Ondulin: purpose and characteristics of the material

Quality material for the roof - an important component of the design of residential and non-residential buildings. It performs a protective function for the roof system, participates in the insulation of the room, affects the aesthetic appearance of the house. For these three tasks are the characteristics of the material and its purpose.

Ondulin - one of the few materials for roofing, which combine aesthetics and practicality.

Features and scope

Ondulin - the name of the roofing material, which has become a household name, as the name "foam" - for polyurethane foam. This material got its name due to the fact that more than half a century ago it was released by the French company Onduline for the production of building materials.

Euroslate, as other manufacturers call ondulin, is a sheet for finishing roofs and vertical surfaces made from cellulose fibers, minerals and resins.

Different manufacturers modify the composition, giving it unique properties, but the basis is made up of fibers and binding components.

This coating has a number of features.

- Ondulin is used not only for finishing the sloping roof, but also for facing some vertical surfaces.

- The building material can be used both in private and planned construction, but is more often used by owners of private houses. This is due to the fact that with its characteristics, satisfying SNiP and fire safety standards, it still belongs to flammable building materials. It can be used in public institutions, but it is important to understand that safety requirements will be stringent.

- Ondulin or "soft" roof - not an innovation. Euro slate is produced in Europe since the pre-war times, and production technologies continue to be improved, therefore, ondulin is distinguished by favorable technical characteristics.

- Regardless of the country of origin, the material complies with the requirements of the standard.

- Euro-slate sheets are soft and plastic. This property makes it possible to lay it on the roof of any architectural form.

- Temperature range of use - from - 60 to +110. The melting point and fire - 250-300 degrees.

- In the case of heat, ondulin acquires increased plasticity, and in frost it becomes brittle.

The material is produced in a number of European countries, in Asia, the CIS countries and Russia. Corrugated sheets for the roof according to the patented technology in Russia are produced only in Nizhny Novgorod.

Manufacturing process

The process begins with the fact that in a special device - a pulpator, the substance of a liquid consistency is mixed. It is called pulp and consists of cellulose fibers and liquids. The main fluid is water, and the additive is chemical elements. The proportions of fibers and liquidations are strictly observed, so that at the exit the product retains its unique qualities.

The liquid pulp from the pulpator after cleaning enters a kind of conveyor table several meters long. While she “floats” on this table, the excess moisture from her is removed.It turns into a dense plastic mass.

The remaining water is squeezed out of the mass, passing it through the shafts of the press. The press rolls the substance into uniform, still plastic sheets of great length. Further, these sheets of neutral color undergo the procedure of dyeing with special compositions penetrating deep into the sheet and improving its waterproofing.

Pigmented sheet material enters the next conveyor, which gives it a relief shape. After the formation of corrugations, the already undulated ondulin is sent to the drying chamber.

Inside the chamber are devices for the supply of natural gas. The air temperature in it is 270 degrees. Such an atmosphere hardens the sheets and finally dries them. From there, the roofing material is sent to the production guillotine, where cutting into standard fragments in width and length takes place.

The final (and most important) stage is the impregnation of finished fragments of Euro-slate. For this, sheets are immersed in a pool several meters long, which is filled with hot bitumen. The temperature of the solution is 200 degrees.

Impregnation lasts a quarter of an hour, and it is this procedure that makes ondulin absolutely waterproof.

After impregnation in the bitumen basin, the sheets of material are cooled by sprinkling with cold water, and then sent down the conveyor to cool naturally. Sheets on laying machines are already cooled down to 50-60 degrees. Then they are kept in stock for 3-4 days until they cool down completely and are sent for packaging. During this time, bitumen becomes a full-fledged part in the composition of the material and serves as a reliable hydraulic protection.

So it turns out easy, strong and cheap material for long operation.

Composition and properties

Raw materials for the production of Euro slate refers to multicomponent. It consists of a fiber base, liquids, mineral dyes, plasticizers, impregnation.

The basis of cellulose fibers and fiberglass. To make pulp from them, cellulose is soaked in water with the addition of chemical or mineral components (each manufacturer has its own secrets) and processed. The mixing process resembles the rotation of a centrifuge, and the cellulose is cleaned of all unnecessary substances, so in the production of pulp is often called "washing machine". Various resins are used as hardeners and strength agents.Coloring of the material occurs due to mineral dyes, and bitumen impregnation provides protection from the harmful effects of the environment.

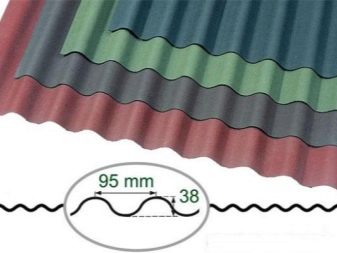

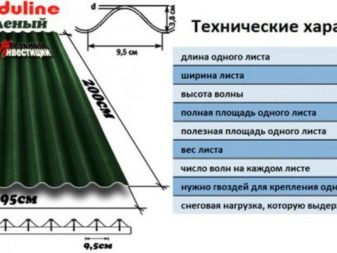

Euroslate, which is made according to the rules with the observance of technology, has standard technical characteristics.

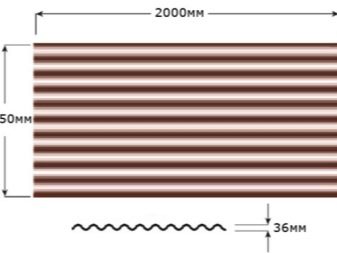

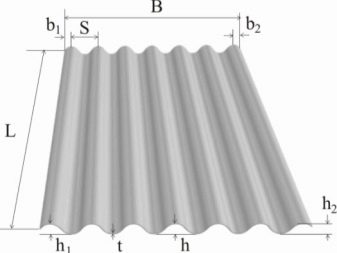

- Overall parameters. This is the width, length and area of the sheet, as well as the height of the corrugated wave.

The width of the sheet - 0.96-1 m, length - 2 meters. The area is 1.92 m2, the wave height is 3.6 cm. Thickness is up to 6 millimeters.

- Weight. One sheet due to its high density weighs 6 kilograms. This makes ondulin a good insulating material.

- Fire safety class. Of the five possible euroslate belongs to the lowest, so it is not recommended in children's institutions. It ignites at about 300 degrees. Also not used to cover the roof in buildings, from which evacuation is difficult (hospitals, nursing homes and other municipal organizations).

- Maximum load on the material. One square meter of ondulin withstands enormous pressure - 900-950 kg.

- High chemical resistance.

Types, pros and cons

The growing production of Euro-slate has ensured the emergence of new varieties of material.Modern ondulin is not only corrugated, but also smooth, and with imitation of the texture of other materials. It is also used not only for finishing the roof, but also for other purposes.

All types of ondulin have common advantages.

- Water repellent properties. Soft material does not absorb moisture from natural sediments, so its structure is not disturbed, the thermal insulation of the roof does not deteriorate, microbes and microorganisms that get wet are not appearing between the sheets.

- The maximum hermetic roofing. One problem is peculiar to all corrugated materials - sheets do not adjoin tightly to each other, forming a gap in which moisture and dust get into. With Ondulin, this problem does not arise. Sheets of material are overlapped, ensuring complete tightness.

- Relatively light weight sheet. Different manufacturers of this indicator varies in the range of 5-7 kg. For comparison: a sheet of asbestos slate of the same size weighs about 20 kilograms. With a relatively lower weight, it is convenient to work in one hand.

- Simple installation technology on the roof or surface of the walls. Cover the roof can be quite quickly and efficiently without the involvement of roofers.

- The material is malleable in processing.It is simply cut into fragments of various sizes and shapes, it fits well on the roof of any type.

- Ondulin already creates a good waterproofing and insulation of the roof, which simplifies further finishing work from the inside.

- Low cost per sheet of material.

- The soft surface of the Euro-slate makes the sound of rain inaudible indoors.

- Maintains heavy snow masses.

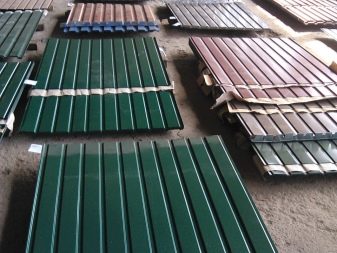

- It happens in different colors and textures.

- Tells the building an aesthetic and neat look. The range of Euro-slate is large enough to choose materials for buildings of different styles.

- You can purchase corrugated sheets or flat ondulin, imitation slate and brick-like styling. Even the so-called "soft tile" is made from the same raw materials as ondulin.

- Warranty period from the manufacturer - 15 years.

Not devoid of this building material and some drawbacks.

- Finishing the roof with ondulin requires a special design of the truss system - with a small step.

- Walking on such a roof in the frost is not safe, the corrugated surface of the sheet becomes fragile and can deform.

- The material is considered to be biostable if it is constantly illuminated by the sun and is in a dry state.In the shadows and dampness, dark spots and “blooms” appear on it, as on a slate.

- For a good fixation of the sheets, you need to attach at least two dozen screws to one sheet. This is painstaking work and an increase in the cost of purchasing fasteners.

- Ondulin fades. Who would not promise, but the coating loses its color saturation from the constant exposure to sunlight and moisture.

- Low fire rating.

Euroslate varies by several criteria: size, sheet thickness, wave height, sheet texture, color, design, country of origin.

The texture, color and design of the Euro-slate distinguish standard models that mimic the appearance of asbestos-cement slate and other materials.

Popularly evroshifer under ceramic tiles. Less commonly used is a euro-slate with a modified wave height and distance between the waves, which simulates corrugated sheets.

The deciding factor may be the country of origin. Euroslate of the German manufacturer belongs to the bitumen sheets of the new generation, which can be used for roof finishing, and for covering vertical surfaces.

Ondulin Russian production is intended only for roofs.

Sheets of the Belgian manufacturer surpass analogues of other firms with its multi-layered structure. This makes them more durable, but does not deprive of flexibility.

Ondulin French production, which became the prototype for Russian factories, is somewhat different from the domestic product quality and price.

American manufacturers produce their own variety of material - Nulin or Nulain. It differs from ondulin in that only solid wood species are used as cellulose fibers. The pigment is applied before the impregnation in the bitumen bath in several layers, so the nulin retains its color longer than ondulin.

Another advantage of Nulin is that its top layer is designed for painting without prior priming. After cleaning the roof of dust, it can be covered in any desired color. And in finished form, Nulin is produced matte and glossy.

Material comparison

Identifying the real advantages and disadvantages of building materials is much more effective when compared. The main selection criteria are: technical characteristics (strength, weight, fire safety, service life), price, tightness, insulating ability, appearance of the material.

Compare these parameters ondulin with popular materials for finishing the roof, to find out what it is better than any equivalent.

Metal tile

Metal tile is called sheet roofing material from sheet steel, copper or aluminum. It received its name due to the fact that the appearance of the sheets imitates the cells of a real ceramic tile.

In some technical aspects, profiled steel sheets and ondulin have similarities. Sizes of one sheet vary within 2 meters in length by 1 meter in width. Approximately the same will be the weight of products - 5-7 kg. This facilitates the transport of material to the roof and simplifies installation.

The service life of metal tiles manufacturer claimed more than ondulin. In practice, such figures - 30-40 years old, are not confirmed. The polymer coating from the sheet metal comes from constant precipitation and exposure to weather conditions. To extend the life of the material it is necessary to clean the old coating, primed and painted.

Its advantage is that the polymer layer fades a little slower than the color of ondulin. Among the types of euroslate, such a problem is not only American Nulin, which is covered in two layers of pigment composition, and on top of a glossy layer.

The metal tile is inferior in strength. It can not withstand the weight of 400 kg per square meter, and ondulin is not even afraid of a load of 800 kg per square meter.

Metal tile is a cold material. If the cellulose composition of resin-impregnated ondulin itself already creates a heat-insulating layer for placement on the roof side, then the roof under the metal sheets must be insulated additionally.

Despite the low class of fire safety of ondulin, at a temperature below 300 degrees it does not burn, but only melts from above. The same thing happens with metal tile, but its appearance suffers more. As a result, both materials will need to be restored.

The roof of the metal does not leak the first few seasons. This is due to the fact that the material is attached to the truss system with bolts with a rubber gasket under the cap. This gasket closes the hole from moisture, but over time, the rubber begins to deteriorate from changes in temperature and humidity. After 2-3 seasons, the roof will inevitably begin to flow in the place where the fasteners are located.

And the main advantage of ondulin is that its soundproofing properties are 15 dB higher than that of a metal tile.This difference can be illustrated by example.

If a person is asked to say something in a whisper to another behind a wall of ondulin, he will not hear, and behind a wall of metal tile, completely.

This property of ondulin plays the decisive role in the rain. If the roof under the Euro-slate misses only a quiet rustling into the room, the roof of the metal tile turns into a drum in the rain.

Working with Ondulin does not require special skills and tools, and in order to cover the roof with metal tiles, you will need to hire a team of professional installers.

These are objective reasons, so that with the same financial availability of materials, Ondulin is preferred.

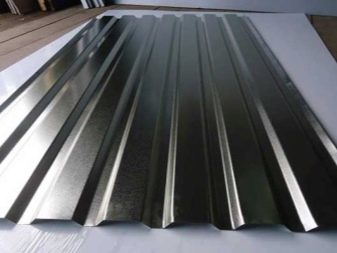

Decking

Sheeting is a sheet of roofing material from cold-rolled steel. The steel sheets on the profile bending machine are given a corrugated shape. The wave step is larger than that of ondulin, and in shape it is less sloping.

By production of a professional flooring sheets of roofing material are covered with protective materials against corrosion.

Decking and ondulin in many respects have similarities.

- The width and weight of a standard-sized sheet is about m per 1 m and weight is from 4 to 7 kg.This provides ease of delivery of materials, easy lifting of sheets on the roof and ease of installation.

- High strength. Cold rolled steel is much stronger than normal. Do it with doors with a level of protection for banking premises.

- Service life - 15-20 years.

- For the foundation you need a step crate.

- It is possible to move on the roof covered with a professional flooring or ondulin without fear.

- Both materials are suitable for installation over the old coating.

- Used not only for roofing work.

A square meter of profiled flooring will be cheaper if only the cost of materials is taken into account. However, for the installation of steel sheets need special equipment and some skills, so you have to hire a team of installers, and you can lay down the euroslate with your own hands.

Profiled has more colors in the range and it is less prone to fading. On it snow masses stay worse in winter.

Ondulin supports combustion (smolders), but corrugated board does not. At high temperatures, an unpleasant odor emanates from ondulin, and at low temperatures it becomes brittle, which is not characteristic of professional flooring.

The professional flooring fastens on a rafter system in the same way with a metal tile. Accordingly, the problems with the leakage of the roof appear the same already in 2-3 seasons.

For the roof of corrugated board requires not only good waterproofing, but also high-quality sound insulation. During rain and hail, she skips 15-16 dB more than ondulin.

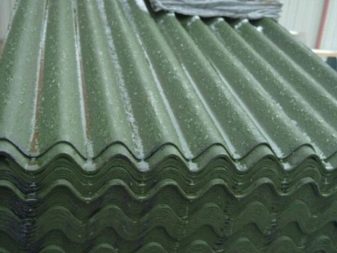

Slate

In appearance, ondulin resembles precisely this material - asbestos-cement slate. There are practically no other similarities, except visual ones, for roofing materials.

Sheet ondulin weighs 6 kg, slate - 24. This gives the load on the roof structure 4 times more, and also complicates the transportation of material to the roof and its subsequent installation. Independently perform roofing work using slate will not work.

Ondulin is flexible and easy to process. It can be cut into the desired fragments and give it the form of complex elements of the roof.

Slate does not possess such properties. The sheet is hard, not flexible and it is easy to prick when trying to cut it into smaller pieces. When carrying with him you need to be careful because of the high fragility. The same feature of asbestos cement sheets makes walking on the roof difficult during the cold season. From the temperature difference, it becomes more fragile.

Both materials support combustion. However, the sheets of ondulin simply melt, giving off a pair of bitumen that is unpleasant to the smell, and the slate begins to explode.

Loses slate and in insulating qualities. The material is cold, so the roof will need additional insulation. It begins to flow through several seasons at the attachment points. All for the same reason - rubber gaskets under the screws are worn out and leak moisture.

The noise level at rain and hail under the roof of slate is less than under the metal tile and corrugated flooring, but more than under the undulan roofing.

The aesthetic qualities of slate also leave much to be desired. Its color is always gray, the shades may differ only slightly. This roof will need to be painted.

Both materials are considered to be biostable only when used on the dry and sunny side. In dampness and shade, fungus, dark spots, and other problems will appear on them.

Ondulin manufacturers give a guarantee for their products for 15 years. Manufacturers of slate such impressive terms are not called.

Ondulin can be laid over the old flooring on the roof, and slate is not desirable.

Ondalux

If before it was about materials that largely lose ondulin, then the situation with “ondalux” is exactly the opposite. Ondalux is produced by the same manufacturing company as classic Euro-slate, but this roofing material is more modern. Manufacturers have taken the technology, which has been verified for years, as a basis, and have improved them by launching a product with a similar name.

"Ondalyuks" differs from ondulin in all technical characteristics.

- More variable and convenient for mounting sheet sizes. Accordingly, the weight changes up or down, but only slightly.

- Improved fire safety performance. "Ondalyuks" refers to materials a class above and it is permissible to use as in low-rise construction, and at municipal facilities.

- Improved production technology and a change in the composition of the raw materials ensure the stability of the ondalyuks to low temperatures. If ondulin is a weak point - it becomes fragile, then “ondalux” is more resistant to sub-zero temperatures.

- Improved ductility of sheets.

- Emerged enhanced protection from ultraviolet rays.“Ondalux” burns out twice slower than ondulin;

- Increased resistance to mechanical damage.

- Increased price.

The rest of the "Ondalyuks" retained the advantages of evroshifer: simple installation, good insulating qualities, aesthetic appearance.

Onduvilla

Onduvilla is a kind of roofing material, similar to Ondulin in terms of technical characteristics and composition of raw materials, but differing in appearance. It does not imitate the surface of a slate, but the surface of a tiled roof.

Onduvilla is not made as long as the euroslate - about 10 years. But she took the best of ondulin production technologies, which are improving from year to year.

According to the main technical characteristics, they are similar: high strength, low weight, temperature range from -60 to +110, flexibility, high-quality insulation.

One of the main differences in onduvilla is the way of coloring. The first layer is applied primer, and in the next 3 approaches - the pigmenting layer using 3D technology. As a result, the roof looks as close as possible to the tile and retains its color for a long time.

Onduvilla warranty period is 25 years.

The price of shingles is more expensive than euro-slate, so ondulin is more likely to work for practical homeowners, and onduville is for aesthetes.

Sizes, weight and colors

The effective area of a single sheet of Euro-slate, as well as its weight, is not a universal characteristic. Many European manufacturers offer 4 types of ondulin: classic, compact “Smart”, “Diy”, each of which has its own characteristics and overall parameters.

Classic euroslate meets the standard of production in everything: 2000 mm length with a tolerance of more or less from -3 to +10 mm, width - 950 mm with a deviation of 5 mm up or down. The weight of such a sheet ranges from 5700 grams to 6300.

Evroshifer "Compact" differs in the smaller sizes and thickness. With a sheet thickness of 2.5-2.6 mm, it is intended for finishing the roof of a complex architectural form. Accordingly, the weight of the product is reduced. With a sheet length of 100 cm and a width of 75 cm, it weighs only 2.5 kg.

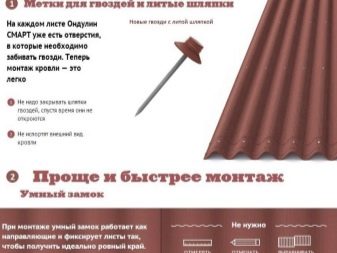

Smart lists are an improved version of the classic Euro-slate. At higher density sheets have less weight. Also attached to them are attachment points for better sealing of the cover and locks, hydro-barriers.

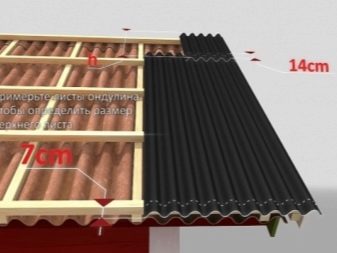

Sheet dimensions are 190-195 cm by 92-95 cm, weight is 5400 g. The effective area is a little smaller, since the ondulin sheets are mounted with overlapping length and width.9.5-19 cm is lost from each edge during installation. This is the width of one or two waves.

Sheets "DIY" different standards of their own. The name of the line is translated as "Do it yourself." This means that the shape of the sheets is most suitable for use by unprepared installers. The size of the DIY-ondulin - 200 cm in length and only 75 in width. There are eight waves per 75 cm, while on a classic sheet - 10. The weight of one sheet is 5 kg with a tolerance of 0.2 kg.

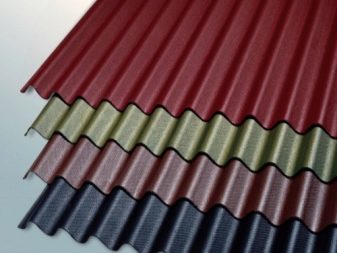

The color range of Euro-slate is very limited.

It includes less than a dozen flowers.

- Brown. Calm, discreet, deep color. It harmonizes well with white, shades of blue, yellow and green on the facade of the house.

- Green. Depending on the country of origin, the color may be closer to salad or emerald. Both shades perfectly manifest themselves in the decoration of the roofs of country houses and buildings, successfully in harmony with the surrounding greenery and nature. They are combined with facing materials of light shades.

- Red. Expressive color, reminiscent of ceramic tiles. It harmonizes with the lining of natural materials: wood and stone, with a neutral palette, white, beige, gray and darker facade decoration.

- The black. Rich shale color belongs to the achromatic spectrum, which makes it absolutely universal for combination with the facade decoration. With bright colors, it forms an original and unexpected tandem, and with natural and neutral ones - classic combinations.

Black ondulin has a special advantage - the ability to absorb heat. This increases the heat savings in the house.

American nulin (nulain), which is a kind of soft roofing materials, has, in addition to 4 common colors, burgundy and blue.

Basically, it comes with a matte texture. It is made glossy by a transparent protective layer on the surface. This gives the roof a beautiful shine and prolongs color fastness.

Choice and calculation: what to consider?

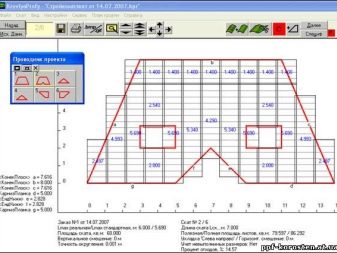

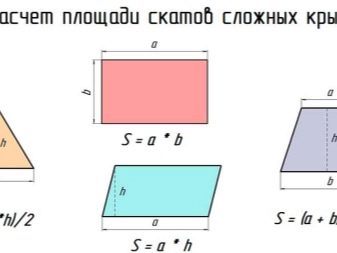

One common way to calculate the right amount of material is to use special programs. Their disadvantage is that the program calculates the number of solid sheets, representing the roof area in the form of a flat square, not taking into account difficult moments, angle of inclination and design features. This leads to the fact that the material is often not enough during installation.

For the most accurate calculations, in order not to buy more sheets already in the process and not to spend money on surplus, you need to use a proven method - an account manually.

It includes several steps:

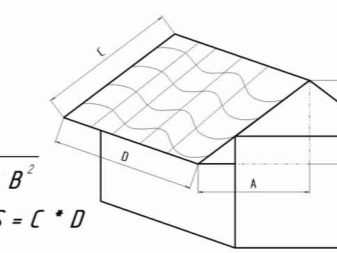

Measurements of the pediment and ridge of the roof (length and width)

To do this, you need a stepladder to get to the top edge of the roof, a tape measure and drawing supplies. Measurements are made at several points, and the area of the entire surface is calculated by the highest indicators.

Sheet measurements

For a standard ondulin, the procedure is not obligatory, its parameters are exactly the same as those specified by the manufacturer - 195x95 cm. For all other types, it will not be superfluous to measure the sheet in length and width.

After that, you need to calculate the width of a single wave: the width of the sheet should be divided by the number of waves.

The standard sheet of waves is 10, so the width of one is 9.5 cm.

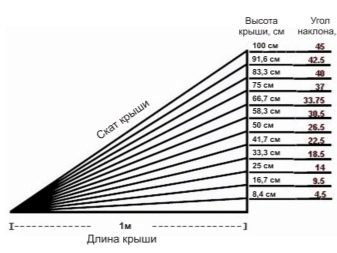

Tilt angle calculation

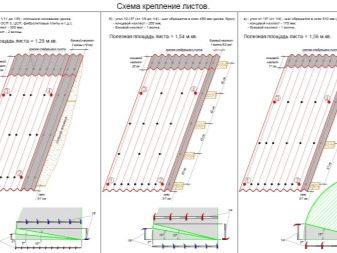

When tilting from 5 to 10 degrees, manufacturers recommend using a useful area of the sheet, equal to 1.29 m in a square.

If the slope is from 10 to 15 degrees, the effective area increases to 1.54 square meters. With a slope of 15 degrees - 1.56 square meters.

The overwhelming majority of residential premises are built with a roof, the angle of inclination of which exceeds 15 degrees.

The effective area is the area of the sheet that covers part of the roof after the overlap width is subtracted from the total area of the sheet. This is one or two waves.

Calculate total material area

To do this, the area of the roof should be divided by the useful area of one sheet. For example, with an area of 64 square meters with an inclination angle of more than 15 degrees, 42 sheets of ondulin will be needed.

It is important to bear in mind that during installation one or several sheets may be damaged. You should not be limited to an equal number of sheets. A small margin of 5-10% of the total amount will help out in unforeseen circumstances.

If the number is uneven, it is rounded up.

Calculation of additional materials

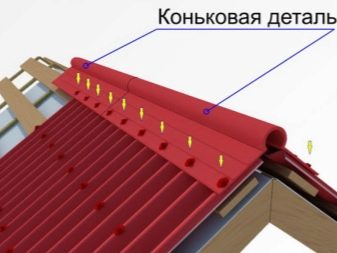

In addition to sheets of evroshifer, need details for the decoration of complex sections of the roof: the joint of the slopes, pediment, fractures in the structure. For a simple gable roof is required to purchase another horse and gable.

The useful length of the ridge is 85 cm. We divide the length of the roof by this indicator, add one spare part to the number obtained.

The effective length of the gable is 95 cm. The calculation is made in the same way. Additional parts will need from 1 to 4.

In addition to the soft elements of the roof, we need branded nails to secure the sheets on the truss structure and among themselves. On 1 sheet of ondulin 20 nails are required. Calculate the number of nails you need, taking into account spare parts.

For example, on 45 sheets for a roof of 64 meters you will need 900 nails.

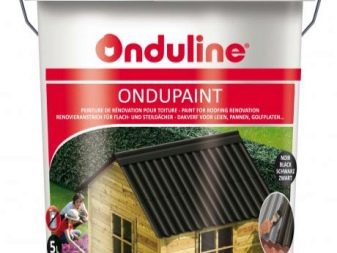

One of the advantages of ondulin is that the material can be painted. The term of its operation is quite large, in ten years the weather conditions will significantly change the appearance of the roof and will want to be updated. And some homeowners initially want to give Ondulin more vivid color. This also requires the selection of suitable materials and the calculation of their quantity.

Not any paint is suitable for onulin. It is possible to restore a small area damaged by the sun, moisture or other factors with ordinary acrylic paint. Work on the complete overlap of color requires special tools. This is a paint that contains the same components that are used in the production of Euro-slate.

Ondulin manufacturers have made it easier for their customers to find the right material by launching the Onduleate product line. It consists of roofing paint, which is the most suitable in texture and color to Ondulin, prolongs its life and gives a beautiful appearance to the faded material. Its frozen surface has a UV filter and water-repellent properties.

The consumption of one layer of paint - 130-150 grams per square meter. For dense coating requires two layers.

Laying: technology and stages

Euroslate is often chosen for small construction due to the fact that this roofing material is suitable for quick installation with your own hands. One person can lay the roof area of 60-70 meters in two days.

These terms include only the flooring material. Insulation, waterproofing and vapor barrier, lathing and related activities require additional time and skills.

Before starting the installation work you need to make sure that all the components are available.

- Branded nails from the manufacturer. Made of high carbon steel with a protective coating of zinc and a decorative hat. The cap covers the nail, creates additional tightness and makes it invisible against the background of the material.

- Fad. A small but important detail for the design of the ridge of the roof.Made of the same material as ondulin.

- Endova. The name of the part is consonant with the name of the part of the roof. It is necessary for the design of roof end and the junction of the roof to the vertical walls of the building.

- Gable. With it, gables and slopes of the roof.

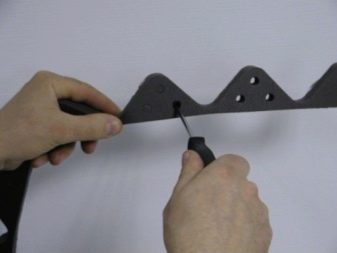

- Curtain holder. The first part in the kit, which is made not of cellulose and resins, but of polyurethane foam. Its purpose is to fill the space between the sheet of euroslate and the crate. Dirt and dust get into this space, as well as small birds can build nests there, so you need to install fillers.

- Covering an apron. This is a polypropylene part, which is necessary to create tightness at the junction of pipes and vertical walls.

- Waterproofing tape. It is used for sealing elements protruding above the roof: skylights, corners, balconies, pipes and others.

All components are recommended to purchase from one manufacturer. Do not forget about working clothes and equipment for compliance with safety regulations.

Crate

Mounting of the sheathing under the roofing material is often more difficult than laying the material itself. But without this step is not enough, will have to adapt.It is especially important to make a proper and high-quality crate for Ondulin, since the material is flexible and prone to sagging.

Despite the fact that the permissible load per square meter of material is very high, at the same time a youth football team could stand on such an area and the material would not be deformed. Evroshifer differs in elasticity and plasticity. Without crates with a small step under the weight of one man of average build, he will already sag, as well as under the snow masses in winter.

To avoid such problems, a special crate is mounted under the euro slate, with a small step or solid.

The following construction materials are suitable for installation:

- timber;

- edged board;

- tes;

- plywood sheets;

- OSB-plates.

To any of these materials, a rather strict requirement is presented: all elements must be equal in thickness and even. Under the sheets of ondulin, the defects will be clearly visible in the places of adhesion of the material. Also the tree needs impregnation which will prolong its service life.

To mount the batten you will need a set of tools: construction level, drawing supplies, materials for sawing wood, woodworking means, hammer, fasteners, screwdriver.

The sheathing profile is mounted step by step.

Preparatory work

They include the calculation of materials, the calculation of the crate step, the selection of optimal weather conditions and the preparation of tools.

The distance between the elements of the batten may be absent if it is solid, or increase to half a meter.

Solid crate needed on the roof with a small angle of inclination or lack thereof. On such a roof, euro-slate sags under snow masses and precipitation; water flows worse from it, so a reliable foundation is needed for laying ondulin sheets. For a tilt angle of 10-15 degrees, the allowable pitch of the batten can be up to 40 cm.

For the roof, the angle of inclination of which exceeds 15 degrees, and this is the majority of typical roofs in private houses, the sheathing step is half a meter.

For installation, you need to choose dry and warm weather, which will last several days. Laying ondulin on a wet crate is not recommended. We bury only dry materials on a dry basis.

Mounting elements of crates

This fastening to the truss construction of boards, timber or plywood plates, OSB with the help of nails. The crate should come out with a smooth surface. The nail pitch is about 20 cm.

Treatment

Processing of wooden structural elements with protective impregnations can be done in advance, so as not to wait until the impregnation dries on the already assembled crate.

Waterproofing installation

This stage raises many questions: why do we need waterproofing for the vaunted hermetic coating of ondulin? The answer is simple - for insurance.

You can do without waterproofing in two cases: the space under the roof will never be used for domestic purposes; roof mounted professional roofers. If the fate of the attic space has not yet been decided, and the owner puts the sheets without experience, it is worth to be safe, organizing a waterproofing layer. It will protect the roof from leaking in case of improper installation of the lathing or ondulin and will create an additional air gap between the PVC film and the Euro-slate. This increases the efficiency of heat and sound insulation of the roof.

In the end, additional waterproofing is simply necessary when processing joints, pipes, windows in the attic, the space around the chimney and in other difficult places.

Waterproofing is easy to install: These are sheets of PVC film, which are often marked.Marking is the recommended overlap width of two sheets of film on top of each other. These materials are fastened and mounted to the crate with adhesive tape and a construction stapler. Finally, they will fix roofing euroslate.

It is important to bear in mind that it is not necessary to stretch the film, it should sag a little and not cling tightly to the sheets of Ondulin.

Mounting sheets

Laying sheets of Euro-slate on the crate is carried out subject to simple rules:

- Works are performed at temperatures from 0 to +20 degrees in dry weather.

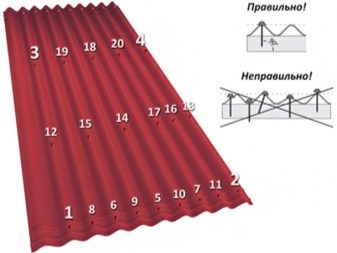

- The nail is driven into the highest point of the wave.

- One sheet has at least 20 nails. Savings are fraught with loose fit, leakage and damage to the coating in strong winds. Repair of the roof is a laborious process, so the sheets need to be fixed securely immediately.

- The head of the nail should be slightly “drowned” on the ondulin sheet.

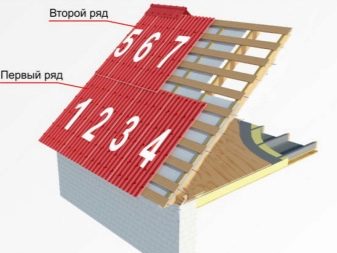

- Sheets are laid first on the bottom row, then on the top. It is worth starting from the lower left corner, moving to the lower right corner.

- Sheets are stacked in a staggered order so that no such joints are formed, where 4 sheets lie at once.In order for the “chess” to work out, each even-numbered fragment must be equal to half of the sheet, that is, consist of 5 waves.

- Ondulin is plastic, but in no case can one stretch sheets wide. Even if it is 1-2 mm at first glance innocent, the roof will be damaged.

- Sheets are overlapped. Vertically - by a width of 1 or 2 waves, horizontally - by 10-20 cm.

- For cutting sheets not a ruler is used, but a narrow piece of ondulin.

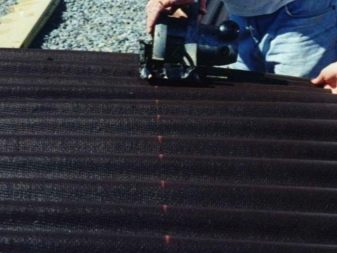

- It is recommended to cut sheets with a wet hacksaw.

Sheets are laid according to the universal scheme.

- The first sheet is applied to the bottom corner with allowances in length and width. Usually to the left, but if the prevailing direction of the winds is to the right, then to the right. Allowance length covers the cornice, and the width - wind board.

- Before you drive in nails, you need to make sure that the sheet is lying without distortions.

- The sheet is fixed with 4 nails at the edges, top and bottom. The remaining 16 nails are distributed evenly over the sheet in three rows at a distance of approximately 50 cm. It is important to take into account that the top edge of the sheet will fix the next row of ondulin, therefore you can retreat up to two feet from above.

- The next sheet is overlapped on 1 or 2 waves, again fixed with nails. In this way all solid sheets of the bottom row are laid.

- The top row starts with a whole leaf, if the last one in the bottom was half, and from half, if the last one was whole. Solid and edged sheets alternate. Cutting edge fits inside the roof.

- The last sheet should again be with an allowance for the edge bar.

- Similarly, each roof slope is sheathed.

Setting items

When the installation of sheets of Euro-slate is completed, it is time to fix the components so that the roof has acquired a complete aesthetic appearance and maximum tightness.

You can start with fastening tongs. These elements are designed to design a “seam” at the junction of sheets of ondulin along a roof gable. That is, on the acute angle of the slope, its top point.

Nipple elements overlap each other with an overlap of 8-10 cm and are fixed by the same nails with caps. The inner part of the seam will not be superfluous to process the sealing tape that comes with the sheets. The edges are closed with ridge elements.

Covering the apron is needed for tight connection with elements such as stoves or chimney pipes, windows, protruding parts of the roof or attic.

Consider the installation on the example of a brick pipe.

Like all work on laying ondulin, it is made step by step.

- Measure out on the factory part the desired length for plating the pipe, add one spare wave to the left and right.

- Attach a fragment of the covering apron to the pipe (the ondulin should already be fixed on the crate), drive a few nails, departing from the lower edge by 5 cm.

- The upper part of the apron needs to be fixed close to the pipe with three separate fragments for each side with Onduflash tape.

- On the upper edge of the tape is applied a metal profile, fixed with screws.

Option on the old roof

Ondulin is convenient because its low weight and elasticity make it possible to lay it over the old roof. This gives advantages in terms of heat and waterproofing, saves a little time and money.

It is important to mount the euro slate on profiled sheeting and roofing material, but optimally - on asbestos-cement slate, since slate repair is impossible, and dismantling work is long and dangerous (splinters, heavy weight, asbestos dust, which is harmful to health). In addition, the slate can not just be thrown to the nearest landfill. This material is combustible and explodes; it must be disposed of in a special way.

When installing ondulin on the old roof, many make a mistake - they use it as a crate. But between the new and old material there should be a ventilation layer, therefore the old roof is only a convenient base for the batten, but not its replacement.

The edges of the old roof are covered with wide wind boards. They are mounted after installing the crates from the timber.

All other steps of laying the ondulin repeat the installation of sheets on the usual crate.

Beautiful examples and reviews

In favor of the ondulin speak mostly positive and laudatory reviews from homeowners who covered the roof with this material more than a year ago.

Among the positive characteristics in the first place is called the efficiency of the material and its presentable appearance at a low price per sheet.

Many owners who personally covered the roof, note the ease of installation: Ondulin sheets have markings for overlapping and imperceptible from afar a line for driving nails. Thanks to these small nuances, ideally even rows of nails are obtained, and much time is saved on the markings for the width of the overlap.

The compactness of the sheets is pleasantly surprising: the material for covering the roof is 150 square meters. m in folded form is half a meter in height and placed in the family car during transportation.

After 5 years or more, the material does not cause complaints in relation to performance and appearance. It fades over time, but it happens evenly.

They talk a lot about the beauty of Euro-slate. Still unusual for typical housing in our country looks like a black roof. This is the most interesting, masking defects and versatile option for combining with exterior trim.

Ondulin looks natural and aesthetically colored using 3D technology for ceramic tiles.

A bold decision - a combination of different colors. With this design you need to be careful that the roof does not look coarse.

A universal way to transform an ondulin roof is to coat it with paint from the same manufacturer. The roof gets bright color, wet shine and additional protection.

On how to install ondulin, see the following video.