Foam block: types and application

Nowadays, block houses are not uncommon and are found on almost every street. Such structures have a distinctive appearance that is difficult to confuse with something similar. Today we will take a closer look at the characteristics and properties of materials such as foam blocks and find out what types of them exist on the market today.

What it is?

The foam block is a material that is made from a special cellular concrete - foam concrete. Such materials are made from simple cement mortar with the addition of water and sand, as well as an important component - the foaming agent. Foam concrete is a relatively new material - it has been on the market for no more than 100 years. This is an artificial stone with a cellular structure.It can safely float in water, and is also resistant to low and high temperatures.

Features, Pros and Cons

Today the choice of building materials is wider than ever before. It is possible to build a high-quality housing not only from a log or brick, but also from various kinds of block elements with many positive characteristics.

One of the most relevant materials recognized foam concrete blocks. They are purchased by many consumers, because such products are quite inexpensive. In addition, from high-quality foam blocks you can build a house with your own hands, without spending extra money on the services of experienced builders.

Thanks to these features, we can safely say that foam blocks are cost-effective materials that almost every consumer can afford.

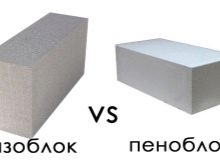

Many people think that foam blocks are an analogue of gas blocks. In fact, this popular belief is erroneous. First of all, you should take into account the fact that the geometry of foam blocks is poorly calibrated. In this matter, these materials are inferior to more "correct" aerated concrete blocks,which boast almost perfect geometry.

Foam block houses are warmer than gas block houses. Of course, the latter also have good thermal characteristics, but they are inferior to the characteristics of foam blocks.

Another important feature of foam blocks is that their shape often requires additional alignment during the work. If we neglect these processes, the walls of the dwelling may turn out to be sloppy and crooked. In addition, such wall ceilings can cause the penetration of drafts into the house through the cold bridges.

These features must be taken into account if you decide to purchase foam blocks for the implementation of certain works.

To get acquainted with this building material, you need to consider what advantages and disadvantages are characteristic of it.

Let's start with the positive moments - we will find out what the foam concrete blocks are good for.

- One of the most significant advantages of this product is that it has a very low thermal conductivity. Thanks to this characteristic, very warm and comfortable dwellings are obtained from foam concrete,which in many cases do not require additional and expensive insulation.

- These materials are frost resistant.

- Foam blocks are lightweight. Due to this characteristic, working with them is very easy and simple. They can be seamlessly moved from one place to another without causing special equipment (for example, a crane).

- One more positive quality follows from the above-mentioned advantage: due to low weight, foam blocks do not exert a significant load on the foundation structure.

- Due to its structure, foam block parts contribute to the natural ventilation in rooms. Thus, a pleasant microclimate is created in the dwelling, as evidenced by reviews from many consumers.

- Foam blocks have high sound insulation performance, so in the dwellings of them, as a rule, there is no unnecessary noise coming from the street.

- These materials can be used not only in the manufacture of country houses or cottages. They are suitable for the manufacture of smaller items, such as flower beds on the site, fences and even a toilet or gazebo of any modification.

- The foam block is a product with a high volume.That is why the foam block houses are manufactured in the shortest possible time.

- These materials are particularly ductile. If required, you can easily file or cut the block.

- The lion's share of the units sold today are safe in terms of environmental friendliness - they do not provoke allergic reactions and do not adversely affect human health in general. Of course, synthetic components are used in the production of these materials, but their share is so small that it does not affect the quality.

- The creation of such products takes quite a bit of Portland cement.

- The foam block is a durable material, from which the same durable structures are obtained.

- Many people opt for foam concrete because it is fireproof. Such a product not only does not ignite, but does not enhance the burning.

- Foam concrete blocks do not require additional treatment to prevent rotting or drying out. Moreover, these materials are not subject to attacks by rats, mice and insects, such as wood.

- According to the majority of consumers, only standard homes / outbuildings can be built from foam blocks.In fact, foam concrete is a product from which it will be possible to build the original structure of any modification. The main thing is to show imagination, and make the necessary efforts.

- According to experts, foam block buildings do not need to finish on a mandatory basis. As a rule, to conduct these works are addressed only in order to give the structure a more aesthetic look.

- Foam-concrete blocks are famous for the fact that, even after many years, they do not lose their positive qualities, especially if the construction work with them was carried out according to all the rules.

- Usually, when working with foam concrete, you need to use a very small amount of special construction glue.

Thanks to such an impressive list of advantages, foam concrete blocks today are in great demand. However, these materials, like any other, have weaknesses.

Consider them.

- The foam block is the material differing in cellular structure. Because of this distinctive feature, these elements are extremely fragile, which has to be taken into account when transporting them.

- Foam blocks are distinguished by a rather high level of moisture absorption.

- The cellular structure also affects the choice of fasteners. For foam concrete, special fasteners should be purchased, rather than simple self-tapping screws - they simply will not hold securely in such bases.

- As mentioned above, finishing a foam block house is an optional procedure, but without this the structure may not look very attractive. Here, many consumers and face a small problem - for the foam block, you need to buy specialized finishing materials, and simple paint or plaster will not work.

- These materials differ in that they give a significant shrinkage. This is especially true of blocks produced by non-autoclave method.

- Foam block buildings should not be left without reinforcement. Usually, the reinforcement is fixed in the areas where the openings are located. Reinforcement will need to do every 4-5 rows of block masonry. If you neglect the installation of a reinforced belt, then you will not get enough reliable overlap.

- In the modern construction market there is too much falsified goods. Since the raw materials used in the production of foam blocks, is very cheap, and the technology itself is simple and affordable, such materials are often made in artisanal conditions.Such products can not boast of good quality, so it is not recommended to build houses from it.

- Residential buildings from foam blocks can be erected only on the molding grounds.

- Foam blocks do not have verified geometry. That is why they make uneven walls that require additional processing.

- The carrying capacity of such blocks leaves much to be desired.

Kinds

Today on sale you can find several types of foam concrete blocks. Each of them has its own technical characteristics and features. Let's get acquainted with the different versions of this material used in construction.

Based on the basic performance characteristics, there are the following types of foam concrete blocks.

- Constructional. Such types of foam blocks are in great demand because they are designed for the impact of significant loads. Very often such materials are used in the construction of solid buildings with several floors.

However, variants of constructional type are distinguished by the fact that they conduct heat very well, therefore they always need high-quality insulation.

- Heat insulation. These types of foam blocks have nothing to do with construction options. Their main difference is that they do not conduct heat at all. Thanks to this excellent quality, the insulating blocks perfectly protect the room from the penetration of cold from the street.

But here it is worth pointing out that such materials are far from the most durable. Because of this, experts do not recommend their use in residential construction. It is possible to use such blocks only as an additional layer that will provide better thermal insulation of the base materials.

- Structurally insulating. Otherwise, such blocks are called universal. They combine the high strength characteristics and good thermal insulation properties. It is possible to use these types of foam concrete blocks when erecting supporting wall structures or partition walls. In addition, these elements can be used in the construction of baths, low-rise buildings or single-storey / two-story residential buildings.

Foam concrete blocks differ in the technology used in production.

There are such varieties.

- Molded. The name of these varieties of foam blocks speaks for itself. They are made using special containers / forms with partitions. Such a production process is considered the most profitable, but it has a significant disadvantage - as a result, the blocks are obtained with the wrong geometry, which complicates the construction.

- Sliced. Such foam blocks are made from an already prepared solution by cutting into individual elements using a special steel string. Threaded blocks are good because they have the correct geometry and smooth corner sections.

In addition, foam concrete blocks are marked differently.

Consider the most popular and common options of different mass and density, are in great demand.

- D300-D500. Thus, insulating foam blocks are marked. In most cases, these materials are used for insulation, and we can talk not only about a simple dwelling, but also about a balcony or loggia. A feature and disadvantage of such blocks is that they are not designed for heavy loads.

- D600-D900. Such markings are heat-insulating construction materials. They are also called construction.These specimens can withstand light loads. They are characterized by excellent thermal insulation properties. Such foam blocks can be used in the construction of residential buildings (in 1 or 2 floors).

- D1000-D1200. This designates construction blocks that can withstand heavy loads. In construction, they are not used very often.

Foam concrete blocks differ not only in the manufacturing process or field of use, but also in their basic design.

There are such options.

- Wall. It is impossible to imagine most of the works in which this material is used without wall foam blocks. To date, such units are considered the most popular. Very often they are turned to in the manufacture of country houses of various modifications. Due to the operational characteristics, it is permissible to acquire wall blocks for the creation of various economic structures.

- Partitioning. These types of foam blocks are intended for the construction of partitions. Their main feature is considered to be a small thickness, amounting to 100-150 mm. These materials produce very strong and stable internal partitions.

It should be noted that such elements are easily and quickly filed or trimmed if necessary (due to the small thickness). Because of these characteristics, partition masters are used by many craftsmen to make non-standard structures, for example, wide arched openings.

- Special purpose. Today there are special purpose foam concrete blocks. These materials are usually used in the manufacture of specialized trays. These parts are subsequently used for fixing reinforcing bars.

- Reinforced. Such demanded products are foam concrete constructions, supplemented with reliable reinforcement in the form of a frame base. Usually reinforced varieties of foam blocks are used as bridges instead of standard reinforced concrete elements.

- Non-standard. Non-standard foam blocks are made to order. They can be of any size that the buyer only requests. As a rule, these materials are more expensive than the usual options.

Foam concrete is also:

- autoclave;

- non-autoclaved.

Such types of foam blocks differ in production technology.The main difference between these materials lies in the way they harden. So, with a non-autoclave method, a solution of cement, sand and a foaming agent is dried in natural conditions, without the use of special equipment. The composition is simply stirred in the pressure chamber, and then distributed into forms.

A method of making non-autoclaved foam concrete has its pros and cons.

Let's get acquainted with the pluses:

- materials of any density are created in a similar way;

- such materials are cheaper because they are made simpler;

- such blocks can be made by yourself, adhering to the necessary proportions.

As for the minuses of non-autoclaved materials, these include:

- significant shrinkage rate;

- not the highest heat capacity;

- poor sound insulation.

As for autoclaved aerated concrete, it hardens in a different situation. The solution of the necessary components is poured using pipes or hoses into the autoclave, in the inner part of which ideal conditions are created for the correct manufacture of the material.

The blocks made by the autoclave method have the following advantages:

- With this technology, the solution hardens within 1-2 days;

- autoclave materials give the smallest shrinkage and are almost not deformed;

- they are characterized by a minimum coefficient of cracking;

- such materials are more durable than non-autoclaved;

- have good thermal insulation characteristics.

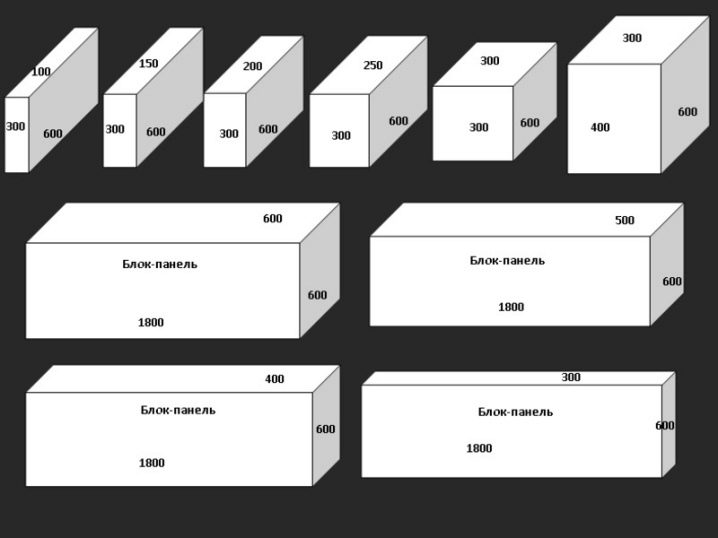

Dimensions

In the modern market, it is possible to find foam concrete blocks having a variety of parameters.

Elements designed for installation using a special adhesive composition are made with the following values:

- length - 188 mm, width - 300 mm, height - 588 mm;

- 188 mm x 250 mm x 588 mm;

- 288 mm x 200 mm x 588 mm;

- 188 mm x 200 mm x 388 mm;

- 288 mm x 250 mm x 488 mm;

- 144 mm x 300 mm x 588 mm;

- 119 mm x 250 mm x 588 mm;

- 88 mm x 300 mm x 588 mm;

- 88 mm x 250 mm x 588 mm;

- 88 mm x 200 mm x 388 mm.

There are also foam blocks that are stacked using cement mortar, rather than building glue.

Such products are manufactured with other parameters:

- length - 198 mm, width - 295 mm, height - 598 mm;

- 198 mm x 245 mm x 598 mm;

- 298 mm x 195 mm x 598 mm;

- 198 mm x 195 mm x 398 mm;

- 298 mm x 245 mm x 298 mm;

- 98 mm x 295 mm x 598 mm;

- 98 mm x 245 mm x 598 mm;

- 98 mm x 195 mm x 398 mm.

For the construction of partitions made foam blocks having such dimensions:

- 600 x 300 x 150 mm;

- 600 x 300 x 100 mm;

- 600 x 200 x 75 mm;

- 600 x 200 x 50 mm.

Also popular are blocks whose dimensions are 20x30x60 cm (600x300x200 mm). Such products can boast of good strength characteristics and high density.

Where do they apply?

Foam blocks are materials used in construction that are in very high demand. Their demand is due not only to good performance, but also to the multitasking of similar products (even floors in houses are made of foam concrete).

Let us consider in more detail in which cases a foam block can be used.

- First of all, foam concrete blocks are very often used in the construction of private houses of various modifications, villas and cottages. In these buildings, foam blocks are made of load-bearing wall ceilings, additional insulation and soundproofing structures, and internal interior partitions.

- Appeal to foam blocks and the device office / residential buildings. In this case, of these materials are also designed insulation and soundproofing structures, combined load-bearing walls, internal partitions.

- Foam blocks are ideal options for the reconstruction and restructuring of buildings. With their help, you can insulate old structures, as well as increase the number of floors without strengthening the foundation.

- It is possible to build industrial structures from foam concrete blocks, the height of which does not exceed 3 floors.

- These materials are also suitable for the construction of commercial / administrative buildings.

- Various outdoor / economic structures are being built from foam blocks.

- From these materials reliable fences and fences are obtained.

What are they doing?

The composition of foam concrete blocks is quite simple.

In the manufacture of these materials are used such necessary components as:

- sand (if special heat-insulating cement is used, then sand is not used);

- cement (usually use a material whose brand is not lower than 400);

- water;

- special blowing agents (required for the formation of bubbles in the block structure).

Due to the availability and low cost of the listed components that make up the foam block, today many users make these materials at home. So, at the initial stage all the listed components are mixed. Only when the resulting composition becomes homogeneous, add a foaming agent.

Mixing the solution with the foam, it must be remembered that the less time it takes to mix, the less will be the mechanical damage to the foam component. The result is a high-quality material.After preparation, the solution is poured into forms, where it subsequently reaches complete solidification.

Tips

If you wish to use foam concrete blocks in construction, you better get acquainted with some of the tips and recommendations of experts that will help you avoid many common mistakes.

- Transportation of foam concrete should be carried out only by a truck. It is not recommended to apply to the transport with a trailer, because at one time you will not take away a large amount of materials and spend a lot of money on gasoline.

- If you do not plan to finish the foam block house outside, then you will need to pay special attention to the correct and beautiful masonry. If you make any mistakes and some parts of the walls turn out to be uneven, then the appearance of the structure may suffer from this.

- Experts recommend buying a rifled, rather than a molded block. This is due to the fact that the first version has a clearer geometry and even angles. Molded products cannot boast of such characteristics.

- Before buying, be sure to pay attention to the color of the blocks. Foam concrete should have a light gray tint.White and yellow options should not be acquired.

- Also, before acquiring foam blocks, it is recommended to study their geometry. For this, 2 different elements are placed on each other and it is checked whether their structure coincides. After this, the blocks are turned over and studied in a different plane.

- Be extremely careful when loading and unloading foam, because it is very fragile and easily damaged.

- It is not recommended to use ceramic tiles, concrete mortars, foamed polymers, and compositions that contain ingredients such as sand, water, and cement to decorate foam concrete houses. Do not use standard paintwork.

- Many consumers are interested in what materials are allowed to veneer foam blocks. It is possible to apply special plaster mixtures and decorative facade compositions. Quite often block houses are revetted with moisture resistant tiles with either natural or artificial stone.

- It is not recommended to leave foam concrete blocks without a canopy, if you have not finished work. Cover them with plastic wrap, which can protect materials from adverse external factors.

- Erecting interior partitions or supporting structures, make sure that between the individual elements do not remain large gaps. If any do occur, they can become cold bridges through which heat will leave the room.

- Experts do not advise buying foam blocks in the spring, despite the fact that at this time they are very inexpensive. This is due to the fact that you will most likely be offered blocks from last year's party, which for a long time lay covered with dust in the warehouse (or even under the open sky, which is worse). Such materials will not be sufficiently reliable and durable, so it is better not to take them.

- Buying foam blocks, it is recommended to immediately purchase and tabs for reinforcement.

- Before you buy blocks, you should check not only their geometry, but also the level of strength. To this end, you can try to break off a piece of the block from the extreme portion of the hand. If you succeed, it will indicate a poor quality material. Acquire it is not worth it.

- Not so long ago foam block materials appeared on the market, which are distinguished by high moisture resistance.Professionals recommend purchasing just such options, although they are significantly more expensive.

- If you want the service life of the foam block construction to be as long as possible, then you should not only choose high-quality material that corresponds to GOST and manufactured in a factory / enterprise, but also competently carry out all the necessary work. If you doubt your own skills, it is better to turn to professional builders.

- Whatever structure you are going to build, in any case, you first need to carry out a number of preparatory work. In addition, the foam block structures need a sufficiently reliable and strong foundation.

- It is best of all to be engaged in construction with the use of foam concrete blocks if the temperature in the yard is from +5 to 25 degrees. If you carry out work at minus marks, then it is worth referring to materials with specialized additives that will make the blocks more frost-resistant.

Successful examples and options

Foam blocks are not only reliable and durable, but also very attractive structures.

For example, with the use of such building materials, it will be possible to create a very beautiful, neat covered gazebo, complemented by a hipped roof with a soft coating of contrasting brown hue. It is not necessary to trim blocks in such a construction; it is enough to build angular bases among them, between which wooden slats and lattices will look attractive. To such a gazebo, you can lay a path, decorated with stone.

Foam block houses can have not only a simple and patterned appearance. For example, this material produces very stylish houses in a modern manner. Such buildings usually have an angular structure and a flat roof. For lining these structures, you can use a special white / gray-colored facade plaster and contrasting panels of wood. To make the house more futuristic, it can be supplemented with glass elements, for example, balcony railings.

Foam blocks are obtained and very beautiful houses with dual roofs. For example, it may be an attractive two-story building, decorated with light facade plaster or paint.For the roof, it is permissible to choose a material of a contrasting, but inconspicuous blue shade. You can complement the facade with dark slats made of natural wood - they will give the structure a more comfortable look. The lower part of such a block house should be sheathed with decorative stone and make small steps to the front door of the same material. Surround this house with a neat green lawn and flower plantings.

It is possible not only to build houses and outbuildings from foam concrete blocks, but also to make attractive flowerbeds. For example, it may be several lined block rows, with the top, supplemented by cavities, which are allocated under the ground and live plants. To make the construction not look boring, it can be equipped with prominent outwardly separate blocks, in which also it is necessary to provide notches for planting.

Also, interesting and original flower beds will be obtained if hollow blocks painted with different colors are used to make them. They should be laid out in a semicircle and each separate block should be covered with one or another color. The result is a very bright and original design, which is sure to decorate the site.

Foam blocks are made of very sturdy and aesthetic fences. Often, in the completion of all the work, they are left untreated - the appearance of the structures does not suffer from this. However, you can use a special plaster, designed to work with foam concrete. Its color is often chosen to the shade of the facade of a residential building, but you can also play on the contrast.

In addition, in the fence, foam blocks can be combined with wood or aerated concrete to make the designs look more interesting. The main thing is that in a single ensemble all the elements look as attractive as possible.

On how to make foam blocks, see the following video.