The principle of operation of vibration pumps

Often in suburban settlements and small villages there is a need to get water from a well, a well or a reservoir for various household needs. And if you raise a couple of buckets of water in order to prepare food and brew tea is not a big deal, then the process of complete water supply at home or watering the garden should be automated. To cope with this task will help the submersible vibration pump, which is chosen for reliability and simplicity.

Special features

Vibrating pump is a submersible device that allows you to pump and lift water. It differs from large pumping installations by its compactness and simplicity.Consuming a very small amount of electricity, it has an affordable price and is elementary to use. This device consists of only three parts - the housing, the vibrator and the electromagnet. All components of the body are made, as a rule, from corrosion-resistant alloys or plastic, therefore it is durable and does not let water through. Vibrating pumps are most often sold with a special nylon cable, which allows you to avoid breakdown of cable insulation.

Outside such a submersible pump there are no rotating and rubbing parts that may require lubrication, therefore the pump lasts longer than usual and weighs no more than 5 kilograms. Nevertheless, there are drawbacks to this device, for example, the need to stop - the pump cannot operate continuously for a long time - or the small depth of immersion (up to 3 meters).

Vibrations from a running pump can destroy a well if it is not reinforced.

Vibration pumps can work in water with a high content of mineral salts, is not afraid of alkalis and can withstand any temperature. With their help, you can carry out:

- the rise of water from various wells for household needs;

- water supply from a closed container (tank, cistern);

- pumping water from various reservoirs, pools and rivers;

- pumping water from basements, trenches and pits.

It is important to understand that using a vibration pump in a well will only work if the soil has a high content of stone fractions (coarse sand, quartz).

In cases where fine sand or sandy loam is found in the soil in large quantities, the pump will constantly become clogged and need cleaning, which will significantly shorten its service life, and may simply damage the device.

Kinds

There are several types of vibratory submersible pumps with different characteristics depending on their design.

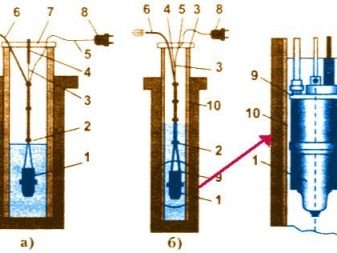

Depending on the type of fluid intake, there are pumps:

- with the lower water intake;

- with the upper water intake.

The first type has a suction valve at the bottom of the housing, and the second - at the top. The device with the lower fence is often clogged with dirty water mixed with small debris and soil, often overheats and fails. To prevent overheating, you must purchase a device with thermal protection. Pumps with the upper intake is not recommended to use when the water level in the well or reservoir is low,since such a device can only work completely submerged, and work on the surface of the water can cause damage.

The material from which the body is made can be:

- Aluminium alloy;

- plastic.

Aluminum is more durable, but also more susceptible to corrosion when it is in constant contact with water. Plastic is a more convenient solution for a water pump housing, but it is less durable than metal.

By the number of valves, vibration pumps are divided into:

- single valve;

- double valve.

The performance of the latter is much higher than the one-valve pump. If the first is only suitable for use in a small country house, then with the help of the second, you can organize high-quality watering of a large garden plot or vegetable garden during the entire dry season.

And finally Vibration pumps vary according to the manufacturer’s country:

- domestic mechanisms;

- imported.

Foreign devices are more expensive to maintain and repair. It is quite difficult to find models from the USA or Germany on the Russian market, but pumps from Belarusian, Chinese and Ukrainian manufacturers can be met often.Domestic vibration pumps are not inferior to imported mechanisms, and they are much cheaper, and it is easier for them to pick up parts for repair in case of unexpected breakdowns. On average, the price of a submersible vibration device varies between 2500 and 5000 rubles.

We should also note that since a submersible vibration pump is not recommended for use in wells drilled in sandy soils, it is better to use a special downhole submersible pump to take water from such a source.

Device

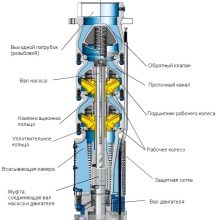

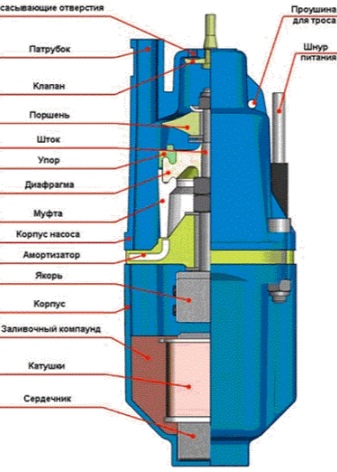

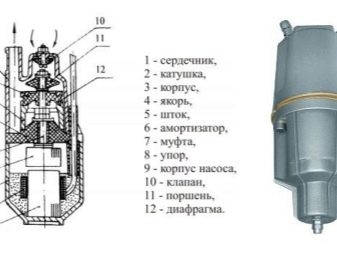

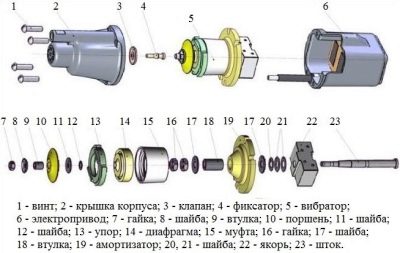

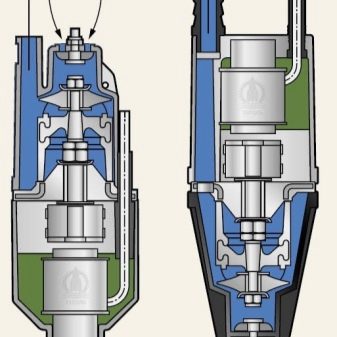

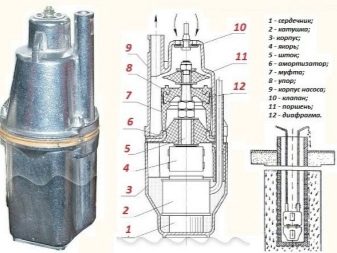

The internal structure of such a compact pump consists of only a few basic elements.

- Power element. The first element is an electromagnet consisting of a U-shaped core. Dialed from steel electrical plates, the core is covered with a winding and a special isolate in the form of varnish. On top of this design is filled with quartz sand, mixed with epoxy resin in order to fix the magnet in one place and additionally isolate its winding from the water. Sand in this case is needed in order to divert excess heat.

- Vibrating element. The second element is the second part of the U-shaped magnet with a fixed stem.As a shock absorber that allows you to create a vibration, there is a small rubber washer attached to the back of the rod. From the quality of this washer almost completely depends on the performance of the pump and its efficiency. A plastic coupling is located behind the washer, which hermetically separates the electrical part of the pump from the water collection chamber. Inside it is the diaphragm, which presses and guides the rod.

- Discharge chamber Water from this chamber under pressure enters the ducts of the pipeline, located on the sides of the sealed electrical part of the pump.

- Suction chamber. Due to the vacuum created by the pump, water flows from the source into it.

- Shock absorber. Round detail made of thick rubber.

- Adjusting washers. With the help of their number you can control the piston stroke and the performance of the entire device.

- Stock. The rod has a cylindrical shape that connects the piston with a vibrator. In some models of vibration pumps, this part can protrude into the suction chamber and walk along special guide rings. This design significantly improves the quality and service life of the mechanism.

- Check valves. Such valves are made in the form of small rubber fungi, through which water can flow into the suction chamber, but it cannot back out. This is achieved due to the fact that when squeezed by the piston, the valve tightly pressed against the hole. If the valve is damaged or dirty, then part of the water when the piston is pressed will go back, so it is very important to monitor their condition and replace it in a timely manner in case of a breakdown.

- Nut. Fixes and fixes the piston.

- Rubber piston. The main moving part of any pump. Dirty water quickly destroys such a fragile material as rubber, so it is the piston that first fails.

- Water drainage channels. With their help, water from the discharge chamber enters the pipeline. Just like the piston, such canals are destroyed by dirty water and cannot be repaired, only replaced. In some cases, the device includes a small filter that sorts out small debris and soil particles before supplying water to the suction chamber.

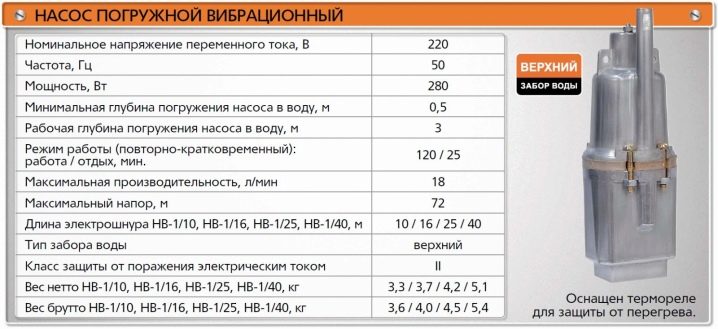

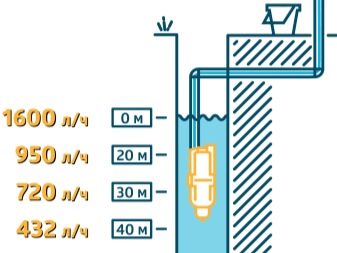

Standard models of vibratory submersible pumps have the following specifications:

- power 245 W;

- rise of water to a height of 40-90 m;

- cable length is 10-400 m, 220 V mains supply;

- external diameter of 7.5-10 cm;

- capacity 360-3000 liters of water per minute.

The principle of operation of the submersible vibration pump is based on the pressure drop inside the water injection chamber. Due to the action of the rubber piston or diaphragm, a vacuum is formed in the suction chamber, which, according to the laws of physics, tends to fill the water from the source.

If you look in more detail, the whole process of pumping water by automation looks like this.

When the pump is connected to the electrical network, a current is applied to the coil and an electromagnetic field is generated around it. As a result of the action of this field, a vibrator located in the discharge chamber begins to be attracted to the magnetized coil. Following the attraction of the vibrator, it bends and attracts through the rubber piston rod, thereby creating a vacuum in the suction chamber. Its space is filled with water, which seeps through the valve-fungi.

Due to the variability of the current, the magnetization periodically disappears, due to which the rod is rejected by the force of the shock absorber and presses the valve against the water inside the suction chamber.Since the valves do not allow the liquid to leak back into the source, it moves into the discharge chamber, from which at the moment of the newly appeared voltage rushes due to the pressure through the channels. The frequency of such cycles is about 100 pieces per second, so the movement of the rod is, in fact, vibration, for which this device was called “vibration pump”.

Installation

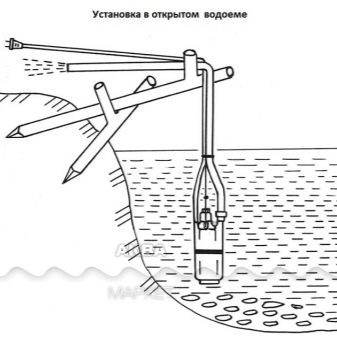

In order for any vibration pump to work effectively all its life, it must be properly installed. You can do it yourself and without the involvement of specialists, the main thing is to take into account a number of features.

- The submersible pump must be completely covered with water, but be at a height of 50-70 cm from the bottom of the well or tank. If you lower it to the very bottom, then the machine will pick up trash and sludge, the water will become dirty, and the mechanism will quickly clog.

- The device should not touch the wellbore walls with its casing and should be fixed on a nylon or galvanized cable. Due to the vibrations, the pump will either destroy the walls of the well, or in the event that the walls of the tank or well are quite strong, can damage its casing.

- It is imperative to check the isolation of the electricity supply cable, since water is easily conductive and this can lead to irreparable consequences.

- All mounts must be adjusted and rechecked. We should also pay attention to the channels through which water will flow from the discharge chamber - check them for blockages and tightness.

If the operating rules recommended by the manufacturer are observed, the vibration pump rarely breaks. And even in case of non-compliance, the first malfunctions can occur only after 3-4 years of work without proper care. If the vibration pump is still under warranty service, in no case should you try to open the case and repair it yourself. It is necessary to contact the seller or the service center with which the contract is concluded.

In the event that the warranty period has already passed, it will not be difficult to restore the operation of the device using the simplest repair kit.

You can diagnose a problem by certain symptoms.

- The vibration pump is buzzing, but no water is coming. The reasons for this problem may be several. For example, the piston fasteners are loose, the valve has been damaged, or the stem has broken. It is necessary as soon as possible to disconnect the faulty device from the network and lift it to the surface, after which you can disassemble the pump and look for the cause of the breakdown.

- The vibration pump is buzzing and hot. The most common cause of such a malfunction is the work of the pump above the surface of the water, which contradicts the rules for using the device. The design of the vibrating pump does not include a cooling element, which replaces the constant presence of the mechanism in cool water, so the pump suspended in the air quickly overheats and disables the electromagnet. Replacing it with your own hands is quite complicated, but it is possible with certain skills of working with a soldering installation.

- The vibration pump is working, but completely silent. Vibrating devices can not work in absolute silence, so the lack of even humming should also be alarming, as well as extra noise. The cause of such a fault is the fallen voltage in the network. In this case, you need to disconnect the device from the power supply as soon as possible and eliminate the malfunction of the network itself. Reconnect the pump can only be after normalization of the mains voltage.

Tips

Before you buy a vibration device, it is not enough just to study the ratings of manufacturers, you need to know what exactly is a sign of product quality.

The main indicator of the pump is its performance. Depending on the model, it can start from 50-100 liters per minute and end with an indicator of 1200 liters. The second most important indicator is the possibility of raising water to a certain height. In a high-quality device, this indicator can vary from 40 to 100 meters. The dimensions of the pump itself must correspond to the diameter of the well or tank and must be so compact as to not touch the walls with the mechanism case.

According to the reviews of Russian buyers, the “most demanded” vibro pump in the CIS is the “Kid”. Equipped with thermal protection, it can have both upper and lower water intake. The pump is produced by several plants: "Electric", "AEC Dynamo".

The model doesn’t get any worse off the shelves "Stream". It also produces different plants, so the characteristics can be different for models with the same name. Ukrainian vibro pump "Aquarius" costs a couple of thousand rubles more, but its model range is so wide that it allows you to pick up a pump for almost all cases. All models of “Aquarius” are equipped with thermal protection and are significantly different from the Russian “Aquarius” for the better.

High-quality vibration apparatus from a trusted manufacturer - this is an excellent choice for a country house or suburban area. A properly selected model will allow free access to clean drinking water for many years.

In the next video you are waiting for the review and repair of the vibration pump.