Horizontal hydraulic tanks: purpose and principle of operation

Systems designed for autonomous water supply have several advantages, the main of which is independence from the centralized water supply. If there is no hydraulic tank in such a system, there is a risk of a hydraulic shock. This is due to the fact that in the event of a sharp opening of the valve in the circuit there is a pressure surge that can damage the pipeline and pumping equipment. Therefore, a horizontal hydraulic tank, which is also commonly called a hydroaccumulator, is used as a safety means in such systems.

Design

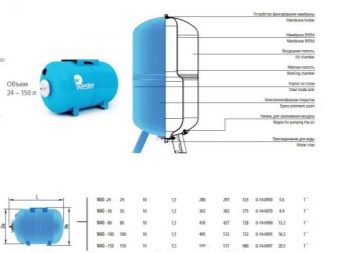

Products of this kind are reservoirs intended for the temporary maintenance of water in them.The welded bodies of such tanks are usually made of stainless steel, and manufacturers use various coatings to protect their surfaces. The most common among them received powder enamel with a reflow.

Addition to such structures are welded racks and counter flanges. Their connection is carried out by means of a galvanized flange with a choke.

The number of communication outputs from such a tank may vary depending on its model. An obligatory element of the design of the water hydraulic tank is also a membrane, made, as a rule, of butyl rubber and replaced as it is worn during operation. This principle of the device is common to all types of such water accumulators, but according to their execution they are divided into two types:

- Vertical small-volume models that take up little space are recommended for use in confined spaces. The body of such equipment is equipped with a thumbnail for bleeding off excess air. When choosing a vertical hydraulic tank, you should focus on connecting the submersible pump and purchase both units together according to the principle of compatibility of their operating parameters.

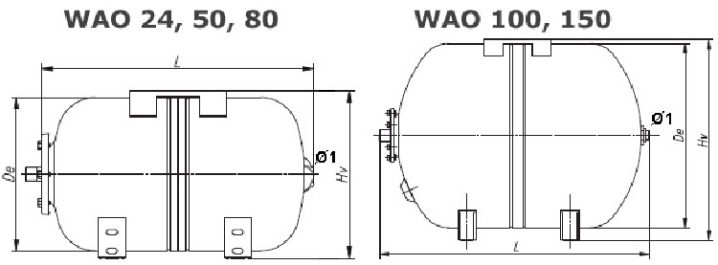

- If it is a question of using a surface pump, then the choice should be in favor of a horizontal type hydraulic tank. This is due to the fact that such tanks are structures with an upper mounting pump placed on the hydraulic tank. Such a unit takes up more space, respectively, but the volume of damping capacity in it is also significantly higher.

The release of excess air from such a tank is carried out through a separate pipe circuit with an outlet nipple and a drain channel equipped with a ball valve.

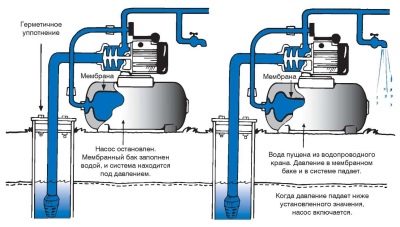

Functioning

The standard indicator of working pressure for water supply systems is a figure of 1-3 atm. Extreme values of this parameter do not have a negative impact on the pipeline and equipment supplying water, but with its sharp drop a hydraulic shock may occur.

In some cases, the system is able to withstand it, but regular loads of this kind will necessarily have a negative impact on the working life of the pump.

The presence of a horizontal hydraulic tank will serve for systems of autonomous water supply with a device that can withstand the load on the circuit with a potential pressure surge, and the water contained in such a tank will be spent primarily on optimal pressure maintenance.

When its reserve is exhausted, the main working resource of the pipeline will be involved, also subject to the condition of maintaining pressure within acceptable indicators.

Specifications

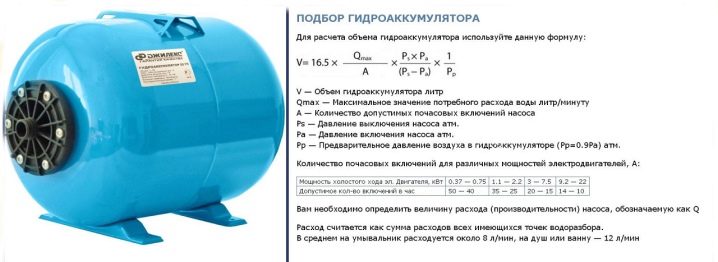

When choosing a horizontal hydraulic tank, its volume and working pressure should be considered as two interrelated indicators. At the same time, in terms of pressure, specialists recommended the use of tanks with a value 0.1–0.5 bar below the optimal load on the pump at the moment of switching on. If the acceptable pressure level for a particular pump is 1.7 bar, then the tank should be acquired with a value of 1.4–1.6 bar.

With regard to the various options for the volume of the tank, then for home autonomous water supply systems, a volume of about 80 liters is considered normal. Even more optimal is the tank capacity, equal to 100 liters.

If the water supply is planned for more than 5 points of consumption, then it becomes necessary to install a hydroaccumulator with a volume of 200–300 l. Such a tank is able to interact with water pumping units with a capacity of over 2 kW.

Interesting: for the supply of water to one consumer will be enough capacity for 25 liters, coupled with pumps with a capacity up to 0.5 kW.

Species

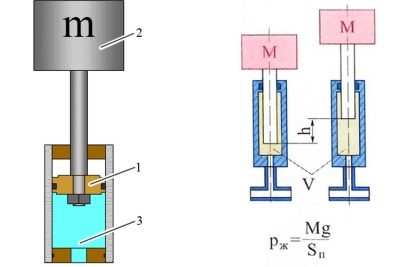

Freight

One of the types of horizontal hydraulic tanks are cargo, characterized by simplicity of design. The work is based on the principle of using the potential energy of the cargo when, during operation, the tank creates the necessary pressure on the water mass, optimizing the load in the circuit. The advantages of such tanks are their high capacity, affordability and ease of maintenance.

However, these units have low parameters of pressure supported by them, large dimensions and certain risks of leakage. This equipment is also characterized by the presence of restrictions on the connection to the pumps primarily on the intensity. The pumping unit in the water supply system with such a reservoir should be rather thin.

Otherwise, the hydraulic tank will not be able to effectively equalize pressure drops.

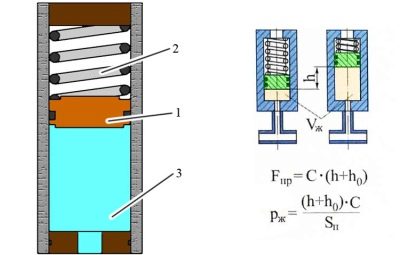

Spring

To the second type belong spring hydraulic tanks. In these tanks, the equalization of pressure in the water supply system occurs due to the exploitation of mechanical energy obtained from the compression of the spring mechanism. This makes it possible to create sufficient force for the accumulation of water and its return back to the circuit in the presence of sudden pressure drops.Compared with cargo tanks, such tanks are more energy-intensive tanks, so they can be used in conjunction with fairly powerful pumps. Nevertheless, sanitary fittings of such units can be damaged under the influence of aggressive media, which somewhat limits the use of hydraulic tanks of this type. Such a reservoir is optimal in systems for supplying cold water, but the presence of high temperatures may adversely affect the condition of the piston seals.

The disadvantages of these devices also include the risk of deformation and breakage of the spring group.

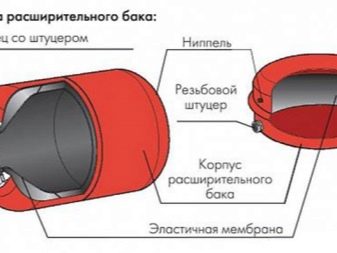

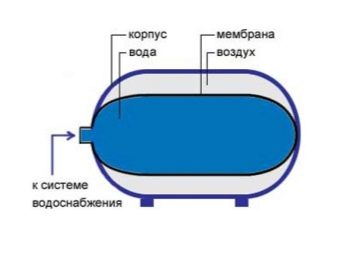

Pneumatichydraulic

Pneumohydraulic hydraulic tanks are the third type of horizontal pump storage tanks. Such devices have been used both in enterprises and in the domestic sphere. The energy required to control the pressure is obtained from compressed gas. This principle of creating the necessary hydraulic effort determines the design features of such a unit. It consists of a floating piston with a flexible membrane and a float mechanism to control the operating parameters of the medium.

To maintain the optimal water level in the hydraulic tank of this type is the membrane. Depending on the current level of fluid pressure in the water supply system, this membrane is either stretched or compressed. The design of this hydraulic tank allows you to use it to supply hot water in the absence of the risk of premature failure.

The element base for the operation of such devices is calculated by manufacturers with regard to elevated pressure levels and with an emphasis on a large number of operating cycles.

In conclusion, it should be noted that typical configurations of autonomous water supply devices equipped with a surface-mounted or submersible-type pump do not necessarily imply the use of a hydraulic tank. In the original version, the design of such systems is carried out taking into account the operation of pumps without installing additional equipment. However, if we are talking about infrastructure with a high level of performance during the water supply, the installation of a horizontal accumulator will provide the necessary protection at the time of an unforeseen overload of the water supply system.

Even if we neglect the risks of serious damage to communications supplying water, an additional means to equalize the pressure will help reduce the degree of wear of the units. In addition, the hydraulic tank can serve as a reserve tank for water. However, this statement refers to containers with a large capacity, which are not so often found in household water supply systems.

In more detail about how the hydraulic tanks are arranged, the following video will tell.