Slate nails: variety, size and weight

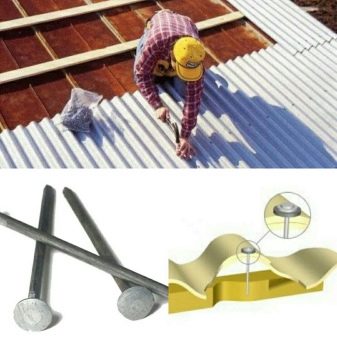

Nails have existed since ancient times, and over a thousand years their configuration has not changed. This fact itself suggests that the design of the nail is very effective and successful. It is held in the material with the help of friction and is one of the main types of fastening slate roof

Description

Any roof is experiencing considerable stress. In winter it is a significant amount of snow, in the off-season - strong winds, which sometimes can have hurricane force. Proper roof fasteners are very important. If the coating is fixed incorrectly, then there is a risk of its deformation up to destruction.

For fixing asbestos cement sheets, slate nails are most often used, which are simple and effective. These simple devices for slate are made in accordance with the requirements of the State Standard, reliably withstand all the negative weather phenomena.This is a fragile material, so products from it must be created in accordance with regulations and standards.

Slate mounts are arranged as follows:

- The leg is the long part of the nail, which ends on one side with a cap, on the other - the point. The product is created by their special steel with a low carbon content.

- The angle at which the product is sharpened, is about forty degrees, which is the optimal value. Such a nail is able to penetrate the material without any difficulty.

- The hat is made of a washer and cap, such a model makes it possible not to deform the sheet. The cap in diameter is usually from 11 to 16 mm. It is arranged in such a way that it does not allow moisture to penetrate under the coating.

Fastening can be of the most different form:

- parallelepiped;

- cone;

- the pyramids.

Roofing nails have their own marking in accordance with GOST 9870-62 or TU 208-82, РСТ 1822-84 and are produced in accordance with these requirements. Slate nails are manufactured in accordance with the same standards as ordinary nails, the steel from which products are made, has good resistance to corrosion and is highly durable

Standards

It is important to remember that the nails of the same brand can vary considerably in diameter, they are made of steel with low carbon content, it corresponds to GOST 3283-74.

To properly nail the nails in slate requires some experience. It is not recommended to drive the fasteners at the very top, there is a great risk that the slate sheet will crack because it is very fragile. It is necessary to stop at the very last moment, leaving half a millimeter to the critical point.

It is recommended to buy nails only on proven trading floors that enjoy a good reputation. There are many fakes on the market that are not capable of performing proper functions. The most popular brand of fasteners for slate coatings are products GOST 9871.

Also on the Russian guests are nails PCT 1823-83. These materials are made of special wire grade GOST 3283-74. On caps the galvanized steel of the state standard specification 14918-80 standard is used. Such steel is very well resistant to corrosion and temperature changes, almost not deformed.

The most popular nails are fasteners with a diameter of 4-5 mm. Their length varies from 9 to 12 cm.

The head diameter should be four times the diameter of the rod, while the height is 4 mm. Such nails are also suitable for mounting rasklinki, which opens the roof. Laying at the same time is fitted with a maximum density to the costal beam, the attachment to the timber is implemented using the same technology.

Nails are easily removed with a nail catcher, and you can remove the sheet without any damage. In order to properly remove fasteners with a nail puller, some practice is required, but even a person far from construction can master it.

Manufacturing

Wire made of high-strength steel is wound onto special coils. It is inserted into a special machine, then sent to the unwinding unit. In the roller mechanism, the process of straightening the wire, its trimming, taking into account the length of the remaining product. The cap is made with a special press, then the almost finished nail falls into a separate container.

After sharpening of the product and its galvanizing. The nail stays in a special solution (copper sulphate) for 60 seconds, it usually happens in two passes.

Often, craftsmen make notches on nails in order to create a stronger connection of slate sheet and sheathing. In such tricks there is a certain meaning, the fastening is more reliably held in the material, which contributes to a stronger connection.

Packing

Nails are packaged in standard in cardboard containers.

Package weight can be:

- 5 kg;

- 10 kg;

- 15 kg.

There is also a larger packing in special wooden boxes of 25 and 30 kg. The weight of nails 5x120 in the amount of one thousand pieces is 24.5 kilograms, that is, 40 pcs. contained in one kilogram.

Nails are of such sizes:

- 4x90 mm;

- 4x100 mm;

- 4x120 mm;

- 4.5 x 120 mm;

- 5x120 mm.

Calculation method

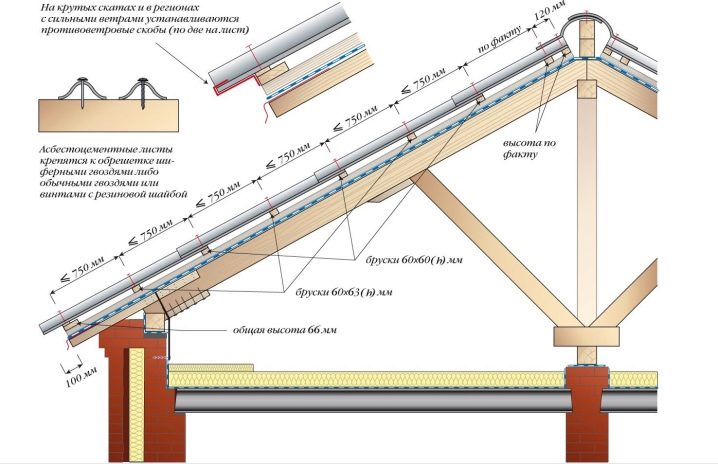

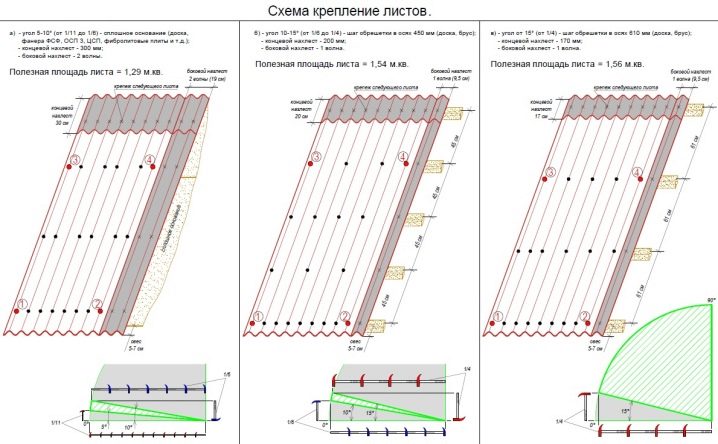

In order to calculate what sizes a nail should be, one should add the length of the batten, taking into account the waterproofing and the height of the slate flange. It is recommended to add another 12 mm to this value. With an increase in the “wave” of slate, the nails themselves are lengthened.

An average of 10-12 nails per sheet, this is quite enough to securely fix the roof. To find out how much hardware is required for work on the roof, you should calculate the area of the roof itself. It is required for this to know the area of skates, add up the resulting figures. Calculations will allow you to accurately calculate the number of sheets of slate required for work.To do this, it is recommended that the entire roof area be laid out on a useful slate area.

Cost of

It is worth 1 kg from 120 to 145 rubles, which is not so cheap. It should be borne in mind that there are special nails with galvanized and composite caps, which are more expensive. There are also simpler options for models. It is much more comfortable to work with more expensive nails; they do not crush fragile roofing material.

Often the holes in the slate are made using an electric drill. Such openings are on the order of 1–2 mm. When creating and calculating coverage, you should consider the area that usually goes to the overlap.

Useful recommendations

During work, nails are contraindicated. There are considerable temperature drops on the roof, the roof should “breathe” a little, otherwise it will collapse.

There is always a gap of one to two millimeters between the head and the sheet. It is also recommended to use nails with a rubber gasket, which reliably prevent moisture from leaking under the coating.

When working, first of all, it is necessary to fix the edges of the sheet, only then the turn of fixing the middle comes, then the remaining areas are “grabbed”. Such technology protects from sheet distortions and its deformation.

For slate nails can also be attributed to special screws, which are made of very strong steel, they are suitable not only for slate, but also for metal tiles. Fastening in screws is designed to use a screwdriver or drill with a special nozzle. Often, such products are supplied with special rubber pads that reliably protect against water leakage. Screws are durable, but they also have a number of significant drawbacks and are noticeably inferior to nails in fastening quality.

Slate features

Slate is not an expensive material, they can cover both farm buildings and residential buildings.

Advantages of the material:

- does not deteriorate;

- not fire hazardous;

- quite durable, though fragile;

- inexpensive.

Slate weighs a lot, but this disadvantage is more than paid off by a lot of indisputable advantages.

Slate is not necessary to "care" and paint it every year, such as a metal roof. Slate does not need to be covered with anti-corrosion primers, which is also a clear advantage. If you make the right slate roof, then it can last for decades.

Advantages over screws

Greater preference is given to nails than to self-tapping screws.

There are several reasons for this:

- Although self-tapping screws have greater strength than nails, nevertheless, nails are better to hold slate, especially in regions where there are strong winds.

- Screws are screwed into the wood and hold the material quite firmly, but they do not work very well "in shear". If the wind is very strong, the slate will break, and the screw will remain in the crate, while the nail may be pulled out, but it will remain in any case with the sheet.

How to make yourself

Slate nails are quite possible to do with their own hands. The tools that are required for this.

- Scissors for metal. With their help, small "squares" are cut from a sheet with a thickness of 1 to 2 mm.

- Electric drill with a drill. With the help of this device, holes are drilled in the cut metal "squares". Self-made nails are in no way inferior to factory products.

It is safe to say that the nails are the most successful type of fastening slate roofing.

For varieties, sizes, and weight of slate nails, see the following video.