What if the pump is stuck in the well?

Work with the equipment can sometimes be complicated for reasons beyond our control. So, using a submersible pump for drawing water, you can most likely encounter an unpleasant obstacle: it can get stuck in the barrel. In this situation, there are certain risks: you can inflict significant damage to equipment and spend a lot of time and effort to eliminate the resulting troubles. That is why you need to know what to do if the pump is stuck in the well.This will help a few simple rules and simple tips. But first of all it is necessary to figure out when it is necessary to get it and why it can get stuck.

Situations and causes

There are many reasons for causing difficulties. Most often, the pump is discharged to the surface when it has already worked for a certain period of time underground and it is required:

- carry out the necessary checks in the framework of maintenance;

- change the unit to a more efficient and productive;

- make repairs.

However, there are times when the device gets stuck when loading to a depth. This can happen if its size was chosen incorrectly for the diameter of the pipe, as well as if a foreign body got into the funnel, preventing the descent. It is important to remember that the pump must be two-thirds smaller than the pipe diameters.

The equipment wedges on the descent very rarely, because all measurements are made long before the work, and the probability of error is practically reduced to zero, and extraneous things can be easily reached or, on the contrary, lowered below.

When performing this operation, you need to be aware of several rules.

- It is necessary to conduct a detailed inspection of the pump on the health of its components.

- Control the absence of unnecessary items that can easily get into the pipe (it can be bags, small boxes, packages and stones).

- Work only with reliable materials: the cable and clamps should not cause doubts in its strength.

If you ignore these postulates, you can suffer significant damage. Both material and psychological.

Now it is necessary to highlight possible problems when lifting the unit, which occur much more often than the above points. Consider the most common reasons for which equipment can jam.

Cased wall

The walls of the casing were stung, and the seams and other parts of the weld were damaged, dents appeared, or edges were flattened. This can be identified by characteristic thuds. Most often it turns out to get the pump yourself by slow rocking. But this is only with minor damage. Otherwise, you will need the help of specialists. To avoid this problem, you need to take a responsible approach to the construction of casing strings and the choice of device dimensions.

It is better to spend more attention and money at the initial stage than to eliminate the defects later.

Cable sagged

This annoying situation leads to the fact that the pump will be pulled out to the surface all tighter, until at a certain level it is completely stuck, because the cable is twisted around its body and literally blocks.

If this happens, you need to perform simple actions.

- Pull the device to the bottom and eliminate the loop formed by measured swinging movements of the cable from side to side and gradually moving it upwards. It is necessary to remember accuracy and not to allow sharp and rough movements.

- Monitor the status of the remaining cords and hoses to prevent the appearance of additional nodes, which can significantly complicate the situation.

- Fix all the elements with special clamps over a certain distance (most often it is a range from one to one and a half meters).

- Carefully reach the jammed equipment.

This is a very common case, so do not worry: everything is solved quickly and easily. However, it will be better to prevent it in advance: when the unit is dipped to the bottom, tie it in the pipe withabout three meters apart. This will ensure its constant tension and help to avoid the occurrence of loops.

Foreign objects hit

Their arsenal is very extensive. This may be a nut, and a piece of cable, and stones, and packages, and packaging. Here you need to try to remove any excess items by swaying the pump or trying to reach them with a stick or hook. They can also be pushed down with a stick or other elongated object, but remember the safety rules and that the pump can be easily damaged.

All movements should be smooth and as careful as possible.

Pump skew

This is a serious problem to which many causes lead. This can happen, for example, due to sagging or abrupt cable jerks. The signs are as follows: up to a certain point, the ascent is carried out smoothly, but at one moment it is inhibited, but the impact is absent. Here you only need to make the cable tension weaker and try to turn the pump over.

In severe cases, you can contact the help of professionals.

Appearance of limestone deposits

In the worst case, they can be layers up to five centimeters thick.This is due to the reaction between oxygen and the metals contained in the well water. This problem can be solved by cleaning.

- Cleaning the well with plain water directed inwards under increased pressure. This will only work if there are small entities.

- Use a solution of water and acetic / citric acid. It is important to note that this is suitable only if the pump has already “served its own”, because such a method can harm the equipment.

- A mixture of chemicals against scale and hot water

Silting of wells

This can happen when the pump is used infrequently or if the operating rules are not followed. Thus, a kind of “trap” of silt is created. It is possible to free the pump from it by alternately stretching and loosening the cable and parallel rocking the pump from side to side.

The material may also harden, which creates additional difficulties. In this case, it will need to be pre-washed with a hose or a fire hose. This is a rather temporarily costly process that can take anywhere from a few hours to two days. You can also check whether the equipment is “released” by trying to get it to the surface by swinging it. If this does not work, then you need to continue to wait.

In order to avoid such problems, you should regularly devote time to cleaning the well and filter.

The cable broke

This is probably one of the most unpleasant and difficult reparable cases, because here the device falls to the very bottom, and it wedges in the pipe. We need to act quickly. Primarily with the help of a hose and an electric cable to stabilize the pump. If its size and weight are not impressive, you can try to unload it to the top. In the opposite case, you need to use a very strong rope with a metal hook. Hooking the unit to them, lift up.

If he fell, “pulling” all the cables behind him, you need to act as follows:

- take an elongated object (a metal rod is best suited) of a length sufficient to reach the fallen pump;

- attach a nozzle in the form of a hook or a corkscrew;

- put a metal rod on the free end of the rod (with its help the structure will rotate);

- lower the built mechanism down;

- try to screw the hook into the pump housing;

- gently and slowly lift the fallen equipment.

It should be understood that this will be possible only with a shallow depth.In this case, the operation of the pump, unloaded using this method, finally stops.

Unfortunately, there are cases when it is impossible to lift equipment even with the help of professionals. Do not despair. It is necessary to fill this well and start building a new one, henceforth without repeating the previous mistakes and observing all the necessary rules.

Of course, if the equipment is still stuck, the most correct would be to immediately turn to professionals. After all, they have the necessary knowledge and skills to quickly and efficiently extract the pump. However, this does not mean that you will not be able to act yourself. Here, as in any other case, it is necessary to approach in detail the solution of the problem, correctly and promptly identify and eliminate its “pathogens”.

How to prevent a problem with raising the pump?

Pulling a deep well pump from the well with your own hands, if it came off, is not difficult if you follow all the recommendations of experts.

The catch phrase reads: “Warned - means armed”. To prevent unpleasant situations, you need to follow a number of simple rules that can save equipment, time and money.

- Work only with strong cables. You can not save on this element.Choose quality products and fasteners.

- The hose must be intact. Purchase it of sufficient length, even if the bundled item does not meet the required indicators. So you will make the risk of a break significantly less.

- Choose the size correctly. The unit should be one third the diameter of the pipe. Otherwise, congestion during lifting cannot be avoided.

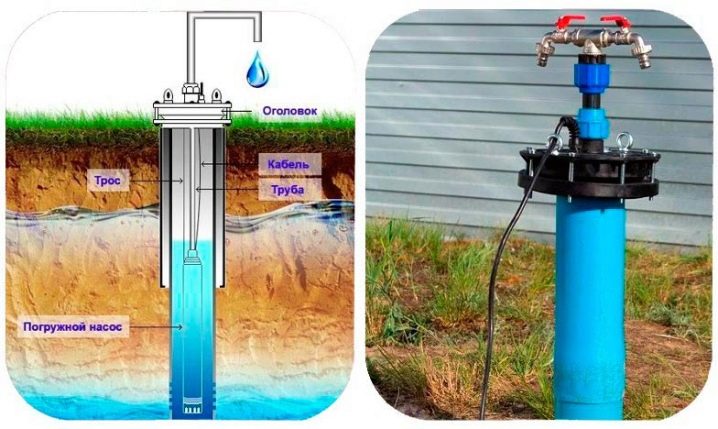

- Install the tip. This will ensure the "protection" of the well from unwanted "guests": garbage, bottles, stones, boxes.

There is no doubt that no one is immune from unpleasant situations when working with complex structures and equipment. This activity requires attention to detail at the stage of developing a future well plan and installing a pump. If we ignore the generally accepted rules of safety, inattentively take measurements, use poor-quality equipment, you can face a lot of problems. But even in this case, it must be remembered that any of them is completely solvable. If you decide to deal with it yourself, you need to remember about the accuracy, regularity of movements, patience.

The procedure of raising the pump from the bottom will not tolerate sudden and rough movements. This will only aggravate the situation.

If there is a feeling that it will be difficult to cope with our own efforts, it is necessary to contact specialists who will fix it very quickly. But you need to understand that sometimes it can be complicated to such an extent that even professionals with many years of experience cannot cope. Therefore, the most important factor in the smooth functioning of the equipment is prevention. Using quality materials and conducting timely installation of the necessary elements of the mechanism, it is possible to prolong the operation of the pump for a long time. Of primary importance is also the initial design. A competent approach to planning the arrangement of the future well and equipment in it is the key to success and smooth operation.

In more detail about what to do if the pump is stuck in the well, tell the following video.