How to collect and put a log house: the nuances of the construction of a log house and tips experts

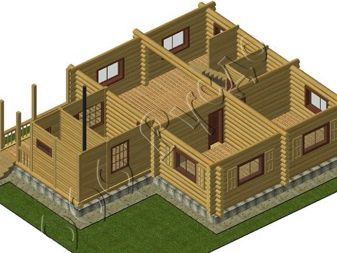

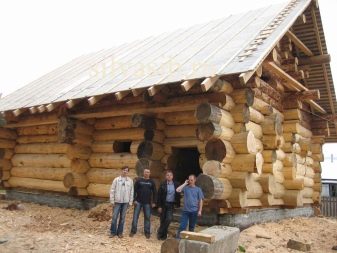

Log houses are very popular in many countries, as they are environmentally friendly and attractive appearance. Such buildings are often chosen by people who want to move away from cutting-edge and futuristic design ideas. After reading this article, you will learn how to collect and put a log house.

What it is?

If you are going to proceed to the consideration of the technology of erection of a log house, you should understand what is a felling.

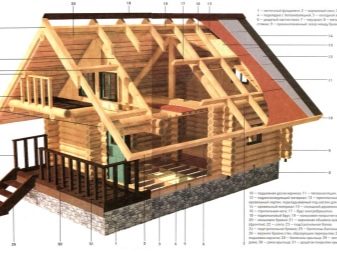

The felling is an environmentally friendly and beautiful structure consisting of wooden logs. Such constructions do not have a floor, roof or crates. Simply put - a log house is a “bare” frame of the house.

Such buildings are ideal solutions for those people who want to "put" a house or a bath in the shortest possible time. In addition, the log house is popular because it has an acceptable cost. This attracts many consumers.

Features and types

Wooden houses have always been in demand, and this is explained not only by their natural appearance, but also by good performance characteristics. In such dwellings at all times it was warm in the winter season, and in summer it was cool and as comfortable as possible.

Currently, wooden buildings are still relevant, despite the large selection of building materials that can be used to build reliable and durable houses. Consumers prefer a log house, since it takes very little time to build it, and all the necessary stages of work cannot be called too complicated.

It is natural that modern log houses are very different from those buildings that were common in the distant past.Today, such homes can be decorated in any style. Log buildings, in which there are a fireplace and the corresponding decorative elements - for example, fluffy floor carpets, look especially harmonious and cozy.

Our ancestors built wooden houses with their own hands, although work with a bar cannot be attributed to a very simple one. Today, you can create a frame construction not only on your own, but also by turning to a team of professionals (with special tools and rich experience).

For the construction of the log house is most often used coniferous woods. The most popular are pine and spruce. Such materials are not only environmentally friendly and fragrant, but also relatively inexpensive. If the budget allows, you can build a log house of alder, oak or larch. These materials will cost much more than spruce or pine, but their appearance and performance justify high prices.

A feature of log buildings is that they are often built in the winter season. Some experts say that such construction is more beneficial, since, for example, a conifer at low temperature is not affected by fungus.In addition, the craftsmen declare that in winter the tree becomes more pliable and is processed easier.

If you are going to build a log house, you need to take the drafting of its project as seriously as possible. It is necessary to think over absolutely all the details and trivialities, taking into account the following distinctive features of natural material:

- you should not forget that buildings made of wood will always shrink with time;

- such materials can be twisted;

- wooden blanks must have a suitable size (there are certain restrictions);

- the frame is not designed for too large loads.

If you make a plan for the future house with errors, then in the future the whole structure may turn out uneven and skewed. In addition, ugly cracks and other defects may appear on the wood, and it will be impossible to get rid of them.

Log buildings are also different in that their lifespan can be prolonged if you provide decent care for them. If you ignore this rule, the house can serve a short time, quickly losing the aesthetic appearance.

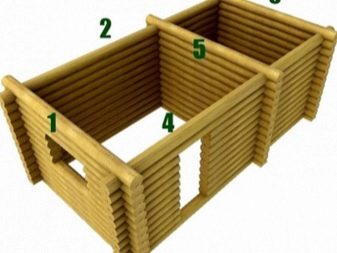

Currently, there are several varieties of log buildings.Their names come from the number of wall ceilings present in the structure. Most often in our time there are the following options for log cabins.

Chetverik

This is the name of the four-wall log house, which is otherwise called the "four-wall". It is rightly recognized as the simplest, even uncomplicated, and therefore it occurs most often.

The name of such a log house speaks for itself: it has four walls. As a rule, the construction of the quadrangle has a square, diamond-shaped or rectangular shape.

Pyatistenok

As you can see from the name, there are five walls in such a building. Outwardly, this frame is a quadrangular frame with an additional partition - the fifth wall. A five-wall is two 2 four-walls with one common overlap.

Six hundred

Sistoyanok is a more perfect version of the five-wall. Such a building differs from the above in that it has 2 partitions. At the same time they are all located on the outer floors. The room is divided into 3 or even 4 rooms.

Eight

Not every consumer knows what constitutes a log cabin under this name.This design is more complex, but also more attractive. The octagon is a luxurious octahedron in which all angles form a single space.

Scum

A log building with this memorable name is something like a tower with a roof built into the main structure.

All these types of log cabins are the most common and common. Of course, there are more original, unusual designs (non-standard shapes and sizes). Before use the tree is exposed to manual or machine processing. If at the same time residual pieces of bark are not removed from the material, the bars are called "debarked logs".

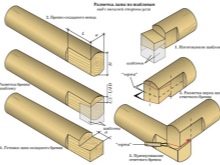

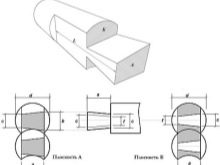

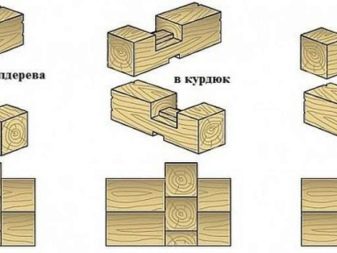

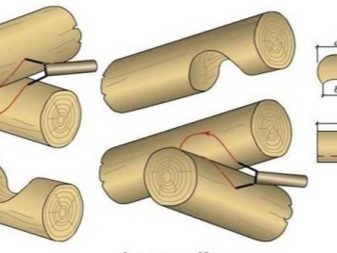

Log structures may differ from each other not only in terms of the materials used and the number of walls, but also in angle joints. There are several main options for such "locks" that are used in the process of producing log carcasses.

"In the paw"

Otherwise, such a lock construction is called the angle without remainder (refers to the Russian wheelhouse). In such a construction, the logs are fastened together with the help of special wooden locks, which are cut down to the end of the logs. In this case, the ends do not fall outside the walls of the log house.These structures have been addressed before, as they have an aesthetic appearance. However, buildings with an angle of no residue and have their weaknesses, which should be aware of before their construction:

- It should be noted that this angle will be blown and quite cold. It will require better and more efficient insulation.

- If you do not fasten the logs together with the help of dowels, as a result, the frame may not be as stable and reliable as you planned.

With the remainder

In designs that have corners with the remainder, the ends of the logs extend approximately 20-30 cm beyond the walls of the log house. This angle is considered more reliable. In addition, it is made quickly and easily, and the result is a windless and rather warm piece.

Today, many masters in the construction of a log house use exactly the angle with the remainder.

"In Okhryap"

With this type of angle in the upper and lower logs, small depressions are selected, into which the articles “get up”. At the same time, the hole in the lower log must correspond to the size of the lower log (and vice versa).

At present, this type of angle is used very rarely, since it can be quite difficult to adjust and make it not windy.The detail "in the hole" is permissible to use if it is necessary that the crests of all the crown logs are in the same horizontal plane.

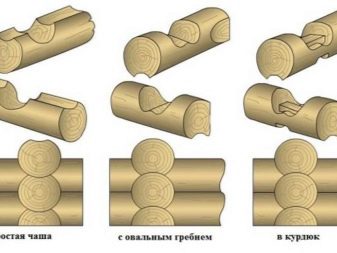

"In the bowl"

The most common angle is recognized as "into okhryap." The main advantages of this option - ease of manufacture and excellent thermal properties.

You can also highlight the variant called the “upper bowl” - a vertical fading of the “lower part”. In this case, the bowl rests on a log.

However, it should be borne in mind that today this (“upper bowl”) type of angle is addressed much more often than the “lower” one, since it is made in a simple way and does not require serious energy consumption.

"Bowl in the fat tail"

So called another kind of angle, which is permissible to use in the construction of the house, and in the construction of the bath. The main advantage of such an element is that it is not blown and has a design that makes it very easy to work with it.

This angle is distinguished by the fact that in the lower part of its bowl there always remains a small ledge that runs along the log. At the same time in the log, which is placed on the bowl, a suitable recess is selected.

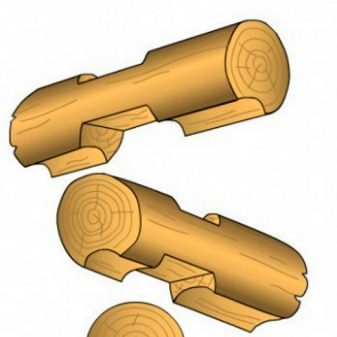

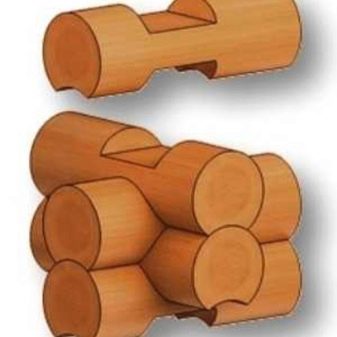

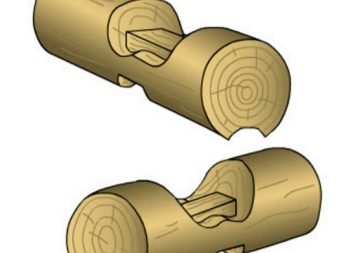

Canadian and Norwegian logging (carriage)

Norwegian logging is most common in Scandinavian countries. With this method for the construction of houses are used not round, but oval semi-bars (otherwise this detail is called the "carriage"). Similar logs are sawn on the sawmill from 2 sides.

In the Norwegian felling, the protrusions on the walls are sawn off, after which a rather dense bowl is made in the corner sections and under the cuts. Such a structure has a positive effect on the thermal insulation properties of the structure. However, it is recommended to protect the blockhouse with a gun carriage from blowing. To do this, you need to install special seals - caulking iron.

The Canadian felling is in many ways similar to the Norwegian and has all its positive qualities.

The main similarity of the two methods is that with them all the connecting elements self-jammed. In the process of drying the crowns become more dense, forming at the same time an almost complete monolithic wall.

Canadian logging is considered difficult and time consuming. The tree should be as closely as possible fitted and prepared for work. It is recommended to carry out such works only to experienced craftsmen who have previously encountered similar processes.

Advantages and disadvantages

Log houses are very popular today.Each person wants to have a dwelling in which he will be as comfortable and comfortable as possible, and such buildings perfectly cope with such tasks.

Log houses have both advantages and disadvantages. With them you need to be familiar if you are going to put such a structure on the site.

To begin with, let's consider what advantages log structures have:

- The main advantage of the log house is its environmental friendliness. Nowadays, safe materials, which contain no toxic compounds, are becoming increasingly rare, so natural and safe products are so valued among modern consumers.

- Another advantage of log buildings is their appearance. And we are talking not only about the attractive facade, but also about the harmonious inner part of the dwelling. Staying in such an environment is a pleasure, allowing you to relax.

- Some log houses do not require additional insulation, therefore, during their construction, you can significantly save money. You can not insulate buildings erected from a log with a diameter of 25 cm.

- The microclimate in the log house is ideal for people suffering from certain diseases.Experts say that coniferous materials have a positive effect on human health. That is why in the past many people turned to conifer treatment.

- Natural and high-quality log house is a practical material that does not require special attention. It does not need to be treated with antiseptic impregnations or anti-fungal agents. It should be borne in mind that wood (especially coniferous wood) produces a lot of resin, which plays the role of a natural antiseptic.

- During the construction of the log-house construction, the logs of such a length are used, at which the materials are spent very economically, and the integrity of large areas remains intact.

- Houses from planed material are characterized by a long service life. It is believed that for such buildings and 100 years - not the limit.

- When you design houses built from natural materials, you can significantly save on finishing.

- Masters (both experienced and beginners) say that the construction of the log house does not take much time.

Due to the large number of positive qualities log houses are very popular today. However, they are not ideal - such houses have their own drawbacks, among which are the following features:

- To many consumers, such buildings seem to be quite expensive. A quality and reliable log house should not be built from cheap and low-grade material.

- Some designs are complex in terms of construction. These buildings include oak houses. Such constructions are not recommended to be done independently - it is better to entrust this painstaking and laborious work to more experienced people.

- Do not count on the fact that you can mark a housewarming in the first autumn, summer or winter after the construction of the building, as you first need to wait for its shrinkage.

- Special attention should be paid to the foundation. Even a small log house will have an impressive weight, so do not rely on piles or poles (except for a bath). Without a high-quality and reliable foundation, the log house structure can tip over - despite the external compactness.

- The log house must be treated with antiprene, which makes the structure more fireproof. It is not recommended to neglect this process.

- Most modern log homes require regular maintenance. Of course, really high-quality materials are not subject to decay, but today there are more common logs that still need to be treated with antiseptic compounds.

Of course, many of the problems associated with a frame can be avoided if it is properly processed and properly delivered. In addition, it is very important to use high-quality natural materials for construction.

Wood requirements

For the construction of the log house you need to carefully select the wood. It must meet certain requirements so that the result is a durable and sturdy structure.

An important role is played by the diameter of the logs. For the construction of houses it is recommended to use materials with a diameter of 24-32 cm. Small logs, of course, are much cheaper, but they look less aesthetic.

For large buildings it is not recommended to use thin trunks - in such conditions they will look ridiculous. The optimum diameter is 28 cm. For the construction of a house, you can purchase logs with a diameter of 30-40 cm, but such materials will be expensive.

On the surface of the logs should not be serious damage, defects, traces of decay, mold or fungus. The wood should not be black, blue and any other dark spots.

Experts do not recommend to purchase a disassembled timber. If the structure has been disassembled for a certain time, then it may simply fail to fold. This is due to the varying degree of drying of the trunks.

Watch for wood moisture. It should be well dried. Materials with a natural moisture level are in many ways inferior to similar specimens.

The choice of building materials

If you decide to build a log house with your own hands, then you should seriously consider the choice of building materials.

Pine

Pine - is unpretentious material, which is characterized by a long service life. Experts say that working with such wood is easiest because it is very malleable.

For construction use the following types of pines:

- ordinary;

- flexible;

- resinous;

- marsh;

- korean

The best option is considered to be pine species that grow in the northern strip: Angarsk, Karelian, and Arkhangelsk.

Most consumers prefer the pine because it is not only practical and beautiful, but also inexpensive. However, it also has its weak points:

- pine shrinks like any other kind of natural wood;

- this material is prone to cracking;

- pine is afraid of high levels of dampness and moisture, so it will have to be especially diligently treated with protective agents so that it retains its qualities for many years.

Larch

Larch log houses are also very common. This wood is strong enough and durable. In addition, larch is relatively expensive. It is also worth noting that in a dried form this tree is not subject to rotting, which is very important for such material.

Such wood is considered medical. As for the strength characteristics, here larch can be compared with a good and expensive oak. It is not easy to damage or break, but it is sold at an affordable price.

However, larch is less pliable and soft than pine. For this reason, such wood is difficult to process.Because of this, working with her can be problematic.

Aspen

The pleasant light shade has a natural aspen. It is very easy to work with such wood, as it is not capricious. Aspen has the following important advantages:

- such a tree is not subject to the formation of wormholes;

- in a dry state, such a building material is very elastic;

- aspen beams differ in the minimum deflection, but at the same time have small weight;

- upon contact with water and its complete drying, the aspen is not destroyed or deformed;

- even at a temperature of +100 degrees, aspen does not emit tar (unlike coniferous trees).

Such a building material is rightfully recognized as practical and durable. However, it is worth noting that in our time it is not so easy to find really high-quality pine blocks. When constructing a log house, only well-dried wood of this species can be used.

Cedar

Cedar has a soft wood structure. In many ways, this material is similar to pine - it is also easily amenable to different types of processing. Cedar can be safely used for interior decoration, as it has a rather pleasant texture and not less pleasant natural aroma.

In addition, the construction of cedar have the following advantages:

- high strength;

- relatively low weight;

- resistance to the damaging effects of moisture and dampness;

- good sound and thermal insulation properties;

- ease of processing;

- attractive appearance.

Buildings built from cedar, as a rule, have a light reddish tint. If there are knots on such wood, they are less dense and strong than those of pine or spruce. However, it should be borne in mind that without additional finishing the cedar begins to darken, and much faster than, for example, the same pine.

Oak

If you want to build a solid and elegant log house, then you should use oak logs. As a rule, such materials are quite expensive, but they look just amazing and have enviable strength characteristics.

Oak buildings have many advantages for which modern consumers choose them:

- Oak logs have a dense structure of wood fibers, thanks to which it is permissible to use this material without regular antiseptic treatments.

- Such wood burns very badly, as it is very dense.

- Oak is not afraid of insects or mice.

- This type of wood is slowly warming, but for a long time it keeps the heat in itself, which has a positive effect on the internal microclimate in the houses.

Oak log cabins are not without certain disadvantages:

- High density is both a plus and a minus. Because of this feature, such a material has an impressive weight, so working with it is not always convenient, and the foundation for it requires the most durable and reliable.

- Not every master knows how to work with oak - it is difficult to process.

- Another serious disadvantage of such wood is its high cost.

Having chosen this or that material for building a log house, it is necessary to inspect it for the presence of the above darkening, destruction and signs of rotting. It is also necessary to purchase materials of suitable diameter.

Stages of construction

After acquiring the necessary material, you can proceed to the construction of a log house. To begin such work is necessary with careful preparation of technical specifications. It is on its basis that the entire list of required works will be formed.

After that, as a rule, they make up a draft design.It is designed to determine all the features relating to both the scheme itself and the design as a whole. In addition, on the sketch, the master will be able to notice in which places something needs to be corrected.

Then you can proceed to the drafting of the working draft. To do this, you can contact the experienced professionals. The working draft is a draft design with all the details and nuances. Such documentation is used by builders to achieve maximum similarity with the initial preferences of the customer. In the working draft is very important to make both text and graphic materials.

When the compilation of the plan is completed, you should proceed to fill the foundation. The base under the frame should be sufficiently reliable and strong, so that over time it will not squint and collapse. Most often for wooden buildings use a tape version of the foundation.

For its construction around the perimeter and under future wall ceilings, you need to dig a trench. Its width should be about 40 cm, and its depth should be 50 cm. Place a “pillow” of sand-gravel at the bottom. Then the reinforcement should be laid down and a formwork 50 cm high should be constructed.After that, you can proceed to the direct pouring of concrete. As a result, you will have a foundation whose height will be about 1 m.

Next you need to make high-quality waterproofing base. To do this, the surface of the foundation can be covered with molten bitumen, and on top you can lay a layer of roofing material. When the bitumen is completely dry, the procedure can be repeated. The result is an effective two-layer waterproofing.

The next step will be the development of the project engineering networks. Its features will depend only on the desires of the owners. Most often for this purpose a simple scheme is drawn up, on which there is an arrangement of all the main points. At this stage it is necessary to develop the design of the future construction.

For further work you will need the following tools:

- chisel;

- special ax of wood;

- chainsaw (preferably stock up with a tool with an average power);

- plummet;

- building level;

- electric drill;

- mallet;

- feature

Special attention should be paid to such a tool as a trait.

To make it, you need to take a steel wire with sharp edges.Bend it in half so that it takes the form of a compass type. It is permissible to additionally fix the handle. This tool is needed for marking logs.

If you have all the necessary tools in stock, you can proceed to the assembly of the log house. Above were listed all the varieties of such structures, but most often it is the Russian felling. It is easiest to do it, and even a novice carpenter can handle this job.

The construction of the log house itself must be carried out in stages, starting with the roundabout crown (from the starting one). Logs, which will play the role of a mortgage crown, need to be trimmed to the edging - for a closer connection to the foundation.

However, to begin with, it is worth putting a “bedboard” on the foundation. For this fit linden. It can be a timber of 50-100 mm in thickness and not less than 150 mm in width. After constructing the mortgage rim, you can proceed directly to the assembly of the log house.

Lay the first pair of logs on the waterproofing basement coating. The second pair should be laid at an angle of 90 degrees relative to the starting parts. Put everything in a “cup”.

When designing such a structure it is permissible to use a chainsaw. With it, you can significantly save valuable time. However, the finishing of the "cups" in any case, you need to do an ax.

After the first one, the second crown should be laid. It is better for him to choose thicker logs, since in the future they will install floor logs. To fit the maximum, in the upper beam is to make a longitudinal groove. This element should be equal to one third of the diameter of the previous log. To delineate the boundaries of the groove, you need to lay the top log on the bottom and make the markup using the dash.

The groove is recommended to make a semicircular shape - this is the best solution. It can be done with a chainsaw. To remove all remnants, a chisel tool is ideal.

An important step is the warming of logs. To do this, most often use a special linen flax. One of its segments is placed on the lower crown, and the second is warmed with a longitudinal groove.

Next, the crowns need to be stapled to each other. To do this, you can use:

- square dowels;

- round wooden dowels.

Experts advise to use wooden pins, because you can buy them already prepared and just make the necessary holes with an electric drill.

Holes should be made in 1-1.5 m steps. In parallel, completely sew some upper rims, and the third crown below is not completely. To avoid the bevel of the structure, after its shrinkage, it is necessary to drown the pins into the crown, located 6-7 cm above

When you raise the wall ceilings to the height you need, you will need to put ceiling beams and rafters on top of them. If during construction you used damp wood, then instead of rafters it is worth using slate sheets. After that you should wait for the shrinkage of the structure. As a rule, it needs only a wintering time, but according to all the rules, it takes a year and a half to shrink.

With the onset of spring, when the shrinkage is completed (partially or completely), you can proceed to the caulker.

As for the door and window openings, it is permissible to equip them in two ways:

- In the first version of the arrangement of these parts all the holes are made only after the completion of construction work.At the same time, in the crowns, which are located on the places of future openings, small gaps should be left (their sizes depend on the size of window and door constructions). When you install all the logs, the openings will only be cut with a chainsaw.

- In the second case, all openings need to be prepared during the construction of the log house. Such an arrangement is considered more complicated and energy-consuming, as you will have a timber with cutting at the ends, as well as special grooves.

Experts recommend to engage in the organization of openings only after the completion of all construction work. Such work will not cause serious difficulties.

When the shrinkage of the entire structure ends, it will be possible to proceed to the next stage. For this you need a hammer and a caulk (wooden or metal).

Getting to work is permissible only after the insulation dries to the end. First you need to twist the materials (moss and tow) into a bundle, and then hammer them into the spaces between the crowns (using a caulk and a hammer).

The use of a tape harness is also acceptable. Such material is established with the help of nails or a special construction stapler.

After wood shrinkage, you can proceed to the construction of the roof. You should not start such work earlier, otherwise the structure may be deformed in the process of shrinkage of the log house. Stages of work:

- Lay wooden beams on the wall trim.

- Lock them in one position and attach rafters to them. At the same time it is necessary to maintain a step of 1 m

- In the ridge part you need to cut the rafters at the right angle (for the connection).

- It is necessary to nail a solid flooring of boards to the rafter legs, especially if you are going to lay a flexible roof on the roof.

- Instead of a solid flooring can be designed and crate. Such basis is most of all suitable for a tile, slate.

- After that, put the roof on the roof.

- The ridge should be covered with a galvanized steel sheet in order to protect it from negative external factors.

- Roof gables will require lining. For this purpose, for example, siding or wall paneling.

After installing the roof, you can proceed to other work: pouring a concrete screed or installing wooden floors. In the second case, it is necessary to cut the logs into the logs of the second crown and fix them securely.Next, you will need to do the laying of insulation and perform interior decoration of the house.

Grinding and processing

When the construction material was just delivered to you (or you brought it yourself), it takes about 25-30 days to rest in bed. After that, you need to carefully consider and sort out all the logs that you bought to build a log house. Leave only the highest quality items. A tree with defects and damage must be rejected.

After sorting the material, you can proceed to its processing. To start the logs must be cleaned of bark. However, it is recommended to do this as carefully as possible, so as not to harm the wood. Small areas of bark should be left on the sides (about 15 cm on each side).

After removal of the bark of the logs need to be deposited. In this case, the materials should be about 25 cm from the ground, and not lie on it. At the same time, logs can be laid as you please, it is only important to leave a distance of 7-10 cm between the individual elements.

In order to serve the log house as long as possible, it is recommended to polish it outside, and then treat it with a special coating.However, it should be borne in mind that the process of grinding a log house is complex and time consuming. To do this, you need special tools and a lot of free time.

High-quality grinding and processing are a guarantee:

- the durability of the log construction;

- its visual appeal;

- protection against mold, mildew and parasites.

It is also worth considering what advantages grinding a log house has:

- Mechanical processing of wood eliminates the material from cracks, irregularities and unpleasant roughness. Treated logs look much neater and more attractive.

- Wood, which has been polished, acquires excellent adhesion properties, so its painting becomes faster, easier. Coverage lasts a very long time.

- After polishing is completed, wood can acquire a pleasant natural texture, which is the main advantage of log structures.

- By grinding, you can protect the tree from premature aging.

Grinding can be done by hand, but for this you need to use special tools. For carrying out such work is perfect belt grinder.

If a log house is built of semi-circular logs, then a belt machine for its grinding will not work. Here it is better to use the grinder with special grinding nozzles.

It is possible to start grinding a log house only after it has completely dried. If you go to this work immediately after construction, the excess moisture in the structure of the tree will not allow the material to be as smooth and smooth as possible.

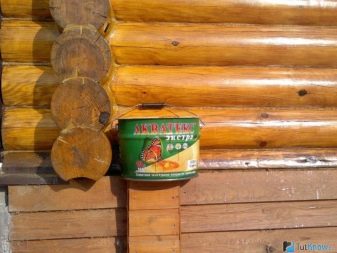

After grinding, the log house should be treated with the following means:

- antiseptic agents that protect the tree from mold and mildew;

- lansing compounds that transform the appearance of wood;

- fire retardants that make the tree more fire resistant.

Warming

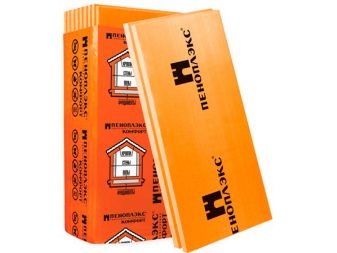

With a properly selected insulation log house becomes more comfortable. Today, the range of such materials is very wide, so choose the optimal products will succeed for any basis.

For warming a country house or a log cottage, you can use different materials, each of which has its own characteristics. There are the following main categories of similar products:

- synthetic, which are composed of artificial components;

- natural mezhventsovye insulation made from natural materials.

Synthetic insulants include polystyrene foam, mineral and basalt wool and other similar materials.

One of the most popular insulation for floors, walls and ceilings is mineral wool. It is made of slags, fiberglass and various rocks.

The main advantages of mineral wool are:

- excellent thermal insulation characteristics;

- water resistant, which is very important for high-quality insulation;

- resistance to most aggressive chemicals;

- good air exchange characteristics;

- sound insulation characteristics;

- resistance to fire;

- durability (the service life of mineral wool is 25-30 years);

- environmental friendliness.

As for the minuses minvaty, these include:

- fairly high level of dusting;

- when wet, this material loses its positive qualities.

The second most popular insulation is polystyrene foam. It has the following positive qualities:

- this material is frost resistant;

- has a solid structure;

- durable;

- differs in low heat conductivity;

- easy to install;

- not afraid of alkalis and solvents;

- heat resistant;

- inexpensive;

- no odor.

However, this insulation does not tolerate contact with sunlight - they simply destroy or deform it. In addition, polystyrene foam can not boast of good sound insulation characteristics. Many consumers refuse to purchase this heater because of its flammability.

Some experts do not recommend to insulate with expanded polystyrene wooden houses, as this material does not let moisture out very effectively, and this leads to accumulation of condensate. Because of this, the wooden base may darken and start to rot.

For the insulation of the log house it is desirable to use materials of natural origin. Of course, you can also purchase synthetic products, but with them you will not be able to achieve the effect of a “living house”, which is so good for wood buildings. So, for example, if you warm the frame with materials without pores, then it will simply “suffocate”, being under a protective film.

Porous insulating materials, which are in great demand today, can badly affect wood constructions.Such coatings, absorbing excess moisture, do not change in size, and this condition is important for natural wood. As a result, cracks and blown parts will necessarily appear in such a structure.

If you want to choose a natural material, then you should correctly choose a high-quality mezhventsovy insulation. In this case, wool fiber, sealants or special heat-insulating ribbons will not work. For warming timber, it is better to choose flax, jute, moss.

Moss has been used for warming wooden houses in Russia since ancient times. However, it is necessary to take into account that not every natural material is used in construction. The best thing for this is the special red moss, which is otherwise called "kukushkin flax." It grows in the swampy northern territories. In nature, red moss is not as common. For warming a log house it is permissible to use white moss sphagnum.

Moss as a natural mezhventsovogo insulation has the following positive characteristics:

- has bactericidal properties, therefore it is not exposed to the appearance of rot or mold;

- is durable and elastic (thanks to its fibers);

- allows you to maintain an optimal microclimate in the log structure, as it boasts excellent steam and gas permeability characteristics;

- able to absorb excess moisture;

- is eco-friendly and safe.

If we compare sphagnum and red moss, it is worth noting that the former is less durable, but at the same time more affordable.

It is possible to seal off intervential cracks with the help of jute insulation. In this case, it is not necessary to use moss.

Jute gaskets for log house insulation have the following advantages:

- environmental friendliness;

- contain lignin fibers that prevent material from rotting;

- have excellent insulating qualities.

Thanks to a special treatment of annual jute receive tow, felt and flax jute.

The main disadvantage of jute is that it can compose over time, and it is quite expensive.

Another natural insulation for the log is flax. It is often used in the construction of houses and baths. At present, insulating materials such as lnovatin and tow are made from flax. Both materials are environmentally friendly and completely safe for human health.In addition, these materials are quite dense, so do an excellent job with their main task.

Consider how to properly finish the log house with natural mezhventsovym insulation.

- First, a layer of insulation material is laid on the log - it needs to be rolled along its entire length.

- Next, on top you need to put the next log to securely fix the insulation. At this stage, you can use the construction stapler, which will provide the most durable and durable fastening.

- Make sure that the insulation does not roll into a thin flagellum. On the contrary - its edges should hang down on the sides by 5 cm, when it will be clamped between wooden parts.

- Hanging excess need to be pushed into the depth of the seam. The most convenient way to do this is with a chisel.

This process of warming timber is otherwise called the primary caulking blade. Only a year later, when the structure shrinks, similar work will need to be carried out again.

Common mistakes

When building a log house, many masters face a number of common problems. Consider them in detail:

- One of the most common mistakes is the wrong selection of materials for construction.For the purpose of building a log house, it is permissible to use logs of pine, spruce, fir, larch and other similar species. The big mistake will be the acquisition of materials with rot and tobacco knots.

- It is very important to purchase dry materials. It will be very difficult to work with raw wood, and it will not serve for too long.

- For dowels, you can use only dry and straight-grained wood, on which there are no knots. If you use birch dowels, they must be covered with antiseptics. Many home masters neglect such works, but in fact this is not worth doing. In addition, it is not recommended to make cones of deciduous and hardwood.

- Do not completely clear bast logs. Otherwise, such materials will attract insects and fungi.

- Do not forget about the installation of waterproofing between the finishing crown and the foundation. For this, some use short-lived materials such as roofing felt. Experts recommend to purchase more modern bitumen-polymer coatings for waterproofing.

- When assembling a house, you need to remember that each log has a certain degree of curvature. Lay these materials need curvature up.If you do not take into account this principle, the logs can be strongly issued in different directions.

- Another common mistake is the failure to comply with the size of the inter-ring gap. It should not exceed 1 mm. When hand-cutting, it is difficult to observe this rule; drying up the wood leads to an increase in the gaps. Avoid connecting logs in crowns in length, otherwise the design will not be very strong.

- Outside the house of wood can not be insulated with vapor-permeable materials - for example, polystyrene foam. In this case, the wood ceases to "breathe" and completely dry, and a high level of humidity will destroy it over time.

- For the insulation of the log house can not use flexible mats. Instead, it is recommended to install more rigid materials in the form of plates.

- Often masters casually transport construction materials. This error may cause damage.

Tips and tricks

- In the process of constructing a log house, all vertical racks can be supplemented with such detail as a shrinkage compensator, which is a kind of jack.

- Track the lateral cracks on the logs - they should not go deeper by more than 1/5 of the diameter of the end of the log.

- You should not leave a log house to dry out without a roof. This may cause it to rot.

- It is recommended to install special visors in the structure that will protect the log house from negative external factors - for example, from rain.

- Chopped houses should not be compacted with foam in the places of window and door openings.

- Do not proceed to weatherization without checking the condition of the wood - first reject damaged parts and areas with defects.

For information on what mistakes can be made in the construction of a wooden frame, see the video below.