Features of wall gas double-circuit boilers with a closed combustion chamber

Heating gas houses found very often. But the problem is that the boilers designed for this can be very different in their performance. Understand this as it should be extremely difficult.

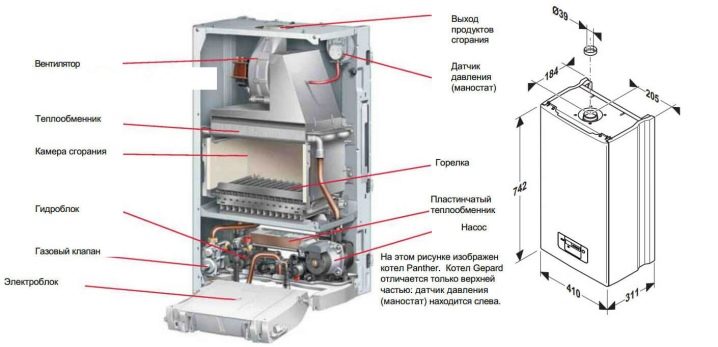

Device and purpose

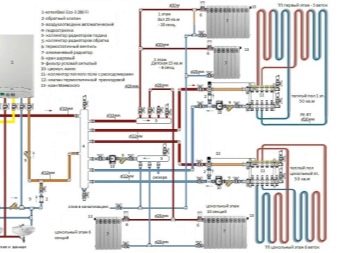

A wall-mounted gas bypass boiler is designed to simultaneously deliver fluid to the heating system and to the “hot” circuit of the water supply system.

It can refer to one of these types of devices:

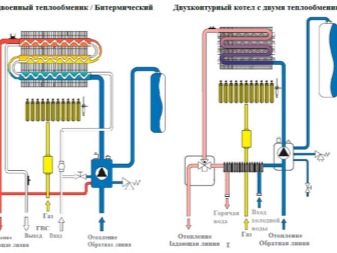

- using a single heat exchanger for the production of hot water and heat carrier;

- preheating water going to the faucet using a separate flow-type heat exchanger (operating at high speed);

- having a flow-through heat exchanger, designed for normal speed (with addition in the form of a warmed tank).

In the apparatus of the first category are put copper heat exchangers, characterized by a complex geometry. The flow system does not provide for direct heating from the burner.

But there is an auxiliary heat exchange apparatus that transmits the received energy between two water circuits. Switching is performed with thermostatic valves. Most of these models are equipped with circulating pumps and several expansion tanks.

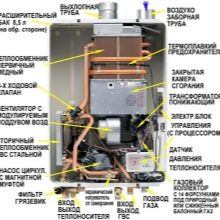

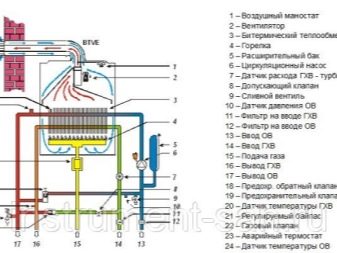

The burner in the described apparatus is invariably equipped with an apparatus for the electronic modulation of fire. The combustion chamber is divided into open and closed types. A fan is installed above the closed compartment, which helps to inject air and remove combustion products. But ventilation inevitably generates noise, albeit rather weak.

The use of such a system is justified by the following advantages of a closed combustion chamber:

- small footprint;

- economic benefits;

- ease of maintenance;

- low cost of the device itself.

Unlike a floor-standing boiler, the wall-mounted version is compact even in the same category as a combustion chamber.

This makes it quite acceptable even for a small-sized “Khrushchev’s” apartment. There is no need to allocate a separate room. The downside of this advantage is reduced power compared to the “floor” counterparts. What exactly is more important in a particular situation - you need to decide the owners of the house.

Principle of operation

Bitumen boilers with a closed combustion chamber heat water streams moving in the same direction. The outer tube is used to supply the coolant to the heating circuit, the inner tube is used to the hot water pipe. The gas burner is located below the heat exchanger, its operation is closely monitored by an automatic valve. Heating mode means warming the water to a temperature set by the thermostat. Turning on the burner depends on how it is supported.

If the valve is opened, the flow goes along the pipes located inside the exchanger, the movement in the heating circuit stops. The liquid swirls along the short line, supplying energy to the flow through the tubes inside; gas burns smoothly.

If the automation detects that the hot water taps are shut off, the circulation of coolant through the heating system is resumed. This principle allows to get rid of the main problem of most automated boilers - depending on the power supply. No less important is the low cost of the device itself in comparison with the two other types.

But the overall performance cannot be great; if it is necessary to supply water to 3 or more consumers, its temperature is forced to drop. In addition, when one of the simultaneously turned on taps sharply open (close), very cold (hot) water can suddenly go out of the others. Heat flow systems supply heat in a fundamental mode to a key heat exchanger. When registering with a special automatic fluid care automatic, the electronics starts the valve with three strokes, the system operates according to the crane's feeding program. The heat carrier flowing from the main heating unit to the secondary one releases energy to water intended for the water supply system.

Flow heating is characterized by the same weaknesses as the bithermic circuit. But in addition to use such a boiler in a de-energized state will not work. To some extent, this is justified by the increased accuracy of the warm-up adjustment and the high rate of heat generation.And also in favor of the flow apparatus is indicated by the increased service life of the secondary heaters. There are systems supplemented by a boiler inside. In them, the secondary heating unit operates in the intervals between heating water for heating. When the coolant is heated as needed, the burner does not stop working, but supplies heat to the DHW circuit.

The transition from one mode to another, as in the previous version, is provided by a three-way valve. The described system is considered by experts to be the most economical solution, in addition, the work of both circuits is optimized.

Automatic systems can be programmed even for 7 days ahead. But any double-circuit apparatus suffers from an increased tendency to accumulate scale on heat exchangers. This can be compensated only by enhanced purification of the incoming water. It is produced using mesh-based filters. Such filters are mounted horizontally, the threaded plug must face down; a upright cleaner will be useless.

The undoubted advantage of a closed combustion chamber is the absence of the need to constantly ventilate the room.Fresh air is supplied to the burner through a coaxial flue. The waste generated during the combustion of gas is also diverted through the same channel. Sealed pipeline, if the combustion chamber itself is intact, completely eliminates the likelihood of an accident. But in addition to the scheme of execution of the gas-burning unit, it is required to pay attention to other nuances.

So, water circulating pumps in high-quality machines are not a source of noise. Its presence means that a bad product is purchased. The three-way valves also play a big role, since it depends on them how the device will switch from the heating mode to the hot water supply mode and back. Professionals recommend immediately get acquainted with the characteristics of heat exchangers and automatic control systems.

Important: even if the seller speaks of a dual heat exchanger, this should not be reflected in the principle of operation of the device.

Advantages and disadvantages

Reviews on a specific model of heating equipment can be very valuable. But it would still be much more correct to first find out whether a double boiler is really needed or not.Its main advantage, as follows from the description, is the possibility of obtaining from one device of hot water in the faucet and in the heating system.

It is important to consider the following weaknesses:

- the double-circuit boiler will be able to supply water only to one point of water pumping;

- it will not be warmed up instantly when the faucet is opened;

- The impact of hard water on the condition of heat exchangers is critical.

Overview of models and manufacturers

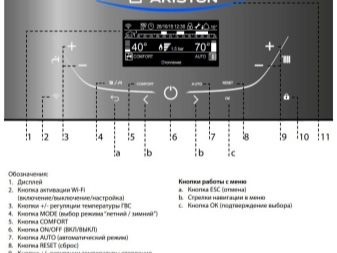

It is useful to pay attention to the properties of specific modifications. So, among the Ariston products stands out Alteas X. The manufacturer claims that this dual-circuit model fully complies with the requirements for premium-class heating equipment. Control of the boiler is possible with the help of remote tools (via wi-fi protocol). The heater adapts to the ambient temperature, which simultaneously provides optimal conditions in the house and minimal absorption of energy resources.

Adjustment occurs smoothly and as efficiently as possible. Coordinating the work of the display module allows you to determine what information to show. The company claims that the modulated pump installed in the system spends 30% less electric current than conventional counterparts.

The device can work even with a small pressure of gas (5 mbar) and with a small water pressure at the inlet. Technical documentation indicates that it is resistant to voltage spikes in the power grid.

An alternative can be a wall-mounted boiler Genus X of the same brand. The gas flow pressure is 20 mbar. And when using liquefied gas, this figure already reaches 37 mbar. Water is heated in the heating circuit to +82 degrees, and in the hot water circuit - to +60 degrees. The system consumes from 117 to 152 watts of current per hour depending on the specific version.

Bosch products also proved to be the best. So, Gaz 2000 W belongs to the number of wall bypass boilers of convection execution. This unit is capable of heating water up to + 40–82 degrees, depending on the settings. The maximum allowable pressure in the water supply system is 3 bar, and the expansion tank is designed for 6 liters. The maximum temperature of the gaseous products of combustion reaches +145 degrees, they are discharged through pipes with a diameter of 6 or 10 cm.

The described system allows to provide rooms with heat and hot water up to 240 square meters. The German concern guarantees, as well as the Italian competitor, excellent work with unstable pressure in the water supply system, gas pipeline.Gaz 4000 W is equipped with an electronic ignition circuit and can be transferred to liquefied gas. The special design of the heat exchanger can significantly reduce the intensity of the occurrence of scale.

Also, this model has a function of protection against freezing and protection from excessive pressure. Automatic blocking the pump and does not allow him to jam. Provides automatic diagnostic functionality. The circulation pump has three speeds.

The choice between these modifications is determined only by personal preferences, necessary functions and material considerations, because they all cope brilliantly with their task.

For information on which gas boiler to choose, see the video below.