Criteria for the selection of a calibrator for metal pipes

Today pipes from metalplastic enjoy wide popularity. This material has good performance and is best suited for the installation of a heating system and domestic water supply. To install such pipes, you must first prepare all the necessary elements of the system, one of which is a calibrator.

Special features

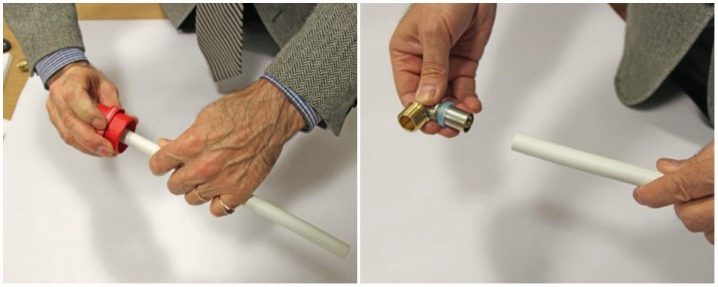

Calibrator for plastic pipes is needed to achieve the most reliable connection of individual elements into a single system. Ideal joining is required before fixing by press models or fittings.The calibrator is a small symmetrical case with a plate and a special cutting edge.

It is designed to perform the following tasks:

- setting the geometric proportions of the elements used after cutting them;

- check and fit;

- creating a chamfer at the end of the pipe.

The design of this element is presented in several versions, which differ from each other in size and marking. It is the marking that contains all the detailed information about the parameters of the calibrator. Since metal-plastic pipes are of different diameters, calibrators can also be of several sizes.

Species

There are 2 main types of such a tool.

- Plastic, for the elimination of geometric end curvatures of pipes. This type of tool is used to align the end of the pipe if any irregularities have appeared on it that have arisen during cutting. As a result of this procedure, the installation of fittings is greatly simplified. The tool is made of durable and reliable plastic, resistant to abrasion.

- Chaser for flaring face with chamfering. With the help of such a tool, the serrations and irregularities from the cut of the pipe are eliminated. The calibrator is used for flaring the edges and removes a small chamfer, thereby preparing the material for fastening the fitting.

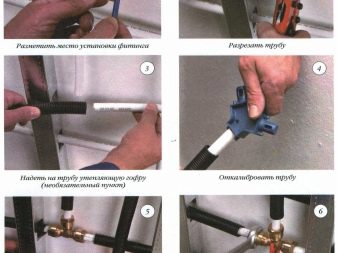

Application

Handling this tool is extremely simple. You do not need specific knowledge and experience. First you need to enter the fitting of the calibrator into the pipe cut. It is important that the cut be made at right angles. At the same time, it is necessary to introduce the tool clearly along the longitudinal axis of the skew, otherwise in the future a skew of the structure is possible, which will certainly lead to leaks in the places of poor-quality joints. The knives of the tool during installation should be based on the inner surface of the part. To complete the installation, you just need to turn the calibrator knob several times around its axis. After that, you can begin to assemble the plumbing system.

Here are some important points to keep in mind when working with plastic pipes.

- Use only a calibrator that fully matches the diameter of the pipe section.

- Sharpen the knives of the tool in time so that the result of the work is always of high quality. On average, the first sub-point occurs after about 250 uses. The exact figure for a particular type of tool is usually always indicated by the manufacturer.

- Strictly follow the rules of storage and transportation, which are recommended by the manufacturer.

- Do not start the calibration, if you are not 100% sure that the pipe cut is made at a 90 degree angle.

- Proceed to calibrate carefully, introducing the tool strictly in the direction of the longitudinal axis.

Do not allow distortions in the process of work.

Recommendations for selection

Calibrator is a fairly simple tool that does not require much attention. However, it depends on him how accurately the installation of metal-plastic systems will be performed. And also how convenient, simple and fast it will be implemented. Therefore, when choosing this tool, we advise you to pay attention to several parameters.

- Manufacturer. Trust only verified calibrator manufacturers. If the tool is of inadequate quality, made of poor materials, then with its help it will not be possible to make a correct system calibration, which will inevitably lead to violations of the entire system setting.

- Provider. Even if the manufacturer did everything correctly and used only first-class materials to create the tool, the calibrator may still be inappropriate. For example, if the supplier did not comply with the conditions of storage and transportation of goods, and did not check it for the presence of a marriage. Purchasing a tool from a bona fide seller is a guarantee of achieving an optimal result.

- Functionality. If you need a universal calibrator for use when installing metal-plastic pipes with your own hands, then it is enough to buy the simplest and most inexpensive option, while for more frequent professional use you need a second type of tool, which has a chamfer removal function.

- Specifications. The main parameter that is important to know when choosing a tool is the diameter of the pipes.

It is impossible to work with inappropriate elements of the system.

Taking into account the listed tips, you will definitely be able to find a suitable tool and use it correctly.

On the little tricks when working with plastic pipes, see the following video.