Wall gas single-circuit boilers: types and technical characteristics

The use of gas boilers is considered to be the most economical and efficient method of heating. Natural gas as an energy carrier is characterized by low cost and good heat dissipation, which differs from other types of fuel. At heating of rooms various types of devices, both old and new, are used. Wall-mounted single-boiler is an excellent option for those who do not want to clutter the room with heating equipment.

Device and purpose

Gas wall one-planimetric copper - the independent unit forheating and hot water systems in the private sector. It is a device with small dimensions.

Its basis consists of:

- heat exchanger;

- control circuit;

- igniter.

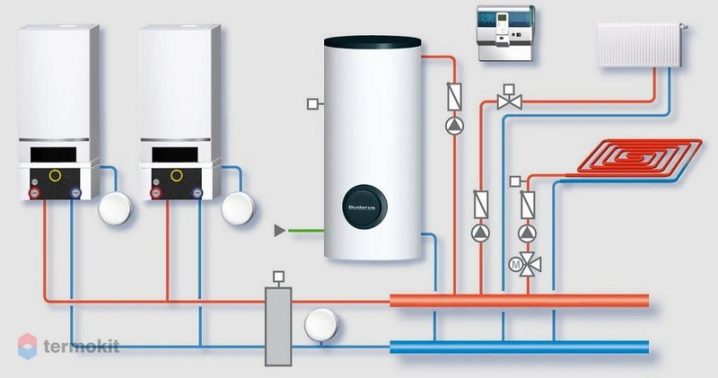

The gas boiler is equipped with one or two pumps and a security system that ensures the stable operation of the equipment. Also, the single-circuit boiler has an expansion tank and sensors for thermoregulation. In the lower part of the tank there are nozzles with the help of which a connection is made to the heating system and water heater, as well as a valve for connecting to the pipeline. Due to this, during installation there is no need for additional water heaters.

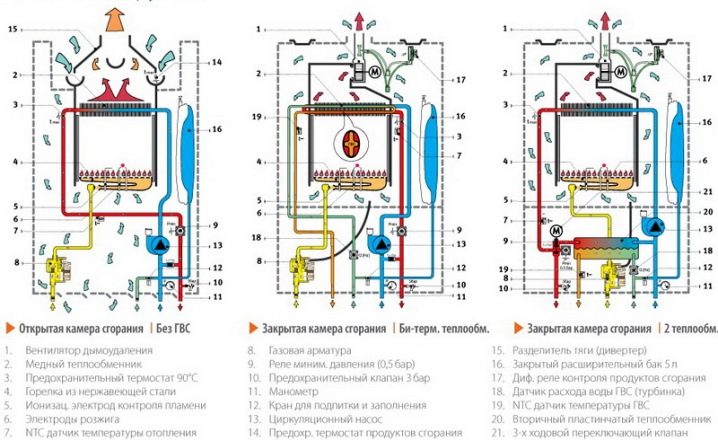

Manufacturers produce gas equipment with a closed and open combustion system, where the heat is formed by the condensation of vapors, as well as turbo boilers.

Principle of operation

The principle of operation of mounted single-circuit boilers with an open combustion chamber is similar to the principle of operation of water-heating equipment. The only distinguishing feature is that the first heat the heat agent, and not water.A cold heat agent is sent to the apparatus and fills the heat exchanger. Turns on the gas burner, which is designed to heat the circulating coolant. Hot thermal agent under the connection scheme is sent to the heating system. After heat transfer, the coolant is returned back to the apparatus through a pipe and again sent to the heat exchange device.

These processes are regulated by electronic or mechanical units. Some devices with “smart” programming perform heating according to a certain program and are controlled remotely.

Advantages and disadvantages

The following advantages of wall mounted gas single-circuit boilers can be distinguished:

- affordable cost due to the simplified method of production of units;

- small sizes;

- attractive appearance (in comparison with two-circuit models);

- the possibility of embodying a variety of design ideas in the design of the exterior equipment;

- ease of use;

- low weight

The disadvantages of wall devices include:

- low productivity (no more than 100 kW);

- possibility of installation only in private houses with an area of less than 800 m2;

- short term operation.

Customer reviews are an indicator that shows which heater is the best. The experience of people who have been using a gas boiler for a long time allows us to make a reliable conclusion about all the positive and negative qualities of such devices.

Kinds

Manufacturers produce a wide range of gas single-wall gas boilers. To choose the optimal model of the device, you need to take into account all the structural and thermal characteristics of each option. Depending on the characteristics of the boilers are classified into several types.

Atmospheric devices

This is the classic version. In another way they are called convection or boilers with an open combustion chamber. To maintain a long burning process when heated, air enters the apparatus from the room. The products of combustion naturally take the turn of the upper chimney. This type of boiler is controlled mechanically. For this purpose, temperature controllers and a built-in thermocouple are provided. With the help of the piezoelectric element, manual ignition of the burner is performed.

The main advantages of such schemes are:

- ease of use due to the absence of unnecessary parts;

- low noise level (noise in this case is formed only by a flame and a circulation pump, if any);

- reasonable price (compared to other types of units).

Among the significant negative qualities include:

- the need for good ventilation;

- small efficiency of the mechanism;

- unstable combustion of fuel;

- the need for a traditional chimney.

Devices with a closed combustion chamber

The principle of operation of such devices is based on forced air intake and smoke emission. They are equipped with variable rotation fans and turbines that help circulate airflow and exhaust gases.

This type of boilers is classified, in turn, into two groups:

- turbocharged;

- condensation

Turbocharged gas boilers are modern models of heating equipment. Their principle of operation is based on closed combustion chambers. Due to the presence of adjustable fans and turbines, there is no need to organize conventional chimneys and the presence of a good ventilation system in buildings. To ensure the optimal functioning of the turbocharged equipment, it is necessary to take care of special devices. These are coaxial or non-firing elements.Each of them consists of a pair of pipes, one of which is inserted into the other. Atmospheric air passes through one pipe into the system, and exhaust gases exit through the second.

It is recommended to install wall-mounted turbochargers in rooms where there is no possibility to install a unit with an open combustion chamber, a gas pipeline and a traditional chimney.

Condensation units have improved technical characteristics. The principle of operation of such equipment is based on the condensation of heat generated. Among the positive qualities are high efficiency (up to 109%) and economical fuel consumption. When using liquefied gas costs are reduced by more than 40%.

Classification by type of burner used.

- Single-stage burner is available in all non-volatile gas boilers. The burner starts heating the heat agent as the combustion mode is activated. The devices are equipped with a stably operating igniter.

- The two-stage burner can operate in two modes (with 30% and 100% power). The advantages include a significant reduction in fuel consumption due to the possibility of smooth power switching.The burner works stably; when the fluid is heated to the optimum temperature, the burner capacity is reduced to 30% automatically. The burner is ignited electrically. The change in performance is controlled by electro-automatics, which means that the two-stage apparatuses are volatile.

- Modulation devices can operate by varying power from 10 to 100%. The control of the combustion process takes place with the help of microprocessor automation. Performance varies depending on the parameters of the heating system (when the heating agent is heated, the pressure in the gas pipeline changes). The advantages include the most economical gas combustion and the minimum under-burning of fuel.

Overview of models and manufacturers

The following European companies are engaged in the production of wall-mounted single-circuit devices: Protherm, Buderus, Viessmann, Lemax, AOGV, Ariston, Beretta. Boilers made in Russia: NevaLux and Siberia. The most effective and reliable devices are produced in Germany and France. However, French boilers are more economical and easy to use. The units of German and French production are mainly premium-class goods, which makes them not always available to buyers because of their high cost.Italian manufacturers are leading the rating of wall units, the price of which is in the middle category.

The rating of the boilers, which is based on the main technical characteristics and design features of the models, can help in choosing a wall heating device.

Vaillant Turbo TEC plus VU 122 / 3-5 - functional device, which occupies the first place among single-circuit boilers. Its purpose is to heat an area of no more than 120 m2. The performance of the device - 0,012 watts. It is adjusted automatically using a modulated burner.

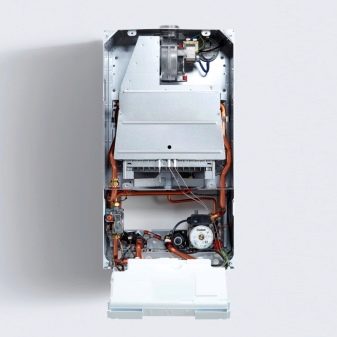

The model consists of:

- closed fuel combustion system;

- turbines for the output of combustion products;

- multi-stage pump, which accelerates the circulation of coolant;

- copper heat exchanger;

- electronic ignition unit;

- control systems for all equipment parameters.

This model can work in systems with unstable voltage due to the stabilizer. Even with low pressure in the pipeline, the apparatus operates without loss of performance. The efficiency of the device is 91%.

Baxi FOURTECH 1.24 F with a closed combustion chamber and forced chimney is also in great demand among consumers. The modulation burner allows you to work when you change performance from 0.0093 W to 0.024 W. The heat exchanger is made of copper.

This single-circuit boiler has:

- water pumping equipment for forced circulation of fluid;

- an expansion tank with a capacity of 6 liters, which compensates for the expansion of the heated coolant;

- indication of modes;

- automatic ignition;

- built-in thermocouple.

Boiler efficiency - 93%. There is one significant drawback - frequent problems with the gas valve in some devices. According to professionals, the best option in terms of "quality-functionality-cost" is the model Baxi FOURTECH 1.24 F.

Korean-made Navien gas boilers adapted to the operating conditions of Russia. They have an affordable price and good technical features. The disadvantages include failures in the automation system and unstable operation of the thermostat. The boiler unit consists of a circulating pump, an expansion tank, an automatic unit and shut-off and control valves. Thermal load Navien - 13 kW.

Criterias of choice

When choosing a hinged gas equipment, it is desirable to have some knowledge of its design and principle of operation.

When selecting the optimal model, you should pay attention to a few points.

- Power equipment, which depends on the area of the room. For example, for a private house with an area of 120 m2, an apparatus with a capacity of 12 kW is required. More accurate values will depend on the region, the quality of the insulation of the building and other factors. In some cases, a room with a capacity of 40 kW may be needed for a room of 120 m2. It is not recommended in order to save to purchase a device of lower power.

- Ignition option: piezoelectric or electric. The latter automatically ignites the fuel. In the first case, batteries are used, and for ignition, human efforts are necessary.

- Type of burner: single-stage or modulated unit. The first always operate with a maximum thermal load. The latter can change the heat load in the range from 30% to maximum.

- The material of the heat exchanger must have good heat-conducting properties and resistance to high temperature.Copper is a metal that conducts heat well and has a low melting point. Steel that also has moderate thermal conductivity and average service life can also be used. Devices made of cast iron are durable, but because of the large weight, they are often performed in outdoor versions.

- Combustion chamber: open or closed. In the first case, the air is taken from the house, in the second - from the street.

- Exhaust gas discharge: natural or forced draft. In the first case, there is a need for good ventilation and flue, in the second case, the exhaust gases are removed with the help of a fan through a special chimney.

- Manufacturer. It is recommended to choose a “long-lived producer” with a good reputation, providing a long warranty period for products.

On how to choose the right wall gas single-circuit boiler, see the following video.