Drywall: characteristics and types of finishes

One of the most common and popular finishing materials is drywall. It can be used for a variety of purposes: from leveling walls to making multi-level ceiling structures. Let us consider in more detail the characteristics of this material and examine its features.

What it is?

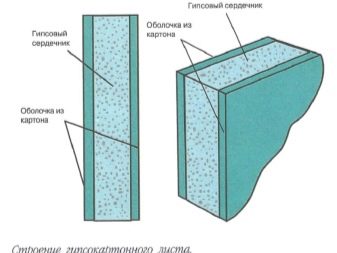

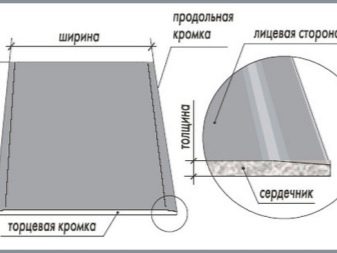

Drywall is a building material that is a perfectly flat sheet, it consists of two layers of special cardboard and core. The second component consists of solid gypsum dough with the addition of various fillers. In addition, the gypsum board contains adhesives and blowing agents specifically designed for gypsum.

Most often, this easy-to-use material is used for arranging even skins., light partitions and ceilings (single-level and multi-level).Different fixtures are often installed in drywall, and this can be not only an ordinary spotlight, but also a full chandelier.

Too heavy and large appliances to hang on plasterboard bases are not recommended, since they can not withstand impressive loads.

Special features

Such a popular material, like drywall, is practical. It can be used for various purposes: with the help of this pliable raw material, it is possible to independently produce various designs without spending large sums and not spending a lot of time on it.

Gypsum sheets can be used not only for interior but also for exterior decoration, for example, it can be the design of the facade of a private house, and with the help of high-quality waterproof plasterboard you can make a very beautiful and original composition that will transform the exterior of the home.

Drywall has its pros and cons, which is worth knowing before buying it.

For a start, let's take a closer look at what advantages this finishing material can boast.

- Sheets of gypsum plasterboard have a perfectly flat surface, which is why they can be purchased for leveling roughing surfaces. This may be the floor, and the ceiling, and walls.The main thing is to make all the work correctly and properly prepare the basics for the installation of gypsum.

- Drywall has a high thermal conductivity. For example, in a room with walls supplemented with sheets of plasterboard, a comfortable microclimate and optimum air temperature will always be maintained.

- This finishing material can be used to make various designs.

- Another advantage of drywall is environmental friendliness: it is absolutely safe for households, as it does not contain toxic compounds.

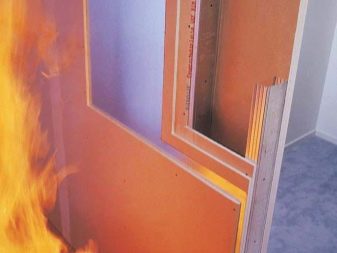

- Materials made in accordance with GOST are fireproof (do not burn and do not support the flame).

- Gypsum sheets have excellent sound insulation properties.

- Also, this finishing material distinguishes vapor permeability. Due to this characteristic, various bacteria do not breed on its surface, and traces of mold or fungus do not appear.

- Drywall is cheap, so almost every buyer can afford it.

- In the installation of this material, you can use not only the frame: it is possible to attach it with glue and even building foam.

- Drywall can be combined with insulation. In addition, there are such types of panels that protect the insulated canvas from negative external factors.

- It is very easy to work with plasterboard sheets, for this you do not need special expensive tools.

- By means of gypsum cardboard it is possible to realize the most non-standard design ideas.

- This finishing material does not exude unpleasant and strong odors.

- GKL is easy to process: it can be painted, finished with wallpaper, tiles and other popular materials.

- Gypsum board, just purchased in a store, can be immediately used in repair work: it does not require special training.

Despite the large number of advantages, drywall has its own weaknesses.

- This material is not recommended to be installed in rooms with high humidity levels. This is due to the fact that drywall in such conditions will soften over time and collapse due to oversaturation with moisture. Even high-quality sheets that transfer contact with water begin to deform over time.

- Drywall may begin to crumble.It is not recommended to hang heavy objects (lamps, paintings, flower pots) on a nail hammered into a gypsum sheet. Otherwise, the fasteners can simply fall out of their base.

- It is necessary to be careful not to damage the gypsum sheets, as they do not have high strength.

- Gypsum plasterboards are distinguished by a rigid structure, and therefore do not withstand shocks or kinks.

What are the types?

A rare consumer knows that there are several varieties of drywall on the market. Each of them has its own characteristics, as well as advantages and disadvantages. Consider them in more detail.

First of all it is necessary to consider which categories of this material exist.

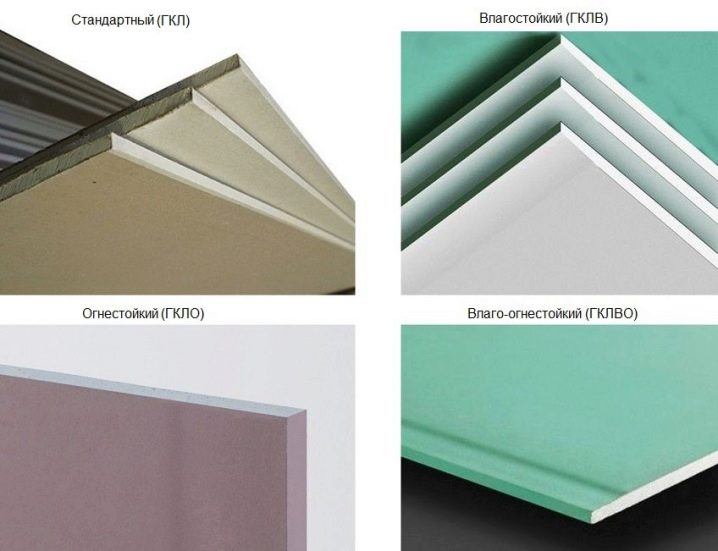

- GCR - This is a simple gray drywall, which is universal. It can only be used in dry rooms with a different level of humidity. Protection against dampness and moisture, as well as fire-resistant characteristics of this material are absent.

- GKLV - it is the plasterboard sheets having green color. They are highly resistant to moisture. Such finishing material can be safely used in the kitchen, toilet or bathroom.

- GKLO - this abbreviation belongs to fire-resistant drywall, the characteristics of which we consider below.

- GKLVO - this name are sheets of drywall, having increased resistance to moisture. They combine the useful characteristics of materials such as GKVL and GKLO.

Now consider the properties of all types of drywall in more detail.

Wall

This finishing material is designed specifically for cladding floors in a private house or apartment. As a rule, the color of the wallboard is gray, and the marking on it is applied with blue paint.

Ceiling

At present, ceiling gypsum board is in great demand. It is used for the manufacture of beautiful and three-dimensional structures that are installed on the ceiling. With the help of this material can be formed as a simple single-level and multi-level box.

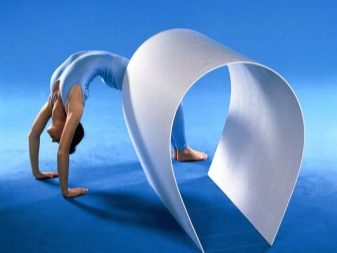

Arched

The thinnest and lightest are the arched sheets of drywall. Thanks to such distinctive characteristics, materials can be bent, without being afraid of formation of cracks and other damages. Moreover, before direct installation work it is not necessary to spray it with water for additionalplasticity.

With this flexible finishing material, beautiful columns can be made., interior arches, semi-archs, niches, as well as the original walls are round or oval. The thickness of the arched drywall is 6.5 mm, this figure is mediocre, so these sheets are most often mounted in two layers.

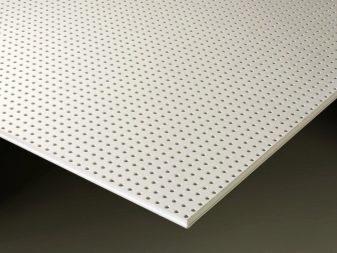

Acoustic (GKLA)

This is a noise insulating and perforated material, which is quite rare. A feature of acoustic sheets is that their surface has a large number of small holes. Their diameter is 1 cm, the back side of the sheet is complemented by a sound-insulating coating, such as spunbond.

This kind of drywall is most often used in the finishing of ceilings and ceilings in recording studios, special music rooms, pump rooms and other spaces where high-quality sound insulation is required.

Fire resistant

GKLO (decoding - fire-resistant gypsum-fiber sheet) - this non-combustible material is also facing and very wear-resistant. Such finishing materials are indispensable in places where there are increased requirements for fire safety. For example, such a drywall can sheathe chimney or fireplace.

In addition, fire-resistant gypsum is often used in lining mines. In the core of such sheets there is a considerable number of fibers and special additives necessary for reinforcement.

Moisture resistant

This type of drywall is less whimsical and more practical. It must be installed in rooms with high humidity levels. This material has a core and cardboard, characterized by an unusual composition, thanks to which it is not afraid of moisture.

In addition, as part of the moisture-resistant fabric, special antiseptic additives are observed that protect it from the appearance of mold and mildew.

Moistureproof and fire resistant

This type of drywall is one of the most practical and wear-resistant, because it combines the useful properties of gypsum plasterboard and gypsum plasterboard. It is often addressed when facing production areas with a high level of humidity and high requirements for fire safety.

Laminated

Such drywall is considered a finishing material of a new generation. It is made according to the latest technologies developed in Germany. The basis of laminated sheets is a special drywall on a woven base.

This high-tech material is durable, easy maintenance, quick and easy installation, and the absence of screws.

Laminated gypsum board is also decorative, as it can simulate different materials quite well: wood, natural stone, brick, different types of fabric. A simple painted sheet with a similar appearance cannot boast.

Facade

Facade drywall panels do an excellent job not only with the function of decorating the house, but also with its insulation, as well as protection from adverse external factors. To do this, these materials have the appropriate structure - the front layer of facade panels is impregnated with special hydrophobic means. This treatment protects the base from moisture penetration.

Many consumers choose facade gypsum plasterboard., as it plays the role of energy-saving coating, stopping the loss of warm air and insulation fibers. This material is installed quite easily and is fire safe. It is inexpensive and does not require complex care.

Reinforced

This type of drywall is often laid on the floor.It has a special reinforcing layer consisting of fiberglass. Due to its composition, this material is also called gypsum fiber. In it, reinforcement occurs immediately from both sides of the cardboard layer, which ensures high strength of the panels.

The back and front sides of gypsum-reinforced plasterboard are treated with a special substance - water repellent, it makes the material moisture-resistant and more durable.

Reinforced drywall can withstand impressive loads, as it is made specifically for the floor. It is also additionally polished and coated with various impregnations that protect the material from chalking. However, the service life of these sheets depends largely on their proper installation.

Dimensions

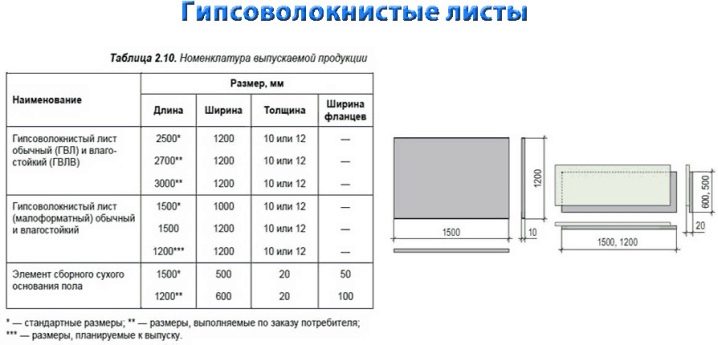

Different types of plasterboards have different technical characteristics and dimensional parameters:

- wall panels: width - 1.2 m, length - 2.3 m, 2.5 m, thickness - 12, 5 mm;

- ceiling material differs from the wall only in thickness, comprising 9.5 mm;

- moisture resistant sheets can have a length of 2.3 m, 2.5 m, width - 1.2 m, and thickness - 12.5 mm;

- the parameters of fire-resistant gypsum plasterboard sheets can be: length - 2 m, 2.5 m, 3 m, the width and thickness of such materials remain standard and are 1.2 m or 12.5 mm;

- arched drywall has a very small thickness - 6.5 mm.

For the manufacture of interior partitions is recommended to use plasterboard sheets, characterized by a large thickness - 14-21 mm. Such materials have high sound insulation. They are not afraid of impressive loads and mechanical damage.

Of course, the drywall sheet may have a different length, different from the above parameters. So, some modern companies produce shorter panels. They cost a little more than standard options, but working with them is much easier. These sheets are most often used in the design of the ceiling in the toilet, bathroom, hallway or corridor.

Most manufacturers in the production of drywall still adhere to the three main standards of size:

- 3000х1200 mm;

- 2500х1200 mm;

- 2000x1200 mm.

Colors

Each type of drywall has its own color:

- standard drywall is gray;

- moisture resistant - green, and the marking is applied to it blue;

- flame retardant material is pink or light gray with red marking;

- moisture resistant and fireproof drywall has a green color and red marking.

Necessary tools and accessories

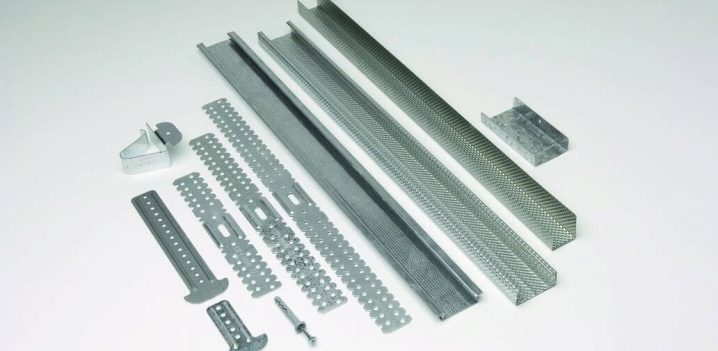

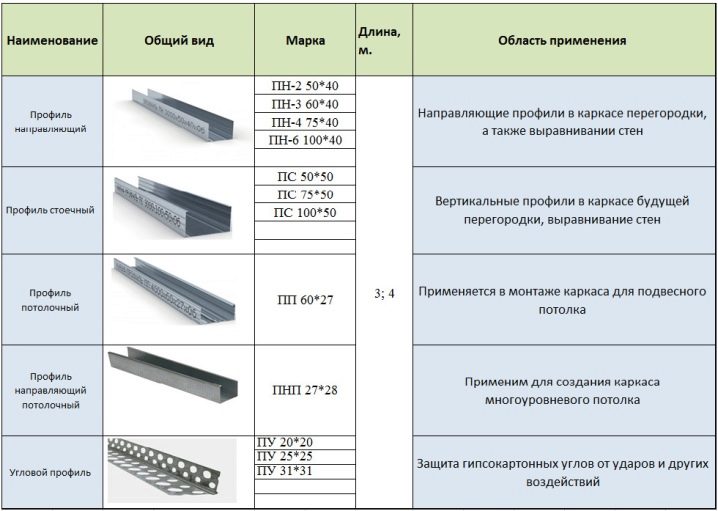

When working with gypsum plasterboard, it is necessary to use various components, it is impossible to do without them even with the simplest repair work. One of the most important are metal profiles; with their use, a strong and reliable frame is assembled, which is then sheathed with gypsum panels.

These necessary elements can be divided into three types:

- for facing walls and partitions;

- ceiling;

- special guides.

Metal profiles, designed for finishing walls and partitions, are guides and rack.

- Guide varieties have a special UD marking. Such parts are used for high-quality fixing racks and guide rails of the frame for drywall.

- The drain profile plays the role of a main rail for installing plasterboard sheets, to which the fastening of the entire plating is carried out. Similar items are labeled CD.

More narrowly focused are special guides. For example, there are special racks designed only for doorways, to which entire entrance systems are subsequently attached.

There are also special arched options that can be customized for the desired configuration.

The combination of all these components, fastened with a special material, as a result gives a fairly strong and reliable frame. A well-made construction will easily withstand substantial loads, as well as the weight of the entire gypsum cladding. As a rule, the guides are treated with zinc, which protects them from corrosion and slow destruction, which makes the frame for finishing almost eternal.

To work with drywall should be stocked up and other necessary components.

- Direct suspensions. They are the main elements of the framework for gypsum sheets and are a rectangular plate. These parts are needed to connect the frame racks with bearing floors.

- CD Guide Connectors (another name - "crabs"). This element is necessary to connect the ends of the profile in a single-level plane.

- Two-level connectors. They are necessary for connecting the framework rails crosswise.

- Anchor suspensions. These parts are needed for the basis of drywall. As a rule, they are used when finishing the ceiling. The main task of anchor hangers is to connect the base directly with overlap.

- Profile extenders. These elements make the frame rail a little longer.They need to be installed in the inside of the profiles and fixed with screws.

- Angle connectors. These parts may also be T-shaped. These elements should be addressed if you make a perpendicular joining of the profile to another rail.

To work with drywall sheets will need a variety of tools:

- screwdriver - it can be used to fix the frame, for example, on the wall;

- perforator - this tool is necessary for more reliable mounting of the frame on the wall, ceiling or floor, it must have sufficient power for such work;

- electric drill;

- Bulgarian useful for cutting profiled parts and cutting off excess parts of the resulting structure;

- circular saw or electric jigsaw useful for cutting drywall;

- electric scissors indispensable for cutting metal, if you need to build a large structure with plasterboard panels;

- gas mounting gun needed for automatic mounting screws, which saves time for installation design.

From hand tools in working with drywall you will need:

- special knife for drywall;

- knife saw for drywall;

- hammer;

- pincers for fastening profiles;

- profile piercer;

- plane;

- edge planer;

- needle roller.

In working with GLK sheets, other devices may be needed, which will significantly simplify and speed up the installation process:

- a device for the emphasis on the overlap, which is a special lever with a lock, with its help it will be possible to hold the panel in the correct vertical position;

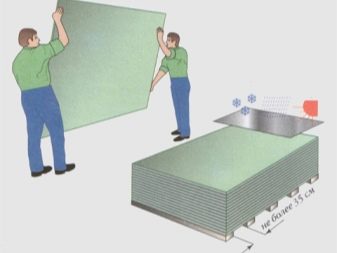

- Carrying handles - curved steel handles necessary for the safer carrying of drywall sheets;

- a tape measure that requires accurate measurements;

- building level;

- mounting belt;

- lift for drywall sheets;

- special whipping cords;

- runners or boards for alignment of a metal profile;

- corner and pencil or marker;

- sealing tape;

- putty for putty corners drywall.

All tools and components must be high quality and reliable, otherwise the design will not last long and can be deformed.

Do not forget that one of the main roles in high-quality and attractive gypsum finish is durable and reliable.frame, so all components must be selected especially responsibly.

Choosing and finishing your own hands

Finishing of one or another base with drywall is quite possible to do it yourself. All the necessary tools and components have been listed above, so you need only a reasonable approach to the choice of gypsum sheets themselves.

The choice of suitable panels mainly depends on the conditions in which they will be.

- For a bathroom, pool or toilet, it is recommended to acquire an exceptionally moisture-resistant material, since ordinary drywall in such conditions will quickly fail.

- For the kitchen, it is worthwhile to select more expensive stoves, which are both moisture resistant and fire resistant.

- In the bedroom or living room, you can use a simple drywall. It is necessary to handle it as carefully as possible, since it is rather fragile, but it is inexpensive and lasts as long as possible.

- In the hallway and the corridor is used as a normal and moisture-resistant material. It all depends on how these areas are used in your house or apartment.

It is recommended to buy the material only from a proven and well-known manufacturer: do not look for cheap plasterboard sheets, since this material is already inexpensive.Too low a price may indicate a poor quality of the goods, such sheets will not last long and will quickly become unusable, so you should refuse from excessive savings.

To finish the plasterboard lasted as long as possible and looked aesthetic, you should follow the following step by step instructions. Consider the installation steps on the example of wall decoration.

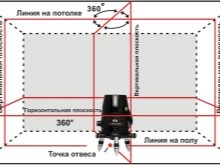

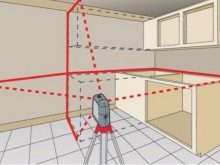

First you need to make the marking of the walls using a level and a special pencil or marker. It is necessary to draw lines designed for fastening metal profile. As for the size, they should be removed using a tape measure or a large ruler.

Skilled masters advise to stick special rubber strips on profiles before installing them, in a different way these parts are called soles. In this case, they will play the role of seals. Based on the pre-lined lines, it is necessary to attach the frame. To do this, you need to drill holes in the ceiling and floor of the desired size. The profiles of these actions do not need to be done, since the necessary holes must be present in them initially.

Vertical profiles need to be fastened using brackets or ordinary screws in the guides, which should already be installed on the ceiling and on the floor.Installation of vertical parts should be done in increments of 0.5-1 cm. Fixing profiles should be as strong and reliable as possible, since this will affect the quality of fixing the gypsum board. Often laying drywall is carried out on a variety of insulation or soundproof cloths, for example, foam or mineral wool.

With the help of drywall, you can not only effectively align the walls, but also hide the ugly wires and various communications behind the wall. Wiring must be done before installing the sheets themselves, otherwise they will have to be removed.

After competent preparation and installation of the frame, you can proceed directly to the installation of drywall panels. For high-quality and reliable fastening, use a screwdriver, working with this tool will take much less time and take less power. The installation of gypsum surfaces should begin with their leveling. Keep in mind that for this you need to pre-cut the holes for the bottom and the place to install the light bulbs.

To the edges of gypsum sheets were more smooth and neat, each edge can be processed with an electric jigsaw or planer.

After carefully aligning the sheets of drywall can be installed on the frame. It is better to fix them using screws; these parts should be fixed in steps of 20-25 cm. If there is a window prem or door on the trimmed ceiling, then a drywall sheet should be fixed along the edge sections of these elements. This is necessary so that the sheet is attached to the base carefully and correctly.

Many home masters think about how much time it will take to install drywall on the frame. First of all, it all depends on the area of the room in which you are doing the finishing work. If we are talking about a very spacious room, then it may take 2-3 days to assemble GLK sheets.

After installing and fixing all the plasterboard sheets, proceed to the installation of such trifles as sockets, switches and lighting fixtures.

When all the most difficult and time-consuming is left behind, you can proceed to the finishing, the most difficult moment, as a rule, is hiding the joints between the sheets. To do this, it is recommended to use a putty, but before that you should attach a special reinforcing strip to the non-aesthetic elements.

When all the joints become invisible, you can proceed directly to the finishing of drywall: here everything depends solely on your desires and preferences. This material can be painted and wallpapered, and decorated with decorative stones, bricks and many other decorative coatings.

In the bathroom and toilet

Installation of drywall can be made in the bathroom and toilet. Of course, To do this, you should choose moisture-resistant plates that are not afraid of moisture and moisture.

- In such rooms, you should first prepare the walls for the installation of drywall.

- If we are talking about the installation of sheets without carrying crates, you first need to get rid of all the potholes and cracks on the walls. This will help you ordinary cement.

- After this base should be treated with a disinfectant composition and a primer mixture (resistant to moisture).

- Then you need a roller to apply glue to the walls and plasterboard sheets.

- All seams and joints between parts should be carefully waterproofed.

- After gluing, go through the finish finishing waterproof putty.

How to install drywall sheets on metal frames, we have already considered earlier.

However, drywall can be used in the bathroom not only for wall or ceiling decoration - it can also be used to make:

- masking box hiding pipes;

- decorative box or bath screen;

- Preparation of plaster baths for future cladding - you can stick tile or ceramic tile on the drywall;

- Seal the window separating the bathroom and kitchen.

In addition, on the plasterboard walls in the bathroom, you can fix the dressing table, sink and cabinet with a mirror. Of course, for this it is recommended to choose lighter items.

For the hallway

Drywall is a versatile material, so it can be safely used in the hallway, Most often in this room the hosts equip a functional walk-in closet.

- For the manufacture of such a structure you will need to attach the guides to the walls, and to the floor, and to the ceiling.

- Then you need to fix the rack, which will be attached gypsum sheets. There must be a distance of at least 60 cm between these elements.

- Do not forget to mark parts of the doorway.

- In the design it is necessary to make reinforcement racks on which the doors will be mounted.It is necessary that the frame is not deformed under their weight.

- Next, one of the sides of the structure should be sheathed with drywall. At this stage, foam can be installed in the inside or on the sash, which will act as a soundproofing sheet. After installing the cladding one side, go to the second. Having separated it, we can assume that the work is almost completed.

- Now you can move on to filling and dressing wardrobe.

Bedroom

Plasterboard designs are very common in bedrooms. With their help, you can create not only a multi-level ceiling, but also a convenient sill of optimal size or make a neat hidden curtain rod specifically for curtains. So, for the latter, it is necessary to determine the depth and width of the niche in which there will be curtains and curtains, as well as measure the position of these parts in the upper and lower planes.

On the marked markers on the wall and ceiling, you need to beat off two lines (on special coated threads). It is necessary to maintain an indent of 20–25 cm. After that, following the marking, it is necessary to install guide profiles for the framework; screws and plastic dowels should be used as fasteners.After that, you can proceed to the direct fastening of frame parts: you need to insert a wider profile into the inside of the box. It must be fixed on the outer board with hangers attached to the overlap by self-tapping screws.

Now you need to drill a few holes along the broken line and insert plastic dowels into them in order to install the suspensions and fix the second wide profile on them.

If you have installed all the necessary elements of the frame, you can proceed to their plastering plasterboard. To do this, through the frame itself, you should fasten a strip of plaster on the screws. However, do not forget about the preliminary preparation of the necessary grooves in the areas of dry plaster. They need to be done on the ceiling, where vertical sections of the profile are installed. It is recommended to screw the screws in increments of 20 cm.

To install the vertical stripes, you will need a base to which the drywall will be attached. Data collection should be based on the depth of the niche. For example, if this parameter is 10 cm, then it will be quite enough to connect the sides of the guide and ceiling profile.Leave the ends of the guide protruding beyond the ends of the profile for 20-30 cm. Of course, the dimensions of the niches can be absolutely any: for each option, you can choose profiles of suitable sizes.

Next, you should proceed to the assembly of the wall niche. Gypsum strip need to be screwed to a pre-prepared basis. It is more convenient to do this on the floor, since there will be very little free space between the wall and the assembly site, which will prevent the use of a tool such as a screwdriver. The gypsum strip should be sawed off, leaving a small margin of width, since then the ceiling plinth will also be glued to it.

Now you can go directly to the installation of the resulting wall. The part that has just been assembled on the floor should be installed along the edge of the horizontally attached drywall. Similarly, you need to collect the side details of the niche, for which only one profile (without a guide) is enough. These elements should also be attached to the drywall construction.

The final stage of the work will be finishing the resulting box. It is necessary to putty angular details, as well as areas where the plaster covering was fastened with screws. After that, you can assemble the frame and make it single or multi-level.

Attic

Drywall is often used for lining the attic. In this case, much depends on the technical condition of the roof of the house. If it leaves much to be desired, then on the wall decoration with the first rain there will be noticeable smudges. That is why before installing drywall, you must repair any damage to the roof.

Also important role played by beams and rafters. They need to be checked for reliability and strength, and also make sure that they do not begin to rot or crack. Do not forget to treat all wooden parts with antiseptic agents.

Gypsum panels in this case can also be installed on a classic frame made of aluminum.

- First you need to measure the room in which you are going to make the installation of drywall. Calculate everything and buy all the necessary items.

- The crate should be installed starting from the walls. The layout of the future construction should also be transferred to the ceiling and floor.

- Now along the perimeter should be installed frame guides. All sections of the profile must be secured at least 3 points. The largest distance between fasteners is the meter.

- Now in the rails should install the rack on the metal screws, and then fix the cross member. At this stage communication should be carried out.

- Next in the frame cells should be installed insulation.

- After that, you can proceed to the installation of gypsum boards in increments of 20-25 cm. Finally, finish the finishing of the material according to the traditional scheme.

Tips and tricks

When purchasing sheets of drywall, always consider the microclimate in your home, as well as the type of surface on which you are going to install them. It will depend on what materials you need - moisture resistant, fire resistant or ordinary. Pay special attention to the manufacture of a drywall frame, its stability and reliability affect the durability of the finish and its aesthetic characteristics.

Even with thick plasterboard should be handled carefully so as not to damage or break it. In most cases, repair of affected parts can not be made.

After buying drywall should be stored in a dry and warm room, which is better to close. The temperature in the room should not fall below 10 degrees.However, it is not recommended to place this material too close to heaters or batteries. The surface on which drywall will be stored must be perfectly flat.

Manufacturers and reviews

Among the large number of manufacturers of drywall can distinguish the following firms.

- Gyproc. Consumers choose the products of this company because of the affordable cost, practicality and low weight. From the shortcomings of drywall this supplier people highlight its fragility and subtlety.

- Danogips. Drywall of this manufacturer is very popular. Buyers talk about its flexibility and ease of installation. From this material are beautiful arches, not afraid of moisture.

- Knauf. Product reviews of this company are ambiguous. Some buyers were satisfied with its quality, while others declare the fragility of this material and its inconsistency with the declared characteristics. For example, some consumers who bought moisture-proof panels noted that they literally “turn into dust” with an increased level of humidity in the room.

Successful examples and options

You can create very interesting and beautiful constructions from the drywall that divide the rooms.They may have a wave-like or rounded shape. Often, they construct small shelves or niches in which various decorative elements are then placed.

This material produces spectacular and original ceilings of unusual shapes., these designs are especially attractive if they are supplemented with LED hidden tape and spotlights around the perimeter.

Drywall in the walls can help build niches. They can have a variety of forms. They often place not only decor, but also various equipment: televisions, stereos and other similar items.

For more information about the technology of installation of drywall, see the video below.