Metal pipes: technical characteristics and operation features

Most residents still remember the times when old cast-iron pipes stood in any house or apartment. Buyers go to construction stores to purchase new products to replace old designs. Most buyers prefer metal pipes. What are their advantages over other materials and how to make the right choice, let's talk about it today.

Design features

Being engaged in repair work, each owner of his own home prefers the most versatile and high-quality materials.Their choice should be approached thoroughly and study the technical characteristics of the chosen material in order to avoid various breakdowns and avoid repair work again.

Metal-plastic pipes, due to their universal characteristics, were able to gain popularity among a large number of residents. They are widely used because of the unique combination of positive characteristics that metal and plastic have.

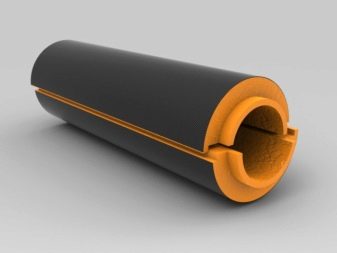

Each layer of the product serves to perform certain tasks. Thus, the inner layer of polyethylene prevents the deposition of salts, scale on the wall. Both layers of material will reduce thermal conductivity, reduce the likelihood of condensation.

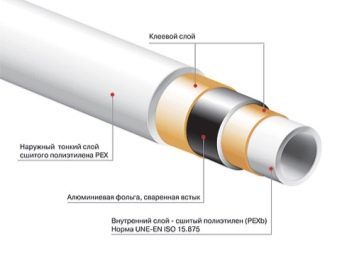

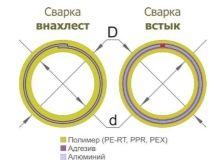

The metalplastic pipe consists of several layers.

- The inner layer is made of polyethylene to give strength, the second layer is aluminum foil, it is used as a stabilizer. To join these layers using a special glue, and the edge of the foil is connected using laser welding.

- The outer layer has a beautiful white color.

Metal pipes can be called universal materialwhich can be used separately and with other types of pipes. Metal pipes use:

- to supply water of different temperatures;

- in the heating system (for radiators, when installing the heated floor);

- in the water treatment system;

- when heating the landing;

- for heating the soil in greenhouses;

- in the pool heating system;

- when laying plumbing and heating systems, in other areas.

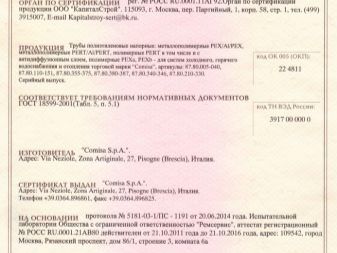

It is easy to work with such material, besides such constructions will last for 50 years. Production and quality of products should be regulated by state standards. According to GOST:

- The maximum allowable temperature for metal-plastic products for 9 thousand hours is 95 degrees Celsius.

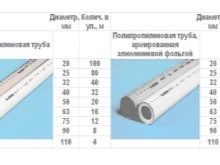

- Products are divided into groups according to their diameter. For group 1, the pipe diameter is 10.0-63.0 mm, for the second group, the diameter is 75.0-110.0 mm.

- Products differ in the way of delivery. For the first category, manufacturers supply pipes in coils or in lengths. In the measured segment should be no more than 12.5 meters, and the bay should have a footage of a multiple of 100. For the second category, the delivery is made only in measured segments.

- Pipes are divided into types depending on pressure. The first category includes pipes with pressure up to 0.6 MPa, for the second group the working pressure will be up to 2.5 MPa.

All pipes manufactured according to GOST standards have a certificate of product quality.

The outer diameter of the MP-pipes may have different sizes. The most common parameters are 16 mm, 20 mm, 26 mm, 32 mm and 40 mm. These sizes are considered the most popular, pipes with a larger diameter for home repairs are rarely used.

The inner diameter is also called the nominal diameter; it can depend on the size of the outer diameter and on the wall thickness. The internal diameter is needed to make calculations for water flow, to determine the pressure and the right temperature, and to connect the fittings for installation.

The wall thickness should depend on the outer diameter and on the materials that were used in the manufacture. Wall thickness can be from 2 to 3.5 mm. These parameters depend on each specific manufacturer and on their standards.

Pipes of this material are plastic, which allows for installation to bend them.You need to know that the minimum bending radius of the pipe is 12 cm. In case there is not enough experience in this case, you can increase the radius to 15 cm. To bend the pipe at a certain angle, you need a pipe bender. It can be manual or electrically operated. For home repairs will be enough manual pipe bender.

To bend the pipe, it is necessary to insert a steel spring of the desired size into the pipe section and bend the product at a certain angle. Next spring must be removed. Using a manual pipe bender, you can bend the pipe at an angle of 180 degrees. To ensure the branching of the pipeline, you must install a tee.

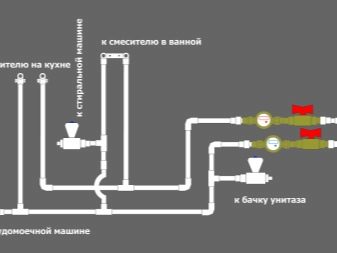

When performing repair work, for example, during the construction of a bathroom, it is worth considering the option of collector water distribution. The advantages of this method:

- Convenience. All communications will be in one place, which is very convenient, especially if you want to turn off a tap when there is no man in the house. You do not need to go under the sink to turn off the mixer.

- Reliability. From the collector to the consumer will pass a solid pipe.When choosing a quality product, leakage in the wired walls will be excluded.

- There are no pressure drops. When the collector wiring will not pressure drops, for example, if you use two sinks at the same time.

The collector is installed so that it is possible to ensure the distribution of water flows. To make it clearer, you can call the collector a set of cranes, which are connected to one product. Metal-plastic pipe is connected to the manifold, as well as to the crane.

The disadvantages of this method include only its high cost, since water distribution with the help of collectors will be more expensive with the purchase of material and its installation, especially if you need to resort to the services of a specialist. In addition, you should determine in advance the place where all this will need to be placed. Collectors can be 2, 3 or 4 outlet, you can make a collector and 5 outputs (3 + 2).

To prevent stratification or rupture of the pipe, it is necessary to withstand the working pressure. Find out what pressure can withstand pipes from MP:

- If the temperature of the liquid is about 20 degrees Celsius, then the working pressure should be up to 25 atm.

- If the temperature of the liquid is 95 degrees, in this case the pressure should not be 10 atm. Sometimes it can be an increase to 15 atm for a short period of time.

If the pressure increases, the pipe may begin to exfoliate, leading to its rupture.

To choose a quality product, you should look at the marking, which is applied at certain intervals on the outer surface of the pipe and decode the designation. This will facilitate the selection of the product, because by marking you can find out the following information:

- who is the manufacturer of these products;

- trademark;

- type and method of use of the product;

- pipe wall thickness and diameter size;

- Recommended operating parameters, i.e. maximum temperature and operating pressure;

- availability of a certificate confirming that the material meets the standards and criteria;

- brand - the letters PP-R indicate that polypropylene was used to create pipes, the letters PE-R, indicate that polyethylene was used, PE-X stands for cross-linked polyethylene;

- diameter and wall thickness, which are specified in mm or inch;

- possibility of use for drinking water;

- batch number and date.

Advantages and disadvantages

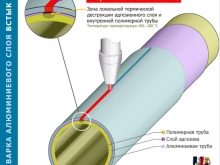

Pipes made of metal differ in the method of joining foil. Distinguish the technology of laying overlap and butt with the use of welding. Manufacturers that produce quality products that are durable and reliable, choose a method using butt welding. Such a seamless technology is considered more expensive, because it requires expensive equipment, but using this method, the seam is more reliable.

If the weld overlap, then normally the pipe will not bend, because the seam will interfere. When bent, it may fold up like an accordion or begin to crack. If the pressure on the seam is increased, it can lead to its rapid destruction. Although sometimes this option is chosen, assuming that fittings can be used at bend locations, but taking into account their purchases, it will not be possible to save.

The material is widely used, as it has a number of undoubted advantages:

- Weight. If we compare it with other metal structures, the weight of the pipes is much smaller, which noticeably facilitates the work of carrying out the installation or dismantling during the planned or unplanned repairs.

- Does not corrode.For the manufacture of products using layers that will not be subject to destruction under the influence of moisture.

- They are resistant to silting and overgrowing.

- High throughput, which is almost 1.3 times the permeability of metal pipes.

- It is resistant to chemicals.

- Low thermal conductivity. This indicator is very good for the heating system, since during transportation the water will be hot.

- The noise level will be much lower than that of metal pipes. Many people remember how strong the noise was in the chimney in the risers of an apartment building. When replacing metal products, this noise will no longer exist.

- Linear expansion will be low due to aluminum reinforcement.

- You can not withstand perfect accuracy in the calculations and in preparation for installation.

- Does not require painting or finishing work.

- Can be mounted inside walls.

- Easy to assemble. You can install metal-plastic pipes yourself, without the involvement of craftsmen.

- At installation there is no need to use expensive equipment in the form of a welding machine.

- Durability of designs.Metal-plastic pipes are distinguished by reliability and durability, the service life of products is 50 years, if the temperature of the medium is maintained at about 20 degrees. At high temperatures, the service life of the product will be less (about 25 years).

- The pipes are able to withstand pressure drops, the so-called hydraulic shocks.

Now you should consider the existing disadvantages of products made of metal:

- not used for wiring fire pipelines, as the material is combustible;

- the scope is limited due to temperature changes - this material is afraid of freezing, and you should not use it at very high temperatures;

- MP pipes cannot be defrosted, as they can become fragile and begin to crumble;

- they are not used outside, as the material does not tolerate ultraviolet radiation;

- when using a large number of fetings, the throughput of the pipe will be significantly reduced.

- when performing repair and installation works, there are cases when mechanical damage to the pipeline may occur, this is especially true for open communications;

- metal-plastic pipes are not used if there is a heat source in the room with a temperature reaching 1500 degrees;

- do not use at excess of pressure of 10 bars.

Choosing products from metal-plastic for home communications, it remains only to evaluate all the positive and negative properties, study the reviews of buyers and craftsmen and make the right choice.

Materials

Let us dwell on the use of pipes where cross-linked polyethylene is used. They are chosen:

- at connection of cold and hot water supply;

- when connecting the heating system;

- at installation of a water heat-insulated floor.

At installation of a heat-insulated floor there can be a question which material is more suitable: plastic or cross-linked polyethylene. This issue will help to understand the views of experienced professionals.

The pipe from the sewed polyethylene will differ in special durability. This is a high-tech material that has a high-quality molecular structure. Designate such products by the abbreviation REX.

Pipes made of metal-plastic and cross-linked polyethylene have always been considered competitors in arranging water pipes, heating systems and installing underfloor heating.

These types of pipes are flexible, durable and have good corrosion resistance. It is easy to work with them, besides at installation there is no need to resort to welding works.Although metal plastic is still easier to mount than REX products.

Metal-plastic pipes do not tolerate freezing inside, while REX-pipes and after thawing will be suitable for use, moreover, they can easily restore shape. Determining the choice, buyers are guided by the features of the operation of this material and on their own budget. REX pipes are often cheaper than competitive products.

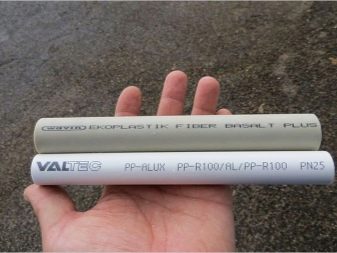

For many buyers, it is not always clear whether the pipes are made of polypropylene and metal-plastic. Since the area of their use is identical, they can be considered competitors. The basis of these products is plastic, so their characteristics in most of the moments will be the same. But these products differ in performance.

Recently, an antioxidant has been added to polypropylene pipes to make it resistant to oxidation by chlorine, so they can be used when transporting drinking water.

Let us dwell on the technical characteristics of pipes based on polypropylene:

- the maximum allowable temperature is 95 degrees Celsius;

- The maximum pressure is considered 25 atmospheres, if the temperature is no more than 25 degrees, and 7 atmospheres, if the temperature is 95 degrees Celsius;

- when hot water comes in, the product will last for 25 years; when cold water comes in, it can be over 50 years;

- due to the low cost of components, the installation of such a water supply will be much cheaper;

- reinforced plumbing can be mounted under the tile.

Now it is worth considering the disadvantages:

- no resistance to ultraviolet rays;

- do not use for the objects having high fire danger;

- their installation is more complicated, since the pipe is not bent;

- for hot mounting, special tools are required;

- pipes do not use in regions with very low temperatures.

Scope of application

Products from metalplastic steel became habitual in use for a long time and are applied in both in life, and on production. Due to the excellent technical characteristics of the product can be in operation for a long time and remain the same quality and reliable. Metal-plastic pipes are used:

- For plumbing. Metal products choose when replacing water supply, if you need a scan. Repair work can be carried out quickly, even without relocating the tenants.

- For cold and hot water supply, heating.

- For transportation of compressed air.

- To protect electrical wiring.

- For air conditioners.

- In production, agriculture is used in the transport of water, used for gas.

- When supplying compressed air.

- As a screen to protect cables.

Criterias of choice

As soon as metal-polymer pipes appeared in Russia, they immediately gained universal recognition. Sales were steadily increasing, although many were wary of new material. At first, valves and pipes were supplied from Europe, but since such products were of very high quality, their price was high. When China started to manufacture pipes, the price of products immediately fell, but the quality of products turned out to be lower. Some time later, Russia was engaged in the production of such products.

- Products made of polyethylene and aluminum will have different indicators, which depend on the diameter. The degree of pressure will depend directly on the selected diameter, so when installing, you need to figure out what pressure the pipe can withstand. May need a larger diameter material.

- In order for products made of metal-plastic to heat the housing well, it is necessary to calculate the heat transfer. The heat transfer of the plastic pipe will be 175 times lower than that of steel products, its coefficient is 0.36.

- Attractive appearance of the products allowed to carry out installation work without breaking the wall. Such pipes were laid outside the walls. This greatly facilitates the installation and repair of water supply.

- To select the desired material, you can look at the label, which is indicated on the product at regular intervals, or to specify the data from the seller in the store or on the market.

- Having carefully studied the labeling it becomes clear how the material is suitable for each situation. Experienced craftsmen recommend to opt for a pipe with 2 layers of cross-linked PE-X / AL / PE-X polyethylene or PE-RT / AL / PE-RT. These polymers are perfectly combined with each other. In the event that the layer consists of PE (ordinary polyethylene), it means that it is suitable only for cold water, when heated to more than 60 degrees, a leak occurs.

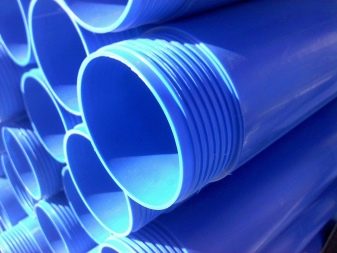

- If you want to select a product for a well, the metal-plastic pipe will successfully replace a metal or asbestos-cement pipe. Currently, a casing pipe with a thread is used for wells, thanks to which a durable and robust frame will be created inside the hole.A submersible pump will fall inside the frame.

- They produce such products with a diameter of 9-40 cm, most often in demand are the sizes of products from 125mm to 225 mm. If you use it at a shallow depth, a pipe with a standard wall thickness will suffice; at a greater depth, you should choose a product with walls at least 9 mm thick. PVC casing products are available in blue.

Fixing the casing in the well occurs due to friction on the ground, so its caliber is worth taking 10 mm more than the diameter of penetration.

Popular manufacturers

Being in a hardware store and choosing a plastic pipe, you can immediately see the familiar names, which many have heard, there are also little-known companies. Many countries, including Italy, Germany, Russia, and China, are engaged in the production of metal-plastic pipes. Let us dwell on the most well-known companies, whose popularity is evidenced by the rating:

- Stout. This company is engaged in the manufacture of pipes for heating. Products of Italian masters are excellent flexibility. The company manufactures products with a diameter of 16 mm, with a wall thickness of 2 mm.

- Oventrop. Pipes made in Germany have proven to be the most reliable. The company has launched the Copipe HS line. Its peculiarity is that even if the upper layer is damaged, all product characteristics will be fully preserved. This pipe does not need to be repaired, even after damage it can withstand pressures of up to 10 atmospheres and temperatures of 100 degrees. Oventrop produces products with a diameter of 16 mm, sell them in the bay at 50, 100 and 200 meters.

- Valtec. China also began manufacturing pipes that are ideal for heating. The manufacturer gives a guarantee of 10 years for its products. This product has a drawback - its thickness is only 12 mm. But such a product will be able to withstand frequent changes in temperature.

- Prandelli. Products of this Italian company are rarely seen in Russia. Judging by the reviews, these products are characterized by a long service life, but at the same time they have the disadvantage of a high price. The pipes have a diameter of 16 mm with the type of stitching RE-XB.

- Henco. The Belgian company that manufactures pipes, gives a guarantee of 12 years for its products. Products are covered with corrugations of different colors, which is convenient when installing hot and cold water.

- Unifit. The Turkish company was established almost 5 years ago. The company is engaged in the production of seamless plastic pipes.

- Rehau. Many are familiar with the products of the German company Rehau, which is engaged in the production of pipes for heating and water supply. With proper use of products, their service life may be more than 50 years. Products have low weight and high flexibility.

Installation

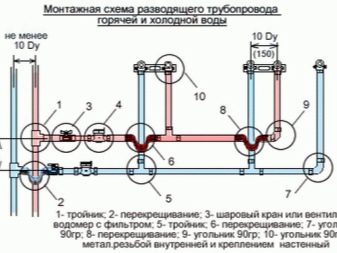

Before starting work, you should decide how the pipes will be placed. When developing a scheme, you need to consider that:

- lines are applied directly to the wall to make it easier to work;

- the starting point may be the place where the pipe will be connected to the radiator or tap;

- the number of crosses, tees and fittings should be minimal;

- it is necessary to provide free access to all elements;

- installation of connecting elements involved after marking and completion of calculations.

If you need sewer or plumbing wiring, you can not do without the installation of pipes MP.

Usually, when they are planning to change pipes, they do it in all the rooms, capturing the kitchen, bathroom and toilet. If you need to install the mixer in the bathroom or connect to the radiator, you can do all the work yourself, having at least some experience in installation work.It is necessary not only to carry out installation work correctly, but also to connect all systems to communication.

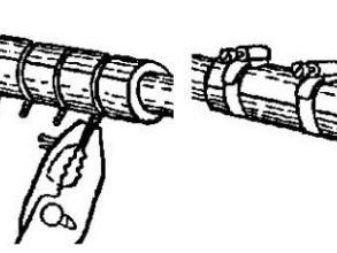

Fastening of pipes from metal-plastic is made with the help of special devices. Fasteners (special plastic clip) is fixed with screws or dowels, later pipes will be inserted into them. Fixing plastic clips is best done before assembling the entire structure.

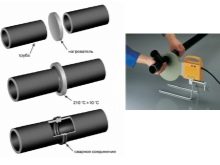

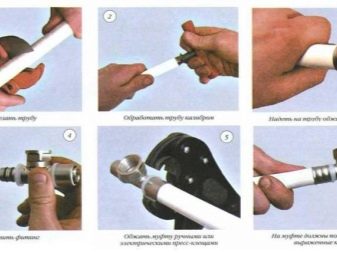

The connection of products is carried out using fittings. They may be different from each other, but they should always have a part that is inserted into the cavity of the pipe and crimp sleeve (ring). It is put on top and compressed tube. Crimping is performed using a special press or simply using press tongs.

When doing the installation yourself, you need to know that the distance between the supports should not be more than 1 meter so that there is no sagging.

For bending products using a pipe bender, thanks to this device, you can provide the necessary radius for bending. If you strongly bend the pipe at a very sharp angle, there is no doubt that the product will be damaged. You should not try to fix the damage, arching the pipe back. This will not give the desired result.It is necessary to cut the desired part, and using fittings, dock.

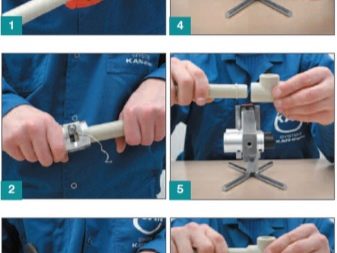

Creating a design of metal, just enough of a few tools. To pipe laying was successful, you must take:

- Pipe cutter to separate the measured pipe sections from the coil. Metal-plastic is pliable material, so you can use metal shears, a sharp knife or a hacksaw to cut it.

- Different types of keys that will be useful when assembling connections for fittings, scissors.

- Caliber. This is a very necessary tool to help create the exact and tight connection of the fitting to the pipe.

- Pipe bender Such a tool will allow you to change the configuration of the product, so you can not buy corner fittings. The pipe bender is very convenient, especially if you expect a lot of corner joints.

These are only the main components that will help with the installation of plastic pipes.

A successful installation option can be considered a hidden room pipes in the channels, grooves and mines. We should not forget that there should be free access to all connections, the installation of removable covers or doors will eliminate this problem.

To ensure the branching of the pipeline, you must install a tee. If it is hidden in the floor or walls, the installation is best carried out in the casing (the method of "pipe in pipe"). Before the final seal, the pipeline is completely mounted and tested with a water jet.

If pipe coils have been stored for a long time at low temperatures, they are kept for 24 hours in a room with a temperature not lower than ten degrees before rolling.

During installation and unwinding it is important to ensure that there is no twisting of the pipe.

To avoid this, it is necessary that the marking is always on the front side of the product. Laying is carried out without tension, plugs will protect the product from contamination. If we talk about the dismantling of plastic pipes, then this process is simple and fast.

Repair and service

Pipes made of metal have very high technical characteristics, with proper operation, the life of this design can be about 50 years.

But failure can occur due to the fact that the connection of parts was not carried out at the proper level or the elements themselves did not meet the technical specifications.The leakage can be in the place of pipe joining or when it is connected to the general system of the house to pipes made of steel.

Breakage may be due to poor-quality fittings or in the event of improper installation. If the cause of the leak is a fitting, you can fix the break with your own hands by shunting. For this, the piece of the product where the leak was formed is cut out, then it is replaced.

To do this, a piece of copper pipe of the required size is selected and fittings are installed on its ends. Copper pipe should be pre-cleaned, get rid of dirt or dust. Then the fittings of the copper tube are inserted into the fittings of the metal-plastic pipe and pressed. In the place of a leak the soldering is made, for this the joint is heated with a soldering iron or a hairdryer.

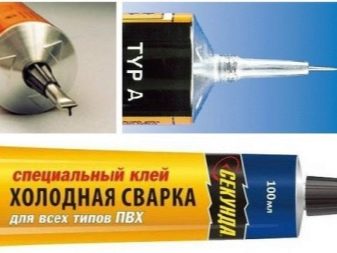

There are cases when the pipe bursts along. In this case, its complete replacement is required. But if a leak has arisen, and there is no possibility to change the pipe quickly, emergency measures must be taken. To temporarily block leaks, use bandage or cold welding. To make a bandage, the place of leakage is closed with a piece of rubber and secured with hose clamps.

If the crack is small, you can repair it by cold welding. To do this, it is necessary to drain water from the damaged area so that the water pressure does not put pressure on the patch. The area to be repaired must be dry. After repair it is cleaned with sandpaper and left to dry for a day.

If a rupture occurs, dry welding may not always help. It is used depending on how much pressure in the pipeline and on what temperature water flows in the pipe.

When the cold comes, many residents of private homes are worried that they do not know how to warm the pipe under the ground if there is no direct access to it. When ice forms, water can increase in volume, which can lead to rupture or cracks in the walls of the pipeline.

In order to prevent the formation of ice jams, during the installation and installation of communications it is necessary to comply with building codes.. The minimum depth of their flow should be below the maximum depth of soil freezing.

When laying communications, pipes with a diameter greater than 48 mm are taken, since thin structures will freeze over the entire thickness. It is better to lay the pipeline in the ground closer to the wall, to structures made of concrete or brick.

To protect against the cold, polyurethane or polypropylene linings or mineral wool sleeves are used. In rooms that will not be heated in winter, the water from the pipes must be drained to avoid a breakthrough.

After replacing old pipes with new ones, many are beginning to wonder whether they can be painted. Conventional enamel paints are not suitable for painting plastic products; it is worth taking an alkyd or polyurethane acrylic paint for plastic. To put it on the pipe, you will need a spray. Before painting, the product is degreased and a primer intended for plastic is applied.

Plastic can be of different types, so some materials will be difficult to paint. So, pipes made of polyethylene or propylene will not be well painted over, any paint will slit from the surface.

You will never have to face the replacement or repair of plastic pipes, if you install everything correctly, purchase quality material in proven places and from reputable manufacturers.

About the characteristics of the plastic pipes, see the following video.