Characteristics and sizes of foam blocks

Nowadays, you can use not only wood and brick for building houses, but also more modern and affordable materials. These include foam blocks. They are very popular, and housing built from them, there are almost every street. Today we will take a closer look at the characteristics of this building material.

Features, advantages and disadvantages

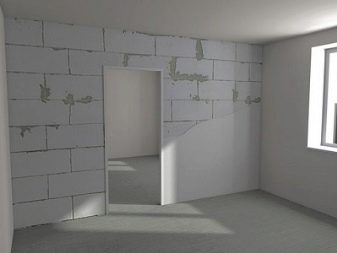

Block houses today are not uncommon. Such buildings are different rustic appearance, but they can be trimmed with high quality, giving a more aesthetic appearance.As for the durability and strength of such buildings, there can be no doubt - if the house was built according to all the rules, and suitable materials were chosen for finishing, it will stand for many years and will not cause any trouble.

If you decide to turn to the use of this popular material today, then you should familiarize yourself with all its characteristics, pluses and minuses.

First you should dwell on the advantages of foam blocks.

Consider their large list:

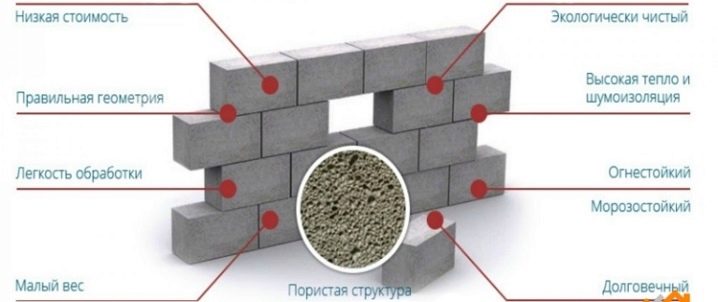

- the main positive characteristic that distinguishes foam blocks from other building materials is the low thermal conductivity, due to which block-type houses turn out to be warm and cozy;

- the foam block is a lightweight material, so working with it is very easy and simple (moreover, it is possible to perform many works alone, without seeking outside help);

- as the foam block is a light material, the buildings made of it do not create significant loads on the foundations;

- this popular material has quite good sound-proof qualities;

- the foam block is very voluminous, therefore houses and outbuildings are built from it in the shortest possible time;

- another significant advantage of foam blocks is that they are inexpensive, which is good news for many consumers;

- the foam block is a durable material;

- It is important to mention that such products do not fear fire - foam blocks are non-flammable and do not sustain combustion;

- foam blocks are also good because even after many years they do not lose their original positive qualities;

- during the construction of houses or outbuildings of foam concrete a small amount of special adhesive is spent;

- foam block is a malleable material, which, if necessary, can be cut with a regular hacksaw;

- From a similar material you can build a house or an outbuilding of absolutely any modification - the structure can be both simple and standard, and very original and unusual;

- buildings of foam blocks do not need a mandatory decorative finish, as a rule, they are painted or plastered solely in order to give a more aesthetic appearance, but there is no particular need for this.

Thanks to all the advantages listed above, foam blocks have gained popularity among consumers. That is why today foam blocks are a frequent occurrence. However, not everything is so smooth - these demanded materials also have a number of negative characteristics, about which every person who is going to purchase them for construction must be warned.

Houses built of foam concrete shrink by 2-3 mm per 1 running meter, so one can only move on to their interior decoration after a certain time (minimum 6 months).

These building materials are distinguished by their porous structure. On the one hand, this is their plus, as they are lightweight. On the other hand, the cellular structure is a disadvantage, since fasteners are more difficult to install in them, and the blocks themselves become more fragile from this.

Despite the fact that finishing foam blocks is an optional procedure, if you decide to do this, you will have to stock up with special materials. Ordinary paint and plaster for such reasons simply do not fit - you need to buy only special formulations. Foam blocks required reinforcement.

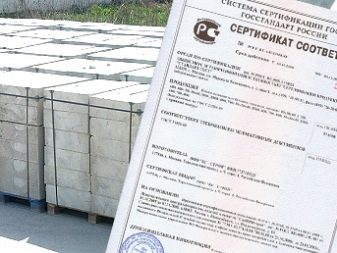

In modern retail outlets there are too many poor quality falsified foam blocks. Since for their manufacture is used inexpensive raw materials, produce similar building materials in large quantities underground. To use such foam blocks for construction is a big risk, since they are not very reliable. Foam blocks can not boast of sufficient carrying capacity. Another disadvantage of such materials is that you can not build houses on all types of foundations.

In most cases, foam blocks do not have an ideal geometric shape, which distinguishes them from more high-tech gas blocks. That is why they often have to file and grind to get smooth and neat walls / masonry.

As you can see, there are as many negative characteristics of a foam block as positive ones. Of course, a lot depends on the particular product you purchased. Try not to buy too cheap goods without packaging. Note that high-quality foam blocks are usually sold palletized and covered with polyethylene.

Production technology

Foam blocks are made very simply. The process of their production is so accessible that you can do this even in the garage.You just need to stock up on a blowing agent. All other components are equally available. A mixture of water, sand and cement should be kneaded in a clean container with the addition of a foaming ingredient. After that, the resulting composition is poured into molds. Foam blocks “reach” in natural conditions - they are left in the fresh air.

This process indicates that it is possible to manufacture such building materials without resorting to special equipment and tools. Quality control in this case will be only conditional - it is important to adhere to the required proportions and technological processes. However, many manufacturers still strive to save money, so there are a lot of foam blocks on the market, the quality of which does not correspond to GOST.

According to the production method, the following types of these materials for construction are distinguished:

- Cassette. In their manufacture, foam concrete is poured into molds resembling cells. It is in them that the further curing of the material takes place. It usually takes about 10 hours.

- Past automatic stripping. Such a cassette version of foam blocks is modernized.Forms for these materials are in a special machine. After pouring the solution into them, the hardening occurs after 14 hours. After that, the finished products are palletized.

- Sliced from an array. With this method of manufacturing a mixture of all the necessary ingredients is poured into a special large form. Its volume can reach 3 cubic meters. m. In this form, the material hardens within 15 hours. After that, the resulting foam concrete slab is cut into individual blocks of the required dimensions.

Density and weight

Foam concrete may have a different density. Usually it is denoted by the Latin letter D. After it, digital marks are set from 300 to 1200 in increments of 100 units. The higher is the density of this building material, the greater will be its weight and strength properties. However, this will reduce the insulating properties of the unit.

Today, foam blocks of different mass and density are divided into several categories. Let's get acquainted with them:

- D300-D500. These designations refer to thermal insulation foam blocks. Usually they are used as insulation (for example, when finishing balconies or loggias).When working with such materials, it is important to consider that they are not designed for serious loads.

- D 600 -D900. These are constructional and heat-insulating foam blocks. Otherwise, they are still called construction. Such materials are able to withstand a certain load. In addition, they have good thermal insulation qualities. These materials are recommended to apply when erecting one- and two-storey residential buildings. D600 and D700 blocks are considered suitable. If they are used, the thickness of the walls will be about 35-45 cm. The resulting floors will not need to be insulated.

- D1000-D1200. These are construction blocks. They can safely withstand impressive loads. However, it should be noted that they have a low thermal conductivity, so they need high-quality insulation. In private construction, such blocks are rarely used.

The density level of foam concrete blocks affects their mass. So, the brand displays the mass of one cubic meter of building material. For example, a cubic meter of foam concrete blocks labeled D400 will have a weight of about 400 kg, and a cube of materials with a density of D700 will have 700 kg. These values are approximate, so you need to allow a small error. The optimum weight is slightly more by 10-15%.However, care must be taken to ensure that there are no unnecessary inclusions. So, some manufacturers, reducing the cost of manufactured goods, mix components such as broken brick or crushed stone into it.

Due to such additions, the mass of blocks increases, which is almost uncritical. However, due to the addition of these inclusions, the thermal conductivity of foam concrete blocks can significantly decrease. As a result, it turns out that you are not buying quality foam blocks, but incomprehensible building materials from incomprehensible raw materials that can manifest themselves during operation completely unexpectedly.

Because of this, it is very important when buying foam blocks to be interested in their mass. Of course, it is advisable to split a couple of individual blocks and see what is inside them.

Dimensions

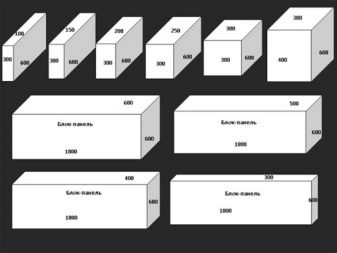

The production of foam concrete blocks is regulated by GOST 215 20-89. This document defines the properties, standard dimensions of these building materials. But do not think that foam blocks are available only with standard dimensional parameters. These materials may have other dimensions depending on the requirements of customers.

If we consider these materials from the point of view of their use, then it should be noted that there are wall and partition blocks. Let us consider in detail what parameters the listed building materials have.

For bearing walls

Wall varieties of foam blocks used in the manufacture of load-bearing walls. As a rule, they are produced with dimensions of 600x300x200 mm. Some manufacturers offer a choice of buyers blocks whose length is 625 mm (other parameters remain standard). Thus, the dimensions of the most popular blocks are 625x300x200 mm.

Anyway, walls with a thickness of 30 cm can be easily laid out in one foam block. And if you refer to the materials labeled D600 or D700, then you can work alone, without resorting to third-party assistance. One such unit will weigh quite a bit - only 21-26 kg. Materials with a weight of 21 kg will be less dense, and in 26 kg - more dense.

Most consumers today use in building more dense blocks for the construction of walls with a thickness of 30-40 cm. With such structures, the house turns out to be warmer. Choosing dense blocks for load-bearing walls, the masonry is the same as brick in terms of heat resistance.In such a house, it will be possible to maintain an optimal temperature regime without significant expenses.

Blocks with the marking D1000 or D1100 can also be used for the construction of bearing walls. Such materials are distinguished by maximum strength, so multi-storey buildings are often built from them.

For partitions

As for partitions, these structures do not face serious loads. They should not be particularly heat-resistant, therefore the dimensions of foam concrete blocks can be reduced to 10x30x60 cm. Materials of more modest dimensions cannot be used, since the reliability and strength of partitions, as well as the useful area of a residential building, can be seriously affected. It is also not necessary to reduce the width, since it will be very difficult to lay out an even and neat wall from blocks of 5 or 7 cm. In addition, it will not be possible to hang various interior decorations on such bases. It will be scary to even lean on a similar partition.

An inner wall with a depth of less than 10 cm, on which no special loads are created, will be economically disadvantageous. The 10-centimeter structures have a good strength margin to seamlessly withstand the weight of interior decorations.In addition, these partitions can boast good sound insulation qualities and a sufficient level of rigidity. To add depth in this case is not worth it - it will lead to a decrease in the usable area of the dwelling.

The 10-centimeter septum foam block is usually made from raw materials labeled D400 or D500. Their weight is 10-20 kg. The reduced mass can easily withstand any overlap of the basement or base between floors. If, however, to use dimensional elements, then they need to install the strongest beams.

We must not forget that in any house there are such components as door and window openings. For this reason, the number of foam blocks can be slightly reduced. For this, the total area of the openings should be divided by the area of the masonry details. It will then be necessary to add about 5-10% to the identified result, thereby creating the necessary margin for pruning.

How to calculate the required amount?

The size of the foam concrete block that meets the standard provides buyers and repairmen with another significant advantage - given the exact length, width and height of the building material, you can easily calculate the required number of blocks that will be needed to build a house.

To do all the calculations correctly, you must perform the following operations:

- To begin, you should correctly calculate the perimeter of the dwelling. To do this, fold his hand. Record the resulting number in centimeters.

- Now you need to decide on the height of the walls. The resulting value is also recorded in centimeters.

- Divide the perimeter of the house by the length of the standard foam block, which is 60 cm. As a result, you get the number of parts in one row of block masonry.

- Now divide the height of the walls by the readings of the height and width of the block (in this case, everything depends on the orientation of the building materials in the masonry), which can be from 20 to 40 cm. As a result, you get the number of block masonry.

- Now you need to multiply the number of rows by the number of foam blocks in the first laid row - so you get the desired result.

For partitions, it is recommended to use foam blocks with dimensional values of 10x30x60 cm. For this reason, the number of individual elements in the masonry should be determined by dividing the inner wall length of 60 cm and height by 30 cm. The resulting value should be multiplied and increased by 5-10%.

Tips and tricks

If you decide to start building a house using popular foam concrete blocks, then you need to take into account not only their dimensional parameters and weight, but also Some useful recommendations from experts:

- It is necessary to transport foam concrete blocks only in a truck. It is not recommended to turn to pickup with the involvement of a trailer, since you can spend a lot of money on gasoline - for one “flight” you will not be able to take a lot of foam blocks.

- To purchase recommended rifled foam block, which is a separate cut elements of the foam concrete mass. Molding blocks do not have the same exact and correct dimensions, and their edges are usually very fragile.

- If you pay due attention to the heat resistance of the walls, then you should get foam concrete with the marking D600. High-strength materials D1100 buy less often - they are more durable, but less heat resistant.

- Buying foam block materials, it is recommended to stock and reinforcing tabs.

- Always pay attention to the color of the building material. Foam block should be painted in light gray color.Do not buy a white or yellowish block.

- It is not recommended to purchase foam concrete blocks in the spring. Often during this period of time they are cheaper. However, it is possible that you will be provided with last year’s materials, which all this time were lying under a layer of dust in a warehouse or in the open air. Such blocks are less strong and reliable.

- Despite the fact that the foam block is a material that does not require additional finishing, it is still recommended to cover it with special plaster from the inside or with a cement-sand mixture for exterior surfaces. Strength characteristics of unfinished blocks can be reduced after several autumn / spring months.

- Before buying foam concrete blocks, check their geometry. To do this, put two foam blocks on top of each other and consider whether they match. Then these elements need to be turned and compared the location of the other surfaces.

- Unload the foam concrete blocks as carefully and carefully as possible. Otherwise, you risk seriously damaging them at the points where the edges pass (these areas are especially vulnerable).

- Choosing a foam block for construction work, you need to pay special attention to its cells. Remember - they must be isolated (they should not be connected to each other). Otherwise, such building materials will actively absorb moisture and moisture, which will adversely affect their performance.

- Check the foam block for strength. It is enough to try to break off a piece from the edge with your hands. If you managed to do this, then this means that the material is of poor quality and you should not buy it.

- It is recommended to build houses or outbuildings from foam blocks in terms of temperature from 5 to 25 degrees. If construction does occur at minus values, it is recommended to use special antifreeze additives.

- Many homeowners are wondering what materials can be used for the lining of the foam block, in addition to the usual plaster or decorative facade mixtures. To do this, it is permissible to use a special tile or stone (both natural and artificial).

- If you have not completed all construction work, then you should not leave the foam blocks in the open air on the street.It is advisable to close them with plastic wrap to protect against negative external factors.

- During the laying of interior partitions or load-bearing walls it is very important to ensure that there are no voids between the individual foam blocks. All remaining seams need to be sealed with special glue. This way you can avoid the problem of heat loss in your home.

- Do not save on the purchase of foam blocks. These materials are already cheap, and in the pursuit of excessive savings, you risk purchasing unreliable and too fragile materials.

If you decide to make your own foam blocks, then you should take into account that you need to follow all the proportions as accurately as possible. For example, an excessive amount of water can lead to the fact that as a result you will get too fragile blocks, from which you can not build anything.

On how to produce foam blocks, see the following video.