Caulking logs: how, when and how to do it?

Wooden houses are distinguished by plasticity, a tendency to multiple changes in configuration and volume during the period of shrinkage and operation. Impact on the condition of the log house also have weather conditions, operating features, time of construction of the building and features of wood protection. In this regard, the standards provided for primary as well as re-caulking.

Features and Causes

Caulking is the process of sealing joints and crevices between logs in a log house or a log building. The main purpose of this process is to increase the thermal efficiency of the structure.It is carried out by filling the gaps with special seals.

You can caulk after all construction (including roofing) work is completed, or during the wall assembly process.

Caulk allows to solve a number of the following tasks:

- insulation of the room and (as a result) reduction of the cost of heating the building from the inside;

- the elimination of gaps and cracks that appeared on the walls as a result of the deformation and shrinkage of wood;

- preventing the formation of condensation on the walls as a result of the difference between the temperatures outside and inside the building;

- protection of wood from rotting.

The first caulking iron is carried out immediately after the completion of the roofing work, the second - after the initial shrinkage of the building, after 6-12 months. After 3-5 years, re-caulking is carried out, since it is during this time period that the wood shrinks completely.

You need to work in the warm season. Winter is not suitable for this because the process will become even more laborious, besides, the tree during this period almost does not shrink.

Houses and baths must be insulated on both sides, the outbuildings can only be sealed outside.

Materials

All materials for mezhventsovogo insulation are divided into 2 categories. They are natural and artificial.

Natural

There are different natural materials, and all of them have certain advantages. Let us consider in more detail their features.

Tow

It is one of the cheapest materials, which, unfortunately, cannot boast of efficiency. The fact is that tow absorbs moisture, resulting in increased heat loss of the building.

The basis of the material - flax fibers. Depending on their quality, the insulation can be baled or rolled. The latter has short and hard fibers, which complicates the installation. Bale tow is softer and more elastic, therefore it is easier to work with it. The material is difficult to work: it is not easy to lay it in the cracks, to replace the damaged area. After insulation, the seam needs to be decorated, since it looks unaesthetic. Various microorganisms may be produced in mole, mole.

Moss

It is an eco-friendly and easy-to-work material for caulks, has antibacterial properties and high thermal insulation qualities. However, this material attracts the attention of birds that pull insulation for their nests.

Red or white moss is usually used.When self-collecting, it is better to perform such work in the late autumn, immediately sorting out the raw materials after collection (you need to remove earth, litter, insects). Then the moss is dried, but not too hard, otherwise it will become very fragile.

Purchase moss before work is recommended to slightly moisten with water.

Felt

This material is made on the basis of sheep wool, it has long been considered one of the best mezhventsovyh insulation. It's all about its low thermal conductivity, combined with high vapor permeability, noise insulation qualities, environmental friendliness, the ability to not pass moisture. Long elastic fibers are easy to lay even in small gaps.

Among the disadvantages is exposure to moths, rotting. Adding synthetic components to felt allows to level these shortcomings, but increases the cost of an already expensive material.

Lnovatin

Material based on recycled flax fibers, characterized by high performance and non-hygroscopicity. It provides a favorable microclimate in the room, because when the moisture level rises, it absorbs excess moisture, and when lowered it gives off.In addition, this feature allows you to protect the wood from rotting.

Due to its composition, the material is absolutely safe.

Jute

The material is made on the basis of wood fibers of exotic wood - jute. Due to the high content of resins in the material, it literally repels water, and also provides antibacterial protection not only for mezhventsovyh gaps, but also for adjacent logs. However, high tar content is also a disadvantage. Under their influence, the material quickly becomes rigid, dries out, which leads to the appearance of cracks. Such a phenomenon can be avoided by mixing jute with lnovatin.

Artificial

Among the materials of artificial origin are also several options:

- Heaters based on polyester fiber. They are characterized by biostability, non-hygroscopicity and vapor permeability. Available in the form of ribbons. Among the most well-known manufacturers are Politerm (Finland) and Avaterm (Russia).

- PSUL (pre-compressed sealing tape). A material with low thermal conductivity, a feature of which is the ability to compress and expand following deformations and changes in the geometry of wood.

- Sealants. Silicone, polyurethane or acrylic based sealants are also used for logs, but they are not separate seals. Their purpose is to seal cracks directly in the logs, as well as applying artificial seals on top. A distinctive feature is the ability of sealants to expand and contract in accordance with the expansion or shrinkage of wood.

Requirements

The main requirement for insulation for mezhventsovyh seams is a low coefficient of thermal conductivity. In addition, the material must be moisture-resistant, since there are no other waterproofing and vapor-permeable layers for caulking. Since the insulation is in contact with the environment, it must be resistant to winds, high and low temperatures and their abrupt change, as well as to UV rays.

If we are talking about warming the inside of the log house, then you should choose environmentally friendly seals. They must be non-toxic, not emit dangerous compounds under the influence of high temperatures.

The biostability of the material is also an important quality due to its durability.Well, if the seal does not attract birds, insects, does not become home and food for rodents and microorganisms.

Given the complexity and high cost, it can be noted that this material must be characterized by durability. The heat efficiency of the seal should be maintained for 15-20 years.

Options for insulation, as already mentioned, there may be several. If we talk about the methods of laying the seal, it can fit in the process of building a log house or at the end of construction work.

In the case of internal insulation, the insulation of interwall gaps can be combined with the organization of insulation according to the principle of a ventilated frame. In this case, after the first and re-sealing of the interventure joints, a wooden crate is packed on the surface of the log house, the pitch of which should be 1-2 cm less than the width of the insulation.

Then between the lags of the frame is attached insulation, on top of it - sheets of drywall. An air gap of 30-50 mm is maintained between the insulation and the finish. Sheets of plasterboard are plastered and decorated.

Before attaching the sheathing, the surface of the log house is covered with an antiseptic.Similar actions are done in relation to the surfaces of the lags.

Selection

The specific technique of insulation depends on the type of structure and climatic features. It is believed that a new well-built log house needs only inter-coat insulation. Additional thermal insulation from the inside will break the indoor climate and hide aesthetic log walls. Do not need warming from the inside and baths, because an additional layer of insulation will get wet, which will lead to freezing of the wall.

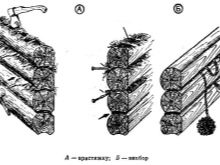

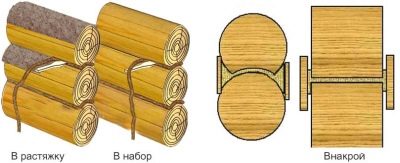

Primary caulking iron, sealing of small cracks are carried out by “stretching”, while re-warming or elimination of wide cracks - by the “set” method.

Instruments

The following materials and tools will be required for the implementation of the insulation procedure for mezhventsovyh seams:

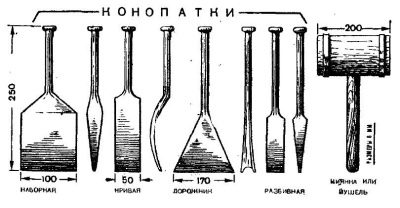

- typesetting cauldron - a tool that looks like a chisel, with which you can warm the gaps of different widths (from 2 to 10 cm);

- smashing cauldron - is a thick narrow wedge for expanding excessively narrow gaps, allows you to fill them easier and more qualitatively;

- flat chiselhaving a blade width of 50-60 mm,thickness up to 5 mm - used for laying the seal in the corners, rounded parts of the log;

- mallet - is a hammer made of wood, used for driving the seal;

- road builder - a kind of caulking iron for the formation of smooth rollers of a twisted heat insulator;

- hammer - they are hit on the mallet, pushing the seal into the inter-ring space;

- insulation.

Experts recommend the use of caulking tools made of wood, as this protects the frame from the appearance of damage. The blades of the tools should not be chipped, as they cling to the material and pull it back.

Power tools, punch lose the described tools, because they do not allow to form a dense roller from the material, but only drive it into the slot.

Ways and technology

There are two technologies for the caulking process:

- "Stretching". Usually used in the initial sealing of seams and involves the maximum stretching of the material along the entire length of the log. First, the first strand of insulation is laid, and on top of it is the twisted second strand. Insulation fibers are perpendicular to the direction of the logs, and the ends are rolled into a flat roller, which is hammered inside the seam.

- "In the set." The method is used for re-caulking iron when the house shrinks. This method involves clogging a small amount of insulation, the strand of which is formed into a loop. Then, with the help of a mallet or a caulk, it is hammered into the slot, and the insulation fibers take a position perpendicular to the wood.

The process ends with a final seal. To do this, use a special tool - road builder.

If it is decided to do it yourself, you should focus on the instructions. Step by step process looks like this:

- Purification of intergap gap from dust and debris. It is convenient to use a vacuum cleaner for this.

- Preparation of insulation: roll material should be dissolved for the entire length of the log house, with a small (about 20 cm) stock. It is necessary because in some areas the material may lie in a wave, and it should be enough for one tier.

- One of the ends of the insulation tape is hammered into the slot with the help of a mallet.

- Then the material is hammered into the slot with a mallet and a caulk. It is important to ensure that the seam is tight, there is no distortion.

- If synthetic insulation was used, a sealant is applied on top of it.

When the insulation is laid in the process of assembling logs, it must be placed immediately on the first row, leaving the hanging ends of the material on both sides. Then put the second crown, on top of it - insulation. So work is being done until the very last log house. When all the work is completed, and the installation of the roof is accomplished, the dangling ends of the compactor with the help of the caulker hammer into the gaps. Properly assemble the hanging ends necessary to the center of the crown.

When laying insulation (in the first place it concerns moss) it is important to ensure that it lies evenly on the surface of the logs. It is unacceptable for them to show through the insulation, otherwise the chopped house will be cold. If tape insulation is used, it is rolled along the crown and fixed with staples. If the tape is over, the next roll starts to overlap (about 5 cm) to prevent gaps.

With any type of insulation, the finished joint must be uniform - protrude from the gap by 3-4 mm, no more.

Tips and tricks

The important point of the log house warming is the observance of the caulk sequence:

- First, insulate the seams outside, then - from the inside.

- Warming begins with a crown, then moves to the element located above.

- Warming between the first and subsequent crowns should be carried out along the entire perimeter of the building - only after that you can proceed to the processing of the next gap. If we neglect this rule and begin, for example, gradual warming, it is impossible to avoid log-house distortions.

If, after the caulking iron, the seam is unattractive, it can be decorated using jute cord. It is also hammered into the cracks, not allowing sagging. If artificial insulators were used, a layer of sealant can be applied on top of them: it will not only fix the insulating material and increase its thermal efficiency, but also take on a decorative function. Modern sealants are available in various shades, so finding the option that matches the color of the log house is easy.

Decorating the walls inside and outside the house can only be done after re-caulking. This is due to the fact that in the process of sealing gaps the height of the walls increases, and this will lead to damage to the finish.

You can not use different materials for insulation of different parts of one log,as they can differ in hygroscopicity, which will lead to a distortion of the building (due to the uneven set of moisture insulation).

Experts recommend using only natural materials to insulate baths., as synthetic analogues under the influence of high temperatures can lose their properties and become toxic.

When laying wool-based insulation in a bath, they are pre-treated with special solutions. This, for example, formalin and similar options.

It is recommended to conduct insulation work at an air temperature of 10-20 C, on a dry windless day.

For information on how to independently perform a log cutter, see the following video.