Polycarbonate visors: a variety of shapes and designs

The traditional use of roofing materials in the construction of sheds, visors is replaced by the use of innovative polycarbonate material. Possession of unique properties allowed to significantly expand the forms and significantly reduce the technical requirements for structures.

Polycarbonate is a polymer plastic, widely used in many construction sites. He proved himself as a high-strength material with a low specific weight. Today has become an alternative substitute for PVC panels. Sheet production takes place through the processing, extrusion of polycarbonate pellets.

Special features

The purpose of the canopies and canopies is to protect a limited space from the elements of the external environment: rain, snow, wind and intense sunlight.The construction is erected with the help of supports, the forms embody all the fantasies of the equipping owner from simple to exclusive design solutions.

The basis of the popularity of polycarbonate consists of the features of the qualities and characteristics of this material:

- plasticity and ability to transmit light expands applications;

- light weight allows the use of lightweight bearing supports;

- the ability to tolerate large temperature differences;

- heat-insulating properties, heat is retained throughout the whole structure;

- a variety of finished colors of polycarbonate sheets, so you can choose what suits best in a particular case;

- the ease and pleasantness of the work during the installation, it is possible to cut the sheet with the help of a usual clerical knife, it does not require special devices and tools;

- despite its light transmission ability, polycarbonate filters and protects against ultraviolet radiation;

- attachment to the frame is possible using conventional screws;

- the main technical characteristic of the material is its strength, achieved due to its viscosity;

- quite high degree of fire safety;

- has a high ability to sound insulation;

- gives a finished design an aesthetic, harmonious look.

This is not the whole range of features of this material. Listed above are only its common merits that customers rely on when choosing a material.

Polycarbonate visors are most often placed above the door or a welded ladder. Such a kind of roof can be on hangers and have various components. It is desirable that there was a beautiful finish. You can sheathe the product yourself.

Kinds

Considering the features and advantages of polycarbonate visor designs, it is permissible to separate them by species.

Simple lean-to

A simple version that requires minimal investment. Designed for structures with a single slope of the slope, in the manufacture and installation do not require additional effort. Installation work is available even to a non-professional.

A lean-to construction will not require bending of the profile during installation. Therefore, there are no restrictions when choosing the thickness of the source material.

When building a structure of this kind of coating does not require the use of scaffolding, only longitudinal and transverse beams are used.

Most often, this view is used for an extension to a standing house or any other structure.

Of the drawbacks, there is a low inclination angle of the resulting roof, as a result of which snow deposits will necessarily accumulate on it in the winter and cleaning will be required.

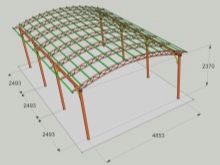

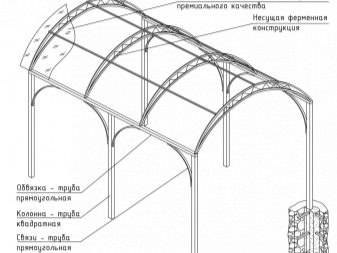

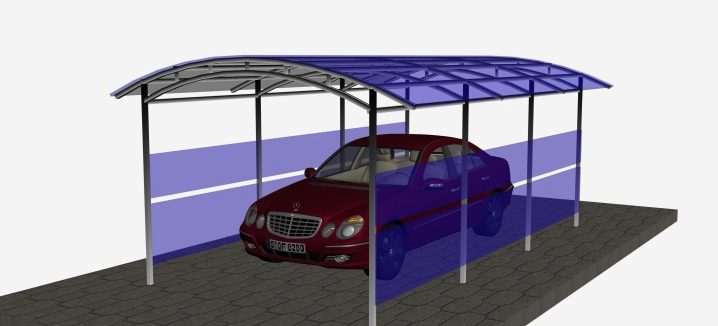

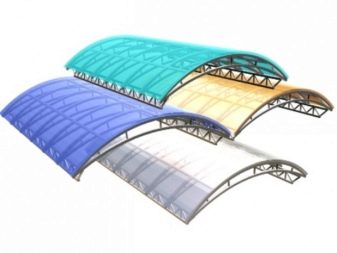

Arched canopies and canopies

Affordable, similarly unpretentious to install, have an arched appearance. The main difference from the first option is the completeness and aesthetics of the finished design. The manufacture of a curved frame and an increase in the area of coverage require additional financial investments.

This species is especially popular today. They can be seen in private courtyards and in the cities with the arrangement of covered parking lots, bus stops and gallery passages between buildings.

The shape of the semicircle allows the snow to freely go under its own weight., but in the rain the water flows on both sides of the shelter. A pleasant feature is that the probability of damage to such a roof is very small, since the lowered sidewalls protect against strong wind gusts. This type is also suitable for small canopies, and for installing roofs over large buildings.

With self-fulfillment, the difficulty is the bending of the profile.

Mnogoskatnye designs

It is a structure that combines several types of rays: both straight and curved. This combination leads to an increase in the cost of the finished product.

During construction, the choice of the correct angle of connection of the slopes becomes the main difficulty; however, the operational characteristics of the finished structure significantly increase.

Lower ends give better surface protection:

- from the elements of nature - wind and precipitation;

- tilt angles prevent accumulation of snow deposits;

- frame structures are made more rigid, which increases the strength of the structure as a whole.

It is used for car parks, arrangement of mangal zone, roofing of pavilions and gazebos.

Complex or cascade canopies

Combine all kinds of designs. Require the development of projects and drawings, large financial investments. Installation work must be performed by highly qualified specialists. The client receives an exclusive design building in accordance with their individual wishes.

The scope of this type of roof - mounting over summer gardens, staircases, gazebos and other structures.

Such a method of roofing is especially important from an aesthetic view of the finished structure, and due to the location of the arches in a cascade of sediments are diverted to the side.

Projects and Drawings

The durability of the design can be guaranteed only with the correct selection of the size of the frame and the technical characteristics of polycarbonate, its thickness and quality.

Prior to construction, the construction project is prepared using the following parameters:

- the design of the visor;

- the selection takes into account the climatic conditions of the area;

- technical characteristics of the building.

It can be:

- parking for cars with an entrance to the building;

- Summer shower;

- open pool;

- barbecue and grill;

- places for rest;

- playgrounds for children;

- wickets and gates;

- outlets;

- open summer areas and terraces of cafes and restaurants;

- greenhouses;

- arch;

- canopy;

- visor.

Calculation of component racks, polycarbonate sheets and guides.

When building light constructions in the form of sheds or canopies, it is possible to resort to calculation using an online calculator.For the design of more complex structures should resort to the help of specialists.

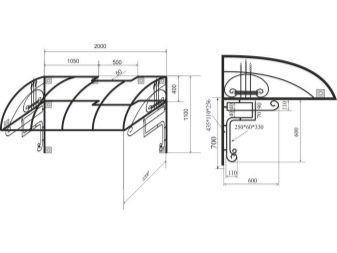

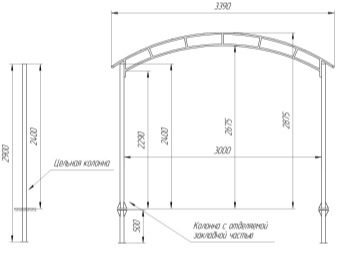

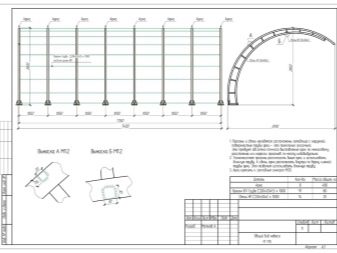

On the example of a visor in the form we will visually consider drawing up a drawing and a project.

Before you make your own canopy of polycarbonate, you will need to make detailed design drawings. But this is possible only after determining the location of its location, since the pivot point of the frame depends on it.

The location identifies three types of finished structures.

- Detached, independent. Depending on the size of the required foundation arrangement. All points of support are made in the form of pillars along its perimeter.

- Extension. A framework for such a design is made beam-supporting. One of the sides of the ramp has points of support for a stand-alone rack. The second side rests on a beam attached to the wall of the building. When used for the bond extensions with the organic structure of metal mortgages on the supporting wall, the method of attachment is called a cantilever support.

- Traditional visors. As a rule, they are fastened by the console method to the mortgages in the wall of the room.

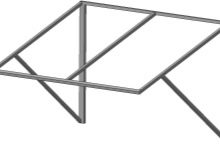

DIY frame

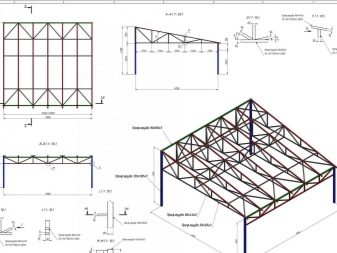

The initial task and the first stage is the creation of a project, the calculation of initial materials and the creation of a drawing:

- we plan the size of the building, taking into account its location;

- when choosing a roofing option, the loads from precipitation and wind are taken into account;

- Design solutions for the design of the frame and the color of the sheets are chosen from the general concept of the surrounding structures.

After collecting all the information, you can proceed to the calculation of the source materials and drawings of the frame. In drawing up the drawing, the exact dimensions and shape of the roof, the technical parameters and material of the supports and the frame itself, the number of fasteners and their characteristics are used.

Special attention should be paid to the standard size of all types of polycarbonate sheets. Therefore, the joints between them must fall on the crate.

The width of the profile girders is taken into account based on the parameters of the roofing material itself.

The height of the future construction directly depends on the wishes of the user, nevertheless it is recommended that the lowest point of the roof should be about 180 cm from the floor.

To create the frame, the support legs are calculated subject to the following standards:

- the minimum allowable section is forty to forty millimeters;

- if the supports will be made of metal, the thickness is chosen from one millimeter;

- the thickness of the pillars lay with a value greater than more than ten millimeters from the taken cross section of the support columns;

- Foundation depth is at least half a meter;

- for rafters, a profile with a cross section of not less than twenty millimeters is used, for battens the thickness is used from fifteen millimeters.

For the proper manufacture of the frame with your own hands, the drawings must be made very accurately and in detail.

If the plans include the construction of your own construction of an area of eight square meters, the creation of the project, drawings and calculation of materials should be entrusted to specialists. The area of the roof over such a building is quite large, and only a specialist can calculate the load level. Errors in the calculations lead to the deformation of the frame or the complete collapse of the entire building.

The choice of material for the frame in the construction markets is quite wide and diverse.

For polycarbonate structures, the following materials are commonly used.

- Metal profile It has durability during operation. Unpretentious and requires minimal care in the form of anti-corrosion treatment.Among the disadvantages are the large weight of the frame and its high price.

- Pipes from metal, for example, aluminum profile. Advantages are the same as the metal profile. Of the minuses - a round section is not so convenient for welding work or other methods of fastening.

- The wooden bar rounded or profile. Environmentally friendly, living material, if the frame of the building is stylized for a specific design. When doing hands-on work, carpentry skill is needed, wood requires a certain care, and its performance is not so durable.

Assembly and finishing works

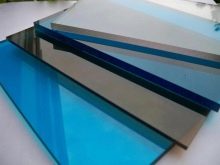

Polycarbonate sheets are presented on the construction markets in two classic versions.

Cellular

These are impact resistant panels with a matte or transparent surface. Inside the shell are balloons with ribs, oriented to the entire length of the panel. This type has high heat saving, increased strength and low weight. A special feature is the ability to change the shape, bend the sheets in their cold state. Actually their use in designs with complex geometry.

The thickness offered by manufacturers has an assortment of products ranging from four to twelve millimeters inclusive.

Monolithic

Have an optically absolutely transparent appearance. There are no voids inside. Sheets are less flexible, which does not affect the impact resistance of the material.

At the moment, there are already new innovations of monolithic polycarbonate with anti-abrasive coating and a wave-like design available. The latter option looks like a metal tile, and is quite often used to repair the roof.

The standard size of sheets is 210 centimeters wide and six, twelve meters long.

For a simple polycarbonate visor, four, eight millimeters thick sheet will do. In regions where precipitation in the form of snow is increased, or rather strong gusts of wind are observed, the thickness is chosen from ten millimeters.

At will the construction markets offer a service for cutting blanks. Usually, to minimize waste, the length is made a multiple of the width of the sheet.

For installation, you will need the following set of materials and tools:

- polycarbonate sheets - the color is chosen according to the color scheme of the building;

- frame visor;

- welding machine;

- set of screws;

- electric drill and screwdriver;

- roulette and level;

- indelible pencil.

Before beginning the process of mounting the visor or canopy over the entrance group, it is necessary to make an accurate marking of the attachment points of the frame to the building.

With the help of a drill, you need to make holes for fastening the frame to the wall.

When installing the frame requires the presence of two people. Massiveness and size will not allow installation by a single worker. The frame must be securely fixed, depends on the safe operation of the structure.

At the end of the installation of the base of the visor is the installation of blanks from polycarbonate sheet. If several blanks are used, it should be remembered that the installation should not be carried out end-to-end. When heated, polycarbonate tends to expand, and to avoid deformation it is necessary to leave a small gap.

The end portions of the visor are treated with a special sealing tape, wound up when installed in the frame profile.

Sheet joints are made using welding, the seams are processed with emery paper. The joints of the structure and the building also require treatment with sealant.

Upon completion of installation of the visor with a polycarbonate protective film is removed, and it is ready for use.

Tips and tricks

From the practical experience of installing polycarbonate canopies, five basic tips and recommendations can be distinguished.

- First of all, you should pay attention to the quality of the source material. Raw materials for a good sheet should be uniform in composition. Quality is determined visually by the absence of bubbles, impurities and the surface with no flaws.

- Carefully treat the thickness of polycarbonate. For a standard sheet of six millimeter thickness characteristic weight of one kilogram of three hundred grams. For a quality product, every 2 mm is equal to the loss or increase in mass per pound.

- UV protection is applied by the manufacturer in the form of a special layer of the light stabilizer on the outside of the sheet. The absence of a protective layer is an indicator of poor quality material.

- On the protective film manufacturer labeling of the goods: the name of the brand, the name of the protective layer and recommendations for installation work.In addition, the seller must have all the documentation confirming the quality of the goods.

- It is recommended to be attentive to the choice of components: washers for fastening sheets must be used from polycarbonate.

Beautiful examples

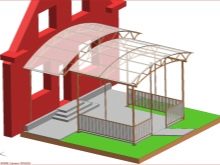

Luxury and splendor combines a beautiful wrought visor. Elegantly designed protection from rain and wind will give the building a finished look.

A visor above the carbonate porch, made in the form of a large canopy, is an excellent solution for the option of arranging an outdoor cafe. Such a construction will not only protect visitors from the weather, but also form a single ensemble with the main room.

On the backyards, polycarbonate visor can easily turn into an open terrace. The versatility of the design depends on the imagination and desire of the consumer.

About what are the peaks of polycarbonate, see the following video.