Replacing membranes in hydraulic accumulators: recommendations for dismantling and installation

Each residential building needs water supply; therefore, special pumping stations are being built on the territory of country houses or cottages, consisting of two parts: a pump and a hydroaccumulator. The most important part of the tank is the membrane, the purpose of which is to perform all the basic functions of the tank.

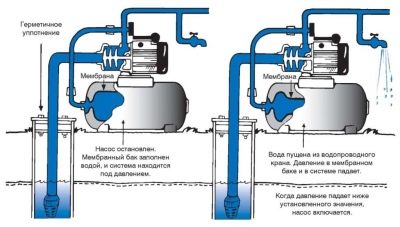

Principle of operation and device

The membrane for a hydroaccumulator can be visually compared to a medical heater that holds about 24–50 liters of water. There are large tanks that can hold more than 100 liters. They are pear-shaped or bottle-shaped. Regardless of external data, the membrane is designed to perform certain functions. It always consists of elastic materials.The container is inserted into the metal case of the tank, than it divides it in half. One part is for water, and the second is for air.

The membrane is designed so that when turned on, the pump pumps water into the tank. Capacity filling is strictly up to a certain level in order to achieve the maximum allowed pressure. The pressure level can be seen on the pump relay, which typically ranges from 1.7 to 3 atmospheres. When the pressure reaches the maximum point, the pump automatically stops its operation. Water will remain under the current pressure, which allows it to flow out of the tap with normal pressure. This happens because the compressed air that is inside the tank no longer affects the water.

The principle of operation of the membrane for the hydroaccumulator allows you to significantly save electricity and increase the operational life of the equipment. The use of a tank for water systems helps to minimize sudden pressure surges inside the structure, which is an undoubted advantage.

Types and characteristics of membranes

Classify the membrane for the accumulator can be on purpose.It can be used for water supply or heating systems. In the case of using the product for the water supply system, it is worth highlighting the following characteristics:

- it is made of rubber;

- ambient temperature ranges from 0 to + 70 ° C;

- its maximum working pressure is 7 atmospheres;

- it is not afraid of bacteria.

The membrane intended for installation in the heating system is distinguished by the following indicators:

- it is made of special rubber compound;

- has a medium temperature from 0 to + 99 ° C;

- maintains working pressure to 8 atmospheres.

Regardless of the purpose, the membrane for the accumulator has several disadvantages, namely:

- does not tolerate frequent and sudden changes in temperature;

- afraid of exceeding the permitted temperature;

- negatively perceives the excess of the maximum allowable pressure;

- deteriorates with frequent or abrupt compression.

The conditions under which water supply and heating systems are used often do not make it possible to avoid the negative influence of external factors. In some situations, the water consumption in the house can significantly exceed the norm, which will inevitably lead to a rapid discharge of water from the tank.Therefore, the service life of a water supply tank membrane often does not exceed five years.

For the purpose of prophylaxis, it is recommended to check the integrity of the product once a year, and to replace it if defects are found. The classification of membranes can also occur in capacity. Modern tanks are available in different volumes, ranging from 8 liters to 2,000 liters.

For home use, models with a capacity of 24 to 80 liters are sufficient.

Integrity Diagnosis and Replacement

Often, the membrane in the accumulator requires repair or replacement. You can assess the quality of the water supply system without removing the rubber bulb. The first signs of a breach in the integrity of the tank may be water supply interruptions and jumps in the gauge needle. To complete a design check, you must first evaluate its appearance. To do this, turn off the pump, shut off the water supply to the tank, and drain the liquid from it. If during the drainage of water from the hole will be observed the release of air, this means that the membrane breaks and requires replacement.

It is possible to check the integrity of the product in another way: by releasing air from the tank.If water leaks from the nipple, the membrane is definitely damaged. In the presence of such a problem will have to immediately change the diaphragm. To replace the product with your own hands, you need to disconnect the accumulator from the pipeline, and then relieve air pressure. To do this, find the nipple, which, regardless of the model, is located at the top of the tank. After it remains to unscrew the hose and cap.

It is necessary to make repairs using a basin into which the water remaining inside the tank will drain. Therefore, it is important to carry out the procedure in the place where the water will not damage the floor covering.

Independently remove the membrane from the tank is possible only after complete drainage of water.

To do this, remove the cover with the pressure gauge and pull the membrane through a special hole. After the done manipulations it is worth examining the body carefully and rinse the pear thoroughly.

Special attention requires rust, dirt and cracks, which ideally should not be. After checking the tank, you need to rinse it from the inside and dry it well. In the future, it is necessary to install the repaired membrane and install its flange in place.After complete assembly of the structure, it remains only to pump air inside the tank so that the water supply system can function normally. This can be done through the pump spool, which is usually located at the bottom of the housing.

Master class on replacing the membrane of the accumulator, see below.