Log block house: selection of suitable material and construction work

Building a house on your own is a very difficult task, but noble, because not everyone will be able to boast with it. Especially, if it is a house made of wood. For the construction of a log of solid natural material requires real experience, which practically no one has, except for the professionals who are engaged in this. Nevertheless, everyone can try to understand the intricacies of this case.

Features of building material

The half-beams or other bar-shaped materials can be of various sizes, for example, 100 x 100 mm, 100 x 150 mm, 150 x 150 mm and 200 x 200 mm.

Species

First of all, it is necessary to divide the material into two types: solid wood and log. Their main difference is that the timber is already ready for work material., which has exactly the same properties as ordinary wood, but is simpler for inexperienced craftsmen. Timber can be distinguished by other parameters. It is ordinary and profiled, glued.

Home construction

If you want to fold or assemble a one-story house with your own hands, then you can apply a longitudinal or angular connection. The thickness of the jute, the distance between the dowels, and the cuts must also be taken into account.

Preparatory work

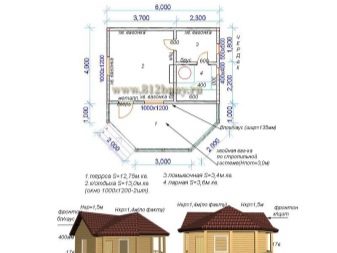

Preparation is needed for any construction, including for this type of work. They always begin with the design of the object, but this can be done both by the design organization, so it is possible to calculate the necessary things yourself. Of course, if you do not have adequate knowledge of materials and materials science, it is better to order the design part from the designers.

In this case, the design and layout can be made independently, but the design department will be engaged in the selection of the technical component.

Do not rely on acquaintances who arguethat their grandfathers and great-grandfathers built and the house still stands - usually this is idle talk, because the houses and buildings were calculated at all times.

When planning the construction it is necessary to consider such moments as:

- the size of the future house;

- foundation;

- material (from which the house will be made);

- insulation (zero, mezhventsovy);

- the number of walls (bearing and conventional partitions);

- arrangement of structural units (stairs, windows, doors);

- type of roof system and roof;

- communications.

After designing it is necessary to make a design estimate sheet, in which the cost of all work will be calculated. Of course, it is possible and easy to write on a piece of paper, but it is better to systematize everything.

After this comes the turn of the purchase of building materials and tools, which can also be rented. The tool will need the following: planer, saw, impeller with disc on wood, removable discs for wood and metal, circular saw, jigsaw, furniture gun, hammer - nail puller, ax.

Then directly prepare the materials themselves for construction. We start with the manufacture of dowels for fastening the crowns, but if finances allow, you can buy them in finished form.In a more economical version, it is better to buy ordinary boards (inches) and prepare 25 x 25 squares (made using a circular saw).

Selection rules

The choice of timber is determined not only by its price, but also by its quality. It is better to use glued laminated timber or profiled, because it is already almost dry, has a thorn-groove system, which accelerates and facilitates the assembly of the log house and finishing work. An ordinary log house will require much more time for shrinkage, it “twists”: when drying, it becomes similar to a fan or a propeller. Warming this design will be much more expensive. When choosing a conventional timber will require adjustment of each log.

There are basic rules that will help you get the best option.

- It is better to take timber that is made of winter wood, it will have a higher resin content, and this prevents early deterioration of materials, including construction materials.

- It is better to take a roulette with you, since natural materials are rarely equal to the declared ones, so the diameter should be measured at the ends and in the middle.

- Checking wood for fungus and mold will also be useful.

- It is absolutely not worthwhile to take a bar with dropped out knots - it reduces the constructive load, there are additional risks associated with the structure's strength.

After the bar is purchased, it must be taken to the object and sorted by size. It is important to remember a few nuances when placing the material on the object. The timber must be laid horizontally, the ends of the timber must be painted over with a water-based composition. For storage, you need to cover the raw material with black film or any other waterproof material, always of a dark color.

It is necessary to protect against dirt, dust, mold and mildew. For a conventional lumber, such a storage method will even help to dry it.

What to consider when designing?

Before proceeding to the construction of the log house, you need to see how the timber in the crown is connected. Having decided on the method, you need to start marking the timber.

- Half-logs it is drawn, after which half of the timber is cut out from one and the diagonal half of the other log.

- T-shaped spike. It represents a thorn drunk in one timber by one third the width of a tree, and in the other - a similar groove.

- Dovetail. The groove in the shape of a bird's tail, therefore, got its name. Start thorn in one-fourth of the logs, then expands to one-third. The other is the same.

Home construction

Foundation and waterproofing

Ordinary strip foundations are suitable for small buildings on normal soil. They can be either integrally molded or made by laying FL-plates on a sand pillow, with partial pouring. It all depends on the size and size. In mountainous areas or areas with little seismic activity, a pile foundation should be used. Coverings are placed on top of both foundations.

Wood in its pure form is very afraid of moisture. More precisely - the chemical processes that occur when moisture evaporates after oxygen enters it. Wood in water, without access to oxygen, practically does not lose its properties. Therefore, in the construction of houses always use waterproofing. It can be both from bitumen mastic, and from special additives, impregnations.

It is also important that, in addition to the external environment, it is necessary to isolate the foundation from the log house. Standard and inexpensive procedure - the use of tar mastic.It is applied to the concrete in two layers, after which two layers of waterproofing (roofing material) are laid, which are glued, after which the joints of roofing material are greased with additional mastic.

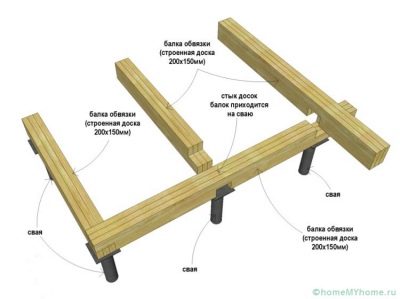

Lower strapping

After completing the zero cycle, you can begin to assemble the crowns. We determine the type of face cuts, which will be involved in the construction in the future, not forgetting about combinations with locks. There are cuttings both with the remainder (with the removal, at the junction part of the bar is carried out about 20 cm, into the floor of the tree or with a thorn), and without it (the floor of the tree with a thorn or key, sometimes there is a dovetail).

Then we put the first crown. It is advisable to choose the most resinous timber, which is or use larch (quite strong and moisture-resistant). Before using the bar should be treated with septic tanks, mastics.

These types of work must be done as precisely as possible, since the entire log house depends on the bottom trim, therefore, if there are faults, they must be eliminated immediately.

Observance of angles should be strictly 90 degrees, and the timber itself must completely encircle the foundation, without any gaps: if you miss this, then there will be a deformation or bend in this place.

After that, we seal the corners (their joints) with dowels.To do this, drill an opening into which we hammer our prepared bars (25 x 25). We fasten timber to the foundation every one and a half meters with special anchors. On the foundation, 1.5 cm planks are laid 30 cm apart, after which the timber as much as possible zero is mounted and laid on it. All gaps and gaps are filled with foam assembly. After that, the remaining crowns are laid.

Floor and walls

After the previous work, the rest are mounted in about the same ways. But do not forget that after the installation of each crown, it is necessary to do warming (with flax wool), which should be straightened throughout the beam without stretching. It is advisable to fasten every 10-15 cm with furniture clips. Nagel is better to drive at once into three bars, for greater strength of the structure.

It is more correct that the drill bit is a little less nog, in this case it will come in more closely. Non-angled fasteners timber does not need to be fixed in one area, it is preferable to run out. In the place where you plan the windows and doors, it is better not to put insulation, it will facilitate the manufacture of openings by drilling.When laying the second crown, it is necessary to determine the sex lag, retreating 80 cm. You can adjust the issue of windows and doors in several ways.

The first option is to drill (cut) the gaps after the whole log has shrunk. Moreover, this procedure is carried out in the quantities that are needed. We leave the plots for the sake of windows and doors for the period of construction.

The place to be left is required to remain at 10% less than the required, as the bar during drying will decrease slightly in volume. At the same time, these gaps must be incomplete, it is necessary to postpone one hollow beam after every two missed crowns. Dowels need to be mounted more often, according to the extreme boundary, two before the opening and two more after.

Already after shrinking, after about 1–2 years, cutting out the required opening takes into account the door frame with an overlap in subsequent shrinkage: about 10–12 cm from the top, about 5–6 cm from the sides.

In addition, it is necessary to take into account the components, which will make it possible not to be afraid, a log cabin with a full weight will ruin a window opening or a door.

The casing is performed in the following ways:

- The cranial, if a recess is cut in the door or window opening, into which, for example, a 45 x 45 beam is hammered.

- Grooveif a bar is used in a bar, and a groove is made in the casing bar. In addition, when cutting out the opening, it is preferable to combine the small components of the timber with the board so that they do not fly out at all.

If your home is built from glued or profiled timber, the procedure described above is not needed. But in the case of ordinary material, it is considered integral. It consists in warming mezhventsovyh combinations by pressing different, preferably natural, materials.

Roof

Roofing is performed by diagonal and horizontal mounting of beams. To begin with, a ready-made calculation of the rafters is taken, which are no longer simply applied to the lock, but screwed onto the metal bolts. The boards are also used for cross-section, in addition to the main beam, which strengthens the rafters themselves until the final installation. The roof covering is made not of wood, but of moisture-proof materials.

One of the most simple and inexpensive is metal, and the most high-quality and expensive - clay tiles, especially the restored German.

Wintering and caulking

As a means for the caulk can be applied:

- Moss. It has low thermal conductivity, breathability and durability. It guarantees protection against the occurrence of mold, it freely draws in and releases water. It would be considered flawless, if it were not for the only drawback - it is used in the natural version, it is inconvenient for them to carry out the caulker.

- Flax-oil fiber. It has a set of advantages, however, it flies in 5 years. And the processing procedure they have to repeat again and again.

- Hemp hemp almost perfect way, it was used by our forefathers. According to the texture is similar to wood.

- Jute. Imported actual material having the properties of hydroscopicity, heat insulation. Available in the form of a tape or rope, which simplifies the process of the caulk, for this reason almost everyone uses it.

- Lnovatin. A mixture of batting and flax, its minus is the powerful absorption of water.

Characteristics of the caulking iron - it is preferable to start the procedure from the upper crown and move down to the lower one. Caulk should be on the crown, first outside, then from the inside, then the top. First, you should carry out a hard caulker, that is, in places where large gaps should be hammered more, for example, jute, and then - a cosmetic cauldron.The final procedure is preferably carried out with jute rope, and if not, then the tape will have to be slightly pulled and twisted.

How to build a bath?

The bath is built in approximately the same way, except that the only difference from a house log is increased thermal insulation and waterproofing, as well as additional fire protection. This is all solved by applying special materials designed specifically for such purposes. You can put and improved ventilation.

Conclusion

The cauldron procedure is perennial, unpleasant. But she is needed. It depends on the heat in your building and the reliability of the log house itself. If you follow a number of simple and clear rules, the result will please you for a long time. It is not necessary to save on impregnations, which rather prolong the service life of wood.

As you can see, building a house from a bar is a very complicated process that requires a professional approach. In this case, all stages are important, even the very first, that is, the choice of materials and components. Therefore, every step in this matter must be approached very thoroughly. Strictly following the recommendations of experts, you can achieve excellent results.

How to build a house from a bar with your own hands, see the next video.