Dowels for aerated concrete: types, features and installation rules

Today, for the construction of a variety of buildings is often used material such as aerated concrete. It has a special porous structure. Due to this distinctive feature, not all fasteners are suitable for this material. Working with aerated concrete, it is common to use special dowels. It is necessary to consider in detail what types of such fastenings exist, as well as learn how to install them in aerated concrete foundations.

Characteristic

Aerated concrete is rightfully recognized as one of the most practical and affordable materials.It makes durable and strong houses, as well as reliable outbuildings. However, it is necessary to take into account that this material is different in cellular structure, when confronted with which it is necessary to take into account many nuances. The main characteristic of such a material is its fragility and ductility. Porous blocks can be easily cut or cut off the excess part from them. And also we must not forget that for this structure use special fasteners. Traditional fasteners, as a rule, do not keep well in such bases, which is why the whole point of their use disappears.

For aerated concrete, use special dowels. The design of such parts is a sleeve in the form of a spiral, on the surface of which there are ribs. The last elements during screwing screw or screw become wider, so tightly fit into a loose concrete surface. This uncomplicated but effective device can easily withstand impressive loads. With the use of special dowels, the owners of the home have the opportunity to hang heavy decorative objects of any size on the walls.

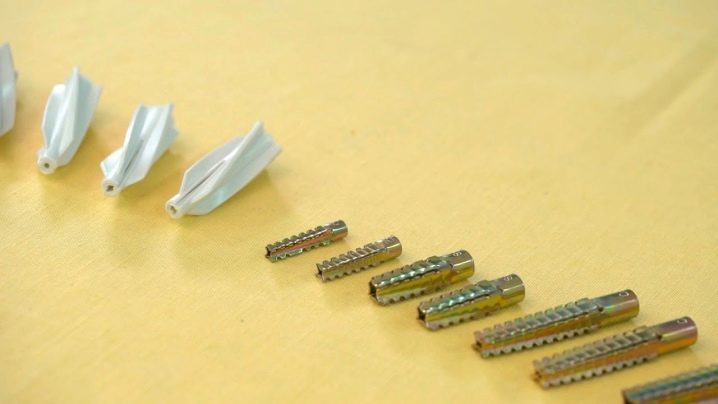

Modern manufacturers produce such types of dowels in two variations. They differ in design features.

- The shape of the ribs fixing. Such fasteners can be equipped with a classic spiral helix or have ribs in the shape of a cone. The edges of the latter may resemble spiral-like blades.

- By installation method. Dowels are either screwed into the base, or driven into it. It is considered the most reliable specimens to be screwed. It is recommended to contact the driven fasteners in the event that it is planned to equip the aerated concrete floor with a collet.

Species

Today in the shops you can meet various options for dowels for porous materials. They are mainly distinguished by the material from which they are made. One or another variant of fasteners should be selected on the basis of the fact that it is planned to install it on the aerated concrete surface.

Metal

Such types of fastenings are most common. As a rule, they are made of galvanized steel. Such elements can boast of fire safety, so they are often installed in fire-hazardous spaces.Besides, metal dowels are great for the following jobs:

- for the installation of guides, designed for the installation of sheets GKL;

- for the installation of furniture and equipment with impressive weight;

- for fixing pipelines of any complexity (it can be a gas, sewage or plumbing pipeline).

Fastenings made of galvanized steel must have a special retaining side or cuffs in their construction. Thanks to these details, the dowel will not turn or fall, which very often happens when it comes to cellular bases. The main and only drawback of metal fasteners is that they are subject to the appearance of destructive rust. Galvanized dowels are the most expensive because they have many positive qualities. In addition, they can be used again if necessary.

Plastic

Such types of dowels for aerated concrete are made of polypropylene and polyethylene. Plastic fasteners are good because they are not subject to the formation of corrosion. Typically, plastic retainers have special spiral-like fins,responsible for the highest quality coupling with the cellular base. A distinctive feature of these mounts is their environmental safety. In addition, they are not afraid of an aggressive external environment. Together with the low cost, these characteristics make plastic dowels simply indispensable elements when it comes to working with aerated concrete.

However, it should be borne in mind that such dowels cannot be used for facade works, which is explained by the fact that they cannot boast of resistance to low temperature values, therefore, with the onset of a cold winter, plastic may simply burst.

Nylon

The nylon plugs can also be classified as plastic. Such options fasteners are good in that they are also not susceptible to corrosion. However, they are more wear-resistant than simple plastic parts - they can also be used for outdoor work. According to experts, nylon fasteners are much stronger and more durable than propylene or polyethylene specimens. Consumers do not often spend on such fasteners, because they are more expensive than other options. However, their characteristics and qualities fully justify the high price. Nylon versions of dowels are addressed when carrying out such works as:

- installation of door and window openings;

- fixing mirrors and lighting fixtures - for such objects it is recommended to use dowels having a diameter of not more than 12 mm.

Chemical anchor

We should also highlight such fasteners as chemical anchors. Such anchor bolts are relevant in those cases when it is required to attach a certain object to the aerated concrete wall, which is distinguished by a large weight that ordinary metal dowels simply cannot bear. The chemical anchor acts in the same way as the metal anchor dowel, but it is installed in the already finished hole using a specialized adhesive composition. This method of attachment makes it possible to conscientiously fix the elements of large volume.

Dowels for aerated concrete differ in their basic use, so it is worth to distinguish several of their varieties.

Universal

This kind of dowels can be installed in a concrete surface of any type. A distinctive feature of these fasteners is their structure of the spacer body.When the fastener is immersed in a full-bodied base, it behaves like a simple dowel of the expansion type. In a hollow or porous coating, these fasteners are rolled into a special stop assembly for tight fixation. Such fasteners are installed differently from ordinary fasteners.

In addition, the carrying capacity of universal dowels is lower than that of spacer elements. The cost of such products at the same time is higher.

Gvozdeva

There is a special dowel-nail, which is ideal for mass installation work. The sleeve of this mount is as simple as possible - it has 2 spacers, and the whiskers or teeth are generally not present. At the time of mounting in a dowel put a nail, and not screw the screw part. For this reason, the liner should be placed to avoid scrolling. There are nail dowels cheaper than other types of fasteners, but have a lower carrying capacity.

Installation of these mounts is quick and easy, as many experienced craftsmen say.

Frame

This mount is made of plastic or metal. The main distinctive feature of these dowels is their “pancake-like” structure, thanks to which the fastener makes it possible to significantly reduce the load on the cellular unit.Due to such features, the strength characteristics of fasteners are improved.

Frame elements should be installed when mounting doorways, as well as window blocks and guides.

Thermal insulation

This mount is also installed in the base of concrete. They are permissible to apply when working with bricks. Thermal insulating dowels can be placed in softer surfaces, since they are lightweight and designed for the installation of the lightest things - insulating materials.

Which is better?

As you can see, there are plenty of different dowels designed to work with aerated concrete. To decide which of them is the best, you should consider more which fasteners should be chosen for different cases, namely:

- if we are talking about the installation of lamps or mounted mirrors, then the best options will be nylon fasteners, the diameter of which does not exceed 12 mm;

- when installing the pipeline should choose metal dowels;

- for installation of heavy items of furniture it is recommended to buy specialized metal fasteners;

- when it comes to facade work, there is one option here - special front fasteners made of plastic;

- when fixing window and door frames, frame types of dowels should be used;

- A compact photo or a picture without any problems will also hold an ordinary nail, which is permissible to fix without a dowel.

Dimensions

Fasteners suitable for aerated concrete foundations are available in different sizes. So, nylon pieces can have such parameters (in mm), such as:

- 4x20;

- 5x25;

- 6x30;

- 8x40;

- 8x55;

- 10x50;

- 12x60;

- 14x70;

- 16x80

Galvanized dowels have such dimensions (in mm), as:

- 6x32;

- 6x36;

- 8x38;

- 8x50;

- 10x60.

Plastic options are made with such parameters (in mm), such as:

- 5x30;

- 6x35;

- 5x40;

- 6x25;

- 6x40;

- 8x40;

- 10x100;

- 12x100.

How to use?

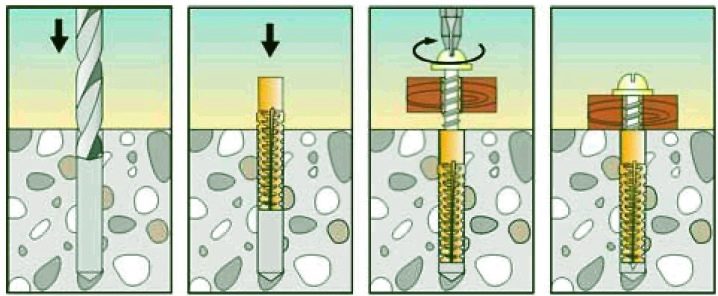

The principle of installation of dowels is the same as for other types of fasteners. You need to act in the following order:

- you must first prepare the holes for the dowel, which should be smaller than the diameter of the mount; for example, for fasteners in 8 mm you will need to use a 7 mm drill bit;

- If you take a tool like a punch, then you need to turn off the impact mode, of course, it is desirable to use a drill, because it is more efficient;

- plastic fasteners must be carefully screwed using a screwdriver; if metal parts are used, they should be driven into the bore with a hammer;

- when making work, it is imperative to ensure that the products do not touch and are not crooked;

- when the cuff is fixed up to the stop, you can proceed to fastening the screw or universal bolt;

- It is necessary to screw the screw with a screwdriver, adhering to the required depth.

As you can see, fixing the dowels for the gas-block is not difficult at all. The main thing is to work carefully and make sure that all the details are firmly “sitting” in the wall without swaying.

Tips and tricks

When installing dowels in the gas block it is impossible to use a screwdriver, since this device works from electricity, which makes it more difficult to control it. Such a device can disrupt the thread by twisting the screw. Making a hole for dowels in the gas block, it is important to consider that they should not be larger than their diameter. Otherwise, the fasteners simply will not firmly hold in the base. The depth of the holes should be slightly greater than the dowel length parameter.The tip of the screw must leave the limits of the dowel in order for the fastening to be as reliable as possible.

Many people, having got acquainted with dowels, begin to use them at any opportunity. However, experts do not advise to contact too powerful mounts, if the plans to hang hooks, paintings and other trifles. For such purposes, simple plastic fasteners, whose size is about 8 mm, are more suitable.

If you make the installation of such elements in due form, then they will be able to withstand even more serious weights. You should not save on the purchase of high-quality fasteners, especially if you want to attach heavy objects of large dimensions to aerated concrete walls.

About fasteners for aerated concrete - dowel nylon and metal (crocodile), see the following video.