Choosing fasteners for the foam block

Foam block is a modern building material with a porous structure. The correct choice of fasteners for it will not only ensure the rational use of funds, but also provide an opportunity to carry out work of high quality within a short period of time.

Features and Purpose

For the production of foam blocks use sand, water, cement and a foaming agent. The choice of fasteners for this building material is influenced not only by the individual characteristics of cellular blocks, but also by the type of finishing work planned on the working surface of foam blocks. Particular attention should be paid to the load that will emanate from the wall-mounted furniture or different types of equipment.

When choosing foam concrete as the main building material, it is necessary to take into account its properties, technical characteristics and features. This type of product has a porous structure with low density, low weight, high level of hygroscopicity. Selected fasteners should correspond to the type of work surface and type of planned work.

Consumables not only fix the hanging interior items, but also strengthen the working structure and increase the percentage of possible load.

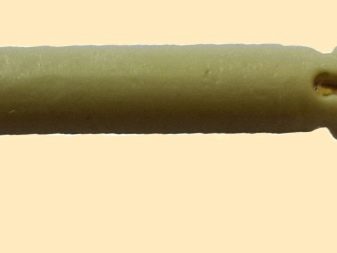

The locking parts for this type of building material consist of a screw, ring, half ring, rim and an empty sleeve with a spacer element. The teeth on the surface of the part are a reliable obstacle to the part turning during installation.

The length of the parts is from 3 to 5 cm, and the diameter is from 4 to 10 cm.

On the shelves of hardware stores, you can buy fasteners, packaged in special packaging, or purchase one by one. The number of units of parts in one package is from 50 to 1 thousand pieces.

Fasteners for foam blocks are of several types and are divided depending on their purpose and the following factors:

- a scope - for performance of internal and external finishing works;

- production material - metal and plastic;

- installation method - screwing, plugging and installation by chemical method.

Kinds

On the shelves of hardware stores You can purchase several types of fasteners:

- dowel;

- dowel nail;

- the anchor is simple;

- chemical anchor;

- screw M4;

- self-tapping screws;

- anchor bolt.

Dowel - the most popular type of mounting material. The main feature is the creation of an internal support during expansion inside the working surface.

Such a fastener does not damage the cellular structure of the blocks.

Consultants of construction departments can offer dowels made of plastic or metal. Before buying, you must consider the type of finishing works. Installation of consumables is carried out using a screwdriver, the regulator of which must be set at low speed.

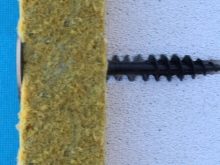

Dowel nail - fixing material used when working with dense blocks for walls. Feature - fast and reliable fixation of structures made of wood, metal and aluminum to a gas-concrete working surface. Dowel nails have a unique ribbed surface, which makes it possible to increase the level of fixation and distribute the load inside the block.This feature of details allows to carry out front works and to make false ceilings.

A simple anchor is a fastener consisting of a spacer or a plastic dowel. Conventional anchors cannot be used for foam concrete due to the porous structure of the building material.

Chemical anchor - an innovative type of fastening, having a universal use.

The adhesive composition of the chemical anchor consists of several components:

- cement mortar;

- organic resin.

Advantages of mounting material:

- high level of durability and reliability;

- resistance to low temperatures and atmospheric fluctuations;

- long period of operation;

- environmental Safety;

- ease of installation;

- universal application.

The disadvantages include the high price range.

Screw M4 - iron fasteners with a locking element made of metal. This mount can be used not only for blocks of foam concrete, but also for the working surface of dense aerated concrete.

Wood screws are simple and inexpensive fixing parts that allow you to fasten objects with low weight.

For a more secure fit, you can drive a wooden dowel into the drilled hole.

Anchor bolt - iron rod with a special thread and locking device. It is used to perform work of increased complexity.

Particular attention should be paid to high-quality German products of the Fisher trademark. The mounts of this manufacturer are made on innovative equipment from modern metal and plastic. The company "Fisher" is the first manufacturer of consumables for this type of work. German fasteners - universal parts with a wide scope, including for the foam block 10x60 cm, and foam concrete 6x52 cm.

Criterias of choice

The right choice and the ability to correctly apply fasteners will not only help you quickly and reliably complete the planned work, but will also make it possible to rationally use the money set aside for repairs.

Features choice of fasteners:

- plastic dowels - fixing parts used for fixing interior items with low weight;

- dowel nails - consumable material intended for through mounting of building materials like insidepremises and outside;

- metric screw - mounting for installation of windows, doors and technical equipment;

- metal anchor - fastener for hanging furniture and equipment that are heavy;

- foundation bolt - fastener used for work with a high level of load and complexity;

- chemical anchor is a versatile consumable material with a wide range of applications.

When choosing an attachment, it is necessary to consider the planned load. The longer the dowel, the greater the load it can withstand.

The most popular metal parts made in Poland, Switzerland, Finland and France. Plastic and metal fasteners of Russian manufacturers are in high demand and have an affordable price and high quality.

By purchasing this type of product, you need to know the parameters that make up the price. These include:

- material;

- the size;

- manufacturer;

- availability of special packaging.

How to fix?

For fastening of waterproofing plates to the working surface, made of foam blocks, use long front dowel nails with a wide hat.Plastic dowels - the expansion base, having a persistent shoulder. Bortiki not only firmly fix fasteners, but also prevent their loss.

The installation of such a fastener consists of several stages:

- wall markings;

- Drilling a hole corresponding to the length and width of the dowel, without taking into account the dimensions of the thread;

- cleaning the cavity from debris;

- dowel mounting;

- screwing the screw to the desired length.

Installation of plastic fasteners takes a short time and does not require special equipment.

Screw-on consumables - a common type of mounting material. On the surface of metal or plastic dowels there is a special thread, through which the dowel is fixed. Installation of this product does not require special skills and professional equipment and is done by screwing the fastener into the prepared hole. Material and diameter of the dowel depend on its functional load.

Drop dowels have large teeth, which expand in the drilled cavity of the working base. Driving fasteners should be carried out only with a rubber hammer.

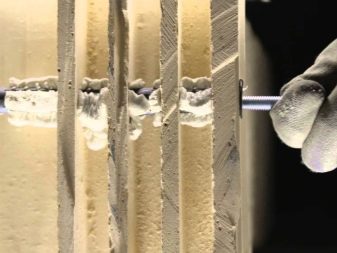

The chemical anchor is the most secure mount that can withstand high loads.

The installation of such a device consists of several stages:

- drilling holes in the form of a cylinder with a tapered cut;

- cleaning holes from dust and construction chips;

- installation of a cylindrical sleeve;

- filling the cavity with a special solution;

- mounting studs with thread.

It is forbidden to continue the following installation work until the construction adhesive is completely cured.

Correctly scoring, as well as correctly fix interior and equipment to the working surface of the foam blocks will help tips and recommendations of experienced builders.

Foam blocks - a light construction material, consisting of 80% of empty pores. The use of conventional nails and anchors on a porous surface will not allow fixing attachments reliably and will lead to the formation of cracks on the working surface. Properly selected consumables fasteners will not only ensure reliable attachment of attachments, but also increase the strength and reliability of the entire structure. Consultants of specialized building stores will help you make the right choice and purchasenecessary fixing elements corresponding to the planned works.

In the next video, see how to fix the TV on the wall of foam concrete.