What is the need to polish a log house and how to properly handle a wooden log house?

A wooden house, its warm and fabulous appearance is the dream of many romantics who want to build not just a home, but a cozy nest for their family. In most cases, this idea has to be abandoned in favor of more durable materials. Grinding a log house and knowing how to properly handle a wooden log house allows you to dispel all doubts and prejudices about wood.

Special features

The process of building a house from any material is always very time consuming and involves several steps.

Grinding is one of the important stages of finishing logs, allowing you to save wood from such factors as:

- rotting;

- the appearance of mold and fungi that destroy the natural building material;

- darkening;

- irregularities of logs;

- moisture and insects.

It should be noted that polishing is necessary regardless of the type of log. So, round and chopped logs must be polished, despite the aesthetic and presentable original look.

Grinding a log has the following advantages:

- additional material protection;

- improving the penetration of antiseptic and paintwork agents in logs;

- savings in the consumption of paint and varnish products;

- removal of dirt from wood, always accompanying during transportation.

Nevertheless, some unscrupulous craftsmen neglect grinding, because this process is rather laborious, time and energy consuming. In addition, it can be done only after complete shrinkage of the logs, which averages from six months to a year, depending on the type of structure. Purchase of laminated veneer lumber helps to reduce time costs, which is already thoroughly dried during the manufacturing process, so there is practically no shrinkage. Grinding of damp wood will certainly lead to its tearing and damage.

So, deciding on the construction of the house according to all the rules, you should abandon the tempting offers to build houses from a turnkey log house. As a rule, they are aimed not at the long-term quality, but at the speed of implementation, which, one way or another, affects unpleasant surprises during the operation of the building. And also you should not save on the services of professional masters in grinding logs, because it requires not only proper skills, but also special tools and means to protect your health.

Experts advise to listen to the recommendations, thus laying the foundation for the happy operation of the house for centuries.

When is it held?

Building a good house is not a quick thing, so you should be patient with patience, which will later be rewarded and paid off. The wooden blockhouse is brought, mounted and covered with a roof in the first season. He can dry about a year, and sometimes two. Influencing such a range of numbers is the season of felling, the type of wood and storage conditions.

Especially it is worth focusing on this when purchasing wood to order, because, as a rule, sellers prefer to keep silent about such nuances.

During the entire time of drying and shrinking, sanding the house is prohibited. According to experts, the tree should not be covered with antiseptics either, since over the year no disruptive changes in the structure can occur. Subsequent polishing will easily remove the darkening and blue on the logs, because the stripping of the upper layer is from 1 to 2 millimeters, and in some cases even more. Installation of windows and doors is carried out after the procedure.

Tools and materials

Grinding a log house is a costly process, as it must be produced correctly. Careful attention should be paid to the acquisition of quality tools, a list of which is considerable. The first and main tool for creating an aesthetic type of wood is a grinder with a grinding disc. It is worth noting that the range of prices is great, because the market includes both unbranded and professional equipment. Experts advise to opt for the golden mean and, if possible, to purchase two instruments at once. Such a solution will prevent the loss of time when changing nozzles from coarse to small. In addition, these tools rarely lie in their home without work, so the purchase of a good grinder is a profitable investment.

The power of the grinder should be from 700 to 1000 watts. More powerful models can deliver a lot of discomfort due to their substantial weight. The best model for working at home is a lightweight model with comfortable handles and a long cord. It is important to remember that the work will be carried out mainly on weight. Another of the arguments in favor of an inexpensive tool is the fact that the working resource of the grinder may end at the end of all finishing work. The optimum disk is 125 mm. For less clogging, air intake should be at the back. The side fence when grinding the house is able to disable any grinder.

Speaking of nozzles, you should choose a plastic rather than a more reliable rubber model. The nuance lies in the fact that the rubber with a random touch will leave a black mark that will certainly spoil the appearance of the log house. Selecting discs for the grinder is another step towards the fabulous home of your dreams.

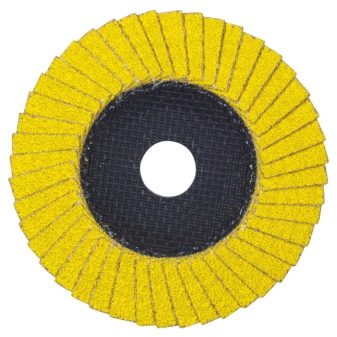

Since the grinding will take place in two stages, during the work such flap discs will be needed, such as:

- with 40–60 grains;

- with grain 100–120.

On sanding a surface of 4 m², on average, it takes one large grain disc. Rounded timber in this process consumes discs more economically than chopped wood.The consumption of fine-grain disks will directly depend on the quality of work done with large grains, therefore it is not easy to predict waste in this case. However, starting such a long procedure, you should stock up with the right amount of consumables, avoiding the subsequent painful search for the right tools.

The next important, though less powerful, equipment is an eccentric machine with a power of 200–300 W. It perfectly is suitable for the rounded equal log. The advantages of the model include a dust collector that can significantly improve the surrounding atmosphere. Circles are used various. So, for rough grinding, models with a grain of 40–60 will be needed, for a more thorough one, 80–100.

Particular attention is paid to the work grooves and corners. For their grinding used an old, but effective tool - a chisel. The optimum width is the knife with the parameters of 20-25 mm. Can be used and the Bulgarian, but with nozzles smaller than the disk. Otherwise, the device will jam, which can later lead to its breakage. The ends are polished with a grinding wheel with sandpaper size 40.You can polish them using an angle grinder.

Ideal smoothness in this area in most cases is not achieved, limited to coarse and medium grinding.

An alternative method of sanding is sandblasting and abrasive blasting to achieve aged and natural wood.

It is performed using special and expensive equipment, such as:

- Kuperslak;

- soda;

- garnet;

- specialized types of sand.

The essence of this processing procedure is the bombardment of sand particles with a powerful stream of wood air. The result is a clean surface of the frame without fungi and mold, even in small cracks. It should be noted that it is almost impossible to grind manually such parts of a log house. And also you shouldn’t make brushing yourself with usual sandblasting, as it is able to beat and spoil the appearance of the surface.

The budget method of brushing is to use a nylon brush. Compared with sandpaper, the nylon brush on the grinding machine is not clogged, which saves time and the number of consumables.

Technology and work order

The grinding process includes steps such as:

- rough grinding;

- average processing;

- fine processing;

- final grinding before applying the varnish.

The first stage of work is the division of the entire surface of the wall into several sections.that will improve the quality of work on grinding and cover the walls with paint and varnish products in time, because it must be done on a clean surface within 1-3 days. After separation into zones, grinding with a large grain is carried out. The wood is covered with a pile, which is subsequently removed with petal discs of a smaller grain. The process of fine processing refers to the work chisel. Final polishing to a perfectly smooth surface is done by hand with grout and emery paper.

Particular attention is paid to the joints and all hard-to-reach places.

Post processing

When the long and laborious grinding process is completed, it is time to cover the log house with special compositions and means. As mentioned earlier, this should be done immediately after cleansing the timber, because the polished wood is defenseless against any dangers, bacteria and pollution.To cover the house from the outside is necessary in several layers and several means that are presented today in a wide range.

Processing should be done in such layers as:

- antiseptic;

- antiprene;

- primer;

- lansing compositions.

It is worth noting that it is necessary to process the house inside as well, using funds on a water or combined basis. Despite a more favorable environment, the timber and logs in the house are also susceptible to fungi, mold and the multiplication of harmful organisms. You must carefully review the label and composition of products for interior decoration and make sure that it can be used inside the house. The first and important layer that polished wood will feel on itself includes antiseptic agents.

Today they are represented by the following two types:

- impregnated compounds;

- coating agents.

The first species is deeply absorbed into the tree, creating a protective barrier for mold and mildew, while the second subspecies forms a film on the surface that protects against moisture and damp. It should be noted that the impregnated compounds are often quite toxic substances, so their use for internal processing is dangerous for health.Attractive to the consumer are biovlagozaschitnye means belonging to the category of antiseptics. Protecting from moisture and fungus, they create an additional decorative layer, revealing the natural beauty of wood.

The second key step in wood coating is the anti-roll treatment. These funds are aimed at making natural material highly resistant to fire. Anti-foams are subdivided into saline solutions and non-saline agents. Salt solutions emit gases when ignited, which prevent ignition. When non-salt products are used, a foam is formed on the surface of the tree, blocking any fire.

The importance of antiprene treatment is difficult to overestimate, because without proper processing, wood will flare up like a match, leading to tragedy.

Today, well-known manufacturers to reduce the number of layers have developed biopyrenes, combining the properties of antiseptics and antiprene. They can be used for both external and internal processing. Painting of the house occurs after priming with water-soluble formulations with the help of scouring compositions or facade paint.The first type refers to the modern means of revealing the beauty of the log with the help of transparent species or varieties with numerous shades that reach more than 40 tones. Facade paint for exterior decoration favorably differs inexpensive cost, however, in most cases, covers the natural charm of wood.

Any type of treatment can be carried out with a brush, roller or spray. Joints and hard-to-reach places are handled with a thin brush. Internal processing is similar to external, however, it is worth starting with the floor, lower floors and partitions, ending with walls and ceiling.

It is worth remembering that quality coverage should cover every centimeter of a log building.

Useful tips and tricks

Experts unanimously advise to make grinding a log house, relying on professionals.

If for any reason this cannot be done, it is important to remember the following key points:

- only fully dried wood can be ground;

- the house should be divided into plots, the beginning of which are the upper floors;

- brooms and household vacuum cleaners do a great deal of dust on the walls;

- installation of windows, ceilings and floors is carried out after grinding. The exception is the roof;

- in the absence of experience it is more expedient to use a grinder with the ability to regulate the speed of rotation;

- Before starting work, new grinding wheels should be ground in auxiliary areas, for example, in interior openings. Such a solution will lead to the removal of the largest disc grains capable of sparking and spoiling wood;

- Experts believe that the typical mistake of beginning grinders is that the grinder works at high speeds. High speed quickly damages the front layer of wood, destroying and spoiling its appearance and natural protective qualities;

- in addition, often the device during operation is subjected to strong pressure, which forms grooves and dents, which can only be corrected by repeated grinding.

For information on how to make a grinding of the log with your own hands, see the following video.