Rules for the selection of insulation for the log house

Wooden log houses are highly valued for their heat-saving properties. To prevent cracks in the walls of the house, it should be warmed. You can learn about the types of insulation, their properties, pros and cons of use from this article.

Insulation features

Wooden houses, like any other material, have some features. During the first half of the year after construction, wooden houses shrink by about 6-8%, therefore it is recommended to warm the walls, floor and ceiling no earlier than one year after the completion of construction work.

Wood is a breathable material with variable humidity. In order to preserve the original properties of the log, the logs need to be ventilated. Therefore, vapor-proof materials cannot be used for insulation - excess moisture will accumulate on the surfaces, which will eventually lead to rotting of the logs.

Types of insulation

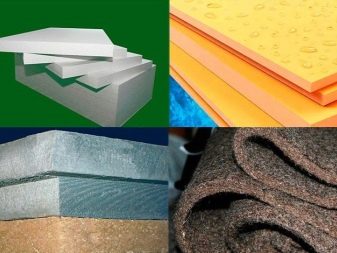

Modern manufacturers offer a wide selection of natural insulation. Among them the most popular are jute, moss, felt, flax and combined materials.

It should be noted that the building materials market offers a lot of synthetic materials, but they cannot be used for premises from a bar.

Felt

One of the most highly effective materials, which surpasses the majority of vegetable heaters with its qualities. Mainly used for buildings of profiled timber, houses, baths. Suitable for wall and partition insulation. Despite the high price, is very popular with consumers. Due to the special production technology, it has fire resistance, high thermal insulation properties, moisture resistance. Resistant to mold and mildew.

Jute

The material of jute is one of the tape heaters. For its production they use annual tropical plants of the family of malvaceae, rich in resinous substances. It is because of their presence that jute has many advantages. It is considered to be a better material than flax, but it is also much more expensive.

High hygroscopicity and thermal conductivity, resistance to rot and fungal damage, and durability are especially distinguished from technical properties. After laying the insulation, the walls do not need additional decoration, as even and tight joints do not violate the overall design of the building.

Among the shortcomings there is fast caking and high price.

Jute is on sale in the form of jute tow, jute felt and jute flax. Each of them has its own method of application.

Jute tow is distinguished by long and solid fibers and is used for caulking windows. Felt has stiffer fibers that break easily. It is used to seal the window and door openings. Jut-flax is characterized by high elasticity and wear resistance. Suitable for caulking in walls and partitions.

Moss

Moss is the cheapest material for warming houses and baths from a log house (most often they use sphagnum and red moss). It is characterized by environmental friendliness, antiseptic properties, resistance to deformation. It absorbs excess moisture well, due to which there will always be an excellent air exchange in the room.

Red moss has a longer service life, the content of antiseptic components and moisture resistance.

Of the minuses there is a low level of fire resistance and installation complexity.

Linen

Flax is one of the oldest materials used to insulate the walls of wooden houses. It is hypoallergenic, has a high level of vapor permeability, is resistant to infection by mold or fungus, resistant to ultraviolet radiation. It does not create electrical discharges and, if properly installed and maintained, will last more than the shelf life. The cheapness of the material makes it popular among analogues.

On sale there are two types of material: tow and lnovatin.

Flax tow is difficult to install. It is characterized by high hygroscopicity and a tendency to rot. Therefore, it is advisable to lay it around the window and door openings.Warm tow should be twice: the first time after construction, the second - after the shrinkage of the building.

For the manufacture of flaxatin use flax fibers, and the finished fabric is stitched with thread. This is a cheaper material that is easy to install. It is economical insulation, while doing well with its purpose. Laying of material is allowed after complete shrinkage of the building.

Combined insulation

This category includes materials made on a natural basis without synthetic impurities. In particular, flax-based materials with high elasticity are widely popular. Jute gives materials resistance to deformation and caking.

Different in composition, composite materials provide a high level of insulation in different climatic conditions.

Ways of warming

At first glance, it seems that the insulation works are not difficult, it is enough just to flash the walls with a certain material. But in fact, this process has its own nuances, knowing that it is possible to provide better work performance.

To achieve maximum efficiency, the material should be laid not only on the walls, but also on the floor and on the roof. This is the only way to completely warm the room.

There are many ways to lay the material. Conventionally, they can be divided into exterior and interior work.

- Outdoor insulation involves laying the material outside the facade of the building. This method is considered to be optimal and practical.

- Internal insulation less popular. When laying the material inside the house, the walls are no longer heated and are not protected from external influences. Condensate begins to accumulate between the wall and the insulation, which results in the festering of the logs. As a rule, internal work is carried out along with the exterior, or in those cases where the facade of the building must remain intact.

Subtleties of external insulation

During the insulation of the facade of the building, the work begins with the wall sheathing. Bars of the sheathing should be nailed horizontally. The pitch should be a few centimeters less than the width of the insulation boards, and the width should be slightly more than the thickness of the layer of the selected material. Between the bars lay the plates of insulation in two or more layers, tying the joints.

A windproof membrane is laid on top of the material - a film that will protect from wind, steam and weather precipitation.

Another crate is nailed onto the bars, onto which the finishing materials will be mounted: paneling, block house, “artificial” bar. This is necessary so that a ventilation gap is formed between the bars and the cladding to ventilate the insulation and the walls of the building.

Internal insulation of the log house

To form a gap between the wall and the insulation, a vertical crate of wood is nailed. A membrane and another counter lattice should be attached to it. And between its bars lay the plates of insulation and hang a vapor barrier film. The final stage is trimming with a decorative material (clapboard, drywall, chipboard).

Inside the house should use materials that do not need steam and waterproofing.

The most effective of them are penofol, OSB, sprayed heat removal. These materials are easy to install and combine well with outdoor insulation.

If we talk about floor heating technology, then there are three options:

- solid wooden;

- double wooden;

- concrete.

The difference between the first two is the presence of waterproofing pads in the second method. As insulation, mineral wool, expanded clay, concrete, roofing material are used.

Concrete insulation involves the use of foam plates, enclosing them in the so-called casing of cement screed.

What to consider when choosing a material?

The rules for choosing insulation are as follows:

- mezhventsovy heater should meet high safety standards and meet all quality standards;

- it is best to choose a material with high elasticity, density, durability;

- the effect of thermal insulation is achieved due to the low thermal conductivity, but the moisture and vapor impermeability must be high;

- the material must be resistant to the occurrence of mold, fungus, harmful microorganisms;

- UV and weather resistance is encouraged.

How to properly insulate the house from the log, see the video.