Features of Al-ko pumping stations

The Al-ko pumping station is an indispensable element of a complete water supply system, which is ideal for your own homes and properties. Since centralized communications in the private sector are an exception, the installation of such equipment is particularly relevant.

Device

This design of the German manufacturer consists of several important details, each of which has its own specific, functional purpose. It is necessary to identify the main parts of the equipment.

- Centrifugal pump - lifting and pumping water device, suitable for wells and boreholes.It has a special container and a filling hole through which it is filled with water during operation.

- Accumulator for storage of water reserve, preventing hydraulic shocks and reducing the number of pump starts.

- Relay pressure is the control link of the equipment. This part automatically starts the pump when the pressure drops in the hydraulic storage tank, and if the water level is sufficient, it turns it off.

- Dry running relay - a sensor that turns off the pump during idle operation. Thus, it does not allow the engine to overheat, which can lead to failures and breakdowns.

Specifications

A special feature of Al-ko stations is the fact that coarse filters are built in to the pump inlet pipe, which are replaced every 4-6 months. The difference in two months is due to the different quality of water: the cleaner it is, the less need for replacement.

It may be noted the main characteristics of these products, which are:

- noiselessness during the operation of the unit;

- compact size;

- high performance;

- availability of cleaning filters;

- automatic control through a special unit.

The station brand Al-ko combines affordable price against the background of high technical and operational characteristics.All functional parts of the equipment are reliably interconnected by additional components in the form of adapters, fittings, connectors, seals, auxiliary components for coordinated work. In fact, such an installation is a pumping facility with many functions.

Of course, the capabilities of different systems may vary depending on the station models. Various modifications have excellent performance (from 3100 to 6000 l / h), therefore they are suitable for a private house and a summer house.

The lineup

On average, the Al-ko model lineup has about 40 stations, so it is worth considering the most relevant of these devices. Choosing this or that model, you need to pay attention to the performance of the unit - if you need a lot of water, it is better to opt for a more powerful installation.

Al-ko HW 601

This is a budget option for home use. The station can be attributed to the surface units. This modification applies if there is a clean water source available. Its capacity is 600 watts, so it has a capacity of 3100 l / h.

The depth at which the water is lifted is 9 m, while it can be supplied to a height of up to 35 m. The capacity of the hydroaccumulator is designed for 20 liters.

The main advantages are lightness (weight 11 kg) noiselessness and compactness. Similar characteristics have designs HW 604 and HW 610.

HW 3000

This is a universal equipment for a garden, a dacha and even an apartment, allowing to provide a constant pressure of the water supply system and the further transfer of water from any tanks for different purposes. It has a similar capacity - 3100 l / h, but it is characterized by a higher power of 650 W, the depth of the liquid intake is 8 m, the lift is up to 35 m.

Due to the anti-corrosion housing and additional components, it is more suitable for country houses (especially when building a more complex water supply system for the house and irrigation is required). The advanced model of the HW 3000 Inox Classic differs from the standard model in that it has a water storage unit made of steel.

HWF 1000

This model was one of the most popular not so long ago, but is currently discontinued. However, its device was used to create a modification of the HW 4000 FCS Comfort. Both units are relevant for areas with low water pollution, equipped with coarse filters. HWF 1000 can still be purchased on the market for used products, it is still relevant and in demand for various needs.

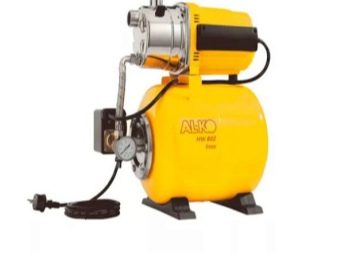

HW 802 Inox

800 W surface pumping station with vertical pump installation and overheat protection. It has a flow capacity of up to 3,400 l / h, light weight (11.6 kg). Designed to raise clean water. The body is made of stainless steel. Mainly used for garden and country plots (for irrigation and technical needs).

Al-ko 4500 FCS Comfort

It has a high suction power, the performance of the equipment is 4500 l / h, power is 1300 watts. It is a floor-mounted unit operating with a depth of 8 m and a lifting height of 50 m. It has electronic control, automatic switching on and off. For operation, a voltage of 230 V / 50 Hz is required.

The device is equipped with a pressure gauge and overheating protection option. The modification is used to lift water from wells, open reservoirs, pipelines.

Equipment setup

After installation, automatics may not always work correctly. It depends on the proper setting of the pressure switch. As a rule, this happens when parts are purchased separately and assembled independently on their own. In this case, you should pay attention to some subtleties.According to the relay diagram, one of the clamping nuts is responsible for the cut-off pressure, and the other for its activation.

The adjustment must begin with checking the pressure on the pressure gauge. If the hydroaccumulator is empty (pressure level does not match the required one), pumping using a pump is required. It is not possible to increase the upper limit above the allowable working pressure of the hydraulic tank. Reduce the pressure by turning the small nut counterclockwise (on the contrary - to increase). If a station is purchased in assembly, there are no such problems.

Proper operation

In order for the equipment to work without failures and breakdowns as long as possible, it is necessary to remember the rules for its use:

- for work the water temperature is provided not higher than +35 degrees;

- do not allow the pump to idle;

- the system operates at 230 V;

- You can connect the device only with an automatic fuse.

Careful and careful use of the system is necessary, so it is not allowed to hang the installation by the wire.

When is repair needed?

Despite the fact that Al-ko equipment is produced by a foreign company, it is not difficult to find and purchase components in the territory of our country if they need to be replaced.Unfortunately, even such high-quality equipment may fail sooner or later, and reconstruction will be required. Usually, this is due to several common faults.

- Jerk water supply. The main reasons are deformation of the membrane of the accumulator or insufficient sealing of its body.

- The pump does not turn on. This situation may arise due to damage to the motor winding, as well as when a capacitor burns out.

- Pumping does not occur.while the pump is working. The case may be a failure of the check valve or a leak in the intake hose.

- Working pressure reduced. This can mean wear or damage to the pump impeller or rust on it. Such a replacement is possible only with the help of service personnel.

Reviews

Reviews of those who have experience with this equipment, in most cases, confirm the high quality of this technology. Especially, it emphasizes its high performance and affordable price compared to similar facilities. Modern Al-ko pumping stations are well-deservedly popular due to high German quality and ease of use.They are durable, compact and do not require repair for a long time.

For how to install an Al-ko pumping station, see the following video.