Flat slate: variations and uses

Thinking about building a house or repairing an existing one, the main problem is working on the roof. Often there is not enough time and energy for it, which then results in leaks, rotten beams and other negative consequences.

Using modern roofing materials, namely flat slate, you can quickly and without much hassle to block the roof and ensure a comfortable life in the house for many years. In addition, with the help of this material, you can finish fences, ceilings, balconies and more.

What it is?

Slate is familiar to man from ancient times, but often in the construction of a wavy version, it was used for the roof of a house or any other building. Since the material itself was inexpensive, and served long and reliably, an attempt was made to create an even version of the same product.This is exactly what a smooth slate turned out to be, which is not inferior to its progenitor, but unlike it has much more possibilities for use.

The material is called flat, because it has a completely flat surface. Such slate is also made of asbestos, which gives it strength and durability, including making it relatively light. With it, you can both cover the roof and make a fence. If desired, the material is used for interior decoration of non-residential premises. Often flat slate cover the lower part of the balconies.

Due to its low cost, slate can be used for any necessary repair purposes, and its long service life, which can reach 50 years, will help to get rid of unnecessary repairs for a long time.

It is very convenient to work with him, because it is easy to cut the slab even with a saw, without worrying that the material will deteriorate, break, or somehow deform. When interacting with slate, you must comply with the safety rules so that asbestos does not get into the respiratory tract.

Flat slate has a large variety of sizes, which makes it easy to choose the right size of sheets.This material differs significantly from wavy slate, where there are only a few options for the dimensions of the product. Working with flat forms, there is very little waste, which is very economical.

Special features

For the production of flat slate is used at least 18% of asbestos, which makes the sheets so strong, and reinforce them. Portland cement is used to bond all the original elements, to which asbestos and water are added, after mixing which the necessary mixture is obtained. When the composition hardens, it turns out durable flat slate.

If you pay attention to the technical characteristics, it is important to mention the methods of obtaining this building material:

- manufacture of slate using a press;

- production of non-pressed slate sheets.

Finished products are distinguished by marking:

- PL - flat sheets;

- NP - flat sheets of unpressed slate;

- P - pressed sheets of flat slate.

Uncompressed slate is less dense, because it is recommended to be used for interior decoration. The pressed version is a more perfect model, and therefore it has more functions. The properties of the future slab depend on asbestos and its characteristics.The strength and durability is influenced by the diameter and length of the fibers of the main component, in addition, a significant role is played by impurities that make up the plates.

The weight of flat slate varies from 25 to 30 g for large sheets, which is quite a lot, because it is important to provide the necessary measures to strengthen the structure under such a coating.

The material is widely used in construction, because it is important to know all its advantages and disadvantages.

The advantages include:

- low cost;

- strength and durability;

- ease of care;

- non-flammable composition;

- immunity to electricity, can be used as a dielectric;

- good sound insulation.

There are a number and negative characteristics of this material:

- relative fragility;

- Resistance to biological effects (moss and mold);

- the need for additional coating material.

To protect the flat slate, you need to use a special paint that will not leak moisture and make the roof attractive. Consumption per 1 m2 can be calculated based on the specific type of paint and the number of layers. If the surface is not too large, then there will be no big expenditure on paint.

Kinds

Flat slate has only two varieties.

- Pressed - the composition of asbestos and cement, which is created using the press. The resulting material is very durable - 23 MPa, has a high density - 1.8 g / m3, and impact strength is 2.5 kJ / m2. Such material may be exposed to high and low temperatures for fifty consecutive times. After such tests, the strength is reduced to 40% of the original.

- Unpressed - the version of flat slate is inferior to the pressed one according to the characteristics, so its strength is only 18 MPa, the density characteristics is 1.6 g / m3, and the impact toughness values will drop to 2 kJ / m2. This type of slate can retain its properties for about 25 cycles of exposure to low and high temperatures. But the performance after 25 cycles will be better than the pressed slate twice.

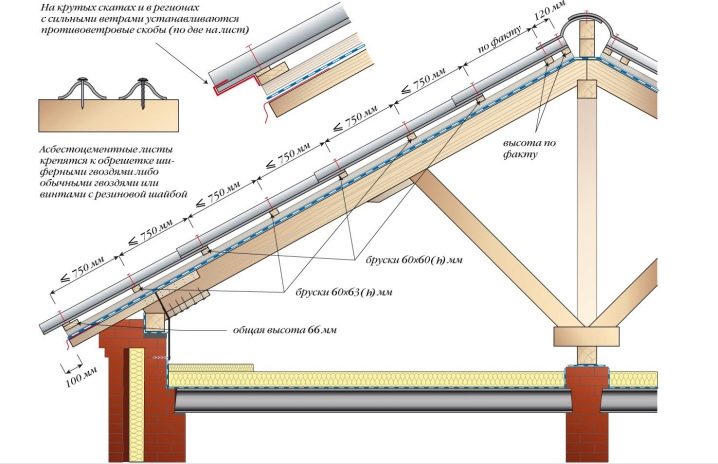

Sheet slate can be used to cover the roof of the house. The roof of such material will be reliable and durable. Sheet thickness should be from 8 to 10 mm, linear dimensions do not matter. The weight of the structure will be significant, because it is important to strengthen the frame under the slate.The tree on the crate is treated with an antiseptic to prevent the appearance of microorganisms and the rotting of the boards.

The horizontal row of such slate is placed end-to-end, and the vertical row is overlapped with half a sheet of slate of small size. It is necessary to fix everything with the help of metal screws, on which a press washer and gasket are put. Holes for them are drilled no closer than 7-10 cm to the edge.

For non-residential premises, a modern version of flat slate made of plastic can be used. This is a transparent and very light material that can cover the roof of the shed, make a shed, a gazebo and so on. If you need to decorate some surface, you can use a flat slate with stone chips. For the special effect often used color variety, which helps to create an imitation of natural stone. Such an additional coating not only decorates the texture of slate, but also improves its properties, increasing its resistance, protecting the surface from external factors.

Manufacturing materials

To obtain a flat slate, you need to have chrysolite asbestos and portland cement.If you mix both substances and add water to them, the mixture will be ready for a future stove. On the production there are special forms in which the prepared mixture is poured. Sheets can be obtained from very large to very small sizes. Thickness is adjustable during the pouring process.

An important feature of the strength of the future material is the uniform distribution of asbestos fibers in shape. After pouring the first layer, another cement composition is poured on top, and then proceed to determine the thickness of the future sheet. When the solution dries, it is pressed using special equipment, which further increases the strength of the slate. When this process is over, the composition of the sheet is sent for drying.

It is very important to adhere to GOST standards so that each sheet of slate contains exactly 18% asbestos. Flat slate can be of two varieties, but the final result depends not on the composition, but on the method of its processing.

Dimensions

The dimensions of the finished slate sheet can be very diverse. Its thickness affects the weight of the entire sheet, especially with large dimensions. It is considered the thinnest slate with a thickness of 6 mm.Thicker options are 8 and 10 mm in thickness.

If we talk about the size of the sheet, that is, GOST standards, which involve the production of products in size:

- 3.6 to 1.5 m;

- 2.5 to 1.2 m;

- 3 by 1.5 m

Each of the options may have a different thickness. So, the first option has a range from 8 to 10 mm, the second - from 6 to 8 mm, and the third - from 8 to 10 mm. Extruded slate is thinner and lighter.

Dimensions and thickness of a sheet of non-pressed products are in the range:

- 3000 to 1500 mm can have a thickness of from 8 to 20 mm;

- 2000 to 1500 - from 8 to 10 mm;

- 1500 to 1000 - from 6 to 10 mm;

- 1500 to 900 mm is made only in one size - 8 mm.

The weight of non-pressed slate is more pressed than the thickness, so it is important to choose the right type of material for certain tasks.

Colors

The original color for slate was gray for both wavy and flat, but in view of the ugliness and monotony of the palette, all sorts of attempts were made to add diversity. With the help of acrylic dyes was obtained color slate in a range of red, brown, blue and green tones. Flat slate is characterized by a palette of both bright gloss and matte, which makes it possible to select such a product for any needs.

Such an additive contributed not only to the decorative effect, but also to the improvement of material properties. Dyes protect the slate from exposure to ultraviolet radiation and some other environmental factors, which significantly prolongs the life of the product.

When buying it is important to pay attention to the quality of paintwork. If the color is even and evenly distributed, then the material is made according to all standards. It is important to pay attention to the similarity of gamma on both sides of the sheet: in high-quality products, the color should be the same.

Slate from plastic can be both color, dense, and transparent. The material of manufacture is polycarbonate, which is an environmentally friendly material. Such products are lightweight, so it is easy to work with them and can be mounted on wooden structures without strengthening them.

How to choose?

In order to make the right choice, you need to clearly understand the purposes for which flat slate is selected. By focusing on the mounting methods, sheet thickness, its dimensions and weight, you can choose the desired option. When buying such products, you need to carefully study the labeling on the packaging in order to accurately understand the characteristics of the product.

For the roof suitable plates of relatively large dimensions, preferably with the lowest weight, which will speed up the process of overlap and reduce the weight on the building. For walls, you can choose a thicker version of slate, but it is better to take small sizes, because you often have to bypass additional obstacles in the form of windows and doorways, which will be extremely inconvenient when using a large sheet.

Installation and installation

To install a flat slate, it is very often necessary to do various kinds of manipulations over the sheets. Whatever it is, the first thing to remember is the rules of personal safety, because asbestos is harmful to humans, especially in the form of dust. Starting any installation actions, you need to take care of a protective mask and goggles.

Cutting

If you need to cut or drill slate, it is important to choose the right tool to minimize the amount of dust.

The easiest way is to break off the required piece of slate. Due to the structure, the sheets can be easily broken without the risk of cracking the rest of the slate. It is very convenient to carry out such manipulations at home, because the amount of dust in this case is minimal.The main thing in this way is not to break the corners, because it will not allow to break off exactly the piece of slate necessary for work.

To make such a scrapping, you need to draw a line along which the fracture will be made, make several holes with a diameter of 1 mm and lay out a sheet on the surface so that the line of catfish is on the edge, and then press it.

If this option is inconvenient, then you can use the tools.

- Grinder If you work alone, then there will be a lot of dust from the cut, if there is an assistant, he must pour water on the saw blade and the cut line that binds the particles, turning them into dirt.

- Diamond wheel Working with him is important to have protective equipment. The edges of the slate will need to be sanded immediately.

- Jigsaw. It is not necessary to have a powerful machine, the slower it works, the easier it will be to cut, and less dust. When working with a slate surface, it is important not to press it too hard, so as not to deform it.

- Cutter. On the planned line with the help of multiple holding the cutter, the furrow increases and as a result the slate breaks in an even piece.

It is best not to use a hacksaw for cutting flat slate, because the process will be delayed, it will be dusty and you can easily cause damage if handled carelessly.

Installation

When all items are ready to go, it is important to mount them correctly. If the slate is mounted on the roof, then it is necessary to drill holes for the screws. You can apply and roofing nail, but screws with washer or gasket in this case will be more convenient, because they do not need to drive, which minimizes the chances of deformation of the coating. In the case of work with the roof, it is important to remember about the need for a waterproofing layer.

To work with the walls and, in particular, their alignment, it is necessary to use a profile and make the desired design, which will be sheathed with slate sheets. To securely fasten them to the surface of the wall, you can use a clamp that will fix the two parts of the slate and make the whole structure more stable and reliable.

The side of the sheet that goes outside should be additionally protected, which will prevent the destruction of the material. Therefore, the corresponding surface must first be treated with acrylic paint. And on the inside, a layer of plaster is applied on top, the surface is leveled, ground and prepared for further finishing. For finishing works, you can choose color slate.

Installation of wall plates is carried out buttwhile at the joints it is better to coat with sealant in order to minimize the chance of leakage. If we talk about the roof, then laying there is an overlap that precipitations under any circumstances do not fall under the surface of the overlap. After installing a flat slate on the wall, it is putty and then polished so that the surface is perfectly flat.

If you need to make a gazebo or sheathe the fence, it is best to use large sheets of slate, which are screwed to the frame or beams of the future fence. The principle of work is almost the same, the main difference is the dimensions of the slate, which must be selected individually for the design.

Tips

In order for the flat slate to serve for a long time and not require repair, it is important to first mount it correctly and produce all the necessary work in a quality manner. If the material is supposed to be for the roof, then it is important to ensure that it is protected. The roof is always exposed to external influences: in the summer it withstands high temperatures, and in winter it is cold and moisture. That is why it is important to use a special paint for slate to protect it: painted colds many times longer.

Paints can be of different colors, but the main thing is to choose the one that is designed for flat slate with the purpose of its impregnation and protection. Any other materials will be inappropriate. If such a mistake was made earlier, then it is necessary to clean the entire surface of the old paint and cover it with a new, specialized one.

For a variety of flat slate, see the following video.