Technical characteristics of centrifugal pumps

Any process line pumping liquid media implies the presence of self-priming pumping equipment. In autonomous water supply systems, the pump is the main unit of the pumping station that supplies liquid from a well or a well. Widely used pumps for pumping liquids are centrifugal. They constitute more than 75% of all hydraulic apparatus for pumping liquid, viscous and corrosive media with solid particles.

Special features

Centrifugal pumps have found application in many areas of industry and in everyday life. They have become popular due to high performance, reliability and practicality. Pumps designed exclusively for pumping clean water, show quite impressive features. With all this, the pump works in an uncomplicated and clear scheme.

The device is cost-effective, does not require large amounts of electricity.

Thanks to the simple design, it is possible to quickly assemble and dismantle, as well as self-replacement. But if there is no experience in such matters, it is better to trust the professionals.

The most significant advantages of centrifugal pumps include the following:

- high performance due to design features and principle of operation;

- the absence of changes in the parameters of the pumped liquid;

- compactness and low weight;

- ease of use;

- long service life.

But we should consider the main disadvantages of such units, such as:

- cannot be switched on when there is no liquid in the working chamber. Otherwise, the pump will soon fail;

- low pressure when installing single-stage pumps, therefore it is recommended to use units with several impellers.

Thus, due to the large number of advantages of centrifugal pumps, they are popular in various industrial enterprises and in private homes that use an autonomous water supply system.

Kinds

On the modern market there is a huge variety of centrifugal electric pumps, which differ from each other not only in their design details, but also in their technical characteristics. They classify pumps according to a number of signs that should be remembered when choosing an apparatus for specific purposes.

Using classification by type of design, the following options exist:

- cantilevered - it is a one-frame construction, where the impeller is mounted with a coupling;

- sectional - has several impellers, allowing to increase the pressure;

- two-way entrance - has a two-sided impeller that compensates axial forces;

- vertical - it is intended for pumping of large volumes of liquid.

By appointment, centrifugal pumps are as follows:

- universal - pumps over exclusively clear water and is intended for the household purposes;

- networked water pumping unit is part of the heating system due to the operation at high temperature differences;

- nutritious - used for the assembly of steam boilers, where the intense pressure and high temperature of the liquid.Such pumps are equipped with a steam turbine and electric drive;

- condensate vertical multistage (horizontal) - designed to circulate condensate in the system;

- acid - designed for pumping corrosive media. It has found application in the chemical, petrochemical, and oil refining industries;

- drainage the pump is equipped with filters. It is designed for pumping dirty water and liquids with insoluble particles.

In turn, there are three types of drainage electropumps.

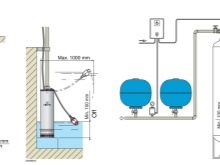

Surface

They are the simplest type of construction, equipped with self-suction hoses for water intake and an electric motor. They are installed on the ground near the well or well. The self-priming hose is designed for pumping fluid from an underground source. The main advantages of such devices is that their location on the surface allows to simplify maintenance and repair.

There are few drawbacks in surface pumps, but in most cases they are of no small importance, namely:

- low power, so that they can not be installed for pumping liquids from sourcesdepth of more than 10 meters;

- the occurrence of problems when idling;

- small performance.

Semi-submersible

Installed in the upper part of the tanks, which are subjected to drainage consoles and guides.

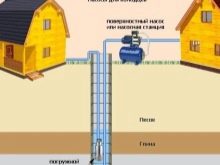

Submersible or deep

Are intended for arrangement of system of the independent sewerage. They are installed directly in the thickness of the pumped liquid. For reliable fixation of them at the required depth, a cable is used, the lower part of which is tied to the pump, and the upper part - to the crossbar located on the ground surface. Since the submersible pump is located in the thickness of the pumped liquid medium during operation, stringent requirements are imposed on the tightness of the housing of the apparatus. The main advantage of such devices is a high pressure at low flow. The most significant shortcomings include the complexity of operation and maintenance, as for the implementation of these procedures it is necessary to lift the hydraulic machine from an underground source.

By the number of impellers, pumps are divided into the following types:

- single stage pump does not have high power;

- a multistage apparatus, on the contrary, has such advantages as high power and productivity due to an increase in the working chamber. But as a result, the system becomes more complex and requires frequent repairs and maintenance.

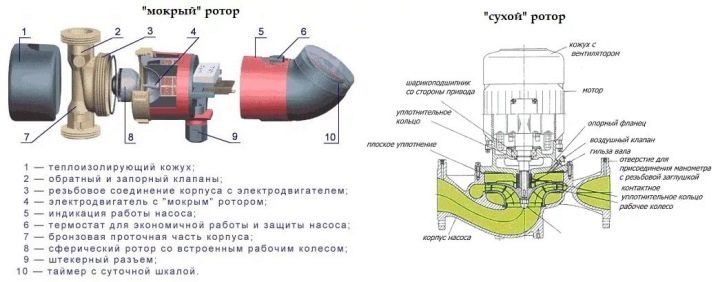

Depending on the design features of the rotors distinguish such pumps as:

- hydraulic pumping machines with wet rotorwhere both the rotor and the impeller are constantly in contact with the transported fluid, which acts as a lubricant and cooling agent for moving parts of the equipment. As a result, the internal elements of the pump cannot be made overall, therefore the equipment with a “wet” rotor has a small capacity;

- hydraulic centrifugal devices with a "dry" rotor practically no different from other centrifugal pumps, because in this case only the impeller that is rotated by the rotor and the electric motor is in contact with the transported fluid. Such devices are characterized by high power and high consumption of electrical energy.

Scope of application

Centrifugal pumps are used everywhere due to their design features, namely:

- in organizing water supply at industrial enterprises;

- when transferring and transporting technical media between production facilities;

- in arranging irrigation systems and livestock farms;

- when organizing a water supply system for small populations;

- in the organization of autonomous water supply, which is used by owners of suburban real estate for domestic needs and the organization of a system of watering plants.

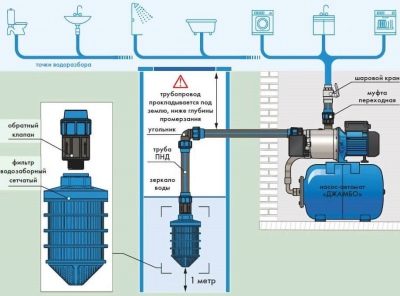

Submersible machines are the basic elements of water supply in the household. It is impossible to do without the borehole pump at all stages of water supply arrangement. After drilling wells and wells, only a submersible unit will help pump out a suspension of dirty water. In the future, based on the pump, a pumping station is equipped for more reliable and efficient water supply. Surface-type centrifugal pumps are most often used for pumping water from wells with good debit.

If the pressure and water flow is weak, you can purchase special impellers that stabilize the pressure at the outlet of the pump.

Device

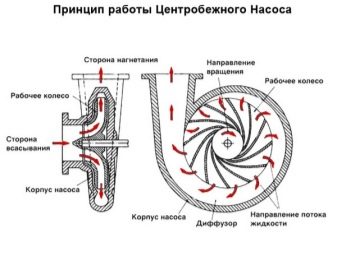

Centrifugal pumps consist of such major parts as the working chamber and the motor.Depending on the purpose and the pumped medium, materials and design features may change, however, the composition of the fundamental nodes is the same, namely:

- electric motor;

- snail type housing;

- Working wheel;

- shaft;

- bearings;

- sealing connections;

- flange connections.

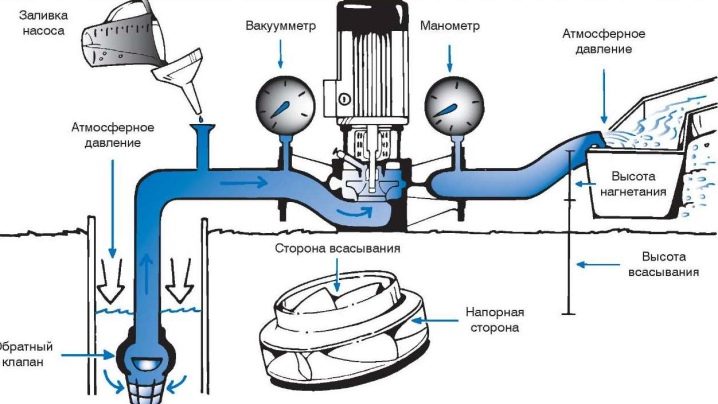

The normal functioning of the pumping system is ensured by additional components and devices, such as:

- non-return valve that prevents fluid from flowing backwards;

- valve on the suction pipe;

- fitting for air release during the filling of the chamber with water;

- valve on the discharge pipe to start and control the pressure of the liquid;

- vacuum gauge, which measures the level of vacuum at the entrance to the chamber;

- pressure gauge designed to measure pressure;

- hydraulic shock protection device;

- instrumentation.

The case of the device can be one-piece and detachable, which allows for repairs and maintenance.

Special conditions are imposed on the inside of the case - it should have maximum smoothness, since due to the presence of irregularities, the passage of fluid will be difficult, which leads to a decrease in the efficiency of the machine.The main part of any pump is a rotor (impeller). It is he who transfers mechanical energy to an electric motor. To increase the efficiency of pumping equipment, several rotors are often installed simultaneously. Thanks to this method, the flow pressure increases at the outlet.

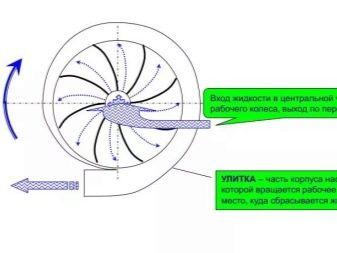

Water is discharged through a spiral-shaped chamber, which is why it has the name "snail". The chamber is connected with a branch pipe, which is located on the pressure pipe. The principle of operation of centrifugal pumps is based on hydrodynamic laws. Thus, due to the dynamic effect of the rotor blades, the liquid acquires a spiral shape. The spirals are located between two discs that are on the axis.

Centrifugal force is formed, which transports the liquid medium from the center of the body to the peripheral part and into the discharge pipe. Centrifugal force creates a vacuum of low pressure on the axis of rotation of the impeller, where the working fluid flows again. The pressure of the liquid arises due to the pressure difference between atmospheric and internal. The described principle of action relates to surface and submersible pumps.The main tasks of the equipment are performed by an impeller with curved blades.

The pump unit ensures that the pumped liquid is sucked in and transported to the pressure pipeline in a continuous mode, which is the guarantee of the stability of all characteristics of the pumped stream.

Installation

The installation process of centrifugal pumps is similar to the installation of other types of pumps. Submersible pumps need to be connected to the mains and suspension at the source itself. You must first connect a float-type switch to prevent dry running. Submersible pumps are labor intensive, but there is nothing difficult to install them. Surface devices are easily mounted in the immediate vicinity of the source. It is important to protect them from precipitation and temperature stress. You can install the pump in a heated utility room.

The pumping unit is connected by connecting it to the water supply system, and a hose with a check valve installed is lowered into the water source. Business remains behind small: to fill a chamber with water and to turn on the pump. Often, pumping equipment fails, so there is a need for repair.

If you have some knowledge and skills you can repair yourself.But if a major overhaul is needed, it cannot be avoided here.

To reduce the risk of breakdown of the apparatus, it is necessary to know the basic rules for operating the pump. Ignoring recommendations provokes 90% of cases of centrifugal failure. The following recommendations should be followed:

- the pump cannot be turned on when there is no liquid in the working chamber;

- If the pump is not designed for pumping contaminated liquids, it can only be used for clean water. The presence of even a small amount of sand in the water leads to clogging of the bearings and the appearance of damage.

The need for major repairs occurs when the engine overheats or burns. In some cases, pumping equipment may be used in conditions unsuitable for this unit. For example, he pumped hot water or worked with an empty chamber. Sometimes there is a short circuit in the power cord. You can use the tester to verify and fix the problem. Raw contacts must be cleaned or replaced, and the cable must be sealed.

In rare cases, there are failures of the impeller, in particular bearing failures and rotor fasteners.This is due to the transfer of water with particles of sand and dirt. Such units will work with strange noise, intermittently supply water. After finding similar signs, you should immediately dismantle the design, clean or change consumables. When driving spirals that remove water from the chamber, they need to be cleaned. If there is no experience in such works, you should contact the specialists.

Tips

When choosing a centrifugal pump, first of all it is necessary to pay attention to the technical characteristics of the equipment. But first you need to decide for what purpose the pump will be installed. Depending on the destination pump is selected according to the following parameters:

- the depth at which pumping equipment is able to pump out liquid from a water source;

- Efficiency, which shows the maximum efficiency of pumping equipment;

- performance - shows the amount of fluid that the pump unit is capable of pumping per unit of time;

- head - the height at which the pump can raise the liquid;

- the indicator of the hydraulics of the pipeline system is the pressure drop of the fluid pumped by the pump as it moves through the pipelines;

- the highest possible fluid pressure when the pumping equipment will function normally;

- pump motor power;

- energy efficiency - the amount of electricity that is spent by the pump to pump a certain volume of fluid.

It is recommended to start the pump only after its installation, fixation and connection to the pipeline line. Initially, the device must be filled with water, as well as the pipeline, by evacuating air.

After filling the cavity of the pump, you must start the electric motor by turning the valve on the pressure gauge. It is necessary to tightly close the valve on the outlet pipe. The vacuum gauge starts to work only after stabilization of the rotor speed and pressure. It is necessary to monitor the lubrication level of moving parts and periodic cooling of bearings. This will eliminate the risk of premature wear of equipment and the occurrence of damage to the entire pumping station.

On how to choose the best centrifugal pump to give, see below.