We select the machine for drilling wells

Today, many owners of country houses want to have their own source of clean water. The most popular are wells that can be drilled almost anywhere where an aquifer is present. The technology of forming such a system involves the use of special mechanisms. There are several types of such devices among which it is possible to distinguish boreholes. It is quite easy to get acquainted with the technical characteristics of these devices on specialized sites.

Special features

The water well is a small cylindrical structure reinforced with a special rigid frame. The formation of such systems is carried out using drilling machines.Technically, these devices consist of several mechanisms interconnected by various fasteners. Drilling rigs have appeared a long time ago, since with their help they extracted various minerals. The extraction of water with their help has been practiced not long ago, especially in the private sector. Drilling rigs allow solving such basic tasks as:

- the formation of holes of small diameter. They are used to solve small engineering problems;

- exploratory well drilling. They are used to obtain information on the status of soils and aquifers;

- drilling wells to find or extract liquid or gaseous minerals, such as oil;

- water well drilling. These mechanisms are relatively simple. This applies to structures that are used to form shallow holes.

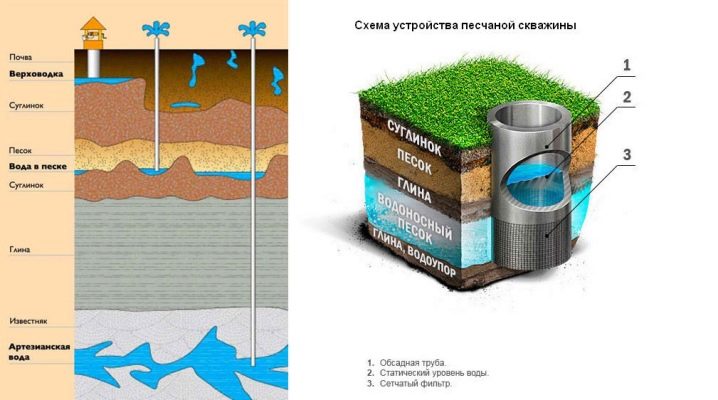

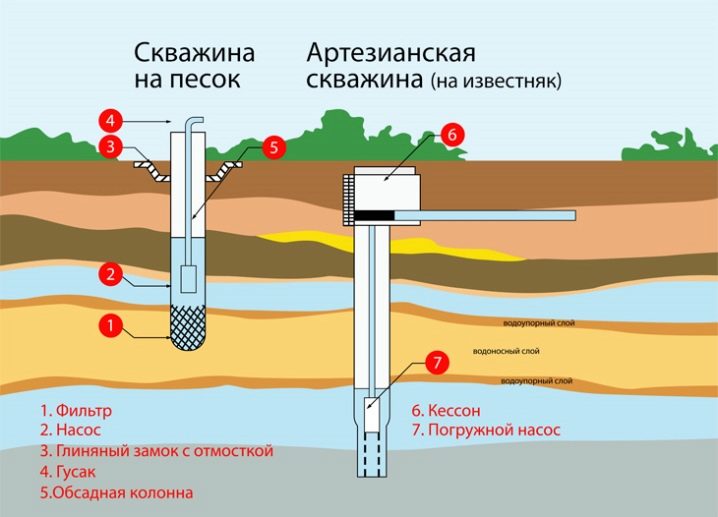

Wells of this type may have different depths. Depending on this, several types of wells are distinguished.

- Tubular well. This is the smallest well, having a depth of not more than 12 m. Only upper aquifers are used as a water source.After drilling, dirt, leaves or other debris will not be able to get into this well.

- Well in the sand. The depth of the average depth, which can reach no more than 30 m. The service life of such a system is about 15 years. At the same time, the well may periodically become clogged with sand and it will need to be cleaned.

- Artesian well. The depth of such a “well” can exceed 100 m, therefore special technologies and mechanisms are used to drill such holes. Drilling rigs of this type are characterized by high power and complexity. But such sources of water can be exploited for over 50 years.

The design of drilling machines may vary depending on the origin. Regardless, such mechanisms have the following common elements:

- frame - as a support can act as a metal structure, as well as directly self-propelled car or other complex system. The strength of such an element is determined depending on the maximum depth of drilling;

- drilling device - these elements constitute a system of mechanisms that set in motion the drill or other object that destroys the soil.When drilling can be used several types of tools that are intended for certain layers of soil;

- drive unit - technically, this device can be either an electric or diesel engine or a person’s physical strength.

Many drilling machines have a more complex structure, as they consist of various auxiliary units.

Kinds

Boring machines are a very popular product on the market. The scope of their application can be both industrial and household. Depending on this, similar mechanisms can be divided into several types.

- Industrial. Such machines are used for drilling deep wells. They are characterized by high power and performance. Very often they are used with various accessories. Similar mechanisms are used in the formation of oil wells. A prominent representative can be a floating platform, equipped with a powerful drilling machine.

- Mobile. Drills of this type are intended to form wells for water. They are equipped with low-power drives (electric motors and others), with the help of which it is possible to form a hole with a depth of up to 100 m.

- Hand held They are the simplest structures with which you can drill relatively shallow wells up to 15–20 m depending on the type of soil. These homemade small mechanisms are used in the domestic sphere.

If desired, they can be built manually from scrap materials.

Depending on the drilling technique, the machines are divided into several groups.

Shock rope

The formation of wells occurs using a special cartridge, which is made in the form of a kind of pipe with a pointed end. The destruction of the soil occurs under the own weight of the device. To increase the energy of impact, the bowl is raised specifically to a certain height above ground level. Among the minuses can be distinguished permeability and the impossibility of organizing fairly deep wells. Shock-rope models are used in everyday life for digging wells.

But it should be noted that such mechanisms can work even on stony ground, which is not always possible to achieve with other tools.

Screw

They are one of the most common types of machines. As a drill used screws of various shapes and sizes. The simplest models can even be used manually.The drill is placed in a rotational way in the ground, which leads to the crushing of the material, while the soil is located between the blades. To remove it, the working body is periodically removed and cleaned of dirt. Installations are driven both manually and with different types of engines.

Handheld models can be lightweight, which makes them compact and easily portable. But if drilling is performed on stony soils with a screw, then its effectiveness may drop significantly.

Rotary rotary

Machines of this class are characterized by high performance, as they allow the soil to pass relatively quickly and efficiently. Technically, the design consists of a vertical pipe and a cutting body. With the passage of the knife to the surface of destruction serves water under pressure. This allows you to soften the soil and make it more pliable. Fluid is also needed to clean the hole from the ground. A similar operation can be carried out in two main ways. The first involves the supply of water through the rod, and the dirt is already removed through the hole of the well itself. The second approach is completely the opposite.The well is filled with water, and the dirt itself is already being removed with the help of special equipment and sediment.

It should be noted that almost all drilling machines have a similar structure to the structure described earlier. This concerns not only devices for the formation of wells for water, but also oil mechanisms. But in powerful machines already use more durable materials that can withstand high loads. Therefore, such equipment cannot be built independently without the use of special technologies.

Manufacturers

The popularity of drilling rigs increases every day, due to the fact that systems of this type are used to solve various problems. Production of machines is carried out by many companies, among which there are several of the most popular.

- IzhNefteMash. The company has been producing drilling equipment for over 50 years. The company's products has many names. The most popular tools of this brand are drilling submersible drainage pumps, sucker-rod equipment, mixing plants, which are used for cementing mines, and many others.

- "Drilling equipment". This is another company with many years of experience, which produces equipment for drilling oil and gas wells. The manufacturer produces turbodrills, screw pumps and much more. The mechanisms are characterized by high performance and quality of work.

- Geomash. The equipment of this company is used in construction, as well as for drilling water wells. The manufacturer produces sets of self-propelled mechanisms capable of solving various problems. Many of them can form seismic and hydrogeological wells.

- Bauer. This German company, which is known on the market for more than half a century. Under the auspices of this brand produced a lot of drilling equipment for both industrial and construction use. It should be noted the high quality of the equipment produced, which is achieved due to the fact that the company manufactures all components for mechanisms independently.

The most popular machines are the Bauer BG 28 and Bauer MBG 24 models, which are used by many professional experts.

- Aker Wirth. This is another representative of Germany, producing high-quality drilling equipment.The product range has many types of products. You can find both small-sized plants and heavy industrial units. Especially popular are top drives, mud pumps and swivels.

The variety of drilling rigs does not end with these brands. Today, more and more cheap Chinese models are taking over the market. But before you buy them, you should make sure of their reliability and endurance.

Tips and tricks

Drilling wells is a complex procedure that is not always possible to do it yourself. Such operations are really performed only for shallow holes. When drilling, follow these simple tips:

- Before starting work it is necessary to analyze the soil. Based on the data obtained, a type of drill is selected that is suitable for the destruction of such a structure;

- you should try to set the instrument strictly vertically. If the system enters the ground at an angle, there is a risk of damage to the working body;

- in the case of manual drilling, be sure to add water to the hole. It will soften the soil and allow you to move faster in depth.

Drilling rigs for wells are special equipment of varying complexity. Their choice for the solution of certain tasks should be trusted to experienced professionals who will select reliable and durable mechanisms. For more information on drilling machines, see the following video.