Features and installation of hydroaccumulators for water supply system

A hydroaccumulator for water supply is not only designed to take some of the pressure on himself, it also performs some useful functions for heating. It is necessary to understand a little more in detail what are the features of the accumulator, as well as how to install it.

Purpose

Before proceeding to the question of the purpose of the accumulator, it is necessary to understand what it is. The accumulator is a metal tank, inside which there is an elastic cavity. Subsequently, the cavity may be filled with water. Due to the air gap located between the metal walls of the tank and the elastic cavity, the water “bag” never comes into contact with the metal.

Such a device gives the hydroaccumulator many positive qualities.

First of all, the hydraulic accumulator allows to partially relieve the load from the pump. Before the water is supplied directly by the pump, it is supplied from the hydroaccumulator. When the water level drops to a certain level, the pump turns on. Thus, the pump unit is protected from water hammer.

Such measures allow to significantly increase the amount of time that the pump will last. Such a careful attitude will save it from premature breakdowns and wear, while the quality of the head will not suffer. Even if you simultaneously use two cranes connected to the selected pumping station, the head will remain at a given level.

Plumbing, working from the same source, will also last longer, since it will not be subjected to water pressure drops. For example, the pipes of the washing machine will not wear out so quickly.And an additional supply of water will allow you not to be afraid of interruptions in its supply, which is convenient if you live in a private house and water in the right amount is always needed.

Functions

Summing up all the useful properties that are provided by the presence of a hydraulic tank, you can determine its functions:

- Pump protection The presence of a hydroaccumulator contributes to the protection of the pumping system from undesirable effects, extending its service life. Due to the fact that the pump will turn on only as needed, it is guaranteed a certain number of unused inclusions. This refers to the deviation from the rate of inclusions per hour.

- Pressure support Due to the fact that there is a hydroaccumulator, you can not be afraid of constant pressure drops of water. For example, if with only a pump there is a probability that the water will go somewhere stronger, then slower, especially when several taps are switched on at once, then this problem disappears if there is a hydroaccumulator. After all, the load is divided into two technical devices, and not one.

- Leveling water hammer. When you turn on the pump, you often encounter the fact that the water starts to go too intensively.Such a sharp push is called a water hammer. The use of a hydroaccumulator allows you to avoid such problems, since water flows smoothly from the hydraulic tank. Thus, the pipeline will also last much longer.

- Providing a reserve of water. If you live in an area where there are problems with the water supply, it may be helpful to have a hydroaccumulator. It provides a certain amount of water suitable for household needs.

Depending on the need, you can choose a large hydroaccumulator (up to 500 l) or very small (up to 5 l).

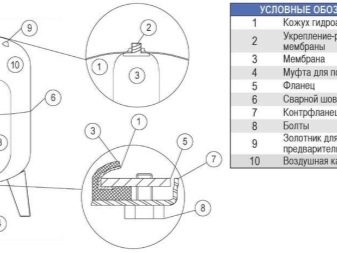

Device and principle of operation

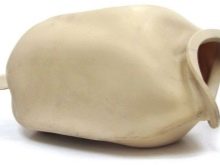

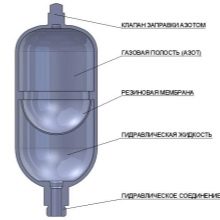

The special feature of hydraulic tanks is that the water does not contact directly with the metal body, but remains enclosed in an elastic cavity, also called a membrane. The membrane is made from butyl, a durable rubber material. Butyl provides the proper level of water protection from bacteria, which the metal cannot boast.

Between the elastic membrane and the metal case there is an air gap. It is pumped with nitrogen, but also the chamber can be filled with ordinary air.The chamber is equipped with a special pneumatic valve through which the pressure inside is regulated. You can fill the chamber through this valve or, conversely, bleed the air.

Hydroaccumulator installation can be disassembled and reassembled at any time. It has a simple device. Such simplicity is ensured so that there is always an opportunity to identify problems to carry out timely repairs. In this case, the device can be repaired without pouring all the water out of it.

Large accumulators have an additional valve in the membrane, which also allows air to be vented, but here we are talking about air that is released from the water. There is no such function in small hydraulic boxes, but then the valve should be on the pipeline.

The operation of the accumulator is as follows.

- First, water is pumped into the elastic cavity, stretching and filling it. A special relay is fitted to the cavity.

- Once the pressure threshold is reached, the relay responds to this and shuts off the pump.

- Then, during the operation of the hydroaccumulator, the pressure drops again, and the relay, in response to this, turns on the water again.The relay can be configured to any level. This type of device is called a hydraulic accumulator with automatic.

Now there are practically no such options, but still there are outdated hydraulic tanks, the degree of fullness of which should be monitored and filled independently as needed.

Types and selection criteria

There are many criteria, based on shared hydraulic tanks. Each of them has its own characteristics that must be considered in the selection process. One of these criteria is the material. If the expansion tank itself is made of stainless steel, then the membrane can be made of various types of rubber:

- Natural. This is a natural rubber for drinking water. It stretches well, but this property can lead to the fact that over time, water will penetrate through the walls of such a membrane. In the cavity of natural rubber can be poured water temperature from -10 to +50 degrees.

- Butyl. This kind of artificial rubber is also intended for drinking water. It fully complies with all safety requirements. Possesses less elasticity, than natural thanks to what is more durable. The temperature that butyl rubber can withstand is higher: from -10 to +99 degrees.

- EPDM. This type of rubber is also intended for the storage of drinking water. Like butyl, ethylene-propylene rubber can withstand temperatures from -10 to +99 degrees, but it fails somewhat faster than butyl rubber.

- SBR. The brand is intended for technical water. For household needs such water can not be used, but it has found application in heating systems. Such hydroaccumulators are used as expansion barrels for heating systems.

- Nitril. Perhaps the most unusual form, since it is intended for the storage of oils and fuel.

When choosing, be sure to pay attention to what kind of rubber is used, since the last two types do not meet sanitary standards and therefore are not suitable for storing drinking water.

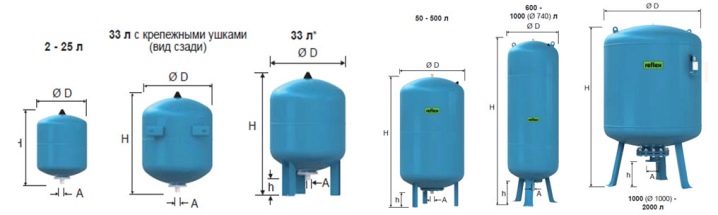

By configuration, accumulators are divided into vertical and horizontal.

- Vertical. Hydraulic tanks of vertical type are chosen mainly for rooms with a small area. Since they stretch upward and practically do not occupy useful space, they are an excellent choice for small domestic boilers. Pneumatic valve located at the top.

- Horizontal. Horizontal accumulators are not so practical. In order to install them, you must have a lot of free space. Valve and such constructs do not, so you have to make a special valve for air bleeding.

The horizontal unit has a mount, through which it is connected directly to the pump. Because of the possibility of fixing an external pump, they gained such popularity.

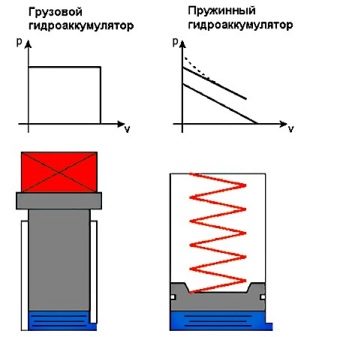

According to the type of accumulator, hydroaccumulators are divided into mechanical and pneumatic.

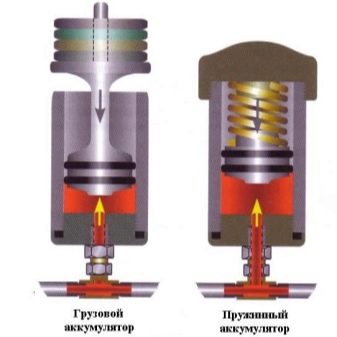

Mechanical

For the operation of this type of drive requires the kinetic energy of the load or spring. These models are practically not used lately, since they have more disadvantages than advantages. Among the shortcomings the most significant are:

- Big size. Such units occupy a lot of free space, which is not related to their volume.

- Inertia This refers to the ability of such systems not to change their original parameters, regardless of external factors.

Sometimes adaptability is needed. However, such hydroaccumulators are cheaper.

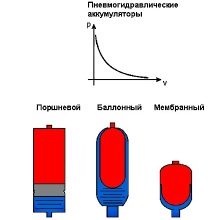

Pneumatic

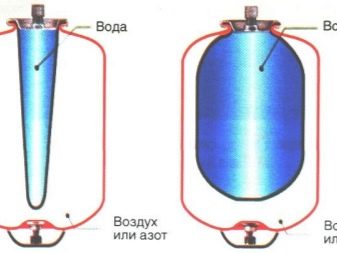

To date, such drives are more common, since the operation due to the effects of gas is easier. This is the device that was described in the previous sections. Devices from this category are divided into piston, pear or balloon and membrane.

- Piston. Devices of this type are extremely rarely used in domestic conditions. They are more suitable for industrial use. Their capacity is extremely high and reaches 600 liters. It is clear that very few people at home constantly need such a volume of water. However, the cost of such installations is quite small.

- With a pear or balloon. Similar hydroaccumulator tanks do not use one by one. Most often they are included in the hydraulic pump system. In this case, inside the metal tank is fixed pear. On the one hand there is a hole for filling it with water. It turns out that the pear is stretched inside the metal tank. The air pumped into the tank around the pear further pushes the water there. When the pressure drops, the pear refills.

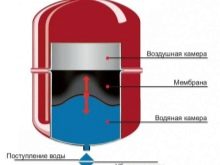

- Membrane. The principle of operation of the membrane accumulator is similar to the variant with a pear, however, in this case, the membrane or rubber acts as an elastic cavity.The membrane is attached to the metal body with only one end. In the empty form, the membrane is pressed against the outlet opening under the influence of the gas inside. Filling with water, the membrane expands.

By purpose, accumulators can be divided into suitable for heating systems, hot water supply and cold water.

- For heating systems. Hydroaccumulator for heating serves to get rid of the accumulated air in the pipes, as well as to prevent the decrease in water temperature.

- For hot water. Membrane expansion tanks are preferably used to supply hot water. They are designed to compensate for the expansion of water that occurs due to temperature extremes. This expansion leads to pressure drops.

- For cold water. For cold water, accumulators are mainly chosen, which are connected to an external source.

This solution is chosen mostly for private houses.

The size of the tanks are divided into small and large.

- Little ones. These units do not have a large volume, but they are ideal for home.For small devices can be attributed to those whose volume is not more than 150 liters.

- Large. These include industrial units, which occupy a lot of space and are rarely installed within private homes. Basically, they are made horizontal. Their volume can be up to 600 liters. They are intended for storage of technical water.

Among other things, attention should be paid to those items that should fundamentally influence the choice of an aggregate. Summarizing all the above, we can highlight the following points that deserve special attention:

- Type of. It is extremely important on what principle the hydroaccumulator works. For each of the needs need a specific sample. So, for hot water, choose an expanding tank, and for cold water - choose a battery with the ability to draw water from a third-party source. When selecting a hydroaccumulator tank for drinking water, pay attention to the presence of a filter. It is best to buy a hydroaccumulator with a pneumatic accumulator.

- Volume The capacity of the tank is better to choose such that it completely covers the needs. For example, if you check how much water you spend per trip to the shower, you can navigate when choosing this indicator.

- Orientation. It is easiest to choose the configuration of the tank: if the room is small, then choose a vertical accumulator, if the area allows, choose a horizontal variant.

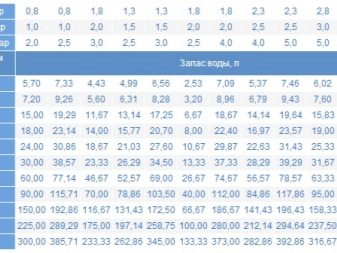

Volume calculation

To make the calculation of the volume more accurate, it is recommended to use the following table. It shows the approximate supply of water, which will be available after the pump stops pumping water due to interruptions in electricity. Please note that this indicator cannot be determined exactly, since it all depends on how the relay is configured.

In order to make more accurate calculations, it is recommended to use a special formula: K (engine power factor) x Amax (limiting consumption of liters per minute) x ((Pmax (pressure when turning off the pump in bar) + 1) x (Pmin (pressure when turning on the pump in bar) + 1)) / (Pmax - Pmin ) x (Pair (air pressure in the accumulator in bars) + 1).

For example, let's count on the table, taking random values.

With the coefficient K = 0.25, maximum flow rate Amax = 2.1, and pressures Pmax = 3, Pmin = 1.8 and Pair = 1.6, we get: 0.25 x 2.1 x ((3 + 1) x (1.8 + 1)) / (3 - 1.8) x (1.6 + 1) = 31.41 l.

Installation steps

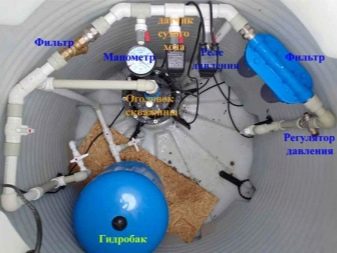

Installation of the hydroaccumulator is performed through several steps, completely different from those that are made for an ordinary tank. It should be noted that the hydroaccumulator tank is practically not at rest. He is constantly working, the membrane or the pear is always involved and is under pressure. Therefore, all steps for installation and configuration should be done carefully and slowly.

First you need to fix the tank.

It should be firmly fixed on the floor, not to stagger. Rubber feet should be placed under the feet so that in case of vibrations, noises and other things, the tank absorbs and staggers not so much.

If we neglect this rule, in the process of operation the metal body can sway and thunder strongly, producing unpleasant sounds, as well as being exposed to unnecessary impacts.

The pipeline must also be connected using rubber pads, which in this case perform an insulating function. It is important that rubber adapters be necessarily flexible, otherwise they may crack and begin to leak water. In addition, flexible materials are easier to set up and operate.

It is optimal if the input of the accumulator and the connected pipeline have the same section. Then there will be no additional connection problems.It is impossible that the cross-section of the wiring to the outlet be narrowed: this will lead to an unreasonable increase in pressure in the hydroaccumulator tank, which can cause a strip, since the tanks are often not designed for this.

Before first use, the tank must be properly prepared. First of all, the membrane or the pear is checked for air. If there is air, it is vented. Next, the tank is filled with water under very low pressure. This is due to the fact that the rubber, caking, sticks together, and if it is too sharply unzipped, it can be damaged or torn. To avoid this, it is necessary to fill slowly and carefully.

When choosing a place for operation, it is necessary that free access to the mechanism be ensured from either side. In general, it is better to reassign the connection of a hydroaccumulator tank in the water supply system to experienced specialists, since it is possible due to inexperience not to take into account some unobvious but important factors, such as pressure drop or mismatch of the water supply pipe section. Such risks are unacceptable, since the accumulator is a rather expensive unit,Yes, and repair the plumbing system will take a pretty penny.

If you decide to take a chance and do everything yourself, use the following step-by-step instruction.

Adjustment

After the tank has been purchased and brought home, the first step is to check the pressure inside it. It is usually 1.5 bar, but often due to leaks due to long storage, the pressure drops. The pressure is checked with a pressure gauge.

You can check it out while in the store. Then right at the time of purchase, ask the sales assistant to make the necessary measurements. The accuracy of the pressure gauge offered in the store is usually high enough so that the error does not greatly affect the final result of the changes.

Usually, experts recommend exposing a pressure that will be 10% lower than in the membrane when the pump is turned on. To adjust the level, flush the air chamber or bleed off excess air. However, it should be borne in mind that pressure drops extremely adversely affect the service life of the membrane. If the difference is more than 1.5 bars, this will increase the load.

TAlso, pressure should be set with an eye to what you need a tank for. For example, some people like to take a shower with a strong pressure of water or use a hydromassage. Then the pressure in the air chamber should be somewhat higher than if you only want to take a bath. However, the pressure in the air chamber should not be too high, otherwise you simply will not be able to pump water into the membrane. Too little pressure is also destructive: the membranes are not designed for an increased volume of water.

Relay Setup

After adjustment of the hydroaccumulator is made, they proceed to the adjustment of the relay responsible for switching the pump station on and off.

To make the setting in the correct way, perform the following steps:

- Open the cover of the compartment in which the relay is located.

- Take a look at what this relay consists of. You will see two springs and nuts. Large spring and nut will be denoted as P, and small - as delta P.

- First, deal with the components responsible for turning on the pump. This is group P. To make the spring more pressure-sensitive, tighten the large nut a little.

- The delta P group is responsible for turning off the pump.Pulling it up, you mark the shutdown of the pump at a time when the membrane is not completely filled with water.

After you have made the settings, test what happened. If you are not very happy with the result, tighten or loosen the nuts again.

It is not necessary to cover the relay with the lid during the tests, but after setting all the settings, the lid must be closed.

Water filling

After the pressure inside the accumulator is set, and the relay is set, you can proceed directly to filling the hydraulic tank. Here you will again need a quality manometer with a detailed scale of values and a small error. It is necessary to connect it to the tank and fill it with water, strictly observing the values.

Arm yourself with the technical characteristics of your tank. They indicate how much pressure can be considered normal, and how much pressure can be considered as extreme. If the gauge values are approaching the limits, immediately stop the flow of water and try to equalize the pressure by bleeding or adding air to the air chamber.

When filling the hydroaccumulator tank, it is necessary to manually shut off the pump at the moment when the pressure becomes optimal. After that, the relay is adjusted according to the desired parameters, loosening or pulling up the small spring. Keep in mind that a pressure of 3 bars is sufficient, although you can vary it to your liking. The difference between the pressure for switching the pump on and off should be about 1-1.5 bar. As practice shows, this is quite enough.

Having made all of these actions, you can safely proceed to the full operation of your accumulator. Once a couple of months, check the pressure in it, inspect the relay and the joints with the plumbing system, and also observe the operation of the pump.

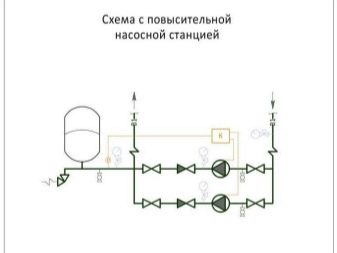

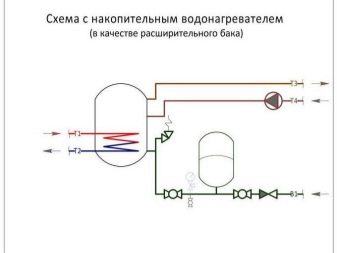

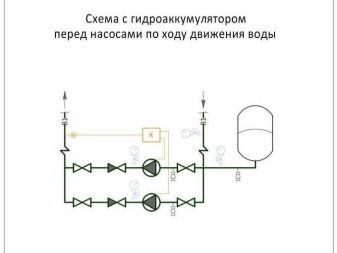

The connection diagram shown here is not the only one. There are several options that have found use in the domestic environment.

Scheme: options

First of all, the connection scheme of the hydroaccumulator to the pumping station depends on the functions that are superimposed on it, as well as on the method of using the hydraulic tank itself. The most popular are the following options.

Strapping pump booster station

Installing the accumulator in a similar way is appropriate when there is a large amount of water consumption.At such pumping stations, there is always a single pump running continuously, which can cause large pressure surges that need to be immediately removed.

Here, the hydraulic tank suppresses pressure surges, thereby extending the life of all pumps. It also compensates for small fluctuations in pressure, which may occur due to the large amount of water consumed.

However, the scope of this type of connection is not limited to this.

It so happens that interruptions in electricity occur constantly, and the presence of water is vital. Similar situations can occur on agricultural facilities, for example. Here, a reserve of water helps to survive such periods of crisis, often lasting several days.

Hydroaccumulator here plays the role of a damper. The more powerful the pumping station, the greater the volume should be at the hydraulic tank and the greater pressure it must cope with. Otherwise, the desired effect will not be achieved.

For submersible pump

In order for the submersible pump not to idle, it is necessary that it only performed from 5 to 20 inclusions within an hour, which is described in detail in its technical characteristics.If the pressure in the plumbing system drops, the pump will turn on automatically. Such falls can occur much more often than 20 times per hour. To compensate for such differences and need a hydraulic tank.

In this case, the hydraulic accumulator is designed to compensate for a small water flow, which also leads to the pump start-up, thereby warning the stupid switching on of the submersible unit. The accumulator relay is not as sensitive as that of a submersible pump. In addition, the pump delivers water in sharp jolts and instantly, causing the pressure to jump sharply. This has a negative effect on pipes. Connecting the hydraulic tank eliminates this problem.

It does not need a large hydraulic tank. To choose the optimal volume, it is necessary to estimate how much water is consumed per hour, how often the pump is turned on, and pumping capacity. It plays an important role where the tank will be installed relative to the pump and at what height the pump itself is fixed.

With storage water heater

If you connect the hydraulic tank to the water heater, it will be used as an expansion tank, not reacting to changes in water temperature.Since the water in the water heater rises under the influence of expansion, the water heater elements that are not always designed for such loads, contrary to the purpose, can be damaged, which will result in the need to completely replace this expensive equipment.

The membrane in the hydraulic tank can easily withstand the expansion that water is subjected to. The cavity is elastic and cannot be damaged by a small expansion of the volume.

In this regard, the connection of the hydraulic tank to the water heater is a good idea, which allows you to save the water heater safely and securely.

Before the pumps in the direction of water flow

In this case, the hydroaccumulator is included in the circuit in front of the imperative pump. It is needed so that the pressure does not drop so sharply immediately after turning on the water and the pressure remains at the same level. The volume of the hydraulic tank plays a special role here. So, the more water is consumed, the higher the capacity must be, otherwise all measures for installing the accumulator will be useless and pressure compensation will not be achieved.

Connection

Hydraulic tank is included in the scheme in the place in which it can provide the greatest return.The exact connection points are indicated in the above drawings. Depending on the problem you are faced with, the location of the accumulator and its volume will vary.

Check

Check of the hydroaccumulator is carried out in order to identify faults of the membrane and timely replace this important component. To date, there are many videos and instructions on how to conduct an inspection yourself at home. Below is the simplest of the instructions.

To begin with, there are several preventive measures designed to ensure the smooth operation of the membrane cavity. There are also signs that clearly indicate that something is wrong with the hydraulic tank. These include the following:

- Monthly pressure check. It is important that the available parameter and those indicated in the technical passport of the accumulator coincide. If this is not the case, you can say that there is some kind of problem.

- The presence of rust on the body. If the membrane were intact, the water would not fall on the case and would not form corrosion on it. On the other hand, it may be due to the fact that the water on the body fell from the outside.For example, a hydraulic tank is under a pipe with hot water, condensate from a pipe systematically drips into the same place on the surface.

- Humidity in the joints. It may also indicate that the membrane has burst and is leaking. Speaking drops can not appear in the cavity, which in theory is filled only with air or gas, just like that.

- Strange sounds. Due to the running pump, it is almost impossible to hear any sound from the hydraulic tank. If the sounds are quite distinct, this may be a sign of serious damage. If you have just connected the accumulator and it is still on the warranty period, it is recommended to return it immediately.

- Visible damage. Armed with a flashlight, you should inspect the membrane in advance for visible damage to the eye: holes, crevices, cracks. They should not be. If there are such defects, replace the membrane.

Such a visual inspection is recommended every six months as a preventive measure.

The verification of the initial pressure was already given in one of the previous sections, so it makes sense to briefly describe the order:

- the tank must be disconnected from the pumping station;

- further, the water present in the hydraulic tank is released;

- by connecting the pressure gauge, the level of air pressure in the accumulator is checked.

Possible faults

A lot of problems can arise during the operation of a hydroaccumulator, and it is necessary to know how to eliminate each of the faults. To do this, take into account the reasons that may lead to such troubles.

- If a pump installation fails, when it is often turned on and off, the matter can be in the membrane. In this case, it is recommended to test its integrity and, in the event of which, replace it with a new one, having previously well dried the metal case of the tank.

- The occurrence of a leakage near the pneumatic valve, through which you can bleed air or fill the tank, is also associated with a violation of the integrity of the membrane. As in the previous case, the membrane must be replaced.

- For too low pressure in the valve there can be several reasons. The simplest is the insufficient thickness of the air gap. In this case, you just need to add some air inside the hydraulic tank. The second reason is more serious.If the part through which air is broken is broken, it is necessary to replace it. May need welding.

- Leaking at the pipe that comes from the pump may occur due to loss of tightness. In this case, you should try to tighten the flange a little tighter, so that it fits snugly. If this does not work, it is recommended to completely replace the parts.

- If the pressure in the crane is uneven, despite the presence of a hydraulic tank, then it may be in an elastic cavity. Perform a full inspection, test it several times. If you still have doubts about its tightness, then replace the existing part with a new one.

- Weak pressure is not associated with the membrane, but with the fact that your pump may not work properly or be completely faulty. Be sure to check the pump for operation. Repair it if a malfunction is found. The second reason may be in the wrong choice of the volume of the accumulator. In this case, there is only one way - replacing the hydraulic tank with a suitable one.

If the fluid comes from the pneumatic valve or is formed next to it, this means that the membrane will have to be replaced with an absolute probability.

The opinion of experts about the need

Below is a video in which a specialist clearly justifies the need to purchase a hydroaccumulator. He states that a hydraulic tank is one of the best ways to level the excessive load on the pumps, thereby greatly extending their service life.