Sensors on the gas boiler: how to choose and check?

It is impossible to provide comfort when living in your own home in the country without using a good and efficient heating system. In such mechanisms a very important role is played by an individual type of heating boiler. It is his work that makes it possible to maintain a comfortable climate indoors.

What is needed?

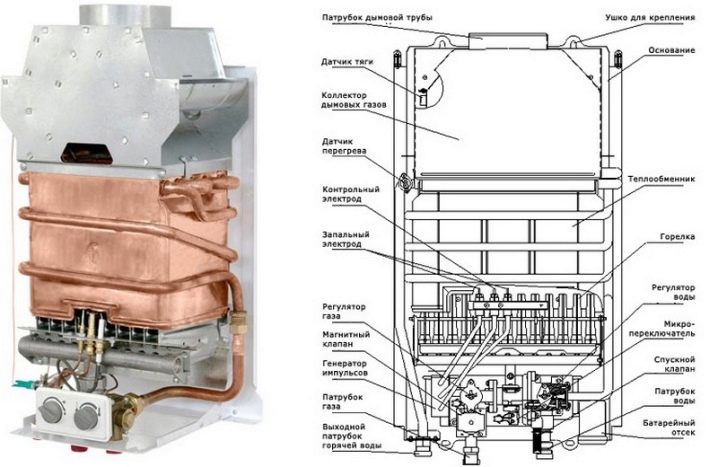

Today the most common are gas-fired boilers, since today blue fuel remains the cheapest when compared with the cost of other energy sources. As a rule, gas equipment for heating usually operates in automatic mode. So that its operation was safe, there are several sensors inside that monitor the performance of the system.

As soon as any deviation occurs, the equipment immediately receives a command to shut down. A thrust sensor of this type works as follows - the controller simply analyzes the thrust and turns off the device if the smoke intensity decreases.

The sensor on the gas boiler is used in accordance with all the basic laws of physics. In fact, it is a bimetallic type relay operating in the “on-off” mode.

Principle of operation

If we talk about the principle of operation of this type of equipment, it should promptly give a signal to the valve, which will allow shutting off the gas supply to the burner. The sensor reacts if there is a violation of the flow of combustion products in the correct and natural direction, that is, from the boiler towards the street through the chimney. If the sensor does not work in this situation, the smoke generated from the flame, which consists of dangerous gases and water vapor, as well as soot, begins to get into the house where the boiler is located, and can cause harm to health, and even lead to death.

If we talk about how it works, then everything is very simple. As already noted, everything is based on the usual laws of physics.

In fact, these are bimetallic relays operating in two modes:

- turning on;

- shutdown.

Inside such a thermal relay there is a strip of metal, whose main task is to respond to temperature drops. Such a device is usually tuned to a specific temperature. Its rate will depend on the category of fuel used. If we are talking about natural gas, the temperature range will be from 75 to 950 degrees Celsius. If we are talking about liquefied gas, the dispersion will occur in the range of 70-1500 degrees Celsius.

You can talk about the principle of operation a little more on the example of the sensor on the gas boiler. If the device, analyzing the information, concludes that the thrust inside the boiler significantly deviates from the norm and an increase in the heating of gas smoke begins, then the device immediately locks out and its almost instantaneous shutdown.

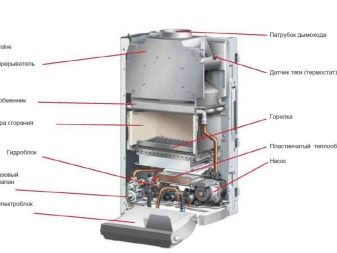

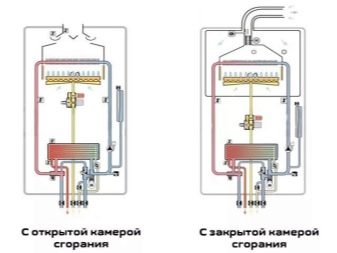

In different categories of devices, sensors can monitor different parameters. For example, in models where there is an open-type combustion chamber, a special thermostat monitors the draft and the temperature of the gases going outside. And if we are talking about a model with a closed combustion chamber, in this case, the sensor monitors the air pressure, which is blown out by the turbine.

It should be noted that the role of this type of controller is very difficult to overestimate in the issue of security. For example, if we talk about the turbocharged models where a closed combustion chamber is installed, the combustion products are displayed using a turbine fan. The controller is usually usually made as a pneumatic relay. Work is controlled by a membrane. If the pressure becomes weaker, the contact is simply opened, which causes the gas supply valve to close.

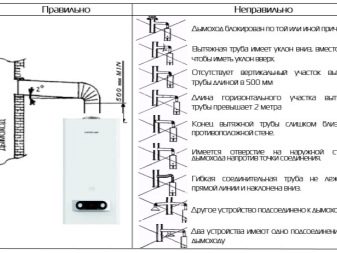

It should be said that the thrust sensor may work in such cases:

- accumulation of debris in the chimney;

- wrong device installation;

- when installing the fan in the boiler, where there is a forced draft;

- if the dimensions of the chimney shaft are smaller than the calculated ones or it was mounted incorrectly.

If the device is turned on, you must immediately search for and eliminate the cause of the fault. It should also be noted that one should not try to forcibly close the contacts, as this may be not only the cause of the unit breakdown, but also the death of a person.

Kinds

The main task of temperature sensors is to control the degree of heating of the heating circuits, as well as air masses, both indoors and outside.They transfer the collected information to the thermal regulator, which allows you to control the process of combustion and heat control. It should be said that there are different categories of temperature sensors.

If we take the device as the main criterion, then there are:

- sensors that are responsible for monitoring the heating of the heat carrier;

- devices responsible for monitoring the temperature of air masses.

If the main criterion is the place where the device is located, then there are:

- submersible;

- room;

- invoices;

- outdoor.

If the main criterion is the method of signal transmission, then there are solutions:

- wireless;

- wired.

Now let's talk about the mentioned categories in more detail.

Room models are designed to measure and control the temperature inside the objects where the heating takes place. If there are any changes in the temperature in the room, the sensor of the specified type immediately transfers information to a special boiler control station operating in automatic mode. Due to this, the temperature increases or decreases due to changes in the heating power of the heating circuit.It should be said that each such sensor can also have remote temperature sensors for the boiler, built-in options, or both categories at once.

If the boiler is not installed indoors, but outside, then the heat balance will be maintained using an outdoor temperature sensor, which is placed outside the building. If there is a temperature change in the direction of cooling or warming, the sensor, adjusting to the changes, starts a specific boiler program, which will control the heating of the water supplied for space heating according to a strictly defined schedule. That is, the heating of the thermal carrier will be carried out in accordance with how the external temperature regime changes. Accounting for changes that occur on the street makes it possible to improve the comfort of the owner and significantly save energy, as well as the finances of the house owner, respectively.

It should be said that there are not only remote solutions of this type for boilers. There are also other elements of changing temperature readings that can be mounted this way.

If we talk about the method of transmitting information to the regulating device, then the temperature sensors are divided into two categories:

- Wired. In this case, the connection with the controlling part is carried out through the postings that transmit information.

- Wireless. Here the information goes to the adjustment module by means of a signal over the radio channel. As a rule, this option consists of 2 blocks. The first is the transmission unit, which is installed in the room that is being monitored. And the second is the reception unit, which is installed on the boiler or somewhere nearby.

Another category is used to determine the heating of the coolant in the heating circuits of gas boilers or boilers.

As a rule, they exist in the following forms:

- Submersible. This type of sensors is placed in special places on the pipelines and in direct contact with the heat carrier. Thermoelectric type transducers such as thermocouples and resistance thermometers that are adjusted for perception in a certain temperature range can be used as sensitive parts here. They can be either uncalibrated or calibrated. The latter usually have a screen and measurement limits can be easily configured.

- Pressostat. So called pressure sensor.It saves the boiler from overheating, when the gas pressure index changes sharply or the water flow decreases. In order to save the boiler from sudden pressure drops, one needs a sensor that works to turn off the boiler at the right time.

Visually, it looks like a normal electrical sensor or a relay. Its distinguishing feature is the presence of two electrical chains-spotters. It is these two chains that determine the sensor modes. There are two of them.

In the first case, the use of normal pressure is assumed. In this case, the thermostatic membrane type does not change its location, which allows you to close the first part of the contacts. Only the boiler works in its normal mode due to the fact that the current passes through this circuit.

The second mode is activated when there is a violation in some parameter of the system. Inside the sensor, the thermostatic membrane is biased and deflected. In the first sensor circuit is disconnected from the membrane, and the second is an automatic closure. After that, the boiler immediately stops its operation. And immediately the standby mode is activated, which informs the user, for example, with an SMS alert about an accident.

It should be noted that this type of device may work even as a result of the minimum temperature increase in the combustion chamber. It can track any value of pressure force and tracks when moisture starts to condense in the combustion products or the gas itself.

Check

A change of the boiler draft sensor may be required if serious disturbances are observed in the operation of the heating equipment. That is, if the boiler is turned off constantly, although there are no serious problems in the chimney and all other components of the system. Or if the controller is working, but around 25 minutes after launch it turns off. But the next start usually happens only after the sensor has completely cooled. And it is for this reason that the boiler thrust sensor will not be superfluous. This can be done in three ways. In the first case, in the place where the sensor is fixed, a mirror is installed. During operation of the device it should not sweat. If this is not the case, there is something wrong with the system.

Another way is to check the flue gas sensor. To do this, it is necessary to cover the chimney with a damper, but this should not be done completely.If everything is fine with the system, then the boiler should turn off at the same time.

The third way to check is that the dual-circuit version is transferred to the hot water mode, but without the support of heating. After that, the valve opens to full. If the controller is disabled in this mode, it is likely that there are some problems with the thrust sensor.

It should be said that all controllers can be used for different units. This includes both wall and floor boilers, as well as geysers.

To understand that it is necessary to replace the sensor, and no matter what - thrust, flow, water pressure, indicate the following signs:

- the boiler is constantly turned off, despite the absence of visible reasons for this;

- after half an hour, the heat generator stops working and it cannot be restarted until it cools down.

If the controller itself works perfectly, then it makes sense to check whether everything is in order with the burden. Also, shutdowns can occur in cases where there are failures in the operation of automation. It should immediately be said that if there are any deviations, one should not try to carry out repairs on their own.The best solution would be to call a gas service specialist at home. He has experience in repairing such devices, and he will definitely be able to quickly and accurately repair the damage in the shortest possible time.

At first glance it may seem that choosing a sensor for a gas boiler is very simple. To some extent this is the case. But this should not be taken as something simple, to which one cannot pay special attention. Since it is the sensor that will be the protection system that, in the event of a malfunction, will be able to prevent trouble and turn off the boiler almost immediately as soon as problems arise.

The same applies to the verification of this type of equipment. Be sure to check the sensor even simply in order to fully ensure that it is completely serviceable. For this reason, special attention should be paid to the process of selecting such a meter and the process of checking it.

For hinged boilers, see below for sensors.