Membranes for hydroaccumulators: types of products and causes of wear

Water supply of living space is an important element of comfortable living. For the uninterrupted movement of water in systems of different designs and from various sources, pumping stations are used. The principle of operation of the station - pumping water with a pump and the creation of the necessary pressure using a hydroaccumulator. The battery membrane is one of the main parts of the equipment, allowing the device to operate with a minimum electrical load.

Special features

To reduce power consumption and eliminate level fluctuationspressure in modern pumps with hydroaccumulators manufacturers install a special separating element - the membrane.

The shape of the membrane part depends on the volume of the tank and there are two types:

- oblong;

- elongated.

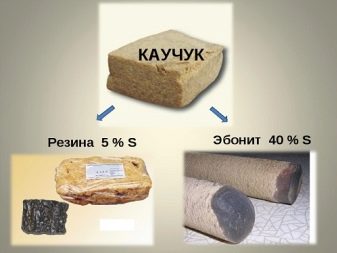

Basis - rubber or specialized rubber. The material for the manufacture of the membrane must comply with all hygienic standards and sanitary standards. Special rubber resistant to mold and fungus, can withstand high pressure and a wide temperature range.

Manufacturers produce two types of membrane:

- flat;

- balloon

Different types of membranes perform the same functions and have no technical differences.

Device

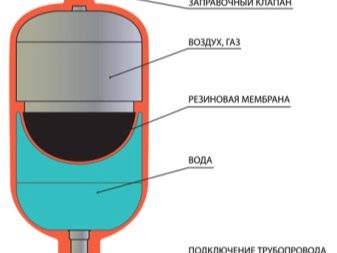

Accumulator membrane - an element that allows to divide the accumulator into the air section and the water section. In the case of the tank have an elastic membrane, forming two spaces that are independent of each other.

The balloon membrane device is filled with water, and in the cavity between its walls and the shell of the accumulator there is air that is injected with high pressure. The flat membrane is mounted on the walls of the battery, forming two isolated spaces.

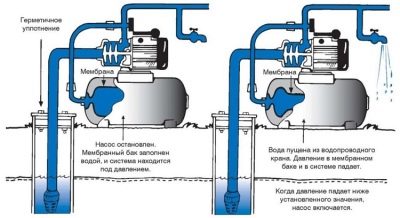

With the help of alluvial systems, water is pumped into the device until the formation of the maximum pressure level. Experts expose the required level using the relay on the equipment case.

Principle of operation

The principle of operation of the hydroaccumulator is to pump water into the membrane. In the cavity between the walls of the membrane and the coating of the hydroaccumulator creates pressure necessary for the operation of the entire water supply system.

At the moment of reaching the value set on the relay, the pumping system automatically shuts off, keeping the internal pressure. This allows you to avoid drops in water pressure and to ensure stable operation of the system. After the pressure has dropped to the minimum level, the pumping unit will again automatically begin to draw in water and inject air.

Kinds

Membrane tank is a special container in which a certain amount of water accumulates. The main function for the expansion membrane tank is to collect water and supply it at a set pressure.

Manufacturers produce several types of rubber membranes:

- pear;

- ball;

- diaphragm;

- balloon.

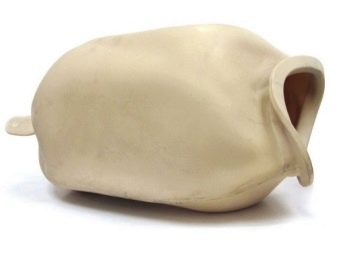

Small types of membranes with a volume of up to 100 liters are similar to a rubber heating pad or glass jar. Models with a volume of more than 100 liters resemble a pear or bottle.

On the shelves of specialized stores you can buy two types of expansion membrane devices:

- with replaceable membrane - has a high price, there is the possibility of timely replacement of parts with the appearance of gaps and deformation;

- with stationary membrane - has a low price range, there is no possibility of replacing damaged elements and restoring the operation of the water supply system.

Modern manufacturers produce a wide range of membranes for hydroaccumulators, the volume of which starts from 10 liters. For home water systems, the most demanded tanks are 24, 50, 60 and 80 liters. In residential cottages with a large number of people install membranes with a volume of 100, 150 and 300 liters.

For the smooth operation of the heating systems in the premises of different types and purposes, experts recommend installing expansion tanks Wester, controlling pressure in pipes and, if necessary, automatically reducing it to an acceptable level.

Material

One of the main criteria when choosing the desired membrane is the type of material from which the part is made. Due to the fact that the rubber element is in constant contact with water, the material from which the membrane is made must comply with all sanitary standards and requirements.

Modern manufacturers offer five types of material:

- natural rubber;

- artificial butyl rubber;

- artificial material EPDM;

- material for heating systems type SBR;

- material for oil and flammable substances like nitril.

For systems with technical water it is possible to use membranes from any kind of material.

Specifications

The technical characteristics and properties of the membranes depend on the type of systems in which they will be used. Manufacturers produce membranes for heating and water supply.

Technical features of membranes for water supply systems:

- maintain pressure up to 7 bar;

- operated in a temperature range from 0 degrees to 70 degrees above zero;

- the basis is natural rubber, which has high environmental performance and resistance to the formation of microorganisms;

- White colour.

Characteristics and properties of membranes for heating systems:

- base - special rubber;

- has a wide temperature range from -10 degrees to +100 degrees;

- maintains pressure to 8 bars;

- black colour.

How to choose?

When purchasing a new part to replace a deformed element, it is necessary to take into account the model of the equipment and its manufacturer. Only membranes of the same brand will have the same size and specifications.

Choosing the necessary part, you need to pay attention to several technical factors:

- temperature range in the working system;

- the period of operation;

- the dynamics of the apparatus.

For tanks of different volume manufacturers produce different types of membranes. Capacity should correspond to the purchased part.

What affects wear?

The membrane is a consumable element of hydroaccumulators, which in the process of work is torn or deformed and requires constant and timely replacement. Manufacturers of this group of products provide a guarantee of up to 5 years for the uninterrupted operation of their goods.

The rate of wear and tear of the part depends on several factors:

- pressure drops in the system;

- constant compression and straightening;

- continuous friction process;

- constant and sudden changes in temperature;

- increased pressure.

For the smooth operation of the system, experts recommend checking every 6 months and, if necessary, replacing parts once a year.

Signs of damage to the membrane:

- changes in water pressure;

- chaotic arrow movement on a pressure measurement device.

Replacement: rules and steps

Before buying a new membrane, experts recommend checking and determining the cause of equipment breakdown several times. One of the main signs of a break in a part is the supply of water in a thin stream with increasing pressure.

Membrane replacement can be carried out independently and without the involvement of specialists. Only by observing all the requirements and standards for dismantling or installing a membrane, it is possible to perform work in a short period of time at a high professional level. If the membrane is torn, and there is no way to replace it, experts recommend to glue the part with a special adhesive.

This will help to increase the life of the element, but after a short period of time it will still need to be replaced with a new one.

Dismantling

Dismantling of equipment is carried out in several stages:

- disconnection of the accumulator from the general water supply system;

- reduce air pressure using a special device located on the upper surface of the tank;

- disconnect the hose and cap;

- drain all residual water from the equipment;

- remove the cover from the gauge;

- get a membrane through a special hole in the bottom of the case;

- check the integrity of the tank, remove residues of dirt and rust;

- Wash and dry the container.

Installation

Installation of the membrane is carried out in compliance with some rules:

- insert the holder into the hole on top of the membrane;

- install the bolt in the holder hole;

- place the membrane in the housing and secure it with a special nut;

- install the membrane flange;

- check the accumulator for leaks;

- connect the appliance to the common water supply system.

Connecting the device to the water supply

Connecting the hydroaccumulator to the water supply system is an important stage in home improvement.

Functions of the hydroaccumulator:

- increase the life of equipment for water supply;

- reducing the number of water hammer;

- reducing the frequency of the pump;

- adjustment of the pressure level in the system;

- create a reserve of water.

Before installing the device, it is necessary to check the pressure level and set the relay. Experienced professionals will help reduce or increase the pressure in the accumulator.

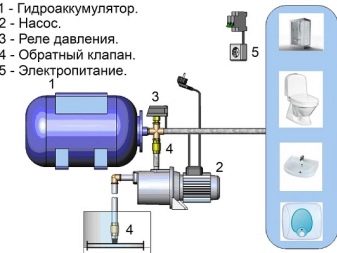

The water supply system has the following components:

- pump;

- hydroaccumulator apparatus;

- pressure switch;

- check valve;

- pressure gauge (if necessary);

- power supply.

Surface pump located near the accumulator, the check valve is attached to the suction pipe, all other elements are connected in turn. Installation details are connected with fittings. One of the connections is connected to the tank, a relay and a pressure gauge are connected to the outputs. To free conclusions fasten a pipe of the pump and distributing to the general system. For the installation of surface pumps it is possible to use flexible hoses with metal winding.

If there is not enough one hydroaccumulator indoors, then it is possible to connect the required number of devices. To do this, you need to install a tee at the input from the first device, connect the input from the pump to the first output, and the capacity to the second.

Modern technologies and the development of new types of devices for water supplyallow you to create high-quality and durable water supply system for residential premises of various types and purposes. Before starting the installation work, it is necessary to carefully examine the entire range presented on the shelves of stores, and experienced consultants will help you make the right choice that meets all the requirements and desires.

You can find out how to replace the accumulator membrane with your own hands by watching the video below.