Why is the pumping station not shutting down?

Pumping stations are designed to improve the water supply system and are used in private homes and cottages. These facilities provide automatic water supply, which is very convenient. But sometimes there are failures in the operation of the equipment - the station simply does not turn off, and often the owners have no idea why this is happening.

Features of the pump

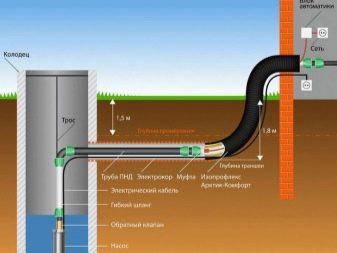

To clearly understand what failures can affect the fact that the station does not shut down, you should once again consider the device of the hydraulic device.

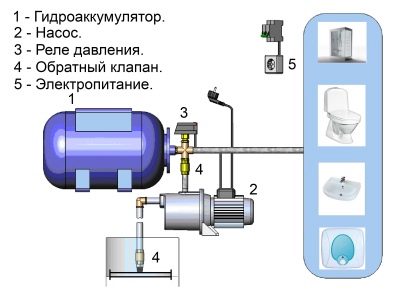

The pump construction has several important components on which the operation of the entire unit depends:

- it is a pump that lifts water from the depth and drives it into diverted tanks for different purposes;

- a hydraulic accumulator, which is a plastic or steel tank, in which there is a reserve of liquid - when the pump is running, the tank is filled with water, when it is turned off, it returns liquid to the pipes to maintain pressure at the same level;

- The station also includes a control unit for the automatic activation and deactivation of its main pumping equipment.

It turns out that the pump is not always involved in the work and periodically "rests", which allows to increase its service life. Therefore, if the pumping station has ceased to shut down, it must be stopped, thus preventing its premature wear.

Correct setting

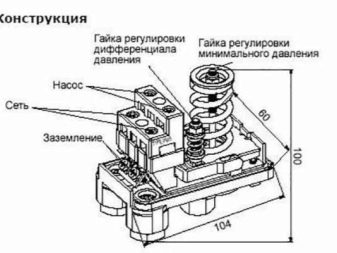

Two nuts in the relay using springs are able to regulate the minimum and maximum pressure.

A large spring is responsible for the lower pressure threshold, and a small one - for the difference between it and the upper indicator. Sometimes improper installation can lead to errors in the operation of the facility, and the pressure switch that is illiterately adjusted becomes the cause of the malfunction.

To make the right settings, do the following:

- stop the station by disconnecting it from the source of electricity;

- then the hydraulic tank is released from water and air is exhausted through a special valve;

- A similar device with a pressure gauge is connected to the pump nozzle;

- pump up the capacity of the hydroaccumulator to the working pressure at the mark on the relay;

- the large spring is turned clockwise with the help of the nut or, on the contrary, setting the minimum pressure level;

- expose the difference between the pressures by turning the small spring control.

With the necessary parameters, the pump will work optimally - it will turn on and off automatically. An important condition for shutdown is a working pressure of 95%, this is the maximum allowable parameter.

If the system pumps over water with significant contamination, it should be borne in mind that the construction can work continuously and non-stop due to blockage of the control unit - there is a hole in its body and it is subject to contamination. Cleaning is best done before adjusting the pressure.

Do not discard the option when the damage concerns the springs with which the pressure is regulated. Sometimes they do not work because of rust accumulated on them.As a result, the part ceases to function, and the contacts are closed, which leads to malfunction.

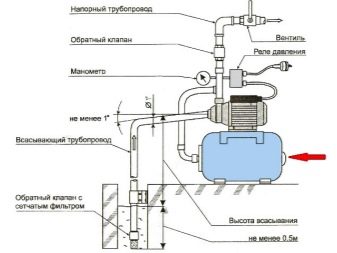

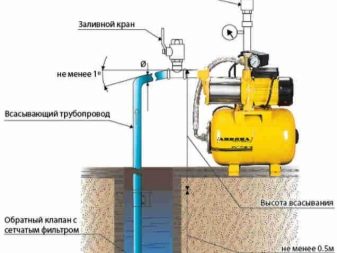

Clogged input filter

This is also one of the reasons that the pump runs for a long time without shutting down. Water taken from a well or a well can be of different quality and often contains small particles of clay, sand or silt in its composition, due to which the filter built into the inlet nozzle gradually becomes debris. This part of the station significantly increases the duration of operation of the water supply system.

But when the supply pipe is damaged, and the filter is clogged, water can no longer flow in the right quantity.

In this case, the problem is solved quite simply:

- clean the filter;

- add water through a special plug and start the equipment.

It is more sensible to monitor the state of the filter continuously to prevent such failures.

Drop in water level

If the water source is not too deep, a decrease in the level of soil water may affect the operation of the pumping station. The lack of water or its absence leads to the fact that the installation air is supplied. This mainly applies to shallow wells in 6-7 meters.No one is immune from this, and the only way to solve the problem is to drill a deeper well.

If the water level in the pump itself is lowered, you will need:

- add water by unscrewing the fastening bolt;

- make a start and wait for the fluid to accumulate;

- disconnect the equipment again and add more water.

Such actions are necessary if you need to speed up the launch of the water supply device.

Water leakage can also provoke uninterrupted operation of the unit, and it can occur anywhere in the water supply system.

It is clear that you will have to inspect all parts of the system in order to identify it. It is necessary to reliably seal the leakage place with a special adhesive tape in order to replace the damaged area in the future.

When water flows from a crack in the mounting flange, you have to remove it and brew damage. In case of leakage on the thread, they replace the gasket or ring, they also use a special sealant in the form of a thread, which reliably fills defects.

Other reasons for not turning off

Automation may not work on shutdown in a number of other common causes.

- Air leaks - this is due to the fact that the settings on the valve, which is responsible for lowering the air accumulated in the system, have been reset. For this reason, the working pressure may change, and the result is that the pump pumps the fluid non-stop and does not shut off. The only solution is to restore the correct settings.

- Power surges in the networkwhich occur not only because of accidents at substations, but also due to poor wiring, contact ignition, the inclusion of additional high-power electrical equipment. Such drops lead to failures and breakdowns in the work cycle of the station. To avoid this situation, you can use voltage regulators (transformers or generators). If this is not done, with a constantly changing voltage, the pump will sooner or later be disabled.

- Oxidized contacts in the pressure sensor. Unfortunately, this option is also possible, and the station does not work normally for this reason. The fix will require de-energizing, disassembling equipment and inspecting all contacts. As a rule, after stripping and reassembly, the operation of the unit is restored.

- Impeller wear, especially if it is made of plastic, directly affects the continuous operation of the pump. This part of the station, located in the power unit, is destroyed over time due to the constant flow of small abrasive particles in the water. It is possible that initially, when drilling a well, the size of the net that captures sand was chosen incorrectly, therefore larger fractions than those allowed are inside the station. The detail will have to be changed, and for the future it is better to purchase a metal impeller.

- One of the serious faults is considered failure of the ejectorif the station is equipped with such a detail. This is due to the fact that this important part is under the surface of the earth, and the repair is fraught with some difficulties. In some cases, the ejector simply requires cleaning, but sometimes you have to replace it completely.

If an emergency drain valve is present in the pressure switch, a failure in its settings will lead to the release of air at insignificant values. To correct the situation, you can adjust its work, if the valve breaks, it is replaced with a new one.

The conclusion suggests the following - there are many reasons, both serious and not so, which may complicate the operation of the water supply installation.In order for the pumping station to work smoothly and not be subjected to wear due to disconnection problems, it is important to check all components of the structure at least once every 2-3 weeks and immediately eliminate even minor problems.

For the reasons why the pumping station does not turn off, see the following video.