Wood cladding of stairs: finishing options and stages of installation

To improve the appearance of the stairs of metal or concrete is used wood cladding. The frame without additional plating not only looks rough and careless, but also carries a danger during operation. The staircase, trimmed with natural material, looks cozy, stylish and attractive. This decor will remain relevant from season to season.

Advantages and disadvantages

The advantages of this type of skin a lot.

- Environmental friendliness. Wood is a natural and environmentally friendly material, completely safe for health.Natural decoration is recommended to use if the house is home to allergies, small children and pets.

- beauty. Appearance is especially important when decorating living spaces. Wooden paneling gives the atmosphere of coziness and comfort. The attractiveness of natural material fascinates and attracts the eye. The choice of customers a huge variety of colors, textures and textures.

- Durability. High-quality finishing material retains its shape and beauty for several decades - this is a profitable investment in decorating and home improvement.

- Security. An improperly designed staircase can cause many injuries and injuries. Wood paneling is used to increase the security level of this object.

- Practicality. Facing will make the structure more reliable and practical - it will become denser and thicker. Experts recommend using this option finish when you need to strengthen the stairs.

The main disadvantage of this decoration is the cost. Finishing materials from natural raw materials have always been more expensive than artificial counterparts.

In addition, this finish is not suitable if the room is constantly high humidity: such conditions adversely affect the lining, changing its shape and destroying integrity. Moisture is quickly absorbed into the wood, with the result that the lining loses its positive performance characteristics.

How to choose the right method?

Depending on the style of the interior, material possibilities and personal preferences, it is possible to sheathe the frame in two ways:

- partial clearance - decoration of individual structural elements: the material covers the parts most exposed to daily loads;

- full plating - outwardly it will seem that the stairs are completely made of wood.

And also when choosing a method, you should refer to such characteristics as:

- condition of the stairs;

- material features;

- configuration.

Natural wood upholstery costs a lot. Elite material from rare and valuable breeds is only affordable for wealthy buyers. To save material resources, it is necessary to choose a covering from the most available grades or to use partial facing.

Used wood grades

Oak

This tree is deservedly bears the title of king among the hardwoods. Finishing material boasts practicality, endurance, reliability and durability. Oak veneer will provide the construction of a long service life and decorate the room.

The color of the rock changes over time: the skin is darker, the color becomes more saturated, noble and thick. The color palette of finishing material is diverse and multifaceted.

Ash

The variety is actively used in the construction and manufacturing of finishing materials. Wood has an expressive texture and a slight gray tint, giving the variety a nobleness and refinement. By strength, ash is very similar to oak.

Beech

Sheathing beech delight long life. The texture of the material is uniform. Designers often use this sort of mahogany decoration.

Pine

Conifers are also often used for the manufacture of finishing materials. This is a practical and cost effective option. The variety is easy to process and tinted without any problems. And also wood possesses the wear resistance and practicality necessary for covering the stairs in houses and high-rise apartments. The best option for self-installation.

Exotic

Especially popular are rare, exotic varieties. Among the many options in the leaders of such rocks as tick, wenge and merbau. Wood attracts attention with a rich and expressive color. If you opt for the above options, it is recommended to turn to the services of professionals for trim the stairs.

Regardless of the option chosen, the product must be of high quality, because the decoration of the stairs with a tree includes both a practical and aesthetic side. In order for the staircase to the second floor to become a key element, the skin should be pleasing in appearance and harmoniously fit into the interior.

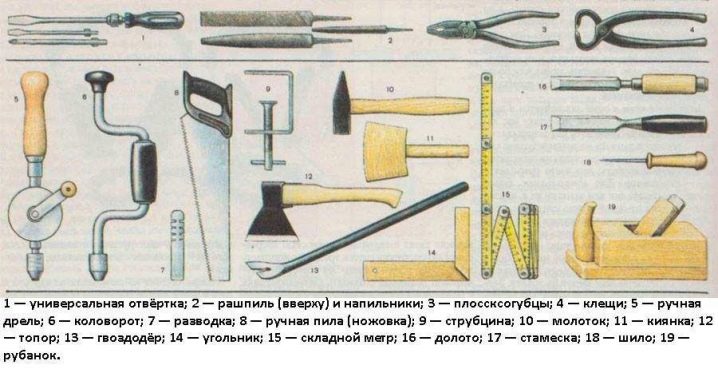

Required tool kit

If you are planning to do the work of trimming the steps yourself, you will need special tools and fixtures. The minimum set for working with finishing materials in living conditions is the following:

- screwdriver;

- milling machine;

- Sander;

- a set of hacksaws for wood and metal;

- construction plummet;

- level;

- jigsaw;

- standard metal hammer;

- rubber or wooden hammer;

- electric drill with adjustable speed;

- set of drills and milling nozzle.

To independently carry out the work, you must have experience with the above tools. In the process of installation, be sure to follow safety precautions, and with the help of clothing and accessories protect yourself from debris and dust.

Features of work with concrete structures

When facing concrete stairs, it is necessary to familiarize yourself with some subtleties. Such structures can often be found not only in residential buildings, but also in shopping centers, industrial and public buildings, office buildings. As a rule, in such ladders the dimensions of the steps differ slightly from each other. Before facing it is necessary to correct this defect.

Frame

To facilitate the installation of wood cladding material can be installed on top of a concrete staircase frame made of natural material. After the installation is completed, it is upholstered in an array of selected wood by the buyer.

In the case when it is impossible to build a frame, it is necessary to be guided by the largest and highest step.The rest must be brought to its size with a special fill. In the process, formwork made of durable and moisture-resistant plywood.

Fill

The most common and widely used option is to buy a cement-sand mortar. It can be found in any hardware store. Cement marking must be at least M150. You can also use special cement-based self-leveling compounds. Such compositions give excellent results in the shortest possible time.

Do not forget to carefully clean the steps before pouring. Reinforcement of stairs should be carried out only if the thickness of the fill allows. The design is reinforced for greater reliability and durability.

Padding

The material absorbs and retains moisture. To prevent this from affecting the practicality of the construction, the stairs are treated with a primer. Ideal composition, based on PVA glue: the solution will block small cracks and pores in the concrete, preventing moisture and damp from penetrating deep into the concrete. Processing is carried out after leveling the stairs, sealing large cracks and correcting defects by means of putty.

Additional finish

In the process of lining the stairs are often covered with a special lining of linoleum or polyethylene foam. Layer thickness - 3 millimeters. Such additional finishing is carried out only if it was possible to perfectly align the steps. Laying will perform the role of a reliable sound insulator.

Otherwise, when the surface of the stairs is far from perfect, Experts recommend using plywood. As a rule, sheets with a thickness of 10 to 12 millimeters are used for work. The dimensions of the material are strictly adjusted to the dimensions of the steps. The material is fixed with liquid nails, and the corners are fixed with screws. If you want to use a sound absorbing pad, it is glued over the plywood.

After laying pre-prepared wooden acts. If you do not plan to use other veneering materials made of wood, free space is covered with a cardboard. If desired, it can be coated with enamel. Steps made of wood can hang down about 10-20 cm from the monolith staircase.

Installation secrets

Optimal baluster distances on the marches are 90, 130 and 220 millimeters.Fasten them using anchor studs, twisting the element to the very edge of the flight of stairs. You can place them at the bottom of the structure. Balusters can be installed on the side (using two studs), if the dimensions of the stairs allow.

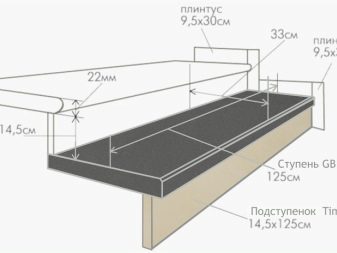

When fully trimming the stairs, leave 20 millimeters on the overhang. At the bottom of the groove is milled, the width of which has 25 millimeters. The element is placed at a depth of 14 millimeters. The upper part of the riser will be installed in the groove and secured with adhesive.

While the composition dries on the march, it is recommended to make blanks under the steps of the stairs: they connect the steps and the walkway between them.

It is necessary to begin installation from the lowest step. In the end of the riser insert a few anchor bolts (2-3 pieces). Before starting work, the structure is placed at the installation site and the points of contact between the studs are marked.

Sheathing

If you intend to carry out the process of plating, we recommend that you read the exact instructions for the work. The method of covering concrete structures can not be called simple. Above in the article we have identified the features of the lining of steps with wood finishing material. Do work only if you are completely confident in your abilities and have all the necessary tools.Otherwise, you run the risk of spoiling the finishing material and even damage the stairs.

First of all, before facing, it is necessary to prepare the ladder structure:

- To begin with, the size of each individual step is measured. Having learned the maximum size, the remaining steps are fitted to it. The usual cement mortar will help to cope with this problem. Work should be done slowly to prevent mistakes.

- With a drop of 1 cm, it is necessary to build a wooden frame and use a special reinforcing mesh to reinforce the structure.

- As soon as the leveling mixture is completely dry, it is necessary to thoroughly clean it from dust and other minor dirt.

- To increase the density of concrete should use different adhesives. They will enhance the adhesive properties of the ladder.

- At the very end, the construction is covered with a deep penetration primer.

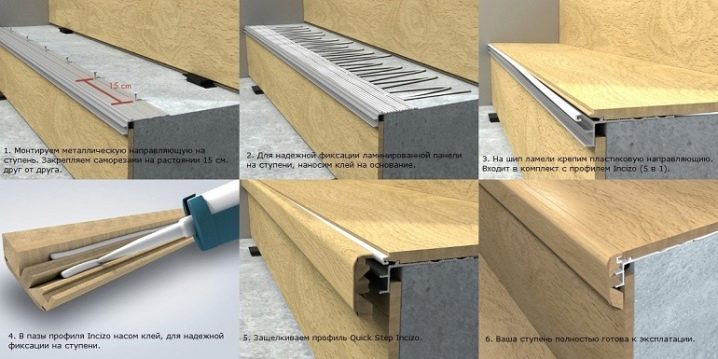

The lining of the concrete structure consists of the following steps:

- the substrate of the steps is cut from moisture-resistant plywood with a thickness of 1 to 1.5 cm;

- using moisture-proof mastic, firmly press the cut parts to the base;

- fixing them in this position, glue;

- secure the dowel;

- lay the substrate (it will help smooth out the irregularities and take away excess moisture from the concrete structure).

The risers and treads are fixed with screws. These elements must be prepared in advance: you can buy them or make them yourself. To fix the treads and risers correctly, You must adhere to the following technology:

- To begin, screw three bolts with a diameter of 0.6 cm (the elements are mounted on the lower side so that the heads of the bolts protrude on the surface);

- remove caps;

- lay a wooden riser on a concrete base;

- mark the location of the bolts;

- make holes in the marks and fill them with epoxy;

- apply liquid nails on plywood and attach wood finishing material;

- arrange the pass in steps: depth - 1.4 cm, width - 2.5 cm (this is done with the help of a milling machine);

- fasten the lower edge of the riser flush with the step;

- From the back side, gently press the tread top edge into the groove.

Using the above principle, trim the remaining steps. To seal the gaps, use a putty or foam.It is necessary to proceed to the installation of the railing only after the completion of the step of facing the steps.

Cuts, sawn at a specific angle, are necessary for the design of the rotary elements. For their installation use glue and screws.

Upon completion, the joints are carefully polished, and the steps are covered with a colorless varnish to maintain the natural color of the wood, or colored enamel. The compositions will not only decorate the stairs, but also will protect the finishing material from the negative effects of the environment. In addition, these coatings increase the wear resistance of wood.

Features of work with metal structures

When finishing iron staircases, you can use any of the methods to choose from: partial finishing, when only steps are faced with wood, or a full skin covering the whole frame.

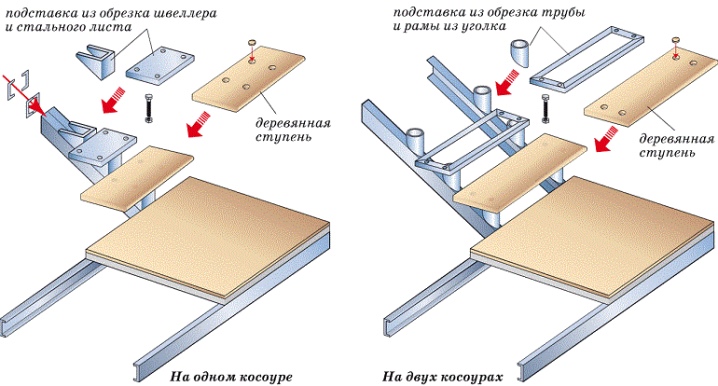

Experts point out that The manufacture of metal stairs requires special knowledge and experience, as this is a troublesome and laborious task. The master must have the skills of a welder and a locksmith, as well as be able to correctly draw up a drawing, calculate dimensions and load. The best solution - ready frame models that are assembled on site.

Subtleties

The process of covering wood with a metal ladder has certain differences from the plating of a concrete structure:

- It is not necessary to level the steps and adjust them to one size. The work begins with the fact that the risers are cut and walk.

- Holes suitable for screw diameters are made from the back of the iron profile. Boards are attached to the bottom of the profile. In this case, it is not necessary to arrange through holes in the wood finishing material.

As for balusters, they are placed on the same principle as in the plating of concrete stairs.

A height difference between the steps is allowed: the maximum limit is 9.5 millimeters. If the difference is greater than the above parameter, it is necessary to carry out work on equalization.

Skilled craftsmen note that the height of the riser should vary from 150 to 180 millimeters, while the optimal width is from 270 to 320 millimeters. Such indicators were compiled, given the average width of the human step. Deviation from the above indicators can lead to inconvenience during operation.

Each type of wood used in the decoration of the stairs,has its own individual operating characteristics, but experts have derived indicators that an ideal finishing material should have: the maximum humidity should be 12%, and freshly chopped wood will not work for work.

Sheathing

As with working with concrete structures, it is first necessary to change the dimensions of the steps and risers. The work must be carried out as accurately and carefully as possible. The resulting dimensions are transferred to the cladding material. Due to the fact that the parameters may differ from each other, it is strongly recommended to number the cladding elements.

Parts of the cladding are cut out of natural material and are customized in accordance with the dimensions of the steps. Experts advise to draw small awnings over the frame. For each individual step, plywood of the same size is cut out (taking into account the dimensions of the wooden siding). It is mounted on a metal frame. This stage will help to block all defects and distortions of the stairs.

For the installation of elements of plywood used mounting glue. Make sure that the composition is suitable for wood and metal.

With the help of screws tread attached at the bottom or top.Placing elements for fasteners from the bottom of the structure, it is necessary to take into account the height of the walk, otherwise the screws can go through.

Fastening from above is chosen less often due to the fact that such a method is less aesthetic, but from the point of view of time spent on work, this method is more profitable: self-tapping screws are tightly screwed into the finish so that the caps “sink” in the body of the tree. After they overlap with furniture plugs or putty. During work, use the building level.

Chipboard, wall paneling or drywall are ideal for facing the back side of the structure. The wood paneling is varnished. Once it is completely dry, the ladder can be used for its intended purpose.

We have designated the standard method for decorating metal stairs with wood. Work can be done on their own with the necessary skills.

Interior styles

The upholstery of the stairs with a tree will harmoniously fit into many stylistic directions, including both modern and classical designs.

Country music

The basic idea of country style: the more wood the better. Natural material is used as a covering for decorative items, furniture,wall, floor and ceiling finishes. Concrete or metal stairs, sheathed with natural material, perfectly fit into the decor.

Color wood does not overlap colors. Allowed to use clear lacquer to cover the skin. Textured wood with an expressive pattern is especially appreciated.

Classic

The tree is an integral element of the classical style. Wooden paneling of valuable and rare varieties will add elegance and nobility to the interior. It is advisable to use a high quality array. The design is complemented by stylish handrails with three-dimensional decorative elements.

If desired, the material can be painted. Often used light, soft and pastel colors.

Loft

In the industrial style wooden staircase will look spectacular and attractive. Partial siding is ideal when wood is combined with metal construction or concrete. The color of the finishing material can be different: from light beige to deep dark.

Provence

A staircase lined with wood can decorate the room in the gentle Provence style. The best option is an array, painted white.And also it is possible to choose any other gentle, light and soft color. In this style often use the effect of artificial aging of wood and faded paint.

Minimalism

In modern style natural materials are practically not used, but modern designers sometimes violate the canons for a new aesthetic effect. A neat and strict staircase structure, decorated with wood, is suitable for the direction of minimalism, if you choose the right color of the finishing material, its texture and texture.

findings

Covering the stairs with natural material is a practical, fashionable and stylish solution. Many companies are engaged in the production of finishing material for metal and concrete structures, which gives the freedom of choice to modern customers. The process of covering is simple, it can be done independently, but there are certain difficulties and features that should be considered in the process of work.

The array can have a different color and texture. Depending on the style, preferences and material possibilities, everyone chooses the best option.A well-designed staircase will become a central element in the room and will attract the attention of everyone who comes to your house.

When choosing a type of wood, consider its performance.

In this video, you will find a master class on facing a concrete staircase with a tree.