Installation of ondulin: features of the material and stages of work

Ondulin is a popular material when carrying out roofing works. Used for more than half a century in construction, it has really proven itself, many use it instead of slate and metal tiles. Therefore, it is worthwhile to examine in more detail the installation of ondulin: the characteristics of the material and stages of work.

Properties and advantages of the material

Ondulin or euroslate is a sheet with a wavy profile, rough to the touch, painted in different colors. This unique organic material is made by pressing cellulose fibers under heat. Bending it is slightly soft, lighter in weight than slate. Due to the impregnation of a special chemical composition, ondulin sheets do not completely pass and do not absorb moisture. Bitumen and mineral additives make the coating durable and durable.

Although ondulin has been used for several decades, it has not lost its relevance, efficiency and easily compete with other roofing materials. It is established by those families who care about their health, it is a harmless building material. In most cases, the warranty period of the material is 15 years, so it is quite durable. Ondulin sheets have bright colors and look elegant on the roof of any country house.

Consider the virtues of ondulin.

- Ecological purity, the absence of harmful substances. Ondulin, even when heated, does not emit harmful fumes that could adversely affect the respiratory system. Living in a house with a roof under such a coating, you should not worry about your health.

- Immunity to acids, petroleum products and other harmful reagents. This building material consists almost entirely of cellulose and does not react with other chemicals.

- Lightweight sheets, usually it does not exceed 5-6 kg. It is easy to transport and serve on the roof of a small village house.

- Easy cutting and installation. Ondulin - soft and ductile material.It is cut with a hand saw on wood or a construction knife.

- Comparative cheap material. It is cheaper than decking or shingles, and the installation costs are much less.

- Due to its composition, ondulin does not pass and does not absorb moisture. When laying the roof does not necessarily make a waterproofing layer.

Another important advantage of ondulin is its noiselessness. If the sheets of metal profiles in the gusts of wind or in the rain produce noise, then this material is devoid of this disadvantage.

Immediately it should be noted, and some minuses of this material. It is not as durable as non-ferrous metal, is susceptible to burning, and eventually loses its color. Some people believe that the ondulin sheets can sag and deform on the roof, for example, under a thick layer of snow, but if you install it correctly, this can be easily avoided.

How to choose a quality one?

To cover the roof with really high-quality and durable ondulin, it is necessary to take into account several factors.

- When wrapped, waves should be identical and fit snugly together. It is easy to check, looking at it in profile, the defects will immediately be evident.

- The thickness of the sheets should also be the same: usually 3-5 mm, depending on the grade.

- The quality of the material is homogeneous, there are no stains and leaks of paint and roofing material on the surface.

Ondulin has a standard color palette, but the number of shades is large, for every taste. When choosing, you need to make sure that the colors in the same batch are the same and saturated. High-quality material retains a shade intensity of 10-15 years. Immediately it is necessary to choose fasteners with hats of the corresponding color.

When buying, you need to examine the label on the label, check the quality certificate. At present, there are many ondulin manufacturers, including those that enjoy proven popularity. From reliable it is worth noting the Belgian Aqualine, German Butuwell, Turkish Corrubit.

Tools and calculation

The standard dimensions of an ondulin sheet are 2000 mm in length and 950 mm in width. Knowing the area of its roof, the length and height of its slopes, it will be easy to calculate the required number of sheets of material. But at the same time, it is necessary to add an amendment of about 15% for overlaps and various sawn-off edges, for example, for the chimney pipe.

Ondulin fasteners to the crate or the old coating is carried out on special hardware or screws with a plastic hat. It has a wide gasket that provides reliable tightness and comes in a variety of colors, so it is possible to choose the right combination for sheets of any shade. Depending on the coating, it is necessary to select the fastener correctly: metal hardware for metal obreshetki, nails for wood sheathing. Both those and those can be found with the appropriate cap and cap under the color of the sheet. On one standard sheet ondulin need 20-25 fasteners.

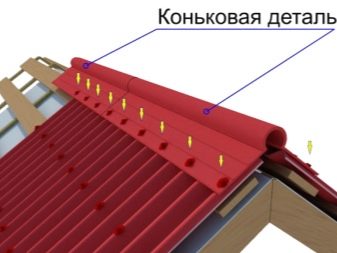

Immediately it is worth counting the number of other components. These include the horse, which covers two slopes, you just need to measure the required length in advance. Still it can be a cornice, wind side strips, plums, endova. In advance to calculate the number of meters of these elements is not difficult.

Necessary tools for roof coating with ondulin:

- hammer;

- hacksaw for wood;

- paint knife;

- roulette;

- level;

- pencil or marker.

A circular saw can also be used as a cutting tool. In addition, you must take care of the stairs or stepladder in advance.

Styling rules

In order for the roof to be warm, protected from moisture, and the coating looked great for many seasons in a row, it is necessary to make the correct installation of ondulin sheets.Works are performed at a temperature not higher than 30 degrees. Otherwise, the material softens, deforms, and becomes sticky. But even in the cold it cannot be mounted, since at low temperatures ondulin tends to crack. In general, like any other roofing work, these should be carried out under comfortable weather conditions.

Ondulin is very similar in structure to slate., only has much more useful properties and advantages. The wavy structure contributes to the most effective drain of moisture, in addition, increases the rigidity of the sheet. It is possible to install the sheets only on the pitched roof; the material is not suitable for flat roofs. Most often, this coating is used for summer houses and private houses.

The device of the sheathing when coated with ondulin is considered mandatory. It helps to avoid unnecessary deformation of the sheets, allows you to further insulate the roof. It should not be necessary to save stretched sheets to save material, since with temperature drops they will deform and, most likely, it will be necessary to cover the entire surface.

Wooden crate is easy to install. In addition, it is an environmentally friendly and well-insulated material. Most of the owners when laying ondulin use a wooden crate. Metal profile frame is lighter, but no less durable. He is also able to prevent sheets of ondulin from deformation. For such obreshetki need grinder and screws for metal with a plastic hat.

It is not worth walking around the established areas a lot: ondulin is rather soft, but if you have to do this, then when mounting the sheets on the already attached ones, you should step on the upper ridges of the wave. For trimming sheets across the waves, it is better not to use a ruler — this is rather inconvenient, and cutting a piece from another piece of a sheet, preferably different in color. So the waves fit one into one and it is easier to mark them. The material is cut very easily both along and across, nevertheless, for safety, it is better to mark all the necessary fragments in advance, and to cut them down to the ground.

For special nails or screws with colored plastic caps, it is enough to use an ordinary hammer. The material itself, due to softness, is very easy to pierce, so much diligence is not required, you need to work carefully.The nail must be driven onto the crest of a wave perpendicularly, until the end, by slightly tapping the cap. It will be correct to fix first the two extreme waves, then in the middle, then the rest. It is wrong to beat each wave in turn.

Laying procedure and technology

Such roofing work alone, including one, is quite easy to do. Due to the ease and simplicity of processing ondulin, they are much easier than other stages of repair and construction of a private house. Roofing ondulin is best in dry and windless weather. This material is installed easier and faster than slate, tile, roofing material: sheets simply fit overlap and are easily nailed with nails or screws. Step-by-step instructions for laying cover consists of several stages.

Crate

The crate for this roofing material can be made of wood or metal profile. For a wooden structure, it is optimal to take bars of 60x40 mm. When the slope angle is less than 10 degrees, it is recommended to make the crate solid, at 10-15 degrees, the step should be 450 mm, with a steeper slope of the bars can be fixed at a distance of 610 mm.

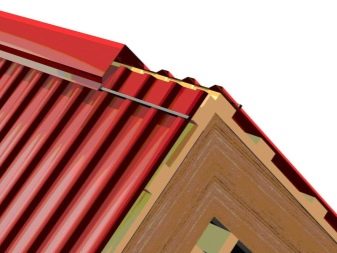

It is necessary to bend the bars for obreshetki as smooth as possible, otherwise further ondulin sheets may be deformed. In these works, levels and suspensions are actively used. At the edges of the slopes in the place where the skates are installed, additional reinforcing bars should be installed. After mounting the batten, you can put insulation and waterproofing film.

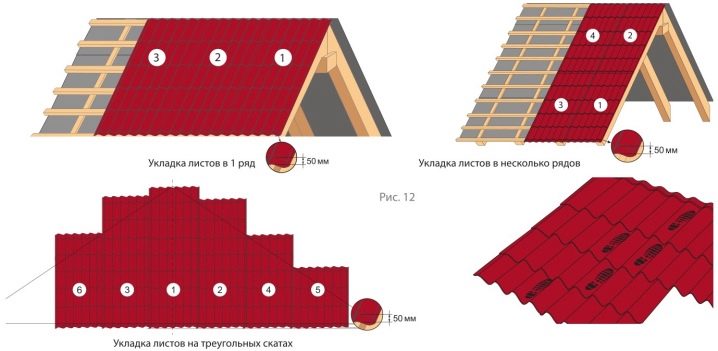

Mounting and layout of sheets

The next step is the mounting and layout of the ondulin roof. Work begins from the lower angle of the side opposite to the direction of the wind, so the gusts will not lift up loose sheets. Neighboring elements must be placed with an overlap on one wave. Above the eaves, they should not protrude more than 40-50 cm. It is necessary to lay the sheets in turn, complete the bottom row, and proceed to the next.

Lay the sheets need, observing the level of the crate and ridge plate. After the correct placement of one sheet ondulin neatly attached to the roof. The fastener is nailed to the center of the upper crest of the wave strictly perpendicular to the sheet, and not tilted. Similarly, two sheets are fixed at the junction of the waves.

If the last leaf in the row is too wide, and this usually happens,it is necessary to make it trim. Cutting ondulin along a wave is fairly easy with an ordinary stationery knife. Across the waves will need to use a hacksaw.

At the same time, ruberoid sticks to its teeth, cutting becomes uncomfortable. Therefore, before such work is to moisten the canvas, and it is better to lubricate with engine oil or silicone. Many use for cutting circular saw or grinder.

Setting items

The installation of elements begins with the installation of the ridge at the junction of the slopes. On sale it is easy to find a plastic profile of the corresponding color. It is easy to make it yourself from the materials at hand. It should be mounted so that it covers the slopes by 30-40 cm.

If there are chimney, ventilation, and other protruding parts on the roof, then it is worth purchasing a passage element for them. In the shops you can find different in size and color parts that are suitable for almost any roof. For example, a passage element for a chimney pipe made of plastic of various diameters. It is attached easily to the same hardware as the sheets of ondulin themselves.

Then you can install other additional and decorative elements: pediments, storm drains. Depending on the material, they are mounted on screws or nails. If endova is needed, then it is installed before laying an ondulin sheet on top of it. For this part of the roof you need to fix additional beams crates.

In this order, work is being done on laying Ondulin for a new roof. It is possible to use this material with the old roofing coating.

Option on the old roof

You can put ondulin with your own hands on the old roof made of slate or other material. This is done in the event that the crate is durable and well preserved. Then the old covering is accurately removed from it, cleared of dust and garbage. It is not recommended to put ondulin on top of the existing slate or roofing felt, so it will not have a solid base, the sheets will be quickly deformed under the influence of temperature and moisture.

In old houses, you can make a new solid crate over the existing roofing. Then cover them with ondulin sheets and fasten them, supply them with skates, endovaya, walk-throughs and other elements. If all the work has been done correctly, then such a roof will last more than a dozen years.

Care: recommendations

Due to the fact that ondulin - quite unassuming material, the roof of it almost does not need to care. If all the installation work is done correctly, then the concerns are almost completely excluded. Nevertheless, care must be taken to ensure that excess moisture and snow do not accumulate on the roof, and, if necessary, to remove them. Do not neglect the fallen leaves and other debris. They are prone to rotting and although ondulin is almost not afraid of the action of the fungus, mold, bacteria, to increase the service life, you should regularly wash it.

It will be useful twice a year (spring and autumn) to prophylactically inspect the roof of ondulin. Do not be lazy to take a ladder and carefully evaluate all parts of the roof. You must ensure that there are no deformations, cracks, holes, and in the event of a defect, relocate the desired section.

Although ondulin is also quite resistant to fading and due to the special chemical composition for a long time it retains its original appearance, it can still fade with time in some areas. Then you can make his cosmetic painting. If the sheets are faded under the action of ultraviolet light, then there is an opportunity to paint them with acrylic or water-based paint.Painting should be done on a dry surface Ondulin using a wide brush with a long pile or roller in 2 layers. Sheets of this material absorb paint well, and their appearance becomes fresh.

How to make installation ondulin do it yourself, see the video below.