Asbestos-cement wave slate: advantages and weight of the roof

The roof is the most important component of any structure. The quality and operational life of the roof largely depends on the material that the roof arrangement was made of, which is why the choice of roofing raw materials must be approached with full responsibility. On the modern market there are many materials of this line of the latest generation. However, asbestos cement wave roofing slate and today holds the leading position in the list.

Features: pros and cons

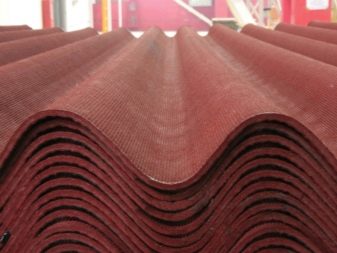

This material is produced using several components - asbestos, portland cement and water. The technology for producing sheets consists in passing the resulting composition through a specially equipped machine,as a result, the raw material acquires its characteristic wave-like state. Due to the presence of a number of specific qualities, asbestos-cement slate material does not come from the number of sought-after products used for arranging roofs of buildings of various types and purposes for more than a hundred years.

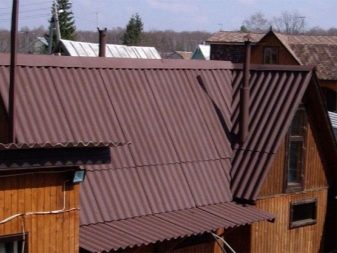

Since the scope of use of slate is rather narrowly specialized, it is purchased for laying on the roof of a standard form, as well as for working on more complex structures. In addition, the use of this material is possible on the roof of residential buildings and on the roofs of industrial facilities, depending on the type of material. However, along with the versatility of asbestos-cement slate, it is necessary to note a certain feature of the material that relates to its installation - the material can be used only on those roofs where the angle of inclination of the structure will exceed 15 degrees.

Although the products are considered roofing, many experts widely use it for the construction of fences, as well as used as a material for the construction of non-residential buildings.

As features of asbestos-cement material, one can distinguish its undeniable advantages:

- High strength roofing products. Asbestos, the main component, is inherent in the fibrous structure, due to this feature, the entire composition acquires enormous resistance to mechanical damage.

- Resistance to heat. As the long-term practice shows, even at high temperatures in the summer period, slate heats up less in comparison with the materials for the roof, which are made of metal.

- Products do not rust and is not susceptible to corrosion, which is the main advantage of such a roofing coating, since the raw materials of this range for metal-based roofs are often subject to similar destruction.

- Fire resistance Asbestos cement slate does not burn, while heating the structure of the building it will not evaporate any harmful substances.

- Affordable cost products. Products made of metal will have a higher price than the price per 1 m² of corrugated slate.

- Excellent sound insulation performance. During heavy rainfall or hail inside the building there will be noiselessly inaudible.

- Repairability slate makes it possible to change only the individual elements of the roof, there is no need to disassemble the entire structure.

- Big operational term Slate roofs of about 30 years.

- The material is allowed for use in a wide temperature range, which ranges from -50 ºС to + 80 ºС, so that the slate is applicable in any climatic zone.

Like any other construction products, asbestos-cement material has some individual disadvantages:

- The fragility of raw materials. Along with high strength, with errors made during the transportation of slate sheets in a pack, they can break. This deficiency may occur during a fire in the building - cracks may form on the material.

- Specific weight of the sheet. The mass of one product is about 20 kg, and since only one product weighs so much, it is quite difficult to lift it onto the roof.

- Permeability slate leads to the fact that rain moisture penetrates into the material, due to which the moss grows on the surface. This feature can contribute to cracking sheets. However, it is easy to fight this drawback; it is enough to put a special compound on the slate surface, which is freely available in all hardware stores.

- According to European scientists, asbestos is hazardous to human healthbecause it removes harmful substances. However, this fact of carcinogenicity of slate has not been fully proven, which nevertheless did not prevent the prohibition of its use for roofing in many countries. Therefore, manufacturers often include in the composition of the mixture for the production of slate a substitute for this component, which by its quality characteristics is not inferior to its predecessor.

Kinds

Slate of the last generation is an excellent raw material for construction, widely used due to its low cost, the mass of positive properties and a large range of species. As a material for the arrangement of the roof, a wave or flat profile is used. The latter material is used several times less often, and asbestos-cement corrugated material is most in demand for such works. Manufacturers offer the consumer several types of this product.

Specifications

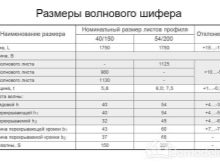

Material is classified as follows:

- wavy slate, which is marked VO - sheets of this product are characterized by the correctness of the forms and are a rectangular material;

- reinforced slate, abbreviated VU - it is produced for use in industrial buildings;

- unified wavy material - HC, which is widely used in the construction of residential buildings.

All varieties of asbestos-cement material are produced according to the requirements of GOST, but at the same time firms that produce this material according to their specifications work on the market of construction products.

This is not a gross violation of the specifics of the release of wave slate, but may entail some inconsistency in size in comparison with the approved standards for different types of these products. As a result, you can make a mistake when carrying out the calculation of the necessary material on the roof.

Options

For consumers, the most convenient will be a somewhat different division of products into types, thanks to which it is easier to calculate the consumption of slate for the roof.

Asbestos cement slate is the following:

- five wave, where the useful area is minimal, since a significant part is hidden under other sheets due to overlapping laying. Product length is 1750 mm;

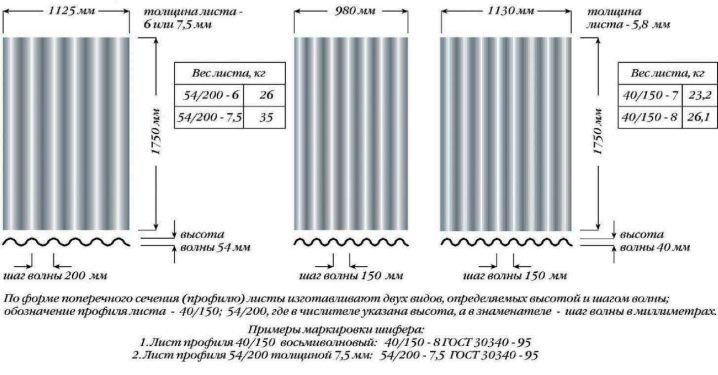

- six wave the material stands out with a thickness of 6 mm, so it is recommended to lay it on the roof, where a serious wind load on the surface is possible. The sheet has the following dimensions: length is 1750 mm, width - 1125 mm, weight - 26 kg;

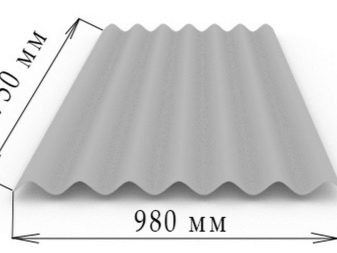

- seven wave - this is the most demanded type of product, the popularity of which is due to the most acceptable dimensions: thickness - 5.8 mm, width - 980 mm, weight - 23 kg;

- eight wave - has the same thickness of the product with a seven-wave sheet. The width of the sheet is 1130 mm, with a product mass of 26 kg. This type of slate is the material that comes with the largest parameters.

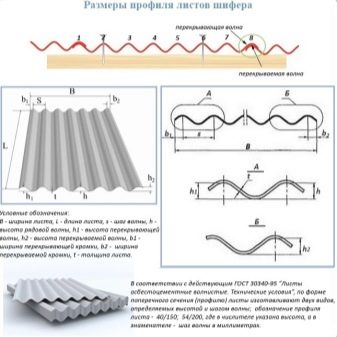

The material varies in height of the crest and the wave pitch of the following types:

- 40/150;

- 54/200.

These parameters apply to products with 6, 7, 8 waves.

Counting quantity

Before buying asbestos cement material, it is necessary to calculate the required number of sheets, taking into account the parameters of each type of slate.

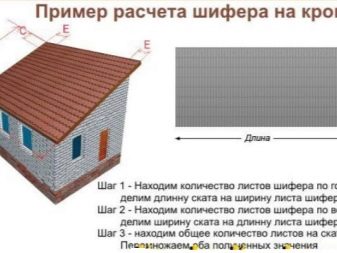

You can perform the calculation according to the following scheme:

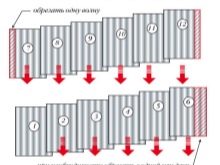

- should determine the amount of material that will fit in the first row.To do this, the length of the roof should be divided by the width of one sheet, always taking into account the overlap that will be on both sides for sheets laid in the middle;

- you need to determine the amount of slate required for the roof slope based on the length. Calculations are performed taking into account the overlap of the material on each other and the presence of the eaves. Measuring the length of the slope, it is divided into the useful length of the product;

- Having determined these values, you can calculate how much you need to buy sheets of slate.

But it is still worth buying products with a small margin - it is best to have 2–3 more sheets than the estimated amount, because any, even six or eight-wave sheets can be damaged during the installation on the roof or if the sheets need to be cut for giving them the appropriate size. As a result, the damage will have to buy additional material, and therefore pay transportation costs.

To have an idea about the mass of the future roofing, it is worth getting acquainted with the specified values in the technical documentation for the material,a passport must be in each product of this type.

Piling

The installation process of the slate itself is preceded by the arrangement of the crates. It is a frame knocked out of planks, on which the roofing material is mounted.

The technology of performance of such works includes several stages:

- Fastening rafters. For this, a 50x180 mm timber is purchased, given that its length must exceed the analogous parameter of the slope, since the projecting part will be responsible for creating the eaves overhang.

- Mounted boards between the rafters. For this, bars of 60x60 mm are used. In the process of installation of timber it is necessary to consider that two boards are needed for one sheet of material. The construction of the horse is performed by a bar of 60x120 mm.

- Work with asbestos-cement slate starts from the bottom corner based on the length of the roof. Stacking can be done in several ways: with offset longitudinal edges and without it. In the first embodiment, there will be no overlapping of several sheets in one place. This is done by placing a new sheet with a small distance from the previous one in the same row. If you choose the second method of work, then during laying you will need to cut the corners of the material, for this purpose you need to have a grinder on hand.In order to avoid additional work during the arrangement of the roof in the house, it is better to dwell on the first method of mounting the sheets, since in the second case it is necessary to cut the material, which can lead to the deformation of the whole sheet.

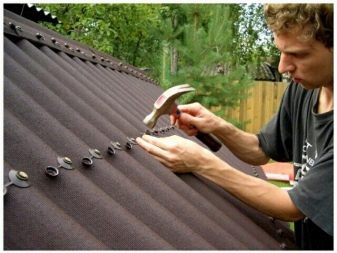

- Fixing products to the crate is performed with the help of nails, possessing not a plastic, but a rubber pad. It is necessary to do this work very carefully, too much effort can spoil the sheet. Experts recommend driving nails into an eight-wave product on 2, and then on 6 waves, for 7-wave slate, the mount is made on 2 and 5 waves.

Slate is the most durable roofing materials. However, a significant mass of the roof needs a stronger roof system, which, along with the low cost of the material itself, may require additional costs for the construction of reinforced rafters. The most competent is laying of slate with a shift of half a sheet.

To learn how to make your own slate adhesive, see the next video.