Methods for joining metal pipes

Metal-plastic pipe is a universal product used for the construction of plumbing and heating systems.

By combining metal and polymer, the engineers created a design that does not threaten either large temperature loads or other negative factors.

Purpose

Being engaged in repair or construction, everyone tries to use high-quality materials. It is for this reason that when connecting heating, plumbing and in other areas mainly plastic pipes are used. They stand out among others for their durability and extraordinary durability.

The main advantages of metal pipes are several important properties.

- Durability.

- Heat conductivity is low.This feature allows you to use them as a hot water pipeline.

- The manifestation of resistance at high temperatures.

- Tightness. A pipe of twenty millimeters does not allow light and oxygen to pass through.

- Frost resistance Metal pipes do not deform at a temperature of minus fifty degrees Celsius.

- Resistant to corrosion.

- Thermal effects do not expand.

- Resistant to salt deposits.

In addition to the advantages, there are drawbacks to such pipes.

- The thermal conductivity of plastic is much less than that of aluminum. If you first piped hot and then cold water through the pipes, the metal foil (after expansion) will take the original form faster than plastic.

- Metal-plastic pipe may leak at the junction where the device is weakened. Differences in metal and plastic expansion ratios are a major disadvantage. Therefore, this feature must be taken into account during installation. But it should also be remembered that pipes should be laid with a margin. In places of a pipe bend the compensation loop is installed.

- Leaks may occur for another reason.For example, aluminum wire bends in different directions, but it can break when trying to regain its original shape. The same principle with metal pipes. Plastic makes aluminum more plastic, but bending at an acute angle is contraindicated. Otherwise, a breakthrough will occur, which can only be corrected by replacement.

Table with minimum bend radii

Outer diameter of metal-plastic pipe (millimeter) | 16 | 20 | 26 | 32 | 40 |

Type of pipe bending | Minimal bending of metal-plastic pipe | ||||

Independently (manually) | 80 | 100 | 130 | 160 | 550 |

With the help of springs | 50 | 65 | 105 | 135 | 220 |

With a bender | 45 | 60 | 95 | 125 | 180 |

When choosing a pipe, it is necessary to build on the length of the universal product. The standard length of the design being sold varies from fifty to two hundred meters. However, you can buy products and shorter (depending on the scale of the planned repair).

It is also necessary to pay attention to the internal diameter. It is considered the thinnest pipe of sixteen millimeters. For a house or apartment, experts recommend purchasing a product that has a small diameter. The best option can be considered a pipe with a diameter of twenty millimeters.

Before deciding how to connect metal-plastic pipes to each other, one should proceed from the budget and the focus of the system.

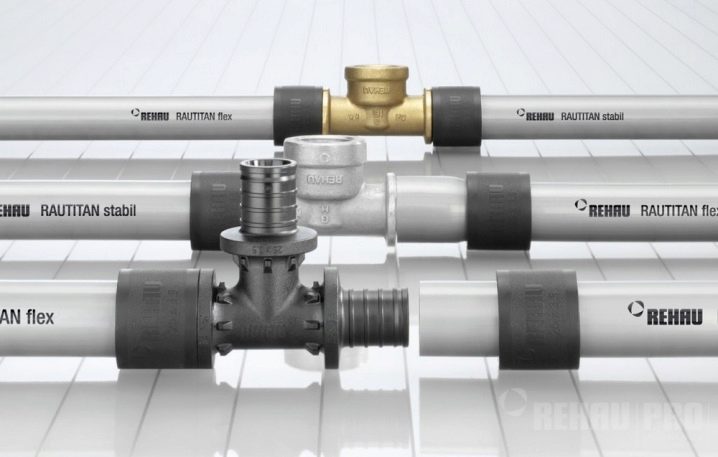

Metal-plastic pipes are connected using special compression fittings made of brass. Fittings may vary in design, but all have a main part that fits inside the pipe and the ferrule that is worn on the outside, which serves to crimp.

The following table shows the general characteristics of all metal pipes:

Temperature coefficient | 95 degrees Celsius |

Maximum short-term temperature | 120 degrees Celsius |

Pressure ratio | 10 atm |

Maximum short term pressure | 15 atm |

Heat expansion coefficient | 0.026 mm / m per 1 degree Celsius |

Heat conduction coefficient | 0.45 W / mK |

Suitability | 50 years |

Table of technical characteristics of interdependent components:

Outer diameter (millimeter) | 16 | 20 | 26 | 32 | 40 |

Inner diameter (millimeter) | 12 | 16 | 20 | 26 | 33 |

Wall thickness (millimeter) | 2 | 2 | 3 | 3 | 3,5 |

Weight of one running meter (kilogram) | 0,12 | 0,17 | 0,3 | 0,37 | 0,43 |

Internal volume in one running meter (liter) | 0,12 | 0,2 | 0,32 | 0,53 | 0,86 |

Connection methods

Metal pipe is assembled using various options. The assembly method depends entirely on the type of fitting chosen.

Metal-plastic piping works well with these types of fittings:

- threaded;

- welded;

- crimping.

Threaded fittings are familiar to anyone who has worked independently with plumbing. Welded - a great option if you have a special welding machine and time.

As for the last option (crimp type), such fittings work on crimping. For pressing of this type manual press pincers are used.

The types of plumbing fittings for metal-plastic pipes differ in diameter and material used for their manufacture.

If you are going to do the installation of the plumbing system with your own hands, then you will be interested in the following information.

To implement this procedure, you must:

- cut off the necessary part of the pipe with special scissors;

- to clean the edges from metal burrs using a file;

- apply silicone grease to the fitting fitting;

- to establish a cap nut and compression ring on the pipe;

- the product must be mounted on the fitting nipple (when performing the procedure, it is necessary to be extremely careful and not to damage the sealing rings);

- the final action is to tighten the connections with a wrench.

And also there is an instruction for installing a compression fitting for plastic pipes, how to connect the hose.

- First of all it is necessary to study the layout of the sewer. It is necessary to take into account the peculiarity of this system, the number of turns and tees in this area (this affects the number of clamps).

- Further the pipe of the necessary sizes is cut off. The edge of the communication should be treated (wiped, degreased with a solution and cleaned using brushes). Look carefully at the junction points - there should be no chipping on them, otherwise there will be a leak when the water is turned on.

- At the input ends chamfer in one millimeter with an angle of forty-five degrees, which are cut by the faskosnimitel.

- This is followed by installation: the installation of the nut, and the compression ring is put on the piece. The fitting needs to be greased with oil or sealant for a better threaded connection. This operation does not require special equipment, you can do with a gas or plumber wrench.

- Making the fit of the nozzle, it is necessary that the pipe rests against the edges of the limiter.

- At first, the connection must be made manually. Screw the nut on the nozzle until it stops, then twist it with a wrench. Do not overtighten the threads; this can lead to tearing. Also, do not pinch the nut.

- At the end of the work, the joint should be covered with a film to protect it from pollution and steam.

Working with a threaded connection, do not forget to cover the junction with a sealed sanitary tape. This will ensure a high level of tightness in the sewer system.

This method requires good thread care. When disassembling, you should also change the ring (even if there is no leak). Despite the peculiarity of operation, once a year it is necessary to check the threads and change the gasket.

Types of tools

To facilitate the work, several variations of this equipment have been developed.

Hand drive

Crimping pliers, which are manually operated, are most often used as a clamp at home. Such equipment differs from other nuances at exploitation and reasonable price.Most of this equipment has a universal crimping head, removable inserts for a pipe clamp with a diameter of ten, fifteen millimeters, and so on. About clamps with a diameter of forty millimeters - no speech. The border for the hand connector is thirty-two millimeters in diameter. The main disadvantage of such equipment is a large size and limited capacity, and therefore the connection process is not always convenient.

Hand tools for mounting metal-plastic pipes are divided into several types.

Mechanical

The mechanical equipment consists of two handles, which are connected to the head by a gear mechanism. The applied force is transmitted to the head, and the coupling with the fitting is compressed.

The structure of the manual pressing machine is often made with telescopic handles that assist in adjustment.

Hydraulic

Make yourself a tool with a hydraulic connection - a problem. But the hydraulic pipe bender is much easier.

However, this initiative is not always reasonable. It is easier and safer to purchase Valtec factory tongs or their equivalent, not less quality.

Among the features of hydraulic mites, there are several.

- The tool has two handles, one of them is connected to a hydraulic cylinder.

- The output cylinder rod is mechanically connected to the crimping head.

- The second knob is connected to the piston of the cylinder.

- When gripping the handles, the piston enters the cylinder. This creates pressure transmitted to the head through the output rod.

- The installation of the coupling and fitting occurs with minimal effort. The price of this device is much higher than mechanical, and it needs maintenance.

Electro-hydraulic option

Electric, or rather, electro-hydraulic drive - the advantage of professional devices.

Small electro-hydraulic tongs are very light and very easy to use, but at the same time they are quite high-performance. This contributes to the easy connection of metal-plastic pipes, their diameter is mainly one hundred and ten millimeters.

Models of electro-hydraulic devices are divided into several types.

- Network tool. To start operating press jaws must be connected to a standard household outlet with a capacity of two hundred twenty watts.

- Rechargeable. This device is completely autonomous, as the operation takes place with the help of built-in batteries.

- Universal. It differs autonomous performance or from the network, it all depends on the situation.

All high-quality electro-hydraulic press tongs are equipped with removable universal heads that adapt to a specific diameter of metal-plastic pipes.

If you have a pipe bender and hand-held tongs in your arsenal, then you can easily make the organization of communications in your house, manor, apartment. To use this type of device will have a little practice. However, after several attempts, you will easily master all the nuances of working with press tongs.

In addition to the acquired pipe and the necessary fittings, you will need a few more fixtures.

- Truborez. A scissor-like tool that provides the right cut is perpendicular to the tube. What is important in the work.

- Calibrator / gauge - a device created for plastic pipes. When cutting the pipe is flattened slightly, and the edges are bent.The function of the calibrator is to restore the shape and alignment of the edges of the metal-plastic pipe.

- Countersink - a device designed for chamfering. A construction knife and a piece of emery paper may well fit. Quite often, the calibrators have a projection for chamfering, so you can do without this tool.

Application features

There are many ways to use metal pipes, namely:

- if necessary, transportation of air under high pressure;

- in various systems of air conditioning and ventilation;

- arrangement of the electrical line of metal-plastic pipes, often used as a protective element;

- in the agricultural and industrial sphere, which are aimed at the transfer of liquids and gaseous substances;

- protection and shielding of electrical power and other wires;

- construction is used in the heating system (floor and radiator).

Metal pipes are ideal for greenhouses, greenhouses, as well as heating pools. They are used for heating open areas. And, of course, indispensable for the supply of hot and cold water.

The use of plastic material in the manufacture of metal pipes does not have in its structure harmful impurities, which makes the product suitable for drinking water supply systems.

However, when using metal-plastic pipes, there are limitations.

In no case can they be used in the following cases:

- devices of the central heating system with elevator nodes present in it;

- in the room to which category “G” was assigned according to the fire safety standard;

- the proposed flow of fluid through the pipes has a pressure in excess of ten bar;

- in a location with sources of thermal radiation with a surface temperature above one hundred and fifty degrees.

But metal-plastic pipes are also used if you are thinking of doing the disassembly yourself. The main rule for dismantling old water pipes is to interfere with the interior with minimal damage to the room. Basically you have to replace the water supply and sewage, and here come to the aid of metal pipes. And collet fittings provide a quality connection.

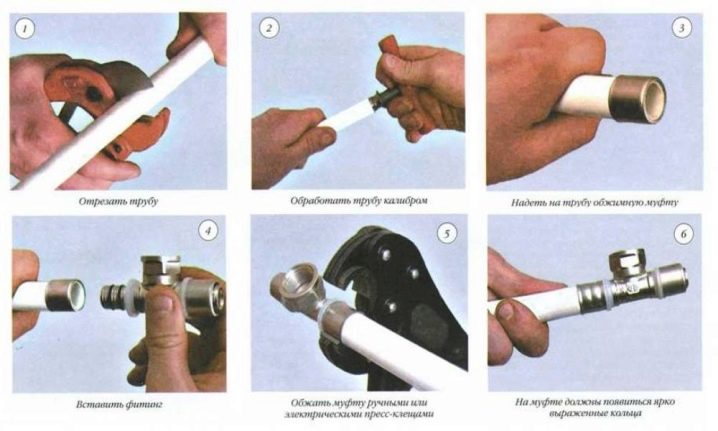

Installation can be done using a pressure connection.

It has the following order:

- using specialized scissors, cut a metal-plastic pipe at an angle of ninety degrees;

- tool calibration and sweep are used when chamfering;

- At one end of the metal-plastic product a sleeve should be worn, which is made of stainless steel, then we place the shaped part of the connector so that it reaches the end;

- manually or on hydraulics pressed, after which the handle of the tool is reduced to the end.

This technology is nothing complicated and scary, if you do everything right.

From here we can come to the conclusion that plastic pipes are ideal for various means of communication, connecting the riser.

This frequency of use of structures associated with their low weight. In addition, this device has a working look that does not require additional costs for painting. Joints at the junction have hermetic insulation, contributing to the high growth of service.

The operating pressure of such products does not exceed ten atm. As well as the low perceptibility of noise in the sewer system.

You can see about this metal pipe and its assembly instructions in this video.