Wall mounted gas boilers: technical characteristics and installation features

Any home requires high-quality heating. Currently, there are many different heating systems, from very simple and simple to complex and intricate. Today we will take a closer look at such efficient units as wall-mounted boilers, as well as consider their technical characteristics and installation features.

Device

Today, wall mounted gas appliances have the opportunity to meet in many homes. Such units are affordable - you can easily find them in specialized stores.

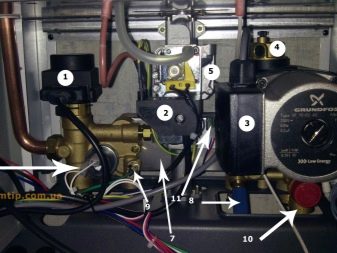

Such types of heating boilers are collected from the following functional elements.

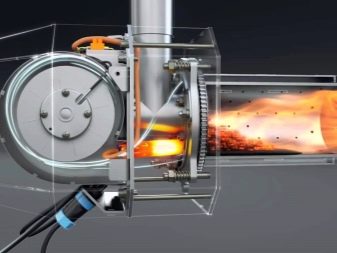

- They present a gas burner. She delivers gas to the combustion chamber.Thanks to the nozzles, the gas is distributed in the chamber as evenly as possible so that the thermal carrier warms up well. Often in the boilers there are special modulated burners that can control the flame and fix the desired temperature.

- Also, gas-fired boilers have a heat exchanger in their design. This detail is usually made of stainless steel or copper. Copper parts have good thermal conductivity and high efficiency. Steel elements can boast excellent strength characteristics. They are not afraid of damage and corrosion. There may be several heat exchangers.

- Circular pumps at the boiler can be one or two - it all depends on the capacity of the unit.

- If due to the heating of the water there was a problem of its overabundance, then the expansion tank compensates for it.

- Wall-mounted gas boilers are often equipped with automation. These elements are a special set of devices that maintains temperature stability in the heating system. Automation is dependent on electricity (for example, electronic sensors,thermostats or programmers) and non-volatile (such automation responds to changes in coolant pressure values due to overheating or overcooling).

- There is a fan in the turbocharged gas boilers.

- Gas wall-hung boilers are not complete without measuring components such as a thermometer and a manometer.

- There are gas boilers and regulating elements, for example, air vent and gas valve.

- An important component of the wall gas boiler is a security system. This component terminates the device if there is no electricity, and closes the gas supply solenoid valve. When the electricity supply is stabilized, the gas boiler is restarted manually.

Many models have a very useful system that protects the device from excessive cooling. If the unit has been operating in a power saving mode for a long time, the temperature of the coolant is controlled by special sensors. If the temperature dropped to 4-6 degrees, then there is a short-term start of the gas boiler, as well as heating of the coolant. Then the unit returns to sleep mode.

A well-thought-out self-diagnosis system makes it possible to detect up to 90% of errors and failures of the heating device. Data on the nature of a specific breakdown are displayed on a small display in the form of a short code.

Principle of operation

The principle of operation of suspension devices on gas is the same for different modifications. In such products, the controller is responsible for the temperature and coolant, and the environment using sensors. The specified element allows you to determine the need for heat, on the basis of which, the flow of gas to the burner. Thus, electric / piezoelectric ignition is carried out.

When the water reaches the optimum temperature, it is supplied using a circular pump from the heat exchanger to the direct heating system. When the maximum temperature values recorded by the thermostat are reached, the burner stops operation in automatic mode.

Advantages and disadvantages

The popularity of gas wall systems is beyond doubt. Many homeowners choose these units because they have many positive qualities.

Consider them.

- The main advantage of such units is that they provide both heating and hot water in autonomous mode. Thanks to this feature, you do not have to buy a separate boiler.

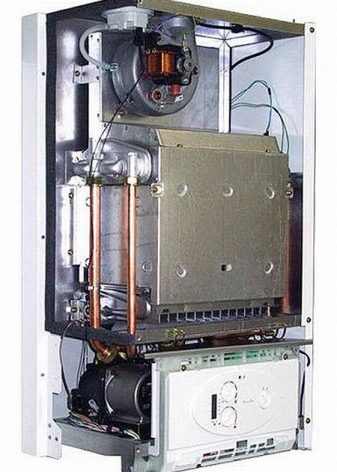

- Modern gas boilers are usually of modest size. For this reason, they have the opportunity to safely have in small spaces - the device will not interfere with the owners.

- Using a gas unit is much more economical than, for example, electric. With the help of such a device you can significantly save on utilities services. If the dwelling has a double-circuit boiler on gas, then there is no need to pay for hot water and heating.

- Having such a boiler, the owners can, at their discretion, change the degree of hot water, as well as the coolant itself in the system.

- Similar devices differ in the democratic prices. Practically every customer can afford a gas heating unit of a suitable modification.

- These devices are easy to operate. Cope with the gas boiler will be able to each user.

- Suspended gas boilers will complement almost any interior.Today in stores you can find units that have a different design, so you can choose a suitable product for every taste.

- Wall gas boilers reliable. They can last for many years, especially if they are faced with quality water.

- Such heating structures are sold in complete sets - you do not have to additionally purchase various parts and hang them around the unit itself. All necessary components are initially located in the boiler body.

- If you wish to operate the acquired boiler on a different type of fuel, then with a wall unit you will succeed. You only need to replace the nozzle and then reconfigure it.

- Modern manufacturers produce many different variations of gas boilers. The range of these devices is very rich.

Despite the impressive list of positive qualities, wall gas boilers have their drawbacks.

- If you actively use a bath, sink or shower, then the effectiveness of this type of heating gradually decreases. The boiler simply switches to the mode of water heating and does not support the temperature value of the thermal carrier itself at the required level.

- Such heating systems have a relatively small amount of hot water.Under the conditions of the largest consumption, the gas boiler may not have time to prepare it.

- Some units are "picky" to the purity of the water. Thus, heat exchangers in double-circuit units that collide with a liquid that has a high content of third-party compounds quickly become clogged and then completely fail.

Gas heating devices are very sensitive to the chemical properties of the coolant.

To overcome this disadvantage, it is necessary to install a special filter to soften the water on the jumper that connects the heating system and plumbing.

- Old heating units known for their "inertness" - when you open a faucet or shower head, cool water flows first, which gradually heats up.

- Even the best types of gas heating units may have a small capacity due to design features. Such units are not recommended to buy for large homes.

- Such devices require annual service, which does not suit many consumers.

Kinds

There are several modifications of gas boilers.Each of them has its own characteristics and quality characteristics. Consider them in detail.

Convection

These variations of gas boilers installed on the walls are recognized as traditional. They are found in many homes. During the combustion of fuel in the unit-convector energy comes out, and then rushes upwards - directly to the heat exchanger. At this site, it is transmitted to the water, which at this time circulates, moving along the contours. After that, all the waste of combustion comes out of the chimney.

The decisive advantages of these devices are that they are simple and inexpensive. However, these boilers use energy not 100%.

Condensation

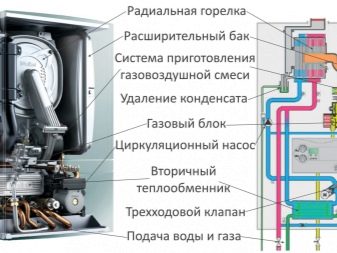

This boiler has a very productive way of working. When burning, the gas in such an apparatus forms water vapor, which carries a certain percentage of heat energy, which is then important to “catch”. For this purpose, the air flows from the burner pass through the primary heat exchanger and then cool down to +56 degrees Celsius. After that, they penetrate into the chamber in which the economizer is located (also known as the secondary heat exchanger). Direct condensation of vapors begins in this area, which appeared during the combustion of gas.

In the course of this action, the pairs transfer their heat energy to the contours along which the water moves. Next, the condensate is accumulated in a separate tank, and then goes out through the sewer.

The main advantage of such a device is an excellent indicator of efficiency (90-95%). However, these variants of boilers have a high price and are distinguished by a complex structure. Moreover, you will have to connect another line to this unit so that the liquid leaves the chambers in which the economizer is located.

Single circuit

These boilers are designed exclusively for heating the area, since there is only 1 heat exchanger in them. However, if it is necessary, you can connect a boiler to such a device so that you can use hot water in your home.

Single-circuit units operating on gas, most often bought in two cases:

- when there is no special need for hot water;

- if the house has several taps and shower rooms.

The main disadvantage of these units is that during their operation the heating of the room ceases to operate.

Double circuit

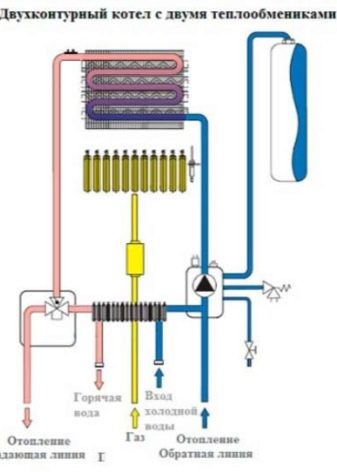

Such types of gas wall boilers are rightfully recognized as one of the most popular.They have 2 heat exchangers - they can be used both for heating living space and for heating process water.

The disadvantages of these devices are:

- opening the tap will have to wait some time before the water warms to a comfortable temperature;

- with this unit it will not be possible to use both the shower and the washstand in one moment - in such a situation, someone can get burned or suddenly “refresh” with cold water;

- double-circuit units are not designed for hard water - because of it on the heat exchanger in a short time can appear destructive scale.

However, it should be borne in mind that high-quality branded models from such shortcomings may not suffer, but such units will cost more.

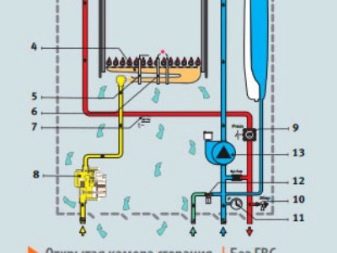

Dual circuit with separate heat exchangers

As mentioned above, in such devices there are 2 heat exchangers. Thus, the primary element is designed to heat water in the heating system. This detail is also a serpentine. It is connected using pipes for the supply / removal of fluid from the radiators.

In the intervals between the turns of this coil there are a lot of metal plates - this detail expands the heating area and also significantly increases the productivity of the equipment as a whole.

The second heat exchanger of plastic type in such equipment is designed to prepare hot water for domestic affairs.

Equipment with two circuits on gas can operate in 2 standard formats:

- in heating mode;

- in hot water mode.

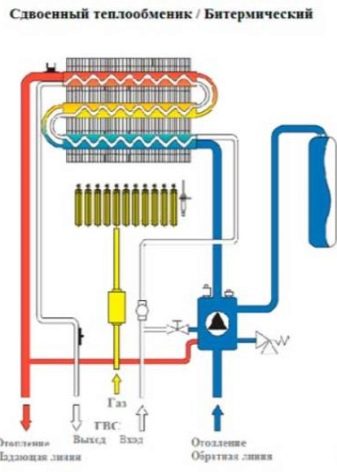

Dual circuit with bithermic heat exchanger

In these devices, both the heating fluid and simple water are heated in a common heat exchanger - a coil. In the inner part of the latter there are pipes divided into 2 channels. So, the fluid for heating moves along the outer channel, and the plain water used in everyday life moves along the inner channel.

The heat exchanger in this unit is equipped with a large number of metal plates, which are located in the coils of the coil.

Thanks to these plates, the area and force / speed of heating increases.

This boiler, like the above, has 2 main modes of operation. So, in a mode that is configured for heating, the fluid moves in the tubes through the external channel. At this time, hot water is also heated, but does not move anywhere. If one of the households turns on the water in the sink or the soul, the situation changes radically - the radiator coolant stops moving, and simple household water, on the contrary, begins its way through the channel insideheating and moving in line, which is hot water.

Similar units have 2 main advantages:

- they are inexpensive;

- different compact size.

However, it should be noted that the bithermic heat exchanger is susceptible to blockages due to water that stagnates in the hot water circuit. In addition, this equipment does not have good maintainability.

Dual circuit with open chamber (atmospheric)

Such equipment is more common. They have a simple design. In these products, the air required to burn the fuel and transfer energy to the heat exchangers is transferred by a natural intake from the space where the boiler is located. All waste is removed through the chimney.

It is in the chimney that the main problem of such structures lies - this communication detail requires additional investments, a lot of free time and effort.

You should also know that in the space in which all the listed elements will be located, you will need to organize good ventilation.

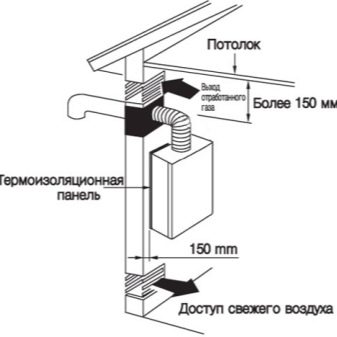

With closed combustion chamber (turbocharged)

These heating units are considered more practical and less troublesome. Air to these units comes from the street with the help of a turbine and a coaxial pipe. Through the latter, there is also a waste of combustion products.

Having a similar device, you do not need to install a chimney. However, such a boiler will cost the buyer a tidy sum. In addition, turbocharged 2-loop units consume much more electrical energy, and also produce some noise.

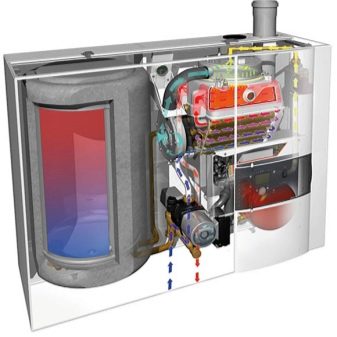

With built-in boiler

Such devices are equipped with a special capacity that holds no more than 60 liters. Such products have a power of 28 kW.

Mounted boilers with a built-in boiler do not have the disadvantages that are inherent in the above-mentioned units. They can work seamlessly even in low pressure conditions. In addition, such devices are undemanding to the quality of water, and also make it possible to use several points at the same time. Under the action of the boiler heating continues to function.

Of course, these high-quality models of boilers have their drawbacks. The main one is the high price.Many consumers for this reason refuse to purchase such units. Usually they cost at least 60 000 r.

Installation rules

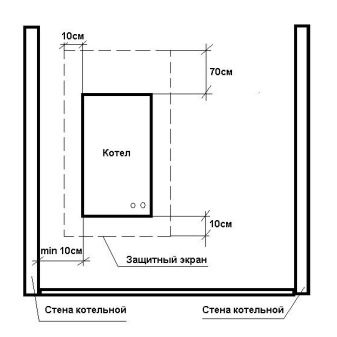

Installation of a gas wall boiler can be made by hand. The main thing is to strictly follow the instructions and do not rush into their actions.

The whole process of installing a gas boiler can be divided into several main stages, which cannot be neglected. Consider this workflow on the example of a simple single-circuit unit.

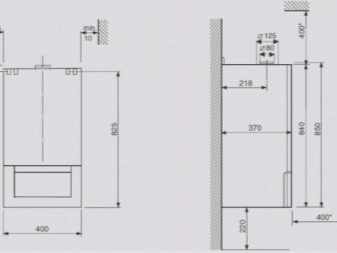

Wall mount

Mounted gas boilers need to be hung on special brackets. These elements most often come complete with units and they do not need to be bought separately. To correctly fix the bracket, it is not always necessary to use fasteners lying inside the box. There are cases when you still have to buy them yourself, based on the material of the walls.

If at this stage you have any difficulties, it is better to contact the specialists.that will help solve the problem. Keep in mind that the bracket must withstand the weight of the hinged structure without any problems. In addition, the boiler must hang evenly and without distortions.

The areas of overlap that are directly behind the equipment must be carefully protected with a special non-combustible material.

The height of the bottom of the boiler should not be less than 800 mm, and the distance from the wall to the back of the boiler - 5 cm.

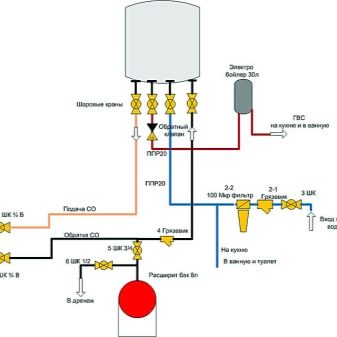

Connection of the main heating pipes

The number of pipes that need to be connected to the equipment depends mainly on the heating system (that is, one-pipe or two-pipe). With any design, it is important not to forget to remove the protective plugs from the boiler pipes before making the connections. At the entrance of the return should put a special filter mesh. This part will protect the boiler from penetration of dirt or any litter from the highway into its internal part.

It is very important to pay attention to the quality of the water used, or rather, its hardness. If this parameter does not meet the requirements of the manufacturer, then it is better to refer to a special cleaning agent or equipment (these may be polyphosphate dispensers). If you do not pay due attention to this nuance, the wall-mounted boiler may soon stop working normally.

Connection to the gas network

The next step is to connect the gas heating boiler to the gas network. These works should not be started independently - you need to contact a specialist with the appropriate admission.

At this stage it is necessary to mount the following parts.

- Ball gas valve. This element should be placed directly at the entrance to the heating unit.

- Gas meter and leakage sensor. These components are mounted in the pipeline to the boiler itself. They are designed for gas metering and security.

- Heat insulating valve. This element must be installed in accordance with the requirements of fire safety. If the temperature near the wall boiler rises to a specific value (for example, in the event of a fire), this valve automatically blocks the gas supply.

Electrical connection

An equally important step is to connect the heating boiler to the electrical network. However, this is not always necessary. For example, for devices of atmospheric type with an open camera, connecting to the mains is not required.

In units with closed chambers there are special fansnecessary for the removal of waste gas, as well as an automatic system to which you need to connect electrical power. As a rule, in this case, use a three-wire connection circuit, implying grounding.

Experts strongly recommend to include a gas boiler in the electrical network through a voltage regulator. With such a detail, it is possible to avoid voltage surges and extend the service life of the heating unit.

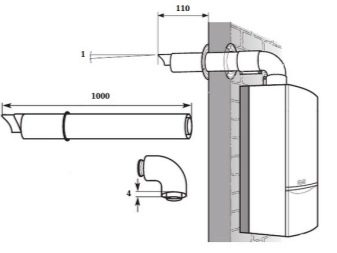

Chimney exhaust pipe

If you installed an atmospheric gas boiler, then you will need to connect it to the individual chimney without fail. Wall equipment is connected to it using an iron pipe of suitable cross section.

Before you connect these elements, you need to check whether the chimney is not clogged with mounting debris or soot.

To install an iron pipe, you should follow these simple rules:

- the vertical segment at the exit of the boiler must have a length of at least 2 diameters before turning;

- further, the pipe should have a slight inclination directed to the heating unit;

- The point of connection to the chimney should be as short as possible.

In units with a closed chamber, the removal of combustion products is much easier. Such devices have the ability to connect to a special collective chimney or use a coaxial pipe that goes through the wall directly into the street. If you mount this type of boiler, then the height of the suspension can not be monitored at all. In this case, a special fan will take care of the necessary.

Water filling system

Before proceeding with a test run, you need to fill the assembled system with water.

To do this, you need:

- open the valve (most often it is located in the lower part of the equipment);

- then water must be pumped, but this should be done until the pressure reaches about 2 atmospheres.

Note that this process should be carried out very slowly. It is necessary that the air in the inner cavity be released.

At the same time, it is important to check the system for leaks.

Starting run

If you have completed all of the listed works (and did everything correctly), then you can proceed to the first launch of the resulting construction with heatingequipment.

To start the wall gas boiler for the first time, you need to contact a certified specialist. Usually, specially trained employees are found in specialized companies that sell boilers and other heating parts. The specialist will be engaged in the system settings, as well as check its operation mode.

In the course of commissioning work, you should ask the certified “guest” all the questions you are interested in on the management and features of the gas boiler. If everything is functioning normally, then you can safely sign on the act of commissioning.

Popular models

Currently on the market there are many well-known and reputable manufacturers producing high-quality and reliable gas boilers. Let us consider in more detail the rating of the most popular and popular heating units from well-known brands.

German

The leader in this category is the world famous German brand Bosh. The products of this manufacturer can last up to 20 years, and if you treat brand boilers with care, they can work even longer.

Bosh boilers are good in that they have a self-diagnosing system that has been thought out to the smallest detail, as well as automatic settings. So, if the flame in the burner goes out, the gas supply will automatically shut off.

The branded gas boilers of the German manufacturer are powered by natural and liquefied gas. The heat exchangers of these units are made from materials such as copper coated with a special oxide film (it protects the metal from rust). Bosh boilers are compact in size. In addition, they have a neat design and easily fit into any decor.

Another well-known German company Viessmann offers the choice of consumers a variety of modifications of wall-mounted gas boilers: one- and two-circuit. Chimneys in branded models are improved - no frost appears on their surface. In a small device from Viessmann the membrane expansion tank takes its place by 6 or 10 liters.

Branded products of this brand can be purchased for 40 thousand rubles.

Italian

Quite good in terms of reliability and durability, boilers are produced by brands from Italy. For example, the company Beretta pleases buyers with a wide range of products, in which there are not only powerful (24 kW) heating units,but also high-quality components to them. These Italian boilers can operate from both natural and liquefied gas. The company offers the main types of heating systems: single-circuit and dual-circuit, as well as equipment with a boiler. In the 60-liter boiler there is a built-in expansion tank.

Italian boilers from Beretta are permissible to use at any temperature values (these can even be unexpectedly low values).

No less popular are branded gas boilers from the Italian brand Baxi. This brand produces high-tech units of the 5th generation, having atmospheric burners and operating absolutely silently. In these models there is a bithermic heat exchanger. As for the direct power of the units, it can be 10-80 kW.

The main feature of Baxi brand gas boilers is their high performance. (Efficiency about 90%).

The minimum warranty for such Italian products is 7 years.

Korean

No less popular today are Korean-made boilers. For example, Daesung offers customers excellent models called Arderia with two heat exchangers. The first one is made of copper, and the second one is made of steel plates.Thanks to this design, Korean boilers heat the water unexpectedly quickly.

Also, brand-name boilers from Korea are equipped with an integrated voltage stabilization system. This component operates in the range from 150 to 280 V.

Units can boast several degrees of protection:

- from overheating;

- from freezing;

- from leaks;

- from pressure surges.

Arderia brand gas boilers are easy to use, as they can be controlled using the remote control.

Russian

Durable gas boilers of Russian production are also in demand among modern buyers. Thus, a major manufacturer of Borinskoe, ISHMA BSK, offers a choice of buyers high-quality units with forced and natural circulation. Russian products differ from foreign ones in that they are non-volatile. This feature is very relevant in a harsh climate and possible power outages.

The disadvantages of the Russian gas boilers from Borinskoe OJSC ISHMA BSK are that to install a unit with a forced circulation system, you will need to purchase additional parts such as a pump, a thermostat, and an expansion tank.

Good gas wall units, collecting positive reviews, offers a domestic manufacturer JSC "Agroresurs". The most popular models are Danko, which have a reliable hermetic combustion chamber, a heat exchanger made of steel, piezoelectric ignition, as well as special micro-flare types of burners. In addition, branded boilers from Agroresurs have gas filters.

The range of the Russian manufacturer is represented by models that have a capacity of from 7 to 15.5 kW.

Such devices are perfect for heating small rooms.

Tips for choosing

Choosing a suitable wall-mounted boiler, powered by gas, it is necessary to pay attention to the following components of the unit.

- Burner. Burners are forced and atmospheric. The latter, as a rule, come complete with a fan, the poet are more noisy, but also more efficient. Atmospheric burners with this work longer.

- Heat exchanger Copper heat exchangers have the highest degree of thermal conductivity. And the most durable are steel options. The most compact - bithermic heat exchangers, but, unfortunately, they are not as durable as coils.However, whatever heat exchanger you choose, it should be borne in mind that in most cases they eventually fail and require replacement.

- Volatility. This parameter is especially important if there is a disruption in the work of electricity in your place of residence. For such houses it is better to buy straightforward units, in which there is no fan, pump and programming.

- Convenience management. If you bought a unit for a private house or apartment that is powered by electricity, it is better to purchase a high-tech copy with an additional set of functions. This may be built-in electronics, remote control, display.

- Manufacturer. Do not forget that only a bona fide manufacturer can guarantee high quality of the unit. Do not look for too cheap boilers - their low cost may indicate dubious quality. Purchase branded products that are covered by the warranty.

Useful recommendations

If you want to use several points at the same time, then you should purchase a boiler that can form at least 60 liters of hot water.Such products, as a rule, have a built-in boiler and a special mixer. Thanks to such components, the temperature of the water does not change at absolutely any level of water or pressure.

Some experts argue that it is very difficult to install wall-mounted boilers yourself and it is better to entrust this work to professionals. If you doubt your strength, then it is better to follow this advice and call qualified people.

Note that a detailed installation diagram must be attached to any modification of the gas boiler. During installation of the unit in the surrounding space, the temperature should be between 5 and 35 degrees Celsius, and the humidity should be about 80%.

When installing the brackets to the ceiling, it is necessary to leave a gap of 3-5 cm between the wall and the boiler.

It is recommended to install a double-circuit boiler in small houses, where every centimeter is valuable. A single-circuit unit with a connected water heater will do a good job with its task in a spacious cottage or apartment (with a separate room for the boiler).

If you want to purchase a unit with complete gas mixing, then you should know that these types of boilers are no longer supplied to the CIS countries.

To prevent bad water from damaging the heat exchanger in the boiler, special filters should be installed.

Only experienced professionals can determine the final power of the boiler for gas needed for your home. To do all the calculations correctly, you need to have the appropriate knowledge and qualifications.

Note that with a single-loop unit with modern automation can work and other circuits. For example, it may be a warm floor system or ventilation in a residential area.

Select the appropriate boiler should be based on the specific situation. It may happen that the gas wall unit, which went to one room, is not suitable for another.

How to install a gas boiler, see the following video.