Metal pipes: how to choose the right size?

Quite often, the composition of several materials allows us to endow products from this raw material with exceptional technical characteristics. Proceeding from this feature, it is possible to consider as a vivid example products from metal-plastic, namely: metal-plastic pipes.

Special features

The material is widely used for plumbing work. Water supply, sewage and heating systems are made of metal pipes of different diameters. Moreover, from this raw material both new water pipelines are laid, and work is being carried out to repair existing canals in apartment buildings and private households.

The specifics of the operation of pipelines involves the occurrence of emergency situations that occur as a result of sharp pressure surges inside the systems, fluctuations in the temperature of the medium in the pipe, and so on. Taken together, either individually, but all of these factors affect the durability of the products that make up the system, they form ruptures, leaks and other deformations, not only of the pipes themselves, but also of the connecting elements. And it is the metal-plastic that manifests itself from the positive side when exposed to it like external and internal factors.

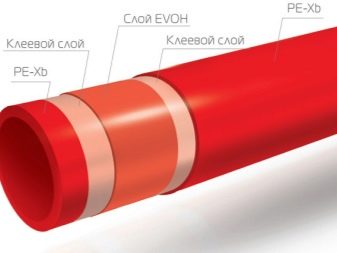

Products from metal-plastic are a structure consisting of three layers:

- outer and inner shells made of polyethylene;

- reinforcing layer, which is made of aluminum foil;

- two layers of heat-resistant adhesive composition.

Based on reviews and information provided by manufacturers, the operational life of plastic pipes is at least half a century. However, in most cases, products manufactured in accordance with all standards can last much longer.

The polymer layer can be made of cross-linked or heat-resistant polyethylene. Used PEX can be: PEX-A, PEX-B, PEX-C, PEX-D. Products differ in the method of combining the molecules of raw materials on the basis of this varies flexibility and strength of the material. Manufacturers consider the PEX-B brand to be the most suitable type of cross-linked polyethylene used for the manufacture of metal-plastic pipes. Such material provides cracking resistance, flexibility and durability to products.

Heat-resistant polyethylene allows pipes to tolerate heat well up to +125 С, at which the structure is not deformed. But this raw material reduces the elasticity of the pipeline, so special tees are used at the corner joints of communications.

All products from metal-plastic, regardless of the diameter and size, are made by the same method. Technology release includes the following steps:

- the raw material is subjected to heat and pressure in the extruder, due to which mass is compacted;

- then from the extruder through the special form out the inner shell;

- at the end of the solidification process, an aluminum layer is glued to the base, the seam is welded using laser welding;

- on the foil using an adhesive composition fix the outer layer;

- The final step is to pressurize the product in a calibration machine.

The reinforcing layer allows products to have a low rate of linear expansion. The outer layer will heat up less, which will have a positive effect on product durability. In addition, the foil reduces the diffusion of oxygen into the liquid medium inside the pipes, and also provides zero vapor permeability of the system, thereby eliminating the occurrence of rust on the inner walls of metal-plastic products.

Aluminum foil layer also serves as a heat insulator, so the products often prefer to use when arranging heating.

The positive features of pipes made of metal-plastic include the following:

- resistance to aggressive chemical environments;

- corrosion resistance;

- due to the smooth inner walls of the product, they are distinguished by a high level of throughput; various dirt and deposits do not accumulate inside;

- light weight, which facilitates the installation of pipes;

- anti-static material;

- low noise level;

- attractive appearance;

- long service life;

- high strength in comparison with conventional plastic products;

- affordable cost;

- environmental friendliness of the material.

The disadvantages of products include the tendency of products to linear expansion during heating, as a result of which the tightness at the joints of pipes can be broken, but proper installation will avoid the occurrence of such situations. It is necessary to identify the main areas in the domestic sphere, where metal-plastic pipes are operated:

- water supply, sewage, heating;

- arrangement of the system of warm floors;

- products are included in the design of country watering systems;

- products are used in ventilation systems and air conditioning equipment;

- creation of high pressure pipelines.

Options

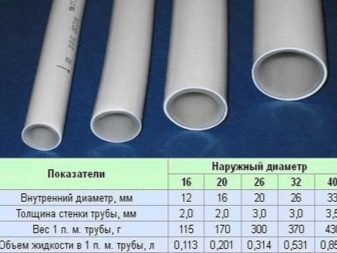

The diameters of metal-plastic pipes on the modern construction market are quite diverse. For water pipelines, products with a section size from 16 mm to 50 mm are more in demand, sewage systems require the use of samples with a larger diameter, as a rule, these are pipes with sizes from 32 to 150 millimeters.However, it is worth noting that the marking of metal-plastic products is usually not in millimeters, but in inches.

Although some manufacturers, in order to avoid confusion, do indicate values in the units of measurement that we are used to. There are special tables that allow you to quickly navigate in the presented sizes of pipes.

It is also important that the products have not only external, but also internal diameter. Therefore, in the selection of goods should pay special attention to this. When conducting measurements and buying it is indicated external diameter.

For household needs, for example, for repair work in an apartment, the following dimensions are used - 16 mm, 20 mm, 25 mm, 26 mm. But products with an external cross section of up to 40 mm are recommended for operation in a system with large volumes of water supply.

The bending radii of pipes for each size are different, they vary in the range from 80 mm with an outer diameter of the product equal to 16 mm and up to 550 mm for pipes with a cross section of 40 mm. These figures correspond to the manual type of bending products, but there is still a specialized tool - pipe bender, through which you can change the radius of the pipe in the communications system. One meter of product can hold up to 0.855 liters of liquid medium.

Metal-plastic products are sold in coils, the length of which can be from 50 to 200 meters.

Criterias of choice

To avoid mistakes when choosing products, you need to pay attention to their size. The inner diameter is indicated by the abbreviation DU, in this case there should be no difficulties. However, when determining the outer radius, it is worth taking into account the thickness of the pipe walls. Therefore, to buy metal pipes of the required size, it is necessary to adhere to the recommendations of experts.

- An important factor in the production of pipes from this material is the method of joining the aluminum layer in the structure; the method of butt welding of raw materials is considered optimal.

- The thickness of the reinforcing layer should not be less than 0.3 mm, but not more than 0.6 mm.

- A mandatory requirement for the quality of the material is to use in the manufacture of only cross-linked or heat-resistant polyethylene. Since the rest of the raw materials will adversely affect the operational life of the product.

- When visually inspecting the pipe on the inside and outside there should be no stratification and violation of the integrity of the product.Otherwise, it will quickly become unusable during use in any communication system.

The composition of products will help determine the seller, in addition, product information is available from the manufacturer.

Tips

When selecting products, the wall thickness will play a big role, since this parameter will determine which valves and fittings should be used for installation. This is especially true when replacing old metal pipes with new products from metal-plastic. Experts recommend that when connecting polymer sections with sections of metal pipes, it is additionally necessary to install special filters in the joint area. Such a precaution will reduce the risk of blockages, debris or rust from the old pipe section to the new pipeline.

In order to efficiently and quickly build a communications system from metal-plastic pipes, it is necessary to purchase a special tool for work - a press key. Its application will ensure maximum installation efficiency, as well as facilitate the work in most processes.

As a result of errors made during the installation of products,after some time, a leak in the system may occur, especially at the joints. As a result, a leak is formed. Most often, such situations arise due to insufficient qualifications and lack of practical experience when working with connecting elements of communication - with fittings. Having drawn a seagull, you can simply break the thread or break the pipe. Therefore, it is necessary to strictly calculate the impact force on the element.

In addition, among the list of the most common mistakes is to highlight the fact that the necessary tool is not purchased for work, for example, in order to save, they neglect to buy a calibrator or a face picker. This leads to deformation of the sealing rings on the connecting elements during installation, which adversely affects the reliability of the bonding of the segments of the pipeline.

By itself, the installation of metal-plastic products is not considered a time-consuming process, for work it is enough to observe accuracy and accuracy during the measurement of the required products and their quantity, as well as adhere to the established markings and precision cuttings.

Installation and operation of pipes requires cleanliness in the room. Cut the pipes only at a right angle to avoid uneven edges, and also be careful when putting on fittings.

The temperature of a liquid in a metal-plastic water pipe at different pressures can be from 25 ° C to 95 ° C, but the maximum permissible limit is 135 ° C. This should be taken into account when creating water mains.

You will learn more about the installation of plastic pipes in the following video.