The subtleties of the choice of oil paints

Among the many types of coloring compositions that are actively used in Russia, oil paints are invariably present. But even the long history of their use does not allow most people to consider their knowledge about these dyes as complete. Meanwhile, behind the general name of the group there is a whole range of original technological solutions. Only knowing the exact features and specifics of marking, you can understand the range of paints and materials and make the right choice.

Special features

Oil paint, or linseed oil, is always made from oils, in most cases from linseed and hemp, sometimes from castor oil.They do not have a high evaporation rate, and some species do not form volatile compounds at room temperature. Exactly because of this reason oil paints - both for interior and exterior use, have a very long drying period. A layer of oil, which occupies only a few tenths of a millimeter on the surface of the coating, can completely evaporate only after a few months.

But there is, fortunately, another chemical mechanism - polymerization under the action of atmospheric oxygen. This process can occur strictly in the thinnest film that contacts directly with the air, there is no progress into the oxygen.

As a result, any oil paint can be applied only in a thin layer; To further speed up the process, driers are added to the drying oils, that is, catalysts, but even with such additives drying will be completed in at least 24 hours. In accordance with GOST 1976, natural drying oil should be 97% composed of processed vegetable oils, siccatives take up the rest of the volume, and other additives are not allowed at all.

Composition Oksol drying oils GOST 1978 was as follows: 55% - natural oils that have undergone oxidation, 40% - solvent, and the rest is occupied by the desiccant.Its cost is less than that of natural brands, but the presence in the recipe of white spirit does not allow to consider the mixture safe. The formation of combined drying oils comes from the same basic substances, but the concentration of the solvent is reduced to 30% by volume. The recipe for alkyd mixtures includes the same resin - glyphthalic, pentaphthalic, xyphthalic. Synthetic drugs are 100% derived from oil refining and other complex industries.

Dried and powdered kaolin, mica of small fraction, talc are used as fillers in oil paints. Any substances that will not react with the main part of the mixture and at the same time will be in a solid state are suitable.

Pigments for oil paints are always used inorganic nature. They are divided into having a pronounced color and black and white. To achromatic dyes are primarily zinc white, which are very cheap, but under the action of high temperatures become yellow. White color in modern oil paints is often attached with titanium oxide or lipotone, which is much more resistant to heat.Black tone can be achieved using carbon black or graphite. As for bright colors, they are created as follows:

- Yellow iron metahydroxide, lead crown;

- Red lead red lead or iron oxide;

- Blue iron blue;

- Dark red - chromium oxides;

- Green - the same chromium oxides or cobalt compounds.

As catalysts for drying (siccatives) take manganese, cobalt or lead salts; It is very important that the concentration of the desiccant is not excessive, otherwise the film will not be sufficiently stable.

Types and characteristics

The main characteristic of any oil paints is the concentration of substances forming the film. They must be at least 26%, since the strength of the coating being created and its ability to remain on the surface depends on this indicator. But it is important to consider that the more formulations are saturated with film formers, the worse they are stored.

All those who experienced had to deal with oil paints, know for sure that they have a strong odor, which, when heated from 20 degrees and above, is especially harsh. Therefore, the proportion of volatile substances in the normal should account for a maximum of 1/10 of the total.Further, it is worth considering such a parameter as the fractional composition of dyes.

They say about a smooth grinding when it exceeds 90 microns, and about fine-grained - when particles are smaller than this bar.

How quickly an oil paint dries depends on its viscosity; This indicator also affects the fluidity and how easily and simply the substance is distributed over the surface. Normally, viscosity is not lower than 65 and not higher than 140 points, deviations to both sides unequivocally indicate low quality of the material. Actual technical indicator can also be considered mechanical strength and resistance to water.

Basic information oil paint manufacturers are communicated to consumers through labeling. First, there are alphabetic combinations: MA - mixed or natural linseed oil, GF - glyptal, PF - pentaphthalic, PE - polyester. The first digit indicates the use in exterior and interior decoration, the second emphasize the type of binder, and the rest are allocated for the index assigned to a particular company. So, “PF-115” should be read as “oil paint on a pentaphthalic base with the addition of natural drying oil for outdoor works, factory index 5”.MA-21 means a mixture based on a combined drying oil for interior use. MA-25 and MA-22 are also similar.

BT-177 is an oil-bitumen paint that can be applied to the surface of bitumen. According to the current in relation to such a GOST composition, it should be completely ready for use. Regardless of the specific brand of oil paint, enamel or another type of paint and varnish materials can be applied on it only with a smooth layer that does not have any external defects.

Artists also actively use oil paints, and for them the typical drawbacks of these materials, which builders constantly complain about, are not significant. If the oil is formed directly on the surface, the paint should be stirred before each use. Only by mixing a few tones can you get a truly original color. Yellow Neapolitan on the basis of lead white is considered to be a fast-drying artistic paint. Tempera dyes in nature are similar to oil. Each artist himself chooses what is most suitable for him.

But for builders and people making repairs, of course, in the foreground are other properties.In many cases it is very important that the painted surface is oil resistant, this requirement is relevant in industry, energy, transport and in some other industries. For pipelines and radiators in the first place will be resistance to elevated temperatures. By the way, disadvantages of oil paints in such an area are far superior to their meritsand no specialist will recommend them unless absolutely necessary. You can create a matte surface by adding a solution of household soap to the paint (40%), initially all the oil compositions are glossy.

When choosing oil paints, there is always a contradiction between price and quality. Thus, the compositions on natural varnish are invariably more expensive than those containing a synthetic base. Titanium pigments always cost more money than simple zinc white. It should also be noted that the paints produced in the nearest regions will be cheaper than those of the same, but brought from afar, especially those that have overcome customs barriers.

Compounds for different surfaces

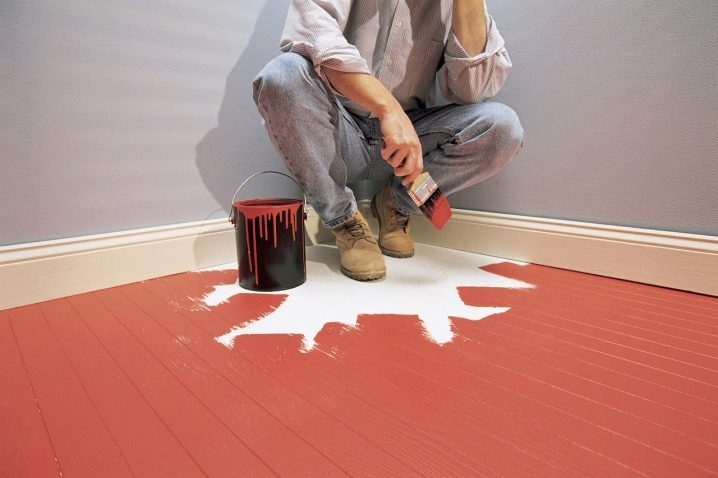

Initially, oil paints were used specifically for decorating wood, and banks traditionally indicate their consumption per square meter. mwooden surface. It should be noted that only perfectly clean and smooth, smooth surfaces are suitable for applying oil paint.

Do not purchase very cheap coloring compositions, because it is impossible to make them 50% cheaper than others without losing quality.

Oil paints for metal in most cases are made on the basis of natural varnishes. They are able to withstand heating up to 80 degrees, which does not allow the use of similar compositions on roofs and heating devices for painting metal radiators. In addition, the low durability of the coating makes it difficult to apply outdoors, on a wrought fence or other fencing, for example.

Plastic painting with oil paints is quite possible, but the result is ensured only if the surfaces are thoroughly prepared. Oil painting compositions are used very often in art glass painting, but since they create a matte surface, this must be taken into account. The coating will not be sufficiently heat resistant, but diluting it with a top coat will protect it from water. On concrete and plaster layer of oil paint falls no worse than wood or metal.If you do not understand the differences in different colors for applying to certain surfaces, it is better to seek the advice of professionals.

It should be noted that in the bathrooms it is impossible to paint the entire surface with oil paints. Be sure to leave a strip of other materials, otherwise the humidity is too high.

When you choose paint on wood, focus on GOST 10503-71, compliance with it guarantees the quality of the coating. The wooden floor will need to be repainted every three or four years to compensate for the rapid wear of the layer.

How to breed?

No matter what material the oil paint is intended for, you may be faced with the need to dilute the mixture. Over time, it thickens or even turns into a solid. The only acceptable way of breeding is to add what is at the base of a certain dye.

When the pot is not too long, adding drying oil helps to make its contents less thick. But it is important to consider that the linseed oil is prepared using various technologies, and making the wrong choice will ruin the whole product. And after a strong compaction (drying), it is necessary to use a solvent. With his help, you can make a primer of paint.

Natural linseed oil based paints can be diluted only with natural compounds. A composite mixture is required to dilute:

- Turpentine;

- White spirit;

- Solvent;

- Gasoline

It is important to remember that whatever reagent is used for dilution, it is injected in batches, because excessive concentration of drying oil will lead to long drying.

First, the paint composition is moved to the tank, where it will be possible to interfere with it and break up clots. Then gradually add the drying oil and immediately thoroughly mixed. When the desired consistency is achieved, the paint must be passed through a sieve that will hold small lumps.

When choosing a solvent, keep in mind that certain types of it can distort the physical and chemical properties of paints.. As the drying oil, the solvent is added in small portions in order to preserve the basic ratio of components. Simple white spirit will not work, you need to use only purified, which is better diluted. Turpentine, which has not been cleaned, cannot be taken either - it delays the drying of the colored layer. Kerosene gives the same effect, so it is used when nothing else can be used.

Consumption

The cost of oil paint, indicated on the labels, is always average, designed only to estimate the volume of material or reflect opacity and the amount of dry residue. But it is important to know all the factors that affect the actual consumption of paint. The base figure for 1 m2 is from 110 to 130 g, but the specifics of the base (material that is painted) are not taken into account here. For wood, the normal variation of values is from 0.075 to 0.13 kg per 1 sq. Km. m When calculating the following are taken into account:

- Breed;

- Heating and relative air humidity;

- The quality of the surface (how smooth and smooth it is);

- There is a preliminary layer or not;

- How thick is the tone and what color is required to form.

On 1 square. m metal standard indicator of oil paint - 0.11-0.13 kg.

In order for the calculation to be accurate, you need to pay attention to the type of metal or alloy, the general condition of the surface layer (above all, corrosion), the use of a primer. Consumption of oil paints for concrete is determined primarily by how porous the surface of the wall, floor or ceiling. On 1 square. m sometimes have to spend up to 250 g of the coloring composition. Simple plaster can be painted at the rate of 130 g / sq.m, but the relief and ornamental varieties are much more complicated in this regard.

The most consumed oil paint tone is yellow, a liter is never enough for more than 10 square meters. m, and sometimes it is possible to paint half as much. Slightly better performance in white, although he has the same ceiling. A liter of coloring mixture allows you to create from 11 to 14 m2 of a green wall, from 13 to 16 brown, or from 12 to 16 - blue. And the most economical will be black paint, its minimum indicator is 17 m2, the maximum is 20 m2.

The general conclusion is simple: light oil formulations are spent more than dark ones. When there is already a paint layer at the bottom, you will have to use more material. Sometimes it is more profitable to clear the base and prepare a plaster or primer layer, this will simplify the subsequent work. Of course, when painting in 2 layers, it is necessary to increase the figures of the standard flow rate by 100%.

Much depends on the tool used. Using brushes, you will inevitably spray paint, it will drip onto the floor and accumulate on the pile. Complicating the definition of the thickness of the layers is complicated, as a result, the material will have to be spent more, and the likelihood that it will be necessary to redo the work is quite high.Most economically among hand tools, perhaps, rollers with silicone pile. And if you consider all the options, the best solution is to use the spray gun. Extremely accurate figures can be obtained using online calculators.

Approximate calculations relate only to a flat surface, painting pipes or other structures of complex shape requires that paint consumption be calculated additionally. When work is done outdoors on a sunny windy day, the cost of oil paint increases by 1/5 compared with painting in a room at room temperature. The drier and quieter the weather, the better the coverage.

Manufacturers: review and reviews

Although oil paint is not considered the most perfect, it is still produced by various manufacturers. First of all, you need to make a choice between Russian and foreign products: the first is cheaper, and the second is more prestigious and modern technologies are used in its production.

Consumers in product reviews Corporation AkzoNobel note the high quality, the ability to transfer up to 2 thousand cleanings. And followers of Finnish Tikurilla often choose it because this brand produces over 500 shades.

Review the oil paint Tikurilla, see the following video.

Tips for choosing

If you do not want to prepare the mixture, but immediately apply it, buy liquid formulations; unlike thickened ones, they need only be mixed to complete homogeneity. For dyeing wood, it is better to take the maximum amount and still leave room for tinting and repeated work.