Submersible drainage pumps for dirty water: technical characteristics and features of use

In order to pump out after a flood or torrential rains, water from the basement, from a flooded summer cottage, from sewage wells, water mains, communication systems, specially designed for this purpose industrial or general drainage pumps are required. These devices can be used to irrigate areas from a nearby reservoir, ditches, water pits. There is a large selection of drainage pumps on the market, but not all of them have the same purpose.

Device and purpose

There are three types of drainage pumps, distinguishing their performance, installation and some functions.

Surface

These are pumps installed on the surface of an object that needs to be pumped out of water: drainage sumps, underground tanks, drain wells, storage reservoirs, pits and other structures. In a production environment, they are often installed permanently and are connected by a piping system both to the pumped object itself and to the object to which the pumped liquid is directed.

TThese units are sometimes used in the composition of the craft on the surface of the water basinthey are supplied with an automation system, and their suction and discharge nozzles are connected to flexible hoses of the respective working pressures. There are portable models used in private households for pumping water from drainage and drainage holes and canals, as well as for watering gardens and orchards.

The class of protection against water ingress into the engine at surface pumps is low; they should not work even in the rain without shelters.

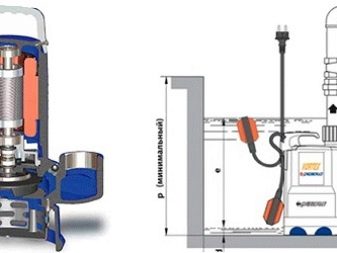

Submersible

Pump models operating below water level. They are sealedimmersion for them is a prerequisite for normal operation: water is the cooling medium for the engine and lubricating - for the pump mechanisms.

Universal

Universal pumps are used not only for dirty water, but also for pumping water from sludge and faeces. Such plants are supplied with suction grinders and belong to the fecal group of pumps. Popular pumps for the needs of summer residents, public utilities, construction companies, farms, water utility services, various boiler houses and onshore facilities are submersible units of various capacities and devices: from portable “gnomes” made of polymeric materials to powerful cast iron models.

They are convenient for pumping dirty water from virtually any emergency flooding sites, where the use of other drainage pumps often becomes impossible. Such places can be deep wells, collectors, too polluted reservoirs, pit and other structures that require to drain their full drainage.

A big plus for the "emergency services" is the fact that submersible installations can work in open areas in any weather.They are not afraid of either rain or snowfall, which can not be said about the surface "fellow".

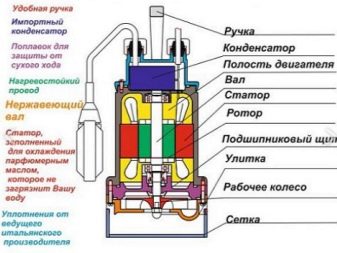

Submersible units have two main parts in their device: an electric motor and a pumping mechanism. All industrial designs of submersible units are manufactured in accordance with the requirements of GOST R 52744-2007 “Submersible pumps and pumping units. Safety requirements". The elements of the electric motor are in a sealed enclosure, the access of water to them is absolutely excluded.

In some models of submersible pumps (for example, borehole pumps), the engines are located in front of the pump mechanism housing in a special cooling jacket, which is also part of the unit intake manifold.

This casing performs the protective function of the motor from overheating due to cooling with water flow sucked into the pump. Only the drive shaft, which is necessary for connection with the driven shaft of the working mechanism, comes out. The electrical circuit of the immersion devices with supply cables is provided by sealed cable connection boxes with motor leads, having basically a separate structure from the case.These boxes are installed on the engine, in the place of its output ends (contact screws).

The pumping mechanism consists of a hermetic case in which parts of the pump shaft with bushings, bearings, a suction chamber and a blade mechanism are housed. The case and blade mechanism in high-power units are made of stainless steel, cast iron cases are common and reliable. In the assortment for private owners there are a lot of models from polymeric materials that are distinguished by reliability and high cost. For suburban needs, cheaper symbiosis of plastics and stainless steel, which are not distinguished by durability, are also produced.

According to the principle of operation, three types of submersible pumping units are distinguished: vibratory, centrifugal and vortex. Vibrating pumps, for example, “Kid”, “Strumok”, “Spring”, are widely used for domestic purposes, but they are not suitable for pumping heavily polluted water.

Vortex mechanisms are more often used in the pumping of sewage (fecal form). For pumping dirty water with possible solid inclusions of up to 5 cm is the best option - centrifugal units.

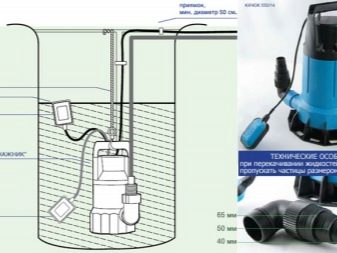

The location of its suction device is important for choosing a submersible pump. If the suction is located above or on the side of the pump, then it is not suitable for complete drainage of the well, pit, channel, and tank. Only the unit with lower suction is capable of completely downloading water. The suction apparatus of submersible pumps is supplied with a grille and a special filter that delays stones and other solid inclusions larger than 5 cm in order to avoid mechanism breakdowns.

Advantages and disadvantages

Drainage pumps are common means of small-scale mechanization used by man for domestic needs. Reviews of ordinary people allow us to conclude that in equal parts submersible and surface models find their followers in different parts of the country. But It is worth noting the fact (and this is confirmed by experts) that submersible pumps have several important advantages in relation to the surface ones:

- noiselessness (they are under water for the most part);

- have higher performance with low power consumption;

- can lift water from a depth of up to 50 m (can be used in wells and mines);

- pump out dirty water with solid impurities up to 50 mm (against 10 mm in cases with surface machines);

- used in any weather, without requiring sheds and shelters;

- have the compact size and the tight case;

- do not require additional devices for cooling and can work without rest up to two hours;

- quick installation on site

Of the significant drawbacks are the following:

- high cost compared to surface options;

- the inability to repair the engine due to its tightness;

- problems with the pumping of water from shallow reservoirs, especially in the case of the upper location of the suction nozzle;

- the danger of failure of the unit when lowering the level of pumped liquid below the upper generator of the device itself.

Brands

The Russian submersible unit called “Gnome” has a particularly high rating.demanded not only by private users, but also by public utilities and the industrial sector.

Among the best are the following units: Unipump Inoxvort 1100 SWpumping out dirty water with solid particles up to 35 mm in diameter, and Unipump Sub 407 Phaving the same characteristics, but at a price significantly lower than the previous one.

But pumps are also good. Unilift by Grundfos, reliably working even when flooded basements and wells with hot water.

Tips for choosing

In order to select the required model of the submersible unit, we need the reasons because of which such an idea arose.

- If there are problems with irrigation, and there is a well or irrigation pond nearby, then the purchase of a submersible pump will be the most correct decision of the owner of the site. In the spring, he will be able to help quickly tidy up the garden, and in the fall - to save the basement from flooding after the rainy season.

- If the river is near, and its spring floods flood the house and the plot, then to help you need to purchase just such a unit and no other.

- The dacha is located in a lowland or in an area with a high level of groundwater, therefore, a submersible pump will also help to drain the entire area in a couple of days.

It is best to carry out your choice among centrifugal units. They are good for watering the garden and vegetable garden with clean water, and for drainage measures with the pumping of dirty liquid from a ditch, pond or well. The fecal (vortex) version of the pump is needed for large volumes of pumping and is used in specialized services, and not in small country economy. And unlike vibration models, centrifugal devices do not destroy the walls of wells and are not erased when placed on a rocky or gravel base of the reservoir.A semi-submersible pump, which is a cross between surface and submersible models (engine outside, pump in water), is unlikely to be interested in the usual summer resident due to its technical and operational difficulties.

Submersible units have a single or three-phase electric motor, so you should not forget about the possibility of subsequent connection of the selected device. The performance of a single-phase pump is much lower, but 500 liters per minute is quite enough for irrigation and pumping out small areas and reservoirs. Their cost is also lower than a device with an electric motor on 3 phases.

Here are the main things to consider when choosing:

- study the characteristics and equipment of the mechanism;

- location of the suction inlet - if it is below, then a higher level of fluid can be pumped out, if at the top and side, it is more convenient to use for irrigation and less danger of falling into the blades of silt from the bottom of the reservoir or well;

- find out the size of the chamber - the larger the better and safer when pumping dirty water;

- for household needs to choose a plastic case and a steel blade device (reliable and affordable).

The general advice is this: for home conditions, the best choice is a household drainage unit for dirty water within the average power and particle size of dirt around 5 mm and with a vertical pressure connection.

Installation rules

It is desirable to purchase a unit with float protection against lowering the level of pumped liquid in the object. This is especially true in the case of installation of equipment permanently.

Functions of the float: turn off the device with an unacceptable level reductionto avoid engine and pump failures due to the lack of a cooling medium, and also to turn it on when the liquid level rises to the set value. Setting up the float is a responsible and only difficult job when installing a submersible unit. When setting up, you need to debug the minimum depth of the device, at which the float protection is triggered.

It is also necessary to protect yourself and those around you from piercing the motor windings on the case, as a result of which you can get an electric shock. Therefore, when choosing, it is necessary to make sure that the protection class of the electric motor against penetration corresponds to the engine operation in water.A big plus would be the presence of a switch that turns off the engine when it overheats.

The latest conditions of the installation rules will be compliance with the maximum immersion depth of the unit, as well as checking the integrity of the power cable of the installation. Many household submersible pumping devices are immersed to a depth of no more than 5 m. It is necessary to consult the attached instruction.

In no case during the operation of the mechanism can not go and even touch the surface of the reservoir in which it is immersed.

In the next video you will find the test of the TOTAL submersible pump for dirty water.