Pumps "Dzhileks": variations and recommendations for use

Among the most popular budget pumping systems can be distinguished products "Dzhileks". It is widely known for its design and high quality, which is combined with an acceptable cost.

Currently, the equipment "Dzhileks" is used in the arrangement of domestic water supply, where the source of water is a well or well. Since the range of downhole machines is diverse, you should consider all the options that the manufacturer offers.

Special features

The most important advantage of the manufacturer "Dzhileks" is the low cost (compared with foreign models). The pump body is made of materials such as: plastic, stainless steel. Most pumping units are equipped with a float that prevents the pump from running dry.

The main parts of pumping stations are: hydroaccumulator, system control unit and pumping unit. Many pumps have a non-return valve that prevents fluid from flowing backwards. The inner part of the pressure tank is equipped with a membrane and compressed air to maintain the required height of the liquid. Experts also recommend to equip the pump station with an additional water filter to clean water from particles that will adversely affect the operation of the equipment.

Kinds

There are several main series of pumping equipment:

- well and well submersible hydraulic machines;

- surface pumps for stationary water supply systems;

- fecal and drainage equipment;

- circulation units.

Borehole and well submersible hydraulic machines are available in two variations:

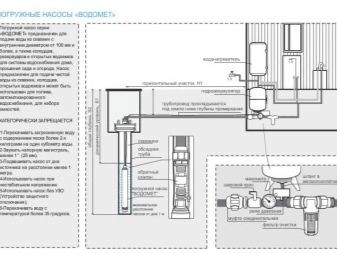

- "Water cannon" - submersible device;

- "Vodomet A" - well equipment.

The principle of operation of such pumps is based on centrifugal force.In this case, the pumped liquid medium acts as a lubricant. Due to this, low noise and minimal vibration impact during maintenance are ensured. Pumps are installed on an underground source, the diameter of which is not less than 11 cm.

"Water cannon" consists of a housing, a multi-stage impeller, an engine and a discharge pipeline, which is connected to the water supply system.

"Vodomet A" differs from "Vodomet" only by the presence of a float-type switch. It is installed directly in the thickness of the pumped liquid medium. When the liquid level drops, the switch is automatically triggered, thus avoiding a dry run.

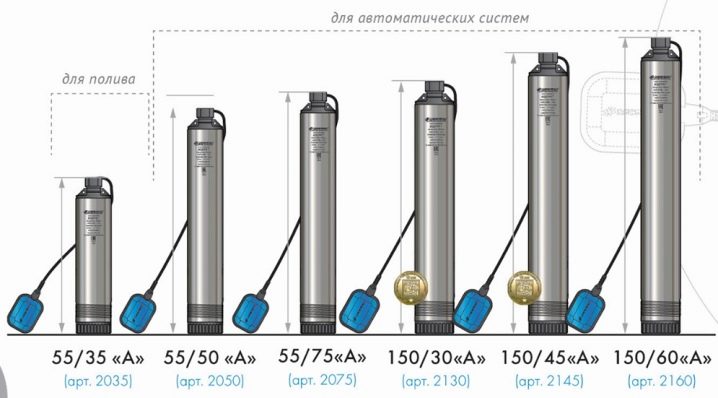

The following models of this series are distributed:

- "Water cannon Prof. 40 75" provides water pressure up to 75 meters and flow rate up to 40 liters per minute, the size of solids pumped by the pump is less than 1.5 mm;

- "Prof-110 110 110" designed for pumping clean water, consumption - 110 liters per minute, lifting liquid - 110 meters.

Equipment "Dzhileks - House" acts as a separate mechanism for the implementation of automation pumping station, protection against water hammer and sudden voltage changes.It is installed on the borehole pumps, which allows to obtain an autonomous circuit of the water supply system.

Popular well pumps:

- "Water cannon 150 30 A" has a capacity of 150 liters per minute, the rise of the liquid is carried out at 30 meters, the diameter of the device - 13.5 cm;

- "Water cannon 150 90 A" designed for pumping fluid from shallow wells and wells, its head reaches 90 meters, capacity - 150 liters per minute.

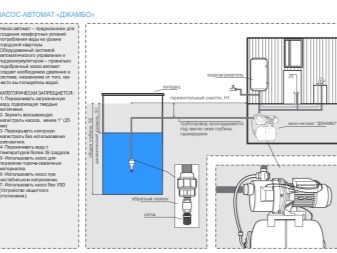

Surface pumps for stationary water supply systems are represented by the Jumbo series. More than 20 models of centrifugal pumps of this series are produced. There are several types of pumps (depending on the working body and maximum power).

- letter "P" in the name of the device (for example, 60 P) says that the pump casing is made of polymers;

- letter "H" in the name (for example, 70/50 N) indicates that the main elements of the pump and components are made of stainless steel;

- labeled equipment "H" (for example, 50 H) is cast iron.

The equipment case has two compartments: one is designed for the working chamber, and the other for the motor.The working chamber consists of an impeller for distilling the liquid into the pipeline. The motor compartment is attached to the working chamber by a flange connection. It is made of aluminum and closed with a lid that protects against the ingress of water droplets inside.

Also "Jumbo" can be equipped with the system "Dzhileks - Dom", which turns the pump into a pumping station. The most popular are several models in this series.

- "Jumbo 60/35 P-25" It has a pressure tank (capacity of 25 liters) to stabilize the pressure during interruptions. Its capacity is 60 liters per minute, the rise of the liquid is 32 meters.

- "Jumbo 60/35 N" It does not have a reservoir, but it can be installed using a flange connection. Head - 35 meters, performance - 60 liters per minute, the depth of fluid intake - 9 meters.

- "Jumbo 70/50 N-24 N" It has a pressure vessel (capacity 24 liters) made of stainless steel. Pressure - 50 meters, performance - 70 liters per minute.

Devices without a pressure tank have found limited use in the summer. Models with a capacity installed in the back rooms and basements.

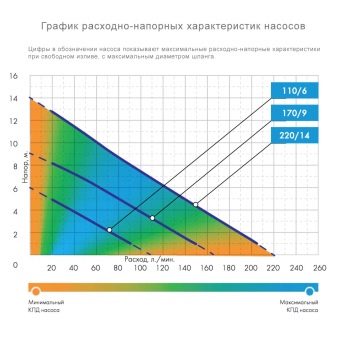

Fecal and drainage equipment is represented by a series of pumps. "Drainage" which contains six models. Pumping equipment is made of polymers, where the main component is polyethylene. Pumps are designed for pumping wastewater: rain, melt and polluted water from underground sources. Models of this series have float-type switches. Among the most popular are:

- "Drainage 110/6" designed for pumping melt water with low solids content;

- "Drainage 200 25" has high performance - 200 liters per minute with the consumption of electricity in 1200 W;

- "Drainage 220/12" allows to drain small ponds or large pools, operates on an economical engine with a power of 750 W;

- "Drainage 350 17" It has a 1200 W engine with a capacity of 350 liters per minute.

Circulation units are used in heating systems. They are included in the heating circuit of the room and distribute the hot liquid in the system, which leads to a uniform temperature distribution over the entire area of the room.

Circulating pumping equipment is represented by the series "Circle", which includes eight models with non-return valves to increase the pressure in the system. Pumps are made from cast iron materials. These devices can operate in three modes, these include:

- "Circle 32 40"which is among the economical pumps, as it consumes 32 watts of electricity, ensuring the rise of fluid to a height of up to four meters;

- "Circle 32 80" designed for heating three-story houses.

Other, no less popular, models of pumping machines should include the device "Poplar 3D"Which is designed to increase the pressure in the pipeline. Its body is made of plastic, and its battery is made of carbon steel. The maximum lifting height of the pumped liquid medium is 35 meters. The pumping station consists of an engine, a pressure tank, a check valve and a multi-stage impeller.

It should also tell about the model "Water cannon Prof 55/35", which consists of a downhole tool "Water cannon", a pressure tank and a frequency regulator, which is designed to automatically control equipment with pressure drops in the pipeline.

In addition to the basic device models, the company also specializes in accessories and spare parts for aggregates. "Dzhileks". A striking example of such equipment is the cartridge filter element. Its main purpose is water purification from mechanical impurities. The filter consists of a glass, a filter cartridge and a lid for removing pressure. It is mounted on the pipe in front of the plumbing.

In order to avoid hydraulic shocks that damage the nodes of the pumping station, two types of hydraulic accumulators are manufactured:

- "Dzhileks 300" (capacity 300 liters);

- "Dzhileks 200" (capacity 200 liters).

They avoid pressure drops in the system and ensure stable operation of the pump.

Scope of application

Pump equipment "Dzhileks" is used in various sectors of the private and public utilities. It ensures the functioning of the water supply system of private houses and provides watering of the garden plots by pumping liquid from underground sources (wells and wells), and also stabilizes heating systems.

Useful tips

Any equipment can not work smoothly forever, and any hydraulic machine to increase the pressure of the fluid has a certain resource for operation.In some cases (with technical education), you can disassemble the pump and fix minor problems with your own hands. But the company "Dzhileks" in the event of a problem recommends to seek the help of professionals to perform repairs.

The main types of breakdowns of pumping equipment:

- depressurization or rupture of the housing of the apparatus due to fluctuations in ambient temperature;

- failure of the electric motor as a result of different diameters of the output and cross-section of the engine (only professionals can correct the problem);

- pump idling (in this case, you must immediately suspend the operation of the equipment and seek the assistance of specialists).

Thanks to the reviews, you can learn about the durability and quality of products "Dzhileks." Pumps are distributed in all CIS countries. Most reviews of the manufacturer "Dzhileks" are positive. Many users are pleased that for a small price they can buy a good quality pump that will last several decades.

But there are a few negative reviews, indicating frequent breakdowns of the pumps.Therefore, you need to consider that the pump unit needs regular maintenance and repair.

You can often find complaints from users about clogging equipment, which leads to failure of the pumping machine. Indeed, most models of pumps "Dzhileks" are not designed for pumping contaminated liquids with solid particles.

In the next video you will find an overview of the submersible drainage pump Drainage 200/25.