How to bend a plastic pipe?

The times of extensive use of expensive, bulky and corrosive metal pipes in the home are gradually disappearing. Increasingly, water, gas pipelines and heating systems are carried out using polymer and metal-plastic pipes. But for their proper installation, it is important to know some of their features, in particular, it is very important to be able to bend the metal-plastic pipe correctly at home, without putting it at risk of destruction.

Properties of metal pipes

Metal-plastic pipes are usually made of a laminated composite material, in which layers of polyethylene, a binder and a metal foil, usually aluminum, alternate one after another.The main advantage of such products over polymer is the ease of installation, which is carried out using various fittings (detachable, compression and press fittings).

Such parts are usually supplied in the form of straight segments of different lengths or already curved products. Selection of curved products for the real conditions of the room where they will be used may be delayed, and far from all the required configurations are on the market. Therefore, sooner or later, any home artist will be faced with the need to bend such parts on their own. Improper bending may damage the inner metal layer, resulting in leaks or destruction.

Flexion techniques

The four most common methods of bending metal-plastic products are most common:

- manual;

- using sand;

- using wire;

- using a spring;

- using pipe bender.

Consider each of these methods in more detail.

Manual bending

This method does not require any additional tools, but it requires considerable physical effort. The main thing is to carry out all operations carefully and gradually with manual bending.The angle of each bend should not exceed 20 degrees, each subsequent bend is carried out at a distance of 1-2 cm from the previous one. So, for a full reversal (180 °) will need about 15 bends. It would be best to first bend the pipe at an angle a little larger than required, and then bend it back - so the pipe would be much better to keep its shape.

Even with maximum care, the probability of pipe breakage during manual bending is maximum among all existing flexion methods. Therefore, “in pure form” this method is used only for products of small diameter (up to 1 cm), in other cases, additional devices are usually used to protect the product from the risk of damage.

Sand application

In the simplest case, the application of this method will require only a certain amount of ordinary sand and any plug that can reliably close the openings of the pipe. To bend the pipe, it is necessary to completely fill with sand and close both holes. After that, the actual manual folding is carried out, while the sand protects the material from damage. To reduce the required effort, one end of the pipe can be gently clamped in a vice.The advantage of this method is the uniform filling of the internal volume of the product with a protective material, and its main drawback is the need to clean the room from the sand after its use.

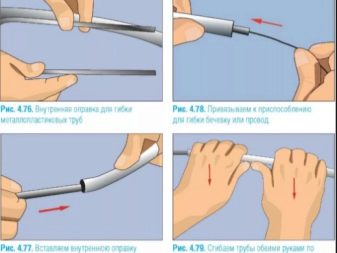

Wire use

Instead of sand, pieces of soft wire can be used to protect products from deformation. You can use almost any soft wire, copper and aluminum are especially well suited. The wire must be cut into small pieces of a length of 30 cm and fill the pipe being bent with them. We need to strive to create as much as possible the density of the wire inside the pipe. After that, the bending is done manually. After bending, it is important to remove the wire pieces one by one, and not all together with a “bundle”, otherwise the curved product may be damaged.

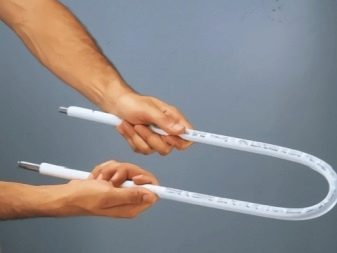

Spring bending

There are two options for bending with the help of a spring - either it will be placed inside the pipe, or outside. In any case, the diameter of the applied spring should not differ from the diameter of the product by more than 2 mm. Like the two previous methods, the task of the spring in this case is to take on some of the effort and protect the material of the part from destruction.When the spring is placed completely inside or outside the pipe, you can proceed to manual bending. This method is also suitable for bending fairly long pipe sections - to accommodate a spring inside such a product, it is sufficient to tie a long thread to its end and pull the spring behind it.

This method can be carried out using any spring of a suitable diameter, but special springs are available on the market, specifically adapted for bending products of certain diameters. This spring is called the conductor, and its cost starts from 130 rubles.

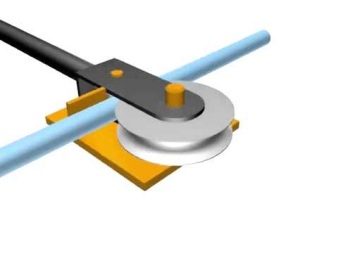

Use pipe bender

The safest method for the pipe and at the same time requiring minimal effort from the operator is the method of pipe bending using a special tool known as a pipe bender. Its application is possible for pipes of any diameter and quality. The principle of operation of such a device is to automatically create a smooth effort, necessary and sufficient to bend the pipe.

According to the principle of action, benders are divided into:

- manual - the muscular strength of a person is transmitted to them through a system of levers to a pipe;

- electrical and electromechanical - in them the source of force is the electric motor;

- hydraulic - create or transmit force using a hydraulic drive;

- electro-hydraulic - transmit force from the actuator using hydraulics;

- heating - bending using induction heating.

For home conditions, the simplest option would be to buy a so-called crossbow manual pipe bender.

Bending with it is as simple as possible. - the required angle is set on the device, after which the bendable pipe is fixed in the device. After that, it is enough to manually reduce the tool's handles, and the pipe will be bent to the required angle. The cost of such a simple and effective tool will be from 1200 rubles.

How to estimate the length of the bend?

The radius of a properly made bend should be half the circumference of the pipe.

Therefore, the length of the pipe section to be bent can be calculated using a simple formula: l = 2 · π · d / 2, where:

- d is the diameter of the pipe;

- π - can be taken equal to 3.14.

Useful tips

If using methods based on manual bending, additionally heat the place of bending with any hairdryer or blowtorch,then the process will go even easier. When applying heating, it is worthwhile to preheat the whole pipe slightly.

It is important to remember that the larger the diameter of the product - the greater its angle you can safely bend.

When working with pipes that are unfamiliar to you, it is necessary to carry out a trial bend on a piece that is “not sorry” before carrying out the work. So you can better understand exactly how this particular material reacts to deformations, and take this into account when bending.

It is best to tolerate the bending of the product in which the foil is joined by a seamless method, a little worse - those where it joins overlap. Tubes, where the metal layer is butt-bonded, suffer the deformations worst of all and can break through at the bend site after a couple of years of operation.

For any method, it is important to carry out all movements slowly and carefully, any careless action can damage the product and make it unsuitable for further use.

To learn how to bend a plastic pipe without special tools, see the following video.