Felling in the paw: the subtleties of the construction process

Felling into the paw is the most convenient option when building a house. However, it requires adherence to certain subtleties in order for the building to be strong, warm and durable. It is necessary, if you do not have experience of such work, then at least have a clear idea of the sequence of actions during the construction of the log house.

Special features

Log house in the paw is most often used in the construction of wooden houses than other types.

This can be explained by its advantages such as:

- flat and smooth corner of the building without protruding logs;

- attractiveness and aesthetics of the building;

- Convenience when exterior finishes at home (for example, when covering with siding);

- the log is used to its entire useful length, which means that the material is consumed as economically and efficiently as possible, which reduces the cost of the work process itself.

However, with all its advantages, this method is not without some flaws, namely:

- the construction of walls that meet the necessary requirements of heat consumption is unlikely;

- the stability of such a structure leaves much to be desired;

- the work is subtle, practically jewelery, it is difficult to perform, without having special knowledge, experience and skills, and the slightest mistake can lead to the fact that the walls will "float" over time;

- possible cracking, drying of the corners.

However, these shortcomings are easily eliminated by a competent approach to the execution of work, a clear adherence to the phasing of the construction, compliance with all the subtleties and features of the construction of such a building.

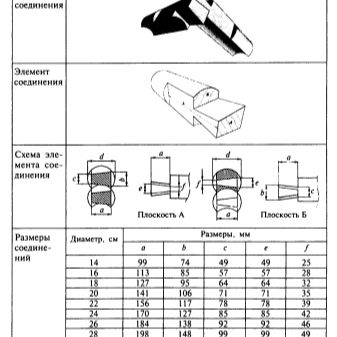

When erecting a log house, it will not hurt to resort to the help of special technical documentation - GOST 30974-2002. It clearly states what sizes of joints are recommended for logs of one or another diameter.

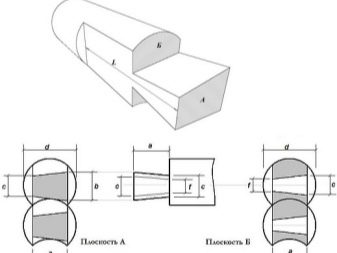

Drawings and markings of logs

Before you start assembling, you need to mark the logs. Early marking will greatly facilitate and speed up the construction process.

This operation is divided into certain stages that must be strictly followed.

- Produced facing logs.

- A horizontal line is drawn in the center of each element from the end. The correctness of the conduct must be monitored using a laser level.

- A template is applied, prefabricated from plywood or thick cardboard on the foot on the first log. Two vertical lines are drawn along it. Vertical building level will help verify the correctness of the lines.

- Along the pre-drawn lines of the cheek paws, they stretch the threads. On them draw longitudinal details of the cheeks with a length equal to the diameter of the logs.

- Using the prepared markings, the cheeks are cut down and they check whether the part conforms to the pattern.

These are the main stages of marking logs to create a log in the paw. They facilitate the work, allow you to complete construction in a shorter time. And - most accurately adjust the logs to avoid crevices, holes into which cold air can penetrate.

A felling in a paw is considered to be colder than, for example, the same felling with carrying out. The reason is that the corners of the house turn out to be open to “all the winds”, and from the outside rain water can get into the cracks between the parts and spoil the logs, while at the log house with the removal of corners closed by protruding parts of the logs.

A classic five-wall, even of a small size (for example, 6x4), will require additional protection of both the inner sides of the corner joints and the outer ones. Despite the fact that this may spoil the appearance of the house, such an operation is necessary in order to make the house warmer, protect it from cold and winds.

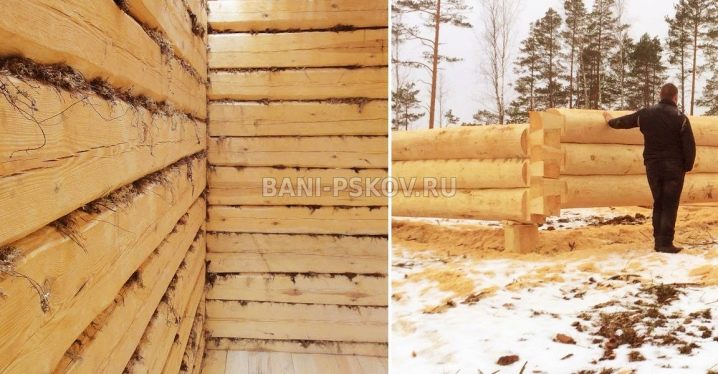

When using round timber in the construction of houses, it is necessary to ensure that the one element fits as closely as possible to the other. For this, the groove along the entire length is most often cut down on the upper log so that it fits tightly to the lower log. In addition, the junction of logs is carefully laid with tow, jute or any other insulation.

How to chop?

Build a house of logs with their own hands - not such a difficult task. The main thing is to prepare the materials correctly, follow certain rules, observe all the subtleties of this process, and then cutting by itself becomes quite an achievable task.

Equally important is the finishing of the corners. Any technology can be applied here, the main thing is to protect the house from wind and cold, which can penetrate loose fitting elements or cracks in cracked corner pieces.connections.

Outside, the corners can be closed with siding, artificial stone, natural or pseudo-brick masonry. From within the junction can be sewn up with the same clapboard. Another thing is that a log house itself is aesthetic, it is a real classic of its kind, and to close it with clapboard or, worse, with siding means to destroy the very image of a log house.

Building a house of logs, especially the erection of a log house in the paw, requires certain knowledge and skills. However, the construction technique is not as complicated as it may seem at first glance. You can learn everything, and a clear step-by-step instruction will help yourself to cut down a strong, durable, warm home.

For this purpose it is better to use coniferous wood. The important indicators are the natural humidity, the time when the tree was cut down (better in winter), the place of growth (optimally - the northern areas). Well suited for the construction of pine (its cost is lower), they also often use larch or cedar (these rocks are more expensive, but they have higher strength and longer service life).

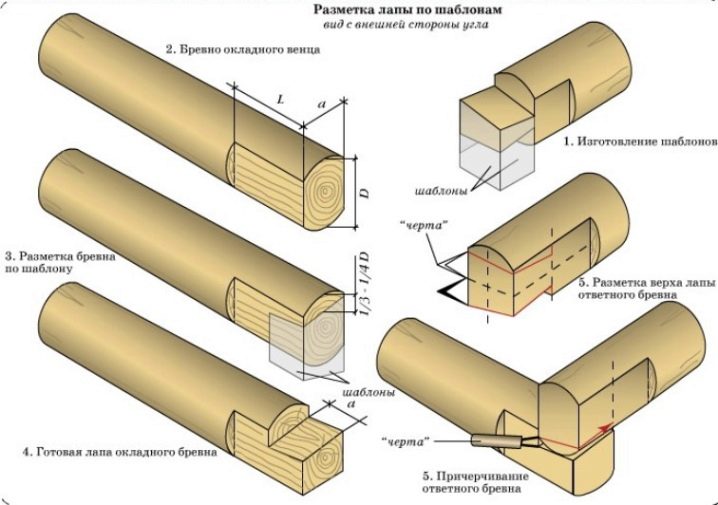

The assembly itself includes several basic steps.

- Preparation blanks.The top and bottom of them are hewn to a depth equal to the width of the blanks. The appearance of the blanks should be in the form of a parallelogram, turned to the master by the side that has a square cross section.

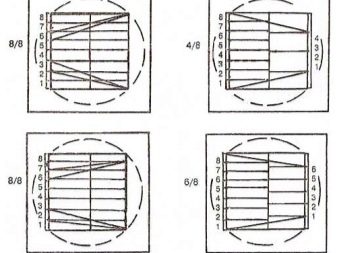

- The parallelogram from the end is divided into eight horizontal components.

- Next you need to arrange the necessary points on the plane. The location of the points depends on the type of paw selected.

- Indicate future offsets. From them draw a line at an angle, which depends on the location of the perisots.

- Excess material is cut, hewed connection elements.

- On plywood or cardboard, the pattern is made on the first joint, which will serve as a model.

It is recommended to apply a special protective composition to prepared pigs., which will reduce the risk of rot, protect against parasites, increase the fire resistance of the entire building. In addition to protection, it is necessary to provide additional insulation of the log house.

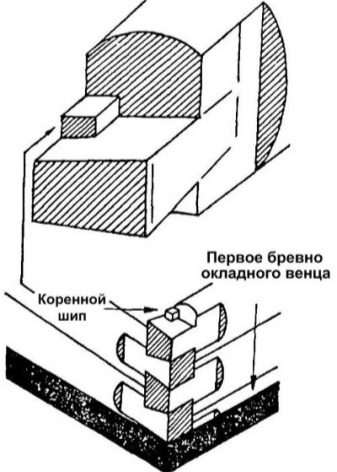

In order to avoid the “pawing” of paws during operation, the joints of the logs on the inner side are supplied with a special spike, which securely holds the upper and lower logs together.

Before proceeding directly to the assembly, pour the foundation.A log house does not have a very large mass, so it is acceptable to use a columnar or low-depth foundation tape.

Thicker logs go to the lower crown. They are laid directly on the foundation tape, laid with roofing felt or a discharge board, whose thickness is fifty-five millimeters.

Before you start laying the next crown, you need to perform a special groove of a semicircular shape on the entire length of the log on the logs. To do this, one log fits on the other, and using a carpenter's line, on the overlying log, draw a line parallel to the underlying one.

Further, the upper log is removed, turned over, and a groove is selected in it. Once the sample is completed, the log is re-placed on top and knocked along the entire length. The purpose of this operation is to determine how well the sampling was performed and how tightly the logs are interconnected. If everything is in order, the groove is made qualitatively, the connection is laid with insulation (tow, jute, moss), and the log with the groove is finally installed in place. And so - with each log of the upper tier.

It is important to accurately monitor the flatness of the walls (they must be strictly vertical), as well as all the geometrical dimensions of the frame according to the plan.

Tips

Logging into the paw - the most common option for the construction of such a building. By itself, the assembly process takes a little time, especially if all the preparatory work was carried out qualitatively.

Although there is an opportunity to build such a house yourself, it is better to consult with an experienced master before starting work. It is necessary to take into account every little thing, because the strength and safety of a new building may depend on it.

Of course, reviews about this method of cutting are inconsistent. But in his favor speak not only his obvious, well-known advantages, but also the fact that such a method is still the most common, despite certain difficulties and disadvantages inherent in it.

A reasonable approach to business, strict adherence to all the necessary rules will help to successfully complete this work and get a warm, comfortable, durable and safe log house.

To learn how to chop a paw, see below.