constructional and constructional and heat-insulating. As for the size of aerated concrete, a lot here depends on their shape.

Simple rectangular elements have the following dimensions:

- length - 625 mm;

- width - 100 mm, 150 mm, 200 mm, 240 mm, 300 mm, 400 mm;

- height - 250 mm.

U-shaped blocks are issued with such dimensional parameters:

- length - 600 mm;

- width - 200 mm, 240 mm, 300 mm, 400 mm;

- height - 250 mm.

Production technology

Foam concrete and aerated concrete are manufactured using different technologies. Consider them in more detail.

Aerated concrete blocks are made as follows:

- First, the necessary materials are prepared in the right proportions (these include sand, lime and cement). Being in a dry state, they are mixed with the help of special equipment for 4-5 minutes.After that, a suspension of aluminum powder based on water is added to the mixed composition.

- In the course of mixing lime reacts with aluminum. Due to this hydrogen is formed. Due to the strong gas formation, air bubbles form in the composition. They are evenly distributed throughout the solution.

- After that, the finished composition is poured into the form. It must be preheated to the 40 degree mark. Fill do on ¼ of the volume of the container.

- When the composition is sent to the form, they are transferred to a special chamber, where further porogenesis of the material is carried out. As a result, the volume of the resulting mass begins to grow gradually and gains strength properties. In order to activate the necessary reactions in the solution, as well as to optimally distribute it in the form, they apply to vibration effects.

- When the resulting composition reaches the preliminary hardening, it is necessary to remove any irregularities from its surface. This is done with the help of wire strings.

- Further the structure gets from the camera and passes to the line for cutting.

- The next step in the manufacture of gas blocks will be sending them into the autoclave.

Often, aerated concrete slabs are labeled with the designation AGB (implied autoclaved material). At the same time, the autoclave itself is a kind of “pressure cooker” of impressive dimensions. In its conditions it is injected, and then a pressure of 12 atm is maintained. As for the temperature, it should be 85-190 degrees. In this setting, aerated concrete slabs are prepared within 12 hours.

When the blocks are fully prepared in an autoclave, they are additionally divided, because during preparation in some places they can connect with each other. After that, these materials are placed in a special heat shrinkable material or polyethylene.

Aerated concrete is made without the use of an autoclave. In this case, the hardening of the composition takes place in natural conditions - in this case, special equipment is not needed.

But these materials will be less reliable. They will shrink more and will not be as durable as autoclave options.

Foam concrete is made slightly simpler and easier. There are 2 ways to produce it - cassette and sawing.

The cassette method involves pouring the solution into special forms.

The technology, called sawing, involves pouring the solution into one large container, after which it hardens and further cutting into individual elements of the required dimensions takes place.

For the manufacture of concrete blocks using cement brands M400 and M500, pure sand without clay, a foaming agent, potassium chloride and, of course, water.

Requirements for use

If you decide to use foam concrete or aerated concrete to build a house, then You should consider a number of specific requirements for the use of these materials.

- The foundation must be as durable as possible, despite the fact that such block materials are lightweight and have a porous structure.

- The horizontal surface of the foundation structure should be waterproofed.

- Drilling of holes, cutting, chipping of blocks with cells is carried out in the same way. A hand saw is used for cutting, the holes are drilled with a drill and drill bits.

- Foam blocks can be laid on cement or special glue. Aerated concrete is mounted only on glue.

- Stop building a house if necessary. Preserve the object for the winter.Foam concrete walls during this time will be nothing, but aerated concrete should be covered with a waterproof film.

- Watch for retention of fasteners on both materials. It is advisable to use special screws, anchors and hardware.

- For lining of such block facades you need to use special plasters, wall paneling, siding, stone and other similar materials. No major limitations.

- Sometimes it is not necessary to warm the houses from porous blocks. If it is necessary, then you need to turn to the heater. It is recommended to contact the basalt wool.

- Not all plaster is suitable for finishing such block foundations. For foam blocks and gas blocks, you need to purchase compounds that will maintain their vapor permeability.

How to choose?

To understand which material is better, should compare the foam block and gas block in several ways:

- Structure. Foam blocks have large and closed cells with weak water absorption. Their surface is gray. Gas silicate blocks have smaller pores. They have weaker thermal insulation and need additional finishing.

- Strength characteristics.Aerated concrete blocks are less dense (200-600 kg / cube) than foam concrete (300-1600 kg / cube). Despite this, the foam is inferior to aerated concrete, as its structure is heterogeneous.

- Frost resistance. Autoclaved aerated concrete blocks are more frost-resistant and vapor-permeable than other similar materials.

- Features of the application. Cellular foam is used in low-rise construction. It is also used in the construction of monolithic buildings (here it is used as an additional insulating layer). Aerated concrete materials are used as the main structural and insulating materials. Of them build houses of very different complexity.

- Production. To run into a low-quality foam concrete is much easier than a bad aerated concrete. This is due to the fact that the first is often made in artisanal conditions, and the process of creating aerated concrete materials is more high-tech and more often carried out in factory conditions.

- Cost The price is the most obvious difference between foam blocks and gas blocks. The latter will cost more, because the foam concrete blocks are made from cheap raw materials.

- Soundproofing.Foam concrete blocks have better sound insulation characteristics than aerated concrete options.

- Life time. Foam concrete averages no more than 35 years, and aerated concrete more than 60 years. This is another important difference that must be considered when choosing the appropriate material.

- Shrinkage. The degree of shrinkage of foam blocks is greater than this parameter gas silicate materials. It is 2.4 (and aerated - 0.6).

Distinguishing aerated concrete from foam is not so difficult. It is enough to pay attention to their surface. The foam blocks are smooth, and the gas blocks are slightly rough. It is more difficult to say with certainty which building material is better, since both of them have their pros and cons. However, it is necessary to take into account the opinion of experts who argue that gas-blocks are nevertheless stronger, and their frost-resistant characteristics are better. As for the foam blocks, they are warmer and cheaper.

We must not forget that low-quality foam concrete is more common than second-rate aerated concrete, as evidenced by reviews of many consumers. Be that as it may, the choice is up to the buyer. It is important to decide in advance for yourself exactly what qualities you are looking for in these building materials.before you go shopping for them.

Comparison of the gas block with the foam block - in the next video.