Slate sheet dimensions and usable area

The number of roofing materials sold on the market is growing in proportion to the emergence of technological innovations. The competitive features of some materials remain the same. For example, slate is in demand today as it was 10 years ago. This material has a stable consumer popularity regardless of the surrounding conditions. Our article will tell about the parameters of slate and where this roofing material is applied.

Material Features

Slate competitiveness is ensured due to the following advantages:

- low price;

- ease of use;

- high reliability;

- standard sizes.

These qualities of slate allow to carry out high-quality installation, thus there will be no special difficulties.In the construction language, slate has the name asbestos-cement corrugated sheet. In fact, the sheets are flat and wavy.

Slate with bends is divided into several subgroups., as there are five-, six-, seven-wave variants. All of them are successfully used as roofing material. For wavy slate GOST 30340-95 is still preserved. The main parameters for selection are the length and width of the slate sheet. As an additional parameter, the width of the bends is important. This value is also called the wave step. There is also such a value as the height of the waves.

Normal wave slate is a profiled sheets, which differ slightly in size. The main production component of slate is asbestos cement.

Asbestos cement of a domestic manufacturer is harmless to human health. The base contains components such as chrysotile asbestos, which is safe for humans and animals. European flat slate has less safe characteristics, so it can not be used for all purposes.

Chrysotile asbestos, an aqueous magnesium silicate, contains a small amount of mineral impurities.The structure of the material is characterized by a fibrous structure. The fibers have a high mechanical density, while pure asbestos is a carcinogen. These substances are harmful to both humans and animals.

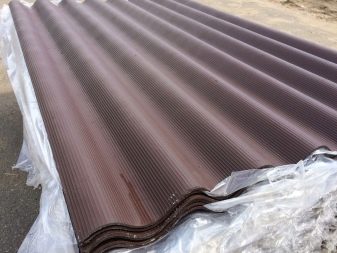

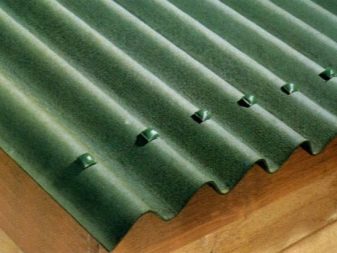

Modern slate sheets are painted in different colors, which expands the decorative qualities of the material. This advantage of an inexpensive roofing material was appreciated by many. In addition, colored pigments form a protective surface layer that extends the life of the roof.

Operational advantages of this material are as follows:

- Absolute incombustibility. Therefore, the material is successfully used in the regions even with very high temperature indices.

- Easy installation. Slate is often chosen for the decoration of roofs with a complex shape, since the material can be cut and laid in pieces.

- High strength. Due to this indicator, the material is popular in the market.

- Manufacturers warranty obligations - 50 years of service. At the same time for 40 years, slate should not lose its original technical qualities.

The disadvantages of slate are a large proportion of the material.When mounting on the roof it is worth considering the need to strengthen the weight of truss structures. In addition, slate is a rather fragile material. Even the slightest mechanical load can cause sheet breakage. Transporting and installing sheets requires extreme care.

Another significant disadvantage of slate is the susceptibility to moss fouling. Especially often this phenomenon can be observed on those parts of the roof that are constantly in the shade. Another moss on the slate roof appears on the north side of the building. Experts recommend to immediately treat these places with special primers.

Specifications

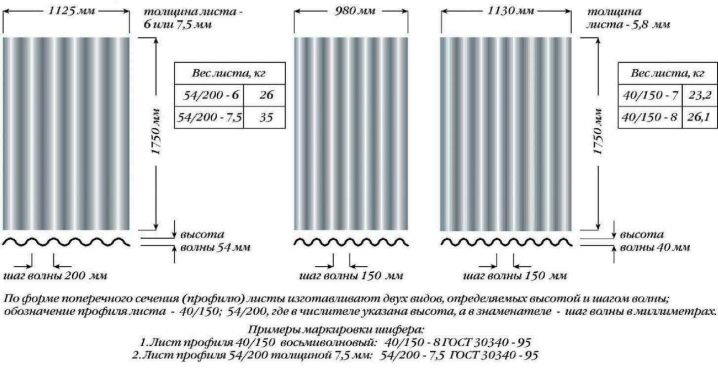

According to GOST, enterprises produce the following options for slate with bends:

- Type 40 * 150. The distance between the bends is 15 cm, and the height of the bends is 4 cm.

- Type 54 * 200. The distance between the bends is 20 cm and the height is 5.4 cm.

Slate has differences not only waves, but also the size of the profile. The first option is a unified profile (HC). Its main advantage is that when working with it the least waste. This type of roofing material can often be found on the roofs of residential buildings. Width of sheets is 1,125 m, length - 1,75 m.

The second option is an ordinary profile (VO). Sheets are characterized by the following dimensions: width - 0.68 m, length - 1.12 m.

There is a third version of the profile, which has the abbreviation VU - enhanced. It is mainly used in industrial construction. Sheet dimensions are as follows: width - 1 m, length - 2.8 m.

Flat slate is not often laid on the roof. It is used for cladding exterior walls and partitions, mainly outbuildings. Fences are erected from this slate, fences of street suburban showers and outbuildings are erected.

The most optimal for private construction are the sizes of slate with bends 7 and 8. These sheets are very popular in the construction market. Sheets are more often bought for summer houses or for covering the roofs of small houses. The main difference between slate and other materials is a small difference in actual usable area.

Standard overlap sheets - in 1-2 waves. This is achieved due to the distinctive features of the waves, which are located on the edges of the sheet. They are different than those located in the center.

When buying a material, it is important to clarify the standard of slate sheets.Modern manufacturers often offer material with non-standard parameters.

The color of the basic coating for slate is light gray. Thanks to the use of pigments, the color palette has been greatly expanded. On sale you can find red, green, blue, brown, yellow sheets. Slate of brick shade is especially popular, as it blends well with the color of the wall of facing brick.

Technically coloring sheets can be done in several ways. Dyes are injected into the liquid asbestos mass at the stage of sheet formation. Pigment slate gets resistant as it penetrates through the entire layer of material.

Painted slate is manufactured according to the manufacturer’s specifications, so it often does not comply with the current State Standards.

The manufacturer’s own technical conditions sometimes imply the use of pigments on the surface of the sheets. For example, it can be acrylic, alkyd, polymer paints. Also, finished sheets of slate can be decorated with his own hands. Thus, the owners of houses covered with slate, inexpensively improve the appearance of the roof.

In addition, the technology of staining increases the resistance of the material, reduces water absorption, protects against cracking.The durability of color slate is confirmed by many owners, as well as production characteristics.

However, the decorativeness of traditional gray slate fits perfectly into the architecture of modern buildings and structures. For example, it goes well with houses built of white brick or standard Cibit.

Due to its excellent technical qualities, slate continues to be a promising roof covering with a fairly wide choice of species.

Kinds

The word "slate" refers to a variety of materials with similar features. The main characteristic of all these products is a profiled base and sheet production.

One type of slate is natural slate. Slate plates are different in shape and size. However, the material has good decorative qualities. Products usually gray, brown, greenish shades. Variable thickness and length of products allow you to choose the material of the desired parameters. Shale slate is not afraid of extreme heat. Even with the scorching sun, the material will not change its characteristics.

Slate slate is characterized by low thermal conductivity, is a good sound insulating material.Shale slate is used even in regions with significant temperature variations.

New in recent years - Euroslate. It is also known as soft, asbestos-free, bituminous. The material is also sold in the form of corrugated sheets, painted in different colors. In comparison with standard slate it has a flexible base, not brittle, light. Euroslate is used as the second layer of the roof, covered with ordinary slate. The material is durable. At cost, it is more expensive than ordinary slate.

Technologies are developing, and the modern market is also plastic slate. The material is in demand among the population. It is mainly used for sheds, fences, fences, roofs of outbuildings. Products can be made of PVC or polycarbonate in various shades.

Plastic slate copes with negative natural influences. Of the material often erected fences for swimming pools, greenhouses, awnings. Plastic slate retains its properties under the action of aggressive media. This coating skips the sun's rays, quite cold-resistant. Slate plastic is easy to install, as it is light, does not require heavy sheathing.

Another type of modern slate is rubber. In the production of these products use rubber waste or fiberglass. Material differs in lightweight and simple installation. Rubber slate is good on multi-level roofs, in particular, on indirect sections of the roof. Rubber is not only easily cut, but also bends. Rubber coating is not resistant to severe frosts. Another rubber slate is flammable.

Fireproof properties are different metal slate. Corrugated sheets are made from steel. They come in various sizes, and waves of different configurations. Sheets may have an upper protective layer of polymers. They are rarely used in private construction. Usually this option is used for roofs of industrial buildings.

Each type of slate has positive and negative sides. Due to the diversity of species, it is difficult to make a choice. Buy reliable material from reputable manufacturers. Check the information about the selected manufacturer with friends or those who have already used the material of the selected company.

Standards

Manufacturers cite the following dimensions for popular types of wavy slate.

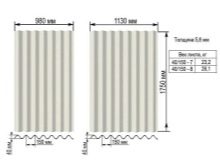

Seven Wave Slate:

- leaf area - 1.71 sq. m. m;

- usable area - 1.33 sq. m. m;

- sheet weight - 23 kg;

- length - 1.75 m;

- width - 0.98 m.

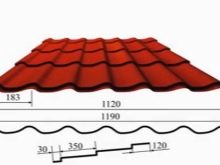

Eight Wave Slate:

- the total area is 1.97 sq. m. m;

- working area - 1.57 square meters. m;

- weight - 26.1 kg;

- Dina - 1.75 m;

- width 1.13 m.

In slate of five or six waves, there is a big difference between the working and total area of the sheet. As a result, with the use of six-wave slate sheet, a significant overrun is obtained. Therefore, in the private construction of the old-style options are rarely used. More often with such slate roofs of industrial premises are covered.

It is chosen because of the sufficient thickness of the material, which is about 7.5 mm. Thick slate breaks less. He also better maintains temperature drops.

A standard sheet of six-wave slate is characterized by the following parameters:

- length - 1.75 m;

- width - 1.12 m;

- wave height - 20 cm.

Slate flat has a thickness of sheets from 8 to 20 mm. Sheet dimensions:

- length - 3 meters, width - 1.5 meters;

- length - 2 meters, width - 1.5 meters;

- length - 1.75 meters, width - 1.13 meters;

- length - 1.5 meters, width - 1 meter.

The popularity of sheet slate with parameters 1.75 * 1.13 is conditioned by the conformity with GOST. Flat slate has the same usable and full area, so it is easiest to make calculations with it.

Calculation of the required amount

Slate is an excellent choice for a simple rectangular gable or single-pitch roof. With the right choice of slate, you get the least waste. Even less they will turn out, if you correctly calculate the required amount of material. For example, the main parameter can be taken as a unified length of sheets - 1.75 m.

You will also need parameters such as:

- the length of the facade structures;

- the length of the slope from the ridge to the outer wall of the house;

- the angle of inclination of the roof slope can be chosen, or it can be calculated using a protractor and a level.

Calculations are performed taking into account the gable and eaves overhangs. For this, we can take into account the standard parameters of the overhangs, equal to 0.3 m. For example, we use an eight-wave slate with a height of bends of 40 mm.

All these indicators are needed in order to calculate the number of sheets for laying in a horizontal row, as well as the number of sheets in a vertical order.

For example:

- length of one side of the facade - 9 meters;

- length of one slope - 6 meters;

- angle of slope - 10 degrees.

This means that for one horizontal row you will need 12 sheets of eight-wave slate, 15 sheets of seven-wave and 14 sheets of six-wave slate.The vertical row will include about 2 sheets of any type of slate, since their length is standard. Total on one side should be 24-30 sheets, depending on the number of waves in one element.

However, the standard sheet size when laying will decrease due to sheet overlap per sheet. There is also an overlap in height. This means that the area of the sheets should be taken into account with smaller values.

A simplified version of the calculation assumes the knowledge of such quantities as:

- roof length;

- leaf width (minus overlap).

With a roof length of 9 meters and a sheet width of 1.13 m (8-wave), the value will be as follows: 9: (1.13-0.08) = 27 whole sheets of slate on one slope.

It is more convenient to do the calculations, knowing the area of the slope and the area of a single sheet of slate, taking into account the overlap. In this calculation, the total area of the roof is divided by the area of the sheet, so you get the total amount of material in pieces.

For example, for the same 9-meter roof with an area of 9 * 6 = 54 meters, when laying a seven-wave slate with an area of 1.7 m2, 32 sheets per slope will be required, and when laying eight-wave slate, 28 sheets per slope are required.

Calculation options everyone chooses the most convenient. As you can see, the numerical parameters of the final results for all variants are only approximately the same. Therefore, experts advise taking material with a margin. So you do not have to re-order the delivery of material and spend additional funds for this service.

Pro work tips

Typical damage due to cracking of slate sheets is due to the strong pressure from screws that are too tightly screwed to the base. Sometimes the sheets crack because of the small holes that are needed for fasteners. To prevent the sheets from cracking at the points of contact with fasteners, you need to drill holes that are slightly larger in diameter than nails. Thus, the nail will not rest on the sheet, leaving it intact.

Unnoticeable cracks appear during careless transportation or storage. Subsequently, the sheets crack even more, so it is better to replace them initially with whole ones. Masters also advise to use patches made of tar or other mastic-based materials. The joints overlap the joints by at least 10 cm.

Asbestos-cement slate sheets are sensitive to mechanical stress.To avoid damage during installation, you can move along the repaired surface only by stairs.

For cutting slate sheets of asbestos cement used file for metal. Some experts suggest to maintain sheets before cutting in water. In the liquid they must be within 24 hours.

Other experts do not advise to keep the material in liquid for a long time, but only to wet it when cutting, since the dust that forms during cutting can seriously damage the installer. Wet asbestos will produce less dust, so it will be easier to work.

Professionals immediately advised to determine the correct place of work. Slate cutting should not be done indoors. The street should be located on the leeward side. Small asbestos particles will be blown away.

Another security issue will be solved by the use of protections. As such, it is advised to use a respirator, special glasses, gloves. Especially protective equipment is needed if the Bulgarian is used for cutting the material.

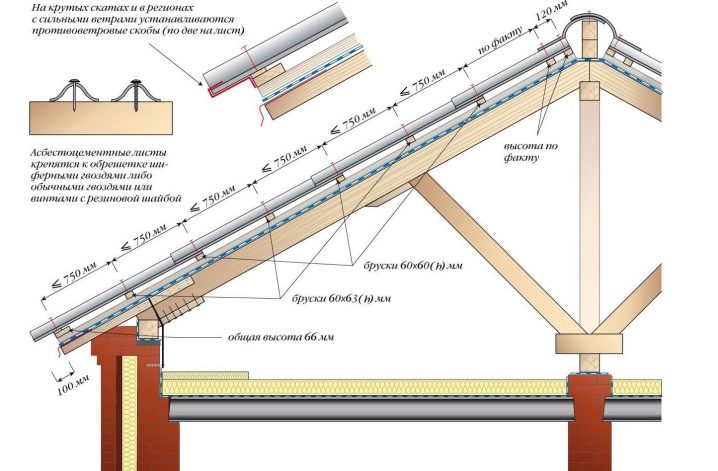

If you use slate that conforms to standards in your work, then lightweight type lathing will do. Bars can be used about 5 * 5 cm.Professionals advise to mount the crate so that there is a support for each sheet.

Professionals are advised to choose for the crate only dry bars. Wood needs to be treated with fire protection. Impregnation will not only protect the wood, but will also increase the service life of the batten.

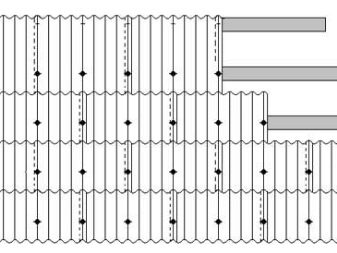

Laying sheets is important to start on the side of the roof that is least exposed to the winds. If you mount the sheets from the correct point, then in the places of overlap in the future will get less snow and rainwater.

For a landmark in the alignment of the rows, you can use a cord that is stretched along the ramp.

Algorithm works may be as follows:

- First, lay the horizontal row below. With the arrangement of this series you need to take only whole sheets. Overlap sheets can be 1-2 waves.

- The second horizontal row is laid in staggered order in relation to the first (vertical lines should not coincide). Overlap over the bottom row can be 15-20 cm.

As a result, it should turn out that all the odd sheets on the roof will be packed with solid slate, and even ones start with a cut sheet. The ridge row is mounted last.If necessary, the sheets of the last row cut across. Roof, covered with slate method with offset rows, more profitable due to the economical waste of materials.

The method is characterized by high labor costs, as cutting sheets alone is difficult. Professionals advise to invite an assistant for this work. With him it will be easier to perform and installation at height.

How to lay the slate on the roof, see the next video.