How to make an extension of foam blocks to the house?

To improve the appearance of the house and expand its usable area, many make extensions of foam blocks. Such a solution is considered popular because the building is insulated, comfortable and durable. In addition, the foam blocks are similar in appearance to the brickwork and fit perfectly into any exterior. The material is inexpensive and has high performance, but in order to lay it out correctly, you need to know a certain technology.

Material Features

The foam block is a building material that is produced from liquid, sand, cement, and special additives. The composition of the material can include both organic and synthetic foaming agents, while the former are environmentally friendly components. They are made from natural products and classified as non-hazardous materials.As for synthetic elements, they are characterized not only by low price, but also by quality. Such blocks are not recommended for the construction of residential premises, as they belong to the fourth class of danger.

The foam blocks are characterized by a cellular structure, the bubbles inside them are obtained by chemical reactions that occur during the mixing of the cement mixture with the finished foam. Blocks are obtained either by pouring into molds, or by cutting the total mass. Unlike other types of building material, foam blocks have a solid and even surface, resistant to rotting processes and provide good thermal insulation to the extension. They are divided into constructive construction, building insulation and heat-insulating types.

Foam blocks have several major advantages.

- Frost resistance and durability. Due to the fact that the construction product has a high resistance to low temperatures, its service life is five times greater than the strength of aerated concrete.

- Heat loss protection. In buildings constructed there is a significant savings in heating.The blocks are not afraid of moisture, therefore they allow to avoid sudden heating of the premises in the summer and cooling in the winter. Thus, in the extensions creates a favorable microclimate, which is similar to a log house.

- Affordable price. In comparison with a brick, walls from the foam block to build much cheaper.

- Versatility. Finishing material can be done in any decorative way, ranging from plaster, tile and finishing wall paneling.

- Fast construction. The low weight and density of the material simplifies the work, especially with regard to the installation of electrical wiring, plumbing and sewage. In addition, the laying of blocks is simple, since the linear tolerance can be up to 3 mm.

- Good sound insulation. The blocks have acoustics that absorb the sounds by the walls and do not reflect them.

- Convenient size. Products are produced with high precision geometric shapes, so they can be laid not only on a concrete solution, but also on glue. This makes it possible to avoid the appearance of cold bridges, which are usually present in concrete or brick walls.

- Fireproof.This material is completely safe in the fire sector, and also perfectly protects buildings from the spread of fire. In case of fire, the foam block heats up, but does not explode and does not collapse, which is possible due to its internal reinforcement, which is resistant to high heat.

As for the shortcomings, they are few.

- The material needs a protective lining. If it is not made, the walls will quickly absorb moisture and over time, cracks will appear on them.

- Sometimes during production there are errors in geometrical dimensions, which complicates construction work.

What buildings can you attach to?

Foam block is a unique product, which is often used to increase the area of buildings constructed of any kind of materials. Such additions to the house are especially well suited, regardless of whether it is brick or wooden.

Before you begin construction work, it is important to think and design everything, taking into account such nuances as:

- additional room can be added only to a solid construction, and if the house is old, then it is best to abandon such a venture; experts allow extensions to buildings that are not more than 15 years old, but you should definitely make the necessary calculations and determine their strength;

- since the extension of the house provides for its redevelopment, it is necessary to obtain an appropriate permit for such work;

- The self-made construction of foam blocks add weight to the main building, so everything should be carefully calculated so that the house does not crack during operation and does not “float” under the influence of the mass of the blocks.

In addition, it is necessary to choose the right type of foundation, technology of installation and method of attaching an extension to the main building. Foam block constructions require a solid foundation, for which, depending on the type of soil, a depth is chosen. The width of the foundation, as a rule, do 10 cm more from the thickness of the walls.

To at the end of construction the architectural structure has acquired a solid look, you need to perform finishing cladding. If this is an extension to a wooden house, then it is additionally sheathed with clapboard; for brick buildings, plaster with decoration elements will do.

Design

An important point in the construction design is considered. If the extension will be done with your own hands, then it is advisable to use the services of architects who will correctly create the design,as the appearance of the additional structure should correspond to the main structure.

Making a project, you must also do the following:

- accurately calculate the load of the new building on the ground, because of this will depend on the type and strength of the base;

- determine the possible lighting options, for example, if it is a veranda, then it should provide for the required number of windows and a doorway;

- to solve the issue of entering the extension, because in most cases only one door is designed, which later serves as a connection element for the additional and main building; Optionally, you can also make two separate entrances: one to the street and the second to the house;

- think about how electricity, sewage and water supply will be conducted; if the construction is being completed as a living space, then heat and noise insulation will need to be laid.

Important: it is quite realistic to perform such design independently; If we take into account all the above-mentioned nuances in our work, then we will certainly succeed in building a convenient and durable building.

The main stages of construction

Anyone can make an extension out of foam blocks with their own hands,the only thing is that before building an additional structure, it is necessary to obtain permits and coordinate the redevelopment with the relevant authorities. The process of building a new construction of the blocks is characterized by a special technology, which involves the implementation of several stages in strict sequence.

Foundation construction

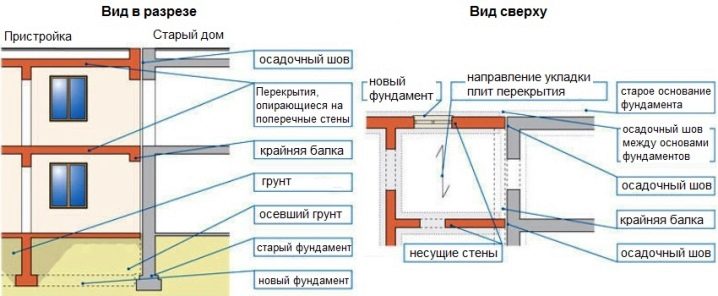

Any extension is installed on a solid foundation. If the building is wooden, then for the completion they choose, as a rule, a columnar foundation. This is due to the fact that the base of the extension must have the same structure with the building itself, and wooden structures, as is known, are erected on a columnar foundation. The only exceptions are the two-story buildings, they use a reliable tape with a concrete fill.

This foundation is laid as follows:

- first, a ditch digs around the perimeter, its depth should correspond to the depth of the base of the house;

- then the installation of the formwork from the boards is carried out, the sand in a layer of 5–15 cm is poured into the bottom of the pit, the footing is up to 5 cm thick;

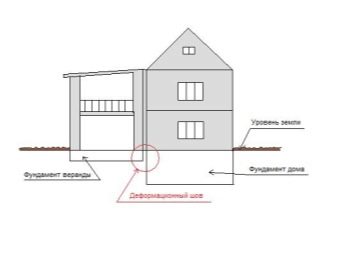

- the next step is to install the frame, which will serve as reinforcement for the extension,after all it is collected from twigs 12 mm thick; A new structure should not be tightly connected with the main one, otherwise it may break during operation due to shrinkage, in order to avoid this, well-tarred boards are laid between the two foundations;

- Completed work by pouring concrete, with the proportions of the binder solution and filler taken in the ratio of 1: 3; it is best to use cement of a grade not lower than M400, and the solution is prepared in a concrete mixer and poured in, while the base must stand for one month.

As for the columnar base, for it, first of all, they are digging holes, observing the 1.5 m step. Then they form a formwork made of rolled roofing felt. Rubble is poured at the bottom and fittings of four rods connected by a clamp are mounted. Then concrete filling is made in such a way that the pillars rise to the level of the building grillage. The rods are released at a distance of 20 cm, as the reinforcement will be tied to them. Before pouring the solution, under the bottom of the future tape, they thoroughly scoop up the soil; after the concrete has set, it is removed.

As in the first case, the base of the house can not be rigidly associated with the base of the extension.

Walling

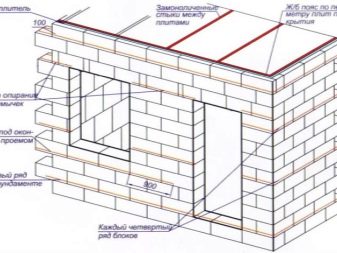

At first glance, laying walls of foam blocks may seem simple, but in reality this is not so. The assembly of the blocks must be performed strictly according to a special whip-up lace. In addition, it is necessary during construction work to constantly check the flatness of the masonry. If it is imperfect, then under the influence of internal stress the fragile structure will quickly crack. Despite the fact that the material is collected on a special adhesive mixture with a fit, the first row should be placed on the cement mortar.

The first row should have a thickness of no more than 1.5 cm, and subsequent glue should be up to 1 mm. Before putting the mixture on the blocks, they should be well moistened with water. To further ensure the walls durability and strength, they must be reinforced. To do this, with the help of grinders in every fourth row, two grooves are made and steel rods are installed in them. If we abandon the reinforcement, then during the operation of the annex, you can encounter various problems, for example, moving walls will begin to crack.

As for the laying itself, it is carried out with the ligation of the seams, making the displacement of 1/2 block. Glue should be applied both on vertical and horizontal edges of the block. At the end, finished walls are fixed with a special armored belt that protects the structure from cracking under pressure from the roof. In addition, if the extension is planned to conduct such communications as pipelines and electrical wiring, it is important to consider the possibility of wall shear in the first year of operation. Therefore, electrical wiring should be placed in special tubes or hoses.

The laying of blocks should begin with a corner, because with possible errors in the size of the corners it will be easier to adjust the length of the blocks.

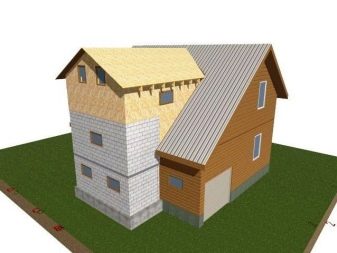

Roof

Any construction is completed with the assembly of the roof, is no exception to this, and the construction of an extension of foam blocks. From what rules will be installed roof, will depend on the durability of the structure. For the construction of foam blocks is not recommended to choose a heavy roofing material, it is best to give preference to sheets or metal tile. Usually on such extensions lined with leaning structures,for which put on armopoyas mauerlat. The uppermost timber is fixed to the upper edge of the wall of the building, and then the rafters are mounted. Further, the crate is installed and the roofing material is attached to it, the rafters on the upper and lower timber are fixed not to the corners, but to special fasteners. During the installation of the roof should ensure that its slope had the optimal angle of inclination, which will depend on the removal of precipitation.

Finishing work

After the construction of the extension has been completed, it is important to seal all the cracks. They are usually filled with foam. If the construction is completed to a wooden structure, then the slots are closed with bars. They are carefully stuffed on both sides of the walls of both the building and the extension. Since at the beginning the connection cannot be made rigid, then after a few years it is tightened with special brackets.

To give the additional construction of foam blocks a beautiful look and extend its service life, it is necessary to perform finishing work. It is simple to handle foam blocks as they have a porous structure. Most often, the lining begin pre-plaster, which is applied to the reinforcing mesh.It is advisable to choose to choose light types of plaster. Good for cladding and foam panels that can be painted. Artificial stone is also recommended for exterior cladding. Depending on the purpose of building it inside you can sheathe sheets of drywall.

The main thing is that the extension should look harmoniously against the background of the main structure.

On how to make an extension of the foam blocks to a residential house, see the following video.