Accumulators "Dzhileks": selection criteria and operating rules

Water supply with a pump can serve as a real salvation for private houses and for summer cottages located far from the central water supply. But even the most reliable pumping systems can fail. To the aid in such cases come cumulative complexes.

Design features

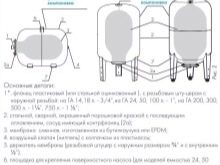

Accumulators "Dzhileks" compares favorably with similar products from other manufacturers. Their developers took into account all the subtleties and nuances of the Russian water supply and achieved maximum adaptability to the existing conditions. The tank has a relatively simple device: a block of metal, inside which is a pear-shaped rubber membrane.There is air between this membrane and the outer walls in household products, and inert gas in the products of industrial grade.

The hydroaccumulator differs from a simple barrel in that it must not only deliver water to the system, but also maintain a certain pressure in it.

The device is divided into two lobes by a membrane. The first part through the nipple communicates with the external atmosphere, and the second - is connected to the water supply network. When the tank is filled with water, the membrane is stretched, it presses on the gaseous medium until pressure is equalized. At the time of opening the valve compressed gas displaces the liquid from the reservoir. As soon as the automation unit registers the reduction in pressure to a certain value, it gives the command to start the pump.

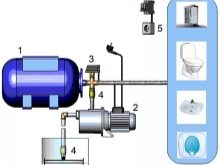

After the valve is closed, the pump will continue to work for some time, thereby achieving pressure equalization again. To ensure that pumps and membranes last as long as possible, cleaners must be mounted on the inlet. In order for the hydroaccumulator to work successfully and solve its task by 100%, a wiring diagram is necessarily considered. In any case, it includes a pressure switch and a check valve. Experts advise installing another pressure gauge to reliably monitor changes in pressure in the system.

Accumulators in the water supply network with a surface pump are usually placed near the pumping machine. The check valve in this scheme is located on the suction pipe. To connect devices into one complex, a five-pin socket is used. Theoretically, it can be replaced with an arbitrary combination of pipe fragments, but this is too time consuming and not always of high quality. For reliable fixation of membranes and their connection to water pipes, it is recommended to use a stainless flange from leading manufacturers.

In particular, the modification of the Belamos SS differs by such parameters as:

- connecting thread - 1 inch external;

- outside diameter - 160 mm;

- the gap between the mounting holes through the center of the part is 12.8 cm;

- the same gap between the centers of neighboring holes is 6.4 cm.

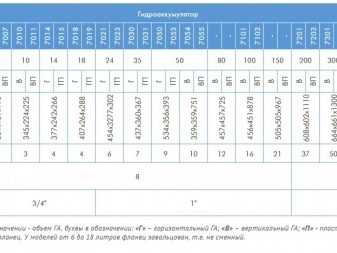

When choosing a flange, it is important to specify whether it is compatible with hydraulic accumulators and expansion tanks of their manufacturers. The accumulators themselves are divided into vertical and horizontal.The choice of a particular type is determined by how compact the device will be, whether it will be convenient to place it in a certain way. But it's not just about design and comfort. Differs approach to the discharge of air out.

So, in a vertical system, oxygen can be blown off by a safety valve - and that’s enough. And horizontal devices require for this purpose the formation of a separate pipeline with a nipple and a ball valve.

Attention: vertically placed devices with a capacity of up to 100 liters may be freed from air only with complete removal of the liquid. In addition, the horizontal tank is much better suited for working with an external pump, and the vertical one is well combined with a submersible one.

Vertical systems will have to choose if you need a very large tank capacity, from 750 liters. For additional storage of liquid stock is ideal. But if simple constructions are required, which can be applied in any place where there is enough space for them, the choice of the horizontal is already justified. Important: do not confuse hydraulic accumulators and expansion tanks, even if they look much alike.The second type of device is used only in heating systems and therefore is always made of a material capable of withstanding high temperature and pressure.

Hydraulic tank for water supply on such extreme loads is not calculated in principle. The purpose of their application is quite different - it is the reduction in the number of pump starts, the prevention of hydraulic shocks and the provision of water for a while when the current is turned off or the pump or line breaks. It is impossible to use not only hydroaccumulators in heating schemes, the reverse replacement is also unacceptable. After all, the contact of water with the tank body will inevitably lead to corrosion. It is important to remember this circumstance in order not to accidentally purchase a membrane heating tank instead of a plumbing one.

The accumulator is part of the Jumbo pumping station 60/35. The 24 liter horizontal tank, which is covered by a general warranty, is made of carbon steel. In an empty tank, the pressure is 1.5 atm, if measured inside the diaphragm. According to technical standards, it is forbidden to use the system to work with a liquid heated to more than +50 degrees.

Warning: Do not start the system in dry mode.

Purpose

Hydraulic tank for water supply systems in addition to the above functions also solves such important tasks as:

- selection of excess pressure during accumulation of fluid;

- maintaining constant pressure even when the pump is off;

- reducing the load on the pumping system and the line at full load.

Therefore, we can assume that the hydroaccumulator is the home analogue of the water towers of the aqueduct. Systems for water supply are painted with blue paint, and heating expansion tanks - red, so it is easy to distinguish between them. Reservation of water is made taking into account peak consumption: 8 liters per minute to the kitchen, 6 liters in the bathroom and up to 10 liters in the toilet room. Pressure in the hydroaccumulator should be at least the same as in the water supply at home, at least 1.5 bar. In addition to capacity and size, you need to remember about the instruction manual; only it allows you to properly connect the system.

You can not use devices that have external defects. You should definitely think about the mass of the device along with the water it contains; It is useful to consider such a nuance as the convenience of emptying the tank.According to the technological standards, it is necessary to mount it only in heated premises with full exclusion of static loads. Very large batteries, allowing you to create a solid supply of water, it is difficult to pull into the house. Of course, all connections with pipes and nozzles are subject to thorough sealing.

Product Overview

The company "Dzhileks" can offer its customers a variety of hydroaccumulators. So model 7101 goes well with submersible pumps. Steel flange with a zinc layer is very reliable; In the case of size 84x45 cm and weight 11 kg up to 100 liters of water can be placed. The external connection is made with a 1 ”threaded choke. Inside the vertical case, the water is under pressure up to 10 atmospheres, and air - up to 2 atmospheres.

Judging by the reviews, this type of product is better to use not with a hose and cap nut, but with a coupling. But the performance characteristics of the device are quite decent and meet the latest requirements.

Model apparatus 7010 allows you to store no more than 10 liters of water (hence the index). A small capacity can not be considered as a disadvantage, such a device is designed to extinguish the effect of drip leakage from leaky pipes or taps. Replacement flange is not provided, the membrane can not be changed.

Product 7053 it is calculated on 50 l, it is executed in a horizontal format. The flange is made of special plastic. The accumulator can be used in combination with both surface and submersible pumps. The outer case is made of steel 0.1 cm thick; the metal is pre-mixed with phosphorus and painted with UV-resistant paint. You can change the flange, the membrane is made of butyl rubber and can also be replaced. Permissible operating temperatures range from -10 to +99 degrees.

"Dzhileks" 24 G excellent for use with surface pumps up to 1 kW, with submersible pumps up to 0.5 kW. Up to 24 liters of water can be poured in through an inch of inlet, its pressure reaches 8 atm. Battery "Crab" holds up to 50 liters of liquid. Consumers note the compactness of this model. But at the same time, experts warn of its incompatibility with pumps such as "Kid".

In addition to these devices and containers of 80 liters, the drive has considerable popularity. 200 VP. This vertical battery has a plastic flange. The tank holds up to 200 liters of water, so its connecting size had to be increased to 1. Proprietary system holds pressure well.Bleeding air is carried out efficiently with the help of the recommended outlet.

Tips and tricks

It is necessary to adhere to the following expert advice:

- In order not to connect a drop air nipple to a small accumulator, you can use either an auxiliary ball valve or disconnecting from the power supply and discharging air through the draw-in points. The optimal effect is achieved with repeated repetition;

- if there are four or more points in the house, use batteries from 50 liters. The lower threshold of the sensors is set at 1.6 bar, and the upper one is determined depending on the pressure properties of the pumps.

Review of the model of accumulator Dzhileks Ga100vp, see the following video.