Gas boiler: features and requirements for installation in a private house

When choosing a gas boiler for installation in a private house, you should take into account a number of important nuances that are associated with the characteristics of its installation, the technical parameters of the building itself and the real needs for effective heating and hot water supply. The modern market is full of offers from Russian and foreign manufacturers, so everyone can choose the model that best suits their operating conditions.

Kinds

Modern boilers used for heat supply and supply of hot water in cottages and private houses, designed to meet the characteristics of use. They have a slightly modified internal structure, which makes it possible to make the combustion of the supplied gas the most economical and significantly improve thermal efficiency.

Far from any boiler in individual houses will provide efficient heat recovery, therefore When deciding on the choice of model, special attention should be paid to several parameters:

- Type of heating system - for traditional boilers, the most optimal radiator heating option, at the same time, many modern products work only in combination with “warm floors”.

- Type of fuel used - the basic criteria for selection of the boiler must always be a high degree of heat transfer and the most economical gas burning. Efficiency and thermal efficiency are fundamental for installations that operate on liquefied fuel.

All types of modern boilers should be divided into several categories according to three basic characteristics.

By type of accommodation

Acquisition of a boiler for a residential house should begin with the selection of a model for the placement option. There are models mounted and floor, and each has its unconditional advantages and disadvantages.

Wall boiler

This is a volatile type of boiler units. To ease its weight and reduce the overall load on support structures, engineers often resort to a wide variety of tricks,the mass is often reduced by the use of lighter metal alloys, as well as the installation of a bithermic heat exchanger.

In single-standing houses single and double-circuit units can be installed., the latter have a special tank for heating water, in the first case there is no such container, so they are used only for supplying heat.

The undoubted advantage of wall modifications is the possibility of significant savings in space, some products are even embedded in kitchen cabinets, and in addition, they are fairly easy to connect to the general heating system.

Floor standing boiler

They have no restrictions on performance, and this is their main advantage over the mounted units.

At the same time, such models require sufficient space, which even without boiler installations in the kitchen is not enough.

In order to choose the right version of the boiler according to the method of placement, one should make a start from the total heated area of the building.

For example, for homes of 200 or more square meters, floor models will be optimal, which are distinguished by high power parameters, but at the same time they are cheaper.

And for small houses it is worthwhile to give preference to models of the mounted type, they take up little space, and their working capacity is enough to heat small-sized buildings.

By type of combustion chamber

Depending on the design features of the camera, there are 3 variants of heating systems.

Atmospheric

These are the most reliable models that are characterized by simplicity of configuration and mechanism of operation. An open combustion chamber is provided here, while air is taken to burn gas, which the installation absorbs from the living space. All necessary adjustments are made using thermomechanical regulators.

The disadvantages of such options include a high level of gas consumption with a rather low efficiency. In addition, these boilers require special installation conditions.

Turbocharged heat generators

Such models include a sealed combustion chamber, while to maintain combustion air is absorbed from the street, and not from the space of the boiler room. The intake of air to the burner, as well as the output of combustion products, is produced by force using a turbine fan.

The advantage of these boilers lies in their high efficiency. in comparison with atmospheric, the gas consumption here is reduced by 25-30%, and the efficiency reaches 98%. Installation requirements are minimal, thanks to which the unit is ergonomic and relatively compact.

The disadvantages include an increased level of noise during use, as well as complete energy dependence.

Condensation

These are the most profitable and practical boilers with an efficiency level reaching 109%. The combustion chamber in such models is closed, with a modulating burner built-in. These are non-volatile models that work quite effectively on both natural and liquefied fuel.

But they also have a drawback, and a very significant one — such options only function when connected to such heating systems as “warm floor” —that is, where floor covering solves the problem of heating the air, and radiators only maintain the required temperature in the living rooms.

The choice of a specific boiler model is made on the basis of information about the voltage in the network and the type of fuel that is planned to be used in the house.

By the number of contours

In residential buildings more often there is no urban hot water supply,therefore, its owners prefer double-circuit models, which allow not only to heat the air, but also to provide residents of the building with hot water.

Single-circuit boilers are mainly installed in homes where there is no need for heating watersuch units are sharpened strictly for space heating. This model is not produced by all manufacturers, as it is in rather low demand from owners of their own homes.

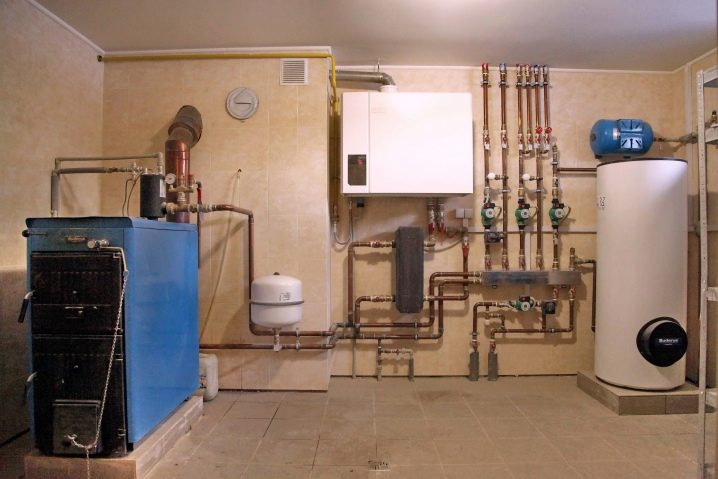

Requirements for the room

In the cottage and private building, when installing a heating boiler, increased requirements are imposed on the room where the installation will take place, due to security considerations. They are spelled out in the SNiP (31-02-2001, as well as II-35-76, 42-01-2002 and 41-104-200) - these standards make it possible to reduce to nil any risks of the occurrence of potentially dangerous situations for life and health. The spaces in which gas coolants are mounted are of the type of fire and explosion hazard, therefore the general requirements for them must be complied with without fail, and the projects of such equipment must be approved by certified enterprises.

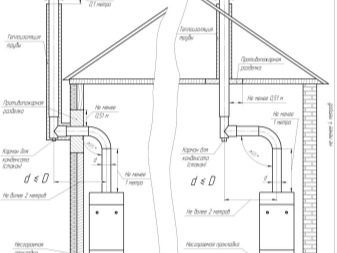

In accordance with existing regulations, boilers should be installed in a well-ventilated space, which can be located:

- on the first floor of a residential building;

- in the basement or basement;

- in the attic.

Any boilers with a capacity of less than 35 kW can be mounted in the kitchen.

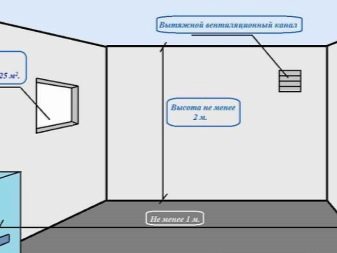

The room where it is planned to install heating units must comply with the following mandatory requirements:

- it must be well ventilated, and the type of ventilation required supply and exhaust;

- a rather high level of natural insolation must be maintained in it - for every cubic meter of free space there must be no less than 0.003 m2 of the total area of the window opening, and the dimensions of the frame and imposts are not taken into account;

- in addition to the window, equipped with an easy-to-open small window, there should be free exit from the room, and in the basements and equipped basements, the exit should go directly to the courtyard.

Supervisory regulations clearly establish the total power of all heating elements located in a building (boilers, as well as radiators, batteries or boilers) - it should not exceed 150 kW in total.

The height of the walls in the room prepared for the installation of the boiler must not be less than 2 m.

The room where the heating equipment is attached,must necessarily be separated from the remaining zones in the building by a capital refractory wall built of brick or some other material having a fire resistance time of 45 minutes. The place where the equipment is supposed to work on gas should be planned so that when there is a fire, there is not a single opportunity for the rapid spread of fire throughout the building.

Boilers that operate on the mechanism of natural circulation, can be installed only in the basement.

Separate standards apply to kitchen halls where we can install low-capacity boilers up to 60 kW:

- the minimum possible volume of such a space is calculated by the formula = 15 m3 + 1 m3 for each kW of unit capacity;

- minimum permissible wall height - 2.5 m;

- the presence of the hood with a capacity of three or more times the volume of the kitchen;

- a window must necessarily include a window, the area of which should depend on the size of the glass: if its thickness is 3 mm, the glass area excluding the window frame is 0.8 m2 and above, with a size of 4 mm it is from 1 m2, but the glass density 5 mm will require 1.5 m2 vents.

- The lower part of the kitchen door should be supplemented with a small opening between the floor covering and a door not less than 0.025 m2 wide.

There is another rule that is not fixed by law, but is in force - the installation of the boiler is allowed only in rooms with doors. Coordination of the project, in which partitions are demolished, and arches instead, are equipped, can give the homeowner a lot of trouble. To avoid this, you can install sliding or folding partitions, or glass products - they do not change the design visually, but, from the point of view of SNiPs, are perceived as doors.

For units with a capacity of over 150 kW, the presence of an individual exit to the courtyard is indispensable.

All of the above standards are mandatory, otherwise you simply will not accept the act of approval and will not connect the boiler to the main gas supply system to the house.

Sometimes in a private residential building there are no rooms that meet safety standards and technical documents, in this situation you need to attach a separate boiler room.

The general standards related to the height of the ceilings, the level of glazing and the presence of ventilation in it remain the same as those set for the interior, however, a number of special requirements are added:

- boiler room can be attached strictly to a solid whole wall, while the distance to the nearest doorway should not be less than one meter;

- walls can be built only from fireproof non-combustible material - for example, from brick, aerated concrete, cinder block or shell rock;

- The foundation of a boiler room should not be integral with the foundation of a residential building - it is carried out separately and independently;

- focus on the fact that the boiler room, like any extension, should be drawn up, because without registration documents one company will not connect it to the central gas pipeline;

- and another important point - when creating a project, all dimensions should be spelled out with maximum accuracy, otherwise the equipment will simply not be accepted.

It should be borne in mind that the operation of two or more devices in the same furnace room is strictly not allowed.

Installation of boilers in a wooden house is allowed, but in this case the room must be equipped with fire extinguishing means.

The installation of gas equipment must be carried out by professionals and only after the project has been fully approved by the technical inspection authorities.Installing such a unit on your own may cause the saddest consequences.

For more information about the process of installation of heating on a gas boiler, see the following video.