Rules for connecting pumping stations

Living in the country temporarily or permanently is pleasant, but there are some difficulties in it. After all, not every holiday village has centralized communications. Residents of cottages and private houses often have to independently improve their living conditions.

One of the important points of a comfortable life is the constant availability of water. Help in this can pump station, which is quite easy to install yourself.

Special features

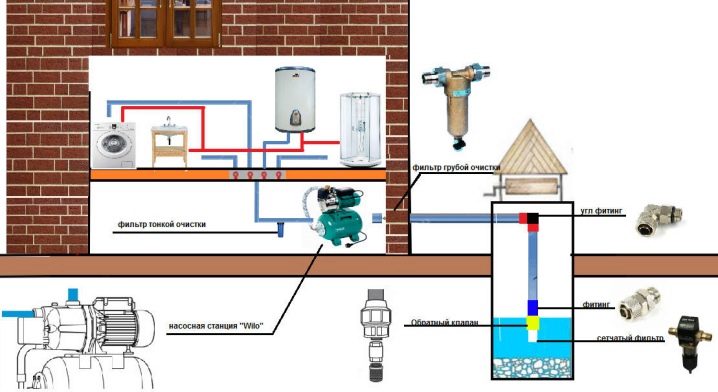

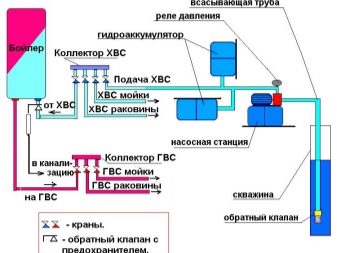

The pumping station is able to supply water to the water supply system at home, as well as automatically maintain the pressure in it. Due to this, it is possible to make a water supply network branched out, making it easy to connect various household appliances to it, for example, a boiler, a shower cabin,washing machine and so on.

The pumping station is a pump, hydroaccumulator, automation, filter, pipelines. A well or well will be suitable as a source for water intake. You can use water from open ponds or other reservoirs. In that case, if the water intake is made of a river, lake or pond, it should be used only for household needs or irrigation. It is better to take water from a well or a well for tests, the results of which will show whether it is economic or drinking.

Basically, the well depth in the sections is about 20 meters, which is the optimal value for the installation of automatic equipment. These parameters allow you to deliver water to the points of analysis without any additional equipment.

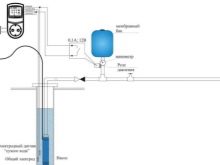

The pumping station operates in cycles, each of which is divided into two stages. When the pump turns on, water rises from the source, fills the system and the hydraulic tank. This happens until the pressure exceeds the upper limit. As soon as this has happened, the pressure switch shuts off the pump and the water stops flowing.

At the time of opening the taps or the use of water-consuming equipment, the flow of water occurs from the reservoir of the hydroaccumulator.The fluid from the hydraulic tank will be consumed until it reaches the lower limit. Then the pump turns on again and raises the water in the hydraulic tank.

Care must be taken that the number of cycles per hour does not exceed the maximum number of starts for the pump that is used.

The advantages of the pumping station are obvious:

- provides autonomous water supply in the house;

- improves the efficiency of the water supply system;

- allows to operate equipment and pipelines more safely;

- allows you to make a certain amount of water and supply it, even if the power supply is turned off;

- provides a stable pressure of water and maintains constant pressure;

- increases the service life of appliances and household appliances connected to the water supply system;

- reduces electricity costs and equipment wear and tear;

- allows you to choose a place for installation of the unit;

- has compact dimensions and low weight;

- just mount.

How to choose?

A pumping station for a dacha or a private house must cope with its functions; therefore, it should be chosen according to its needs. First of all, you should pay attention to a number of the following criteria.

Station specifications

And the most important is the performance of the device. It is best to opt for the pumping station, which provides water pressure from the well, satisfying all the needs in the house and at the local area.

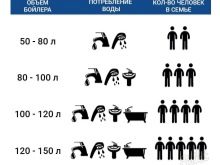

For a normal life of four people suitable device with medium or low power. As a rule, such units are equipped with a 20 liters hydroaccumulator. Such stations supply water from the well in the amount of 2-4 cubic meters per hour and provide a pressure of 45 meters or more. Also consider the size of the station, the water level with the pump running and disconnected, the type of filter, and the pipe width.

Well features, well

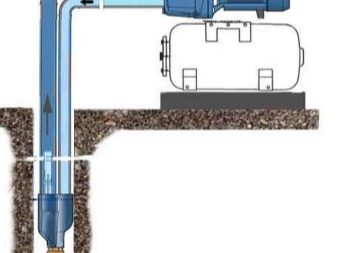

The finished pumping station is an installation with a surface pump that draws water from a well by vacuum. In this case, the ejector may be present in the design of the pump or be remote and it must be placed in the well. However, if you assemble and install a pumping station yourself, you can use a well or submersible pump. This is especially true if it is already in stock.

Pumping stations with a built-in ejector can only lift water from a depth of no more than 8 meters. However, they provide a good head that exceeds 40 meters. Such plants are not afraid of the ingress of air, so it is not necessary to fill them with water before starting work. They quietly pump air first, and then water.

Among the positive differences can also be noted high reliability and performance. Of course, there are also disadvantages. One of them is a strong noise, so these stations are mounted in the house, only in the back rooms with good sound insulation.

Stations with an external ejector are necessary for water intake from a depth of 20 meters or more. In this case, the ejector is placed in the well or borehole, becoming part of the intake assembly. To him from the installation are pressure and suction (vacuum) hoses. Through the pressure hose, water enters the ejector and a vacuum is formed in the suction chamber, and through the suction water rises up from the well.

Such stations are characterized by low noise and low power consumption. However, the efficiency of such devices does not exceed 40 percent.

Pump stations with a submersible pump are also practically not noisy. They can take water from any depth and even with a considerable distance of the water source from the building. At the same time they are not afraid of air leaks and small leaks in the pipeline. However, clean water is important for them, which means that a powerful filtration system and regular cleaning will be needed. Of the minuses, it is also worth noting the high cost of such pumps and possible difficulties during repair and maintenance.

Mounting Patterns

Before installation, you need to choose a place that is optimally suited for the pump station.

It should take into account:

- remoteness of the station from the well or well;

- temperature and humidity in the place where the pump will be installed;

- availability of free space for repair and maintenance of the device;

- possibility of soundproofing the room.

After the place of installation of station is chosen, its installation begins.

Difficulties in installing the finished pumping station is usually not.

- As a rule, preparatory work is carried out first. They consist in the fact that under the pumping device make a strong base, for example, of concrete and brick or wood.However, it should have a flat surface. You can also use a special bracket made of metal.

- When the pump is running, it vibrates strongly enough, as a result, leaks may form at the joints of the pipeline. To reduce vibration and its destructive action, it is necessary to lay a rubber mat or pads under the pump supports. You can also fix the legs more securely with anchor bolts.

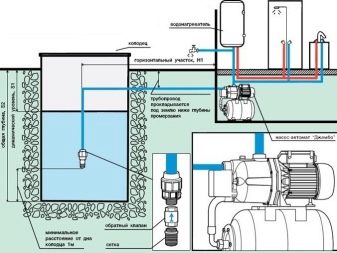

- In order for the pumping station to work without interruption, it is necessary to ensure a constant flow of water from the source. With year-round water consumption should take care of the protection from freezing. To do this, dig a trench from the well or the caisson of the well to the foundation of the house, into which the pipeline will then be laid, preferably with a diameter of 32 millimeters. It is imperative that the trench goes straight, without bends and turns, which lead to a decrease in pressure.

- It is necessary to bury the pipes below the level to which the soil in the given area freezes. Also, when forming a trench, it is necessary to take into account the slope in the direction of water intake, so that during the preservation period the water from the pipeline is drained. In the event that the groundwater is close,pipeline needs to be laid above their critical level. However, the pipes must be insulated and a heating cable must be used.

- If the pipeline needs to be led above ground level, it is necessary to organize good thermal insulation and heating. In this case, as a thermal insulation material, you can use basalt-based mineral wool.

- The water intake unit in the station with an integrated ejector and surface pump is assembled by connecting a metal mesh and a check valve to the outside of the polypropylene pipe. The mesh in this case is a coarse filter, and the check valve is necessary so that the pipes are stably filled with water. The valve can be fixed by means of a coupling having an external thread. If a submersible (borehole) pump is used, only a check valve and a pipe will be needed, and the coarse filter already exists in its design.

- The pump has a considerable weight, so it must be hung on a strong cable. When lowering the water intake unit in a device with a surface pump, one should take into account that the minimum distance from the bottom of the source to it should be at least 1 meter.For a submersible pump, this distance is 0.5 meters. It is also necessary to take into account changes in the level of the water mirror throughout the year, for example, in summer it usually becomes lower.

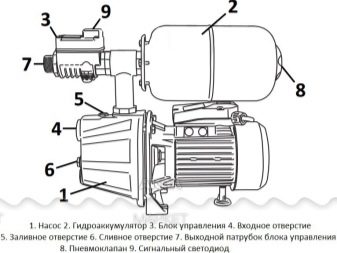

- When the pipeline is connected to the pump, install the hydroaccumulator and the control unit. It is best to connect them with a five-pin fitting, which is mounted in the discharge pipe in a convenient place. A pressure gauge and a pressure switch are screwed into it, and a hydroaccumulator is connected to the side entrance of the nozzle.

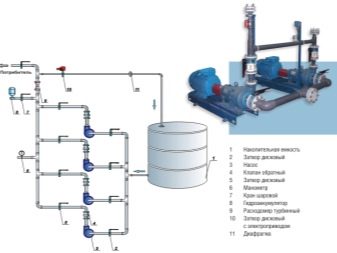

- When installing the surface elements of the station, it is necessary to take into account that all additional devices are best installed through check valves or ball valves with an American. This is necessary in order to easily remove the device when replacing or repairing it, without needing to drain water from the system.

- Of course, it is recommended to foresee the possibility of draining water from the system. To do this, it is necessary to form a tap in the pipeline by installing a tee with a drain valve connected to it. In this case, a coarse filter should be installed on the supply pipe, and a fine filter on the pressure pipe.

- Next is the connection of consumers to the pumping station. As a rule, the very first one is the dispensing water collector.

- Before starting the pumping station, it is necessary to take into account that the pump electric motor has a high capacity, therefore it is better to select your own power supply line for the whole structure, to make grounding, and also to install a voltage stabilizer.

- During installation, check the pressure of the air chamber of the accumulator. Its value should be 10 percent lower than the pump start pressure. This setting is done in working mode. As for preliminary values, they should be for a hydraulic tank with a capacity of 20-30 liters - from 1.4 to 1.7 bar, and with a capacity of 50-100 liters - from 1.7 to 1.9 bar.

- Before starting the installation with a surface pump for the first time, it is necessary to fill the working part of the system with water. This is done by unscrewing the plug from the filler hole, which is located at the top of the pump. If the pipeline is equipped with a filler funnel, you can use it. Water is poured until it begins to pour. After that, you must tightly close the valve (hole).

- When starting the pump must be connected to the mains. Remnants of air trapped in the funnel are removed, slightly opening the valve of the filling funnel of the pipeline.

- After switching on the device, water should flow out of the outlet of the pressure pipeline or the open tap of the water supply system within two to three minutes. In the event that water does not flow, the pump is turned off and water is added to the system and then switched on again. When the equipment has been successfully launched, it is necessary to “run in” it, and then adjust the settings of the pressure relay and hydraulic unit.

How to collect?

To assemble the pumping station yourself, you first need to understand what it is and how it works. You should also foresee the level of intensity of water use.

The main functional units of the station:

- centrifugal pump that raises and transports water to the house;

- hydraulic accumulator, which softens the water hammer;

- pressure switch;

- electric motor connected to a pump and a pressure switch;

- pressure gauge, allows you to determine the pressure;

- water intake system with check valve;

- line that connects the water intake and pump.

The pressure switch allows you to control its level in the system. For example, when the pressure decreases in comparison with a certain parameter, the engine starts, and if it rises, it switches off. By means of the manometer it is possible to make pressure adjustment. The most essential element is the hydroaccumulator. Sometimes a cumulative tank is used in pumping stations instead, but this design is outdated due to the large number of flaws.

Stations with accumulators are more reliable and practical. In addition, they are small in size, which simplifies installation.

How to install?

Installing a pumping station with your own hands in the house is often carried out in a heated room. The most ideal option would be a boiler room with good sound insulation. You can, of course, be installed in the corridor, hallway, pantry or bathroom. The main thing is away from the bedrooms.

Often for the location of the pumping station choose a basement or basement. However, this is on condition that they are heat, sound and waterproof. You can also install in a special box that is located in a subfield and has a hatch so that you have access to the equipment.

To install the station in the well, a specially equipped platform is used. It must necessarily be lower than the level of freezing. At the same time, it is necessary to insulate the well itself from above. This scheme is somewhat difficult to access the station.

In the caisson well, you can also install a station. For this, a room is being built around the well, which is buried a level lower than the soil freezing. Caisson must be closed and insulated near the surface of the earth. It is enough to leave a small hatch required for maintenance.

Also, the installation of the station is possible in a separate building or attached premises. Of course, such a structure requires not only warming, but also additional heating.

Installing a pumping station on your own allows you to save a lot. Depending on the connection of the pumping station to one or another source of water supply, there are various schemes for their installation. Correct installation depends on small parts like a check valve, stuffing box, filters, and so on. These little things can significantly improve and extend the work of the pumping station.

Tips

- After the water supply in the house is adjusted with the help of a pumping station, it needs to be serviced periodically. First of all, you need to constantly monitor the condition of the coarse filter and, if necessary, clean it. If this is not done, the station's performance will decrease, and the water will jerk. In that case, if the filter is completely clogged, the pump will operate in idle mode, and as a result, the station will turn off. How often you have to clean the filter depends on the amount of impurities in the water.

- It is advisable once a month, after idle time, repair or maintenance for the winter to check the pressure in the air compartment of the hydroaccumulator. It should be at the level of 1.2-1.5 atmospheres. If necessary, the air must be pumped with a compressor or an automobile pump. If the station is used exclusively in the summer period, it is necessary to drain the water from the system before the frost comes.

- When installing it is better to use pipes with a value larger than the calculated one. This will compensate for the various bends, turns, as well as the thickness of the foundation, if the station is installed in the house.

- Spin the parts in the process of installation or repair is best with a key.If this operation is performed by hand, then leaks may appear.

- When the pumping station is connected, to adjust it and determine the level of pressure at which it is turned off, it is required to pour about two liters of water into the receiving device. After that, the pump start to work. At that moment, when the station turned off, you need to register the level of water pressure. You also need to know the pressure value when the station starts automatically.

- With a certain water pressure, the pumping station sometimes does not turn off, this problem can be fixed with screws on the pressure switch. They are responsible for the degree of compression of the springs. To do this, remove the cover of the device, and then twist the screw, which has the letters "DR" in the direction of "+" or "-". To adjust the level of pressure at which the station will be turned on automatically, you must use a screw with the letter "P".

To learn how to connect a pump station, see the following video.