Choose a 12 volt pump for water

Water supply at home and the dacha is always important. But water supply is impossible without the use of a pump due to the fact that often the conditions do not provide stationary water supply.

For domestic use, washing machines, watering the garden and lawns are most often used 12-volt compact pumping equipment. Its use is concentrated in the locations of the minimum need for water.

This small-sized design won the love of consumers because of its affordable price, comfort in the process and high quality service.

The 12-volt pump works both from the power supply network, and at accumulators.

Features and Purpose

Low-voltage pumps have received huge demand due to their wide capabilities. To date, the market is represented by a huge number of water models of 12-volt pumps.

They are divided into several types:

- vacuum;

- circulation;

- pump pumps;

- membrane.

These are the main types, there are others.

Vacuum

Actually - already outdated name, and the vacuum is used in all types of similar devices.

Circulating

A modern circulating pump is similar in its working with drainage mechanisms, it can work with pipelines of small diameter. The body is made of cast iron, bronze or aluminum alloys, which significantly reduces the formation of corrosion.

The principle of operation of this type of pump is due to the fact that at the very beginning a sphere with low pressure is formed at the opening of the inlet nozzle due to the rotation of the impeller. Thus, a certain proportion of the coolant is drawn in, exacerbating the overpressure in the outlet nozzle. Due to this compression process, the fluid rotates in a closedheating system or hot water.

There are two types of circulation units: with a wet rotor and dry.

In designs with a wet rotor is located in a liquid, the contacts are hidden in a special compartment of stainless steel. The advantages of this type of pump are small dimensions, long uninterrupted operation time, low noise during operation and ease of setup. Minus - a small efficiency, in some cases not reaching 50%.

Units with a dry rotor, where the latter is clearly separated by metal and ceramic sealing rings according to the idea of engineers, have a higher efficiency. However, also not without drawbacks. For example, due to the use of rings that are sensitive to any kind of contamination, the liquid used must be perfectly clean, otherwise you can break the tightness of the pairing rings.

Pumps with a dry rotor are vertical, horizontal and block.

Pump pump

Used for pumping water from the basement after winter, the pump pump helps to balance the water pressure in the pipeline, and is also used for agricultural purposes. To work in the country hand pumps are an indispensable thing. This type is divided into several groups: surface, submersible and manual.

- The first type is a simple device, it is not immersed in water, the liquid is taken in via a hose.

- Surface models are used for pumping water from tanks, watering the garden, to increase the pressure in closed water systems.

- Submersible pumps are completely immersed in water, hence the name of this group. The body is made of a special material that prevents the formation of corrosion.

There are several types of submersible models: borehole, well, used for pumping water from the well, and drainage.

- Borehole submersible pumps are used to extract drinking water and create autonomous water supply systems. Well pumps are also called deep well pumps.

- Submersible drainage pumps are used for pumping dirty water from ditches and trenches, in sewage systems of yachts and boats, as well as in those places where it is not possible to use a voltage of 220V. Non-stop operation time 15-25 minutes.

- Well pumps help to make better water use.

Both purchased and home-made, pump-pumps are able to work for more than a dozen years with the necessary pressure indicators.

If the conditions are unsuitable for installation of the unit, as they contain clay and debris, then special linings are used that protect the equipment from the penetration of foreign particles.

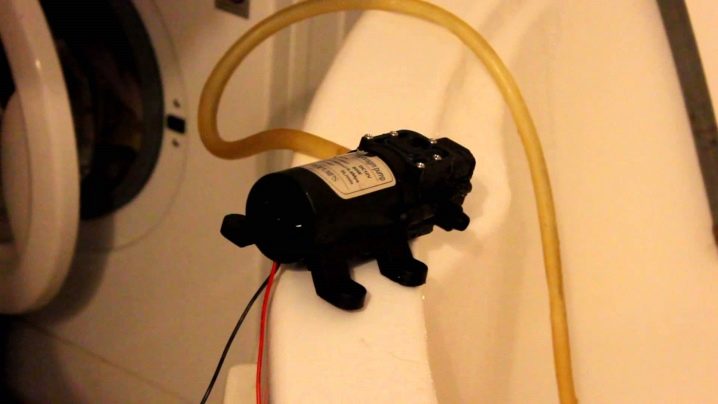

Membrane

Membrane electric pumps, like manual ones, are used to take drinking water from a well, pump liquid from one tank to another, cleanse natural reservoirs and pools, as well as wash equipment.

This type of pump works by changing the total volume of the working medium.

The main elements of such electric pumps are membranes that pull water from the tank and push it through the inlet nozzles.

Popular models

The market offers a huge number of pumps for sale, which can sometimes shock inexperienced buyers. To avoid problems with breakdowns and malfunctions, you need to give preference to proven models.

The most popular are several manufacturers.

- Kent Kent pumps are designed for pumping petrol and diesel fluids.

- DC50F-1250. Quality drainage devices of this brand are able to perform work at a water temperature of up to 60 degrees.

- Membrane models "92 articles". Reliable, strong, low weight mechanisms capable of pumping up to 20 liters per minute.

Other well-known, well-proven manufacturers:

- Propump;

- Rule;

- SHURflo;

- RotoFlow.

Benefits

The main advantages of 12V pumps are:

- possibility of use in conditions that do not have a power supply network;

- there are no noises and vibrations during the work;

- possibility of use near dangerous high voltage points;

- 12 volt power is enough to heat a house of 80 m2;

- equipped with built-in protection against boiling water.

Useful tips when working

In the process, always follow clear instructions. This and other useful tips give professionals and masters of their craft.

- Conventional submersible mini-units have relatively low performance. To provide the entire area with water for watering, you need special powerful pumps, and for pumping an aquarium, for example, such low-power models will be just right.

- Manual models should be used on the road.

- Before buying and choosing a pumping pump, determine the required power, purpose of use, water sources in which the pump will work, and the source of electricity.

- In addition to the direct destination, such mechanisms can be used to create an artificial reservoir, fountains.

Do-it-yourself pump

Homemade pump - the best solution if you decide to save money. In this case, you do not pay for shipping, not for transportation, and also do not overpay to trading companies.

If you have the materials and the necessary knowledge in your head, then do it yourself without any problems.

For the manufacture of a simple electric pump you will need a motor, for example, from a toy, and a power source, for example, from a telephone.

A small hole for the gear wheel is made in the bottle cap. On the side of the lid, another hole is made through which the second lid with the spout will enter.

The impeller for the pump is made of ordinary plastic. Its length should be slightly greater than the length of the second cap.On one of its sides, a hole is made through which the impeller is put on the wheel of the engine. In the future, it will rotate with the engine and create water movement.

If to compare with the scheme of the purchased unit, the difference will be only in that the engine will be of high power, and the impeller will not be made of plastic.

Such a pump, of course, is suitable for filling small tanks due to its small capacity.

For information on how to use a 12 volt pump for water, see the following video.