The choice of installation and production of foam blocks at home

Foam concrete is a very popular material for low-rise construction. In addition to industrial production, it is made independently. The release of blocks of different types can be a profitable business. However, the production of foam blocks in the home has a number of features. Before you buy the desired unit, you need to have an idea about the characteristics of the material itself, the correct choice of related tools, as well as the consumption of the mixtures used.

Material Features

Foam blocks are made from mortar, which consists of:

- sand;

- Portland cement;

- frother (foam concentrate);

- water.

In this case, the bulk density of foam concrete may be different. In fact, it is a concrete with a cellular structure. It is formed by the mass of closed air bubbles. This feature causes a small density and thermal conductivity of the material. At different density indices, foam blocks can be used as heat insulating, structural heat insulating and structural materials with low thermal conductivity.

As a rule, the level of its density is determined by the brand of foam concrete. The lower it is, the less amount of the mixture was used to make the material. This fact is reflected in the cost price (foam concrete is cheaper than concrete). However, at relatively low density, it is considered to be an advantageous material during the construction of partitions inside the house.

The foam block is easy to machine, transfers cutting with a standard hacksaw. In addition, it does not collapse when nails are driven into it. In his work, he resembles wood, in shape it is a rectangle. Blocks can have different sizes: from standard elements to very large ones.

Homemade foam concrete has those dimensions, which are determined by the shape of the purchased unit.

Advantages and disadvantages

Foam concrete has many advantages due to which it is in demand in the construction industry. This material practically does not change its quality and performance over time, it is not subject to aging. Environmental friendliness makes it harmless to the health of the manufacturer, builders and households. It does not emit toxic substances into the air, is considered durable and reliable, and guarantees good thermal insulation.

In addition, it has high sound insulation properties, reduces the noise level, which is important for the modern person. Foam block is inert to fire. It is able to stabilize the temperature background inside the premises, is easy to install, and also has a high profitability of production. Due to the low weight, it does not create an enormous load, like concrete. This allows you to reduce costs when installing the foundation.

However, along with the advantages, foam concrete has disadvantages. For example, despite the fact that it is considered durable, it loses to concrete and reinforced concrete.Other nuances include the fact that the foam block does not work for bending. It is unstable to moisture, because it can absorb it from the environment.

Regardless of whether the material is produced at home or at home, it will shrink.

Equipment and tools

In the manufacture of foam blocks at home You may need the following equipment and accessories:

- feeding device for cement and sand;

- foam generator with a capacity of not less than 200 l / min;

- bar setting;

- water dispenser;

- vibrating screen (raw screen);

- hose to exit the mixture;

- compressor;

- concrete mixer with a capacity of at least 250 liters;

- special forms for blocks or machine for cutting.

Buy today the necessary equipment for the production of building materials in the home will not be difficult. If desired, you can purchase not only a complete production line, but also its individual components. It should be noted that the equipment for the production of foam blocks at home is not only stationary, but also portable. The line can be conveyor or automated.These factors determine the cost of purchased equipment.

At the heart of any set of equipment is a foam generator. Such a device per day can ensure the release of the order of 100-110 cubic meters of material. A distinctive feature of the stationary type of lines is their high performance along with excellent quality and low cost. Given that such a kit will cost about 1.5 million rubles, this calls into question its purchase.

Mobile foam installation does not require the purchase of an expensive foam generator, which makes it popular in the construction market. However, along with this, it cannot boast of high performance. As a rule, in this case they use a barging device, but with all its power it is not capable of producing more than 40-45 cubic meters of finished material per day.

At the same time, ready-made blocks are often created with a high consumption of frothers.

Their strength is inferior to counterparts created on stationary lines. The price of a complete set for home production can vary in the range from 50 to 300 thousand rubles. In this case, as a rule, high-power equipment is expensive.For example, a kit for 300,000 rubles can give about 72 cubic meters of foam concrete per day.

The automatic line needs large areas, which is often problematic, because it is not provided for initially. As a rule, such lines need to create bunkers for cement, water, sand, as well as additives with automatic dosing. In addition, you need to think about areas for drying foam concrete, pouring it into molds, as well as installation for cutting. On average, this equipment can produce about 80-100 cubic meters of material per day, but not everyone can afford this luxury, because a set will cost from 1.5 to 3 million rubles.

When at the initial stage there are not enough funds, they buy used equipment. However, in this case, you should be prepared for the fact that you may need to replace any parts quickly enough.

In addition, you need to understand that equipment that was in operation, can cause poor quality of the finished foam.

Forms purchased for foam concrete may be different. Today they are made of steel, plywood, and plastic. The capacity of the products is different, for example, you can buy plastic forms with dimensions of 390x190x288 mm, options of plywood size 588x300x188 mm, steel analogues with parameters 600x300x200 mm.When buying them, it is important to take into account the rigor of the geometry, since the quality of the finished material will directly depend on this. Even the slightest symmetry breaking is unacceptable.

When choosing forms for pouring foam concrete mass, you should pay attention to the material of their manufacture. Considering that the formwork can be combined, this is especially important. For example, if the seller notes that the metal version with heavy-duty plastic inserts is able to withstand even the highest temperature, you should not blindly trust it.

The fact is that such forms are really short-lived. In the process of drying and curing of the foam concrete mass, a large amount of heat will be released.

Plastic, no matter how high quality, reacts to a rise in temperature.

Consumption and proportions of the mixture

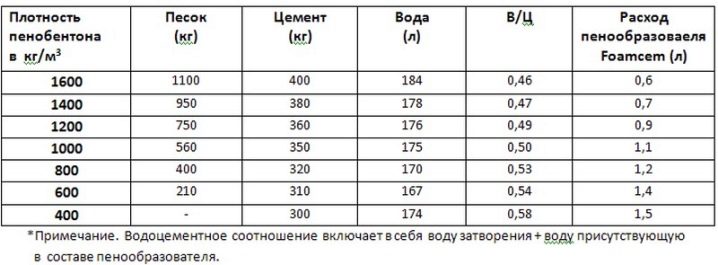

The proportions of the ingredients in the manufacture of foam concrete are as follows: 320 kg of cement (for example, brand M500) take 420 kg of sand, 45 liters of water to produce foam and 120 liters of water for a solution. As for the frother, its consumption depends on the specific brand. Usually for such a volume it is used within 1.2-1.5 kg.Water for production can be taken not only plumbing, suitable and technical, moderate hardness.

Formulation and proportions directly depend on the density of foam concrete, which must be obtained as a result. For example, if you need bulk density foam blocks D 600, take 210 kg of sand, 310 kg of cement, 110 liters of water for the solution and 54 liters - to dilute the foam. In addition, 1.3 kg of foam concentrate and 715 liters of foam are components of the building material. When mixing the entire amount of the components, you get a wet mass of 685 kg.

When a large density is needed (for example, 1000 kg per m3), the foam-concrete mass is made from 590 kg of sand, 350 kg of cement, 120 l of water in solution, 42 l in foam. For this recipe use no more than 1 kg of foam concentrate and 560 liters of foam. As a result, in the latter case, the mass of raw materials for the production of foam blocks will be 1103 kg.

It is important to monitor the uniformity of the resulting foam and solution. This will improve the quality characteristics of the finished material. Choosing the right recipe, it should be borne in mind that according to the current GOST, the shrinkage of the finished material should not exceed 3 mm per 1 square meter. m

How to do?

The production of foam blocks at home is carried out in two ways: by casting and sawing.Classical manufacturing techniques do-it-yourself means the use of special forms of cassette type, which have removable partitions and sides for dividing the total capacity into separate sections of identical size. In such forms, the solution dries and hardens, after which the finished foam concrete is removed. The main advantage of this method of manufacturing a building material is the fact that a monolithic block does not need to be cut.

This eliminates the need to buy a sawing machine, which reduces equipment costs. However, it is the form that can cause a violation of strict geometry. Not all filled-in elements after hardening will be perfectly smooth, even with the purchase of expensive fixtures. Marriage will be in any case, and this is an extra consumption of the mixture used.

In order to prevent the destruction of foam blocks, you must use a special lubricant that decomposes in the open air within a few days.

Such substances are expensive, however, if you do not use them, this may cause chipping or cracking of the foam blocks.

Most often in home production technology is used cut.In this case, first pour one large form, which is then subjected to cutting into individual elements of a given size. For this method, buy a sawing machine. Although it will require certain financial investments, profitability will increase. The advantages of this method are the strict geometry of each element, as well as minimization of the formation of chips at the edges of the foam blocks.

However, this technique may well hit the wallet, as for the production of small blanks will need special equipment, but it is expensive. In addition, cutting a monolithic slab into smaller pieces increases the time spent on the production of the material.

The cutting apparatus comes in two varieties. In the first case, this is an assembly, in which a monolithic material is cut immediately after it is cured (unformed). This is convenient in that it does not need to transfer the entire plate to the sawing machine, thereby reducing labor costs and time. The cutting of foam blocks occurs due to special strings, characterized by high cutting accuracy.

The disadvantages of these cutting elements are their fragility, as well as a decent cost.

The second type of cutting equipment requires the transfer of the foam monolith for cutting. In this case, it has to be cut with disc-type blades. Unlike strings, such knives are durable, and the units themselves are economical to maintain. However, it is inconvenient and troublesome to carry foam concrete slabs on them, to put it mildly.

Curing of foam blocks can be done in two ways: natural and autoclave. In this case, the elements of the second method have the best quality characteristics. So it is possible to create the most favorable conditions for obtaining a good building material. However, the price of such equipment significantly beats the pocket, so when producing in small quantities it is not bought.

Foam concrete, drying out on its own, dries better in summer. As a rule, if the indoor temperature during drying is below zero, you have to cover the formwork or think over the creation of special chambers for steaming foam blocks. In the first case, polyethylene or production batting is usually used. In the second, for these needs, space is allocated inside the production hall.

In such a room, a special temperature regime is created, taking into account the necessary humidity for uniform and proper hardening of the blocks. Often, steam generators are used for these purposes, thus attempting to automate the workflow. When there is no extra money, but I don’t want to increase the drying time of foam blocks, they resort to different budget options for solving this problem. Someone puts in a bucket of water in the cell, in another case, communications with gas heating are carried out in it.

Those who are not satisfied with these decisions enclose a certain part of the production hall with any available material that is distinguished by an acceptable price. For example, old brick, professional sheets or even the same foam blocks are used as a fence. When steaming the chamber with gas, it is necessary to take into account the optimality of the selected mode. Ideally, the humidity in the room should not be less than 65%. However, if the production does not provide for the purchase of specialized equipment in the form of a heat and humidity chamber, this may affect the certification of the finished material.

Manufacturing technology

The standard manufacturing technology for foam concrete blocks at home consists of several operations.

- Initially, foam concentrate is prepared in a separate container. Then it is combined with water and sent to the steam generator. If there is a cavitation unit at the disposal of the independent production, foaming the contents by means of ultrasound, this step is passed.

- In the next step, it is necessary to make a mixture for foam concrete. To do this, the necessary components of the mixture and special additives are placed in the mixer chamber. After that, the chamber is filled with previously prepared foam. According to the rules of technology, mixing in the chamber takes place within a few minutes.

- If a cavitational installation is used in production, initially a foam former is placed in the chamber for mixing. In this case, the remaining components of the working solution are placed later. At the same time stirring time should not exceed 0.5 minutes. At this stage, the solution is ready for pouring.

- After mixing, the composition is poured into the available forms. So that the mass does not stick to the surface of the equipment, the places of contact are preliminarily lubricated with engine oil or a special lubricant.It is desirable that the temperature in the room during hardening and curing of the composition was not less than +20 degrees ° C. After about 8-10 hours, the foam will pick up one quarter of its strength.

This is the best time to cut it, taking into account the required size, as well as packing. The final strength of the elements gain in 28 days from the date of their manufacture. The release strength is considered to be one-third indicator.

It is possible to realize the goods in two days.

What to consider?

Sometimes it may seem that it is much easier to independently manufacture equipment for the production of foam blocks using basic knowledge, power calculations and drawings that today are not difficult to find on the Internet. However, in fact, it is worth considering: the manufacture of foam in the conditions of a home mini-plant does not allow inaccuracies, since its benefit depends on it. You need to understand that in extreme cases, the factory product will be easy to sell in the future as useless, while home-made products will remain unclaimed.

Portland cement M 500 is used for the production of foam blocks. To improve the quality characteristics of the finished elements, various additives are added to it. For example, using the modifier "Bio NM", you can improve the resistance of foam blocks to frost. Due to the additions of Bio-Lux and Laston, it is possible to increase the concentration of air in the structure of the material.

In order for the finished material to have excellent thermal insulation properties, it is necessary to purchase an industrial-type frother for its production. No matter how much you want to save money and make it yourself, it will not have heat retention indicators similar to those made at the factory.

It is also important that high-quality raw materials form the basis of a high-quality foam block.

Instructions for making foam blocks at home, you can find out by watching the video a little below.