Fittings for metal-plastic pipes: features of the application and installation technology

Pipeline fittings, called fittings, are a wide range of products. For example, some types of fittings are suitable for metal-plastic pipes, and others - for polyethylene. Features of application and technology of installation of products are various. This article describes the fittings for metal pipes.

Device and purpose

Connectors for metal pipes can have a different device and purpose. For example, products used more often than others - press fittings.

Such details include several elements:

- outer rim;

- inner rim;

- coupling sleeve.

The outer rim is fixed on the fitting with seals. He, in turn, is inserted into the pipe with special tools.

Connection press fitting today is considered the best option. The outer rim of the product is usually made of special brass alloy. The material is resistant to zinc leaching. These options have a high resistance to corrosion.

Strength is added to crimping sleeves from high-alloy steel.

The device, which is a threaded version, allows you to fix the pipe with a nut with a split tip. This tip is usually placed on top of the pipe and pressed.

Such connectors require the use of special tools and certain skills. With a lack of skills there is a risk of under-tightening the nuts. A large number of prefabricated parts sometimes lead to leaks appearing at joints. Therefore, if threaded fittings are used as connectors, the connections must be accessible for inspection and replacement.

Also connectors are presented by other options. The most common are:

- tees - products consisting of collectors and branches;

- couplings;

- adapters with plastic elements;

- plugs (close the ends of the pipes);

- corners - products that allow you to change the direction of highways (with angles from 45 to 120 degrees);

- crosses (needed when there is a need for branches, the branches of which will be directed in different directions);

- fittings (for flexible bends).

For heating, plumbing and other structures, there are many different fittings. Let us consider the most popular options.

Advantages and disadvantages

Metal pipelines are considered very reliable. Their service life is up to 50 years. The standard size of products supplied to the market is from 16 to 62 mm. The connectors used must be suitable for pipe sizes. Select products should be based on the wall thickness of the lines themselves.

After seeing the variety of products presented, everyone can think about which products are better: compression, press fittings, clamping or other models. Compare the advantages and disadvantages of products.

Performance characteristics of parts are almost identical.

The general advantages of the connectors are the following:

- installation of products is extremely simple;

- the products allow docking with copper and stainless analogues;

- the risk of leakage in the joints is minimal;

- connections to fittings do not require welding, which facilitates the process of assembling highways;

- connecting products offered on the market are relatively inexpensive.

Of the minuses of the threaded options worth noting only one point. Such fittings, even after complete assembly, require periodic maintenance. Therefore, the details can not be hidden in the screed or in other elements of the decor. Details must be open to access.

The advantage of press fittings is the ability to close lines with a tie or décor. Continuous monitoring and maintenance after assembly of parts do not require. In this case, the operational life of products is up to 30 years.

Another advantage of such connectors is the possibility of reducing the consumption of highways. Fewer reinforcement parts make laying networks cheaper. However, the tool needed to assemble press fittings is expensive.The cost of press ticks presented in the sale varies from 1,000 to 5,000 rubles.

Of the minuses of pressed fittings, it is worth noting the poor tolerability of negative temperatures. Therefore, the products are not recommended for laying outdoor systems. The installation itself is not difficult.

Species

Fittings for plastic pipes are divided into:

- one-piece (called a press or press fitting);

- conditionally detachable (called compression or crimp);

- detachable (called threaded or collet), in the same group include push-fittings.

In most cases it is customary to connect metal-plastic pipes with press-fittings. The connection is reliable, but the work must be carried out according to the rules. Methods of installation of each type of products are individual. The basic rules are related to the method of fixing fittings on the highways.

If we generalize the difference, then the issue of choice can be solved taking into account the following points:

- compression fittings can be used on service lines;

- the system with press fittings is monolithic;

- compression connectors can be mounted with tools at hand;

- The press sleeve is mounted with special tongs;

- compression connectors are available for disassembly and replacement;

- line with pressed fittings must be replaced completely;

- regular maintenance of systems with threaded connectors prevents masking in the walls;

- if you compare the cost of connecting elements, then extruded products are 1.5 times cheaper than their counterparts.

Products are divided into different types and materials of manufacture.

Allocate fittings:

- bronze;

- steel;

- cast iron;

- copper;

- brass;

- from polypropylene or polyvinyl chloride.

When installing pipes can be used almost all types of connectors. The choice of manufacturing material may be related to the load characteristics of the system.

For example, threaded models are recommended for structures with bulk loads.

In addition, the choice of product options associated with the following indicators:

- pipe size;

- place of application.

Separation by location involves the use of straight, T-shaped, Y-shaped products.When buying fittings, you need to know in advance the size of the lines to be connected. A competent seller will always ask about the required diameter of the connectors.

The diameter of the fitting can be the same on both sides, or it can have different parameters at the ends. The last version of the products needed to connect large pipes with smaller lines.

Fittings are used when laying various communications. The purpose of the nodes is strictly defined - for polypropylene or for metal pipes. Consider the selection criteria in more detail.

Criterias of choice

The main criteria for the selection of fittings - size and type. Experts also advise to take into account the materials of manufacture. But the use of fittings from materials other than those used in the manufacture of pipes is allowed. For example, brass fittings are great as connectors for copper products. Also, these options can be used for metal pipes. Copper fittings are suitable for any pipes. Products made of polypropylene or polyvinyl chloride should be used for highways of the same materials.

It is strictly not allowed to combine copper elements with highways made of galvanized steel. Corrosion arising from the interaction of two metals badly affects the operating time of products.

Now it is necessary to understand the criteria for the selection of specific products. For example, couplings should be considered as connectors for straight pipe sections of the same size. If at any point the main pipe has to change its direction, then a branch can be created using a tee. If a branch of the perpendicular direction is connected to the main highway, the so-called crosses are needed. These parts are characterized by four outputs and create versatile bends.

If you need to connect highways of different diameters, you will have to buy more adapters. If a new flexible highway is connected to the old rigid line, fittings are required. If one of the ends of the line is a dead end and requires a tight seal, the plugs come in handy. Squares are rarely required, but if the highway at some points should change direction by 90 degrees, then these products will have to be purchased.

Conditionally non-separable elements, which are also called welded, can be used for highways operated in temperature ranges from -70 to +450 degrees. Possible working pressure of the system is 16 MPa. The main difference between these products from others is a smooth surface. The main selection criterion is the identity of the dimensions of the trunks and connectors.

Trunks with semi-detachable connectors can be placed inside structures.

Threaded fittings are ideal for plastics plumbing systems. The thread of the connectors is usually cylindrical. Metal-plastic pipes are supplied with the same thread. Fittings can connect highways with an internal temperature environment up to 100 degrees. The diameter of pipelines, as a rule, is 5 cm. Threaded connectors are used not only for water pipelines, but also for oil pipelines and gas pipelines. They are used in other industries.

One-piece or compression fittings are suitable for the fitting of flexible-type plumbing with the same size. Usually they are also made of flexible materials.In terms of mechanical reliability, these elements are not too good. They are used mainly for systems with cold water. This is because when exposed to high temperatures, flexible materials usually lose their qualities. Due to the fact that the sealing ring of the product is elastic, the tightness of the connections is broken.

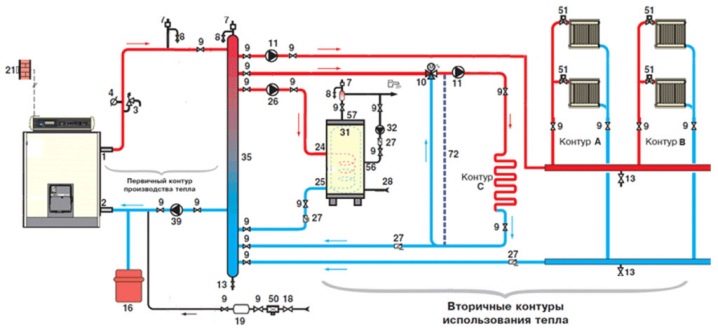

The calculation of the number of connectors can be made in the presence of the scheme of the entire trunk system of metal-plastic pipes. The scheme must include all branches, as well as points, and which will be installed plumbing. At these points, the names of the connectors to be installed should be noted. When the whole scheme is ready, count and write down the desired number of products.

The connecting fittings required for the installation of the system are also selected taking into account the internal diameter of the pipe.

Standards manufacturers vary, but not too (2-3.5 mm).

Installation and replacement rules

Users have long appreciated the main advantage of metal pipes - simplified installation technology. However, compliance with the rules in the work is of no small importance.Careless attitude to the process of assembling and replacing old highways with new ones can lead to negative consequences.

Mounting the plug connector do-it-yourself is very convenient. You can remove and replace the mount if the system is flowing at the junction. It is also possible to reuse the part. Repeated assembly and disassembly is possible due to the fact that the housing of the connecting elements is usually made of metal. At the ends of the parts there is an external thread. A detachable ring and a tightening nut are put on the pipe.

In order to properly connect the trunk with a detachable part, it is necessary to disassemble the elements into components. The parts that are put on the pipe, you need to move a few inches from its end. The connector body of the connector must be screwed into the metal-plastic. On the body part there is a groove in which the end of the trunk should rest.

To the point of contact of the line with the body you need to move the split ring and the swiveling nut. In this case, the ring must be inside. The free element of the connecting part must be secured with a nut.The connection of the part at the initial stage of the assembly of the system is possible with hands, then it should be screwed up with a spanner key.

To achieve absolute tightness of the connection, you need a special tool for crimping. They produce a circular crimp line with a connected fitting. The threaded pair will play the role of a load source. In this work you should not make too much effort. The end of the pipe, pressed against the inside of the connector, may simply burst. The appearance of a characteristic squeak when tightening may indicate the likely formation of cracks on the nut itself.

The category of conditionally detachable fittings includes connecting elements, which are also called compression. These elements also have external threads at the edges. Both ring and cap nut are present. The item is installed only once. Installation of products is generally identical to the installation described above.

The cap nut is put on the pipe. A ring is put on with it. A connector nipple is placed in the pipe end. The nut with the ring is pressed over the point of contact of the union with the line.Sealing rings present in the joint save if the pipe leaks. If a problem arises, the connector can be pulled out, but it will have to be replaced with a new element. Reinstallation is excluded. Crimping is done in an identical way (similar to the first option).

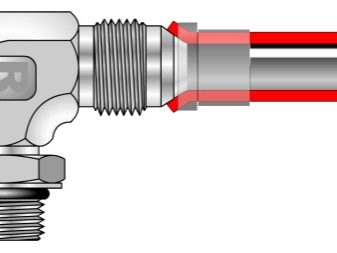

It is impossible to put a press fitting without special tools. This is a must for this part. The press fitting has a similar housing, with mandatory fittings. The difference is the absence of nuts and crimp rings. Here, a special sleeve acts as a tightening element, with which they press the point of contact between the line and the fitting.

When mounting the sleeve is put on the pipe, and the connector fitting is inserted into its end. It is important to achieve the most dense joining of metal-plastic with the connector body. Next, the connection is placed in the vice of the press and molded.

Disassembly of such a connection is not possible. However, tightness in this case is almost 100 percent. Therefore, products can be used in cases where it is necessary to disguise a pipe in the wall.

In conclusion, it is worth mentioning that connectors for metal plastics are made and supplied to the market by leading manufacturers of such highways.For example, the Belgian company Henco is the market leader in press connectors. The company also offers decent compression products.

Another segment representative is Valtec. Compression and press fittings of this company are considered to be of the same quality as the products of the Belgian manufacturer.

A large variety of products offers German brand Rehau. This is a world-famous company that produces high-quality products. However, branded products are usually sold at very high prices.

In order to choose which fitting is better for plastic pipes, see the following video.