Technical characteristics of Grundfos pumping stations

In the modern world, pumping stations are used everywhere, which leads to the displacement of conventional pumps. The pumping station is a convenient, simple and economical device for the plumbing system.

The most common in the market segment of the water supply are Grundfos pumping stations. The equipment is used in various sectors of the national economy: from construction to the activity of public utilities. More than half of the sought-after pumps are accounted for by the manufacturer Grundfos.

Special features

For the water supply system, the buyer is offered a rich assortment of pump systems from Russian and foreign manufacturers.Brand Grundfos, which specializes in the manufacture and production of various options for pumping stations, is one of the first places. Pumping station provides uninterrupted supply of water from ponds and wells. Depending on the purpose, a specific model with certain characteristics is selected.

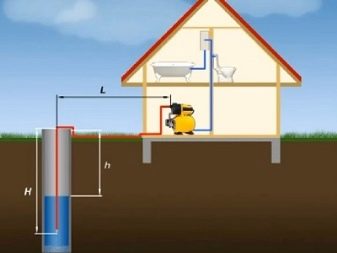

The Danish company produces equipment that allows you to work at a depth of 8 meters. Also, the Grundfos pumping system, thanks to advanced automation, facilitates the user's tasks during management. The automated system not only facilitates the regulation of the parameters of the station, but also protects the internal surface of the equipment from contamination and overheating.

Specifications such as: power, fence height, capacity and storage tank capacity are considered positive qualities of Grundfos products. The fundamental factor is the power, which lies in the range of 600-1500 watts.

In some models, control of the dry running is provided, as a result of which the pump is turned off when the liquid supply is stopped. In addition, the models ensure that the engine does not overheat.The equipment is designed for the presence in the water of various blockages, as well as resistant to possible problems with the electrical network.

Pumping equipment is used in such areas as:

- industrial buildings;

- medical institutions;

- national economy (for irrigation of vegetable gardens and garden plots);

- fire extinguishing, where technological communications comprise working and standby pumps, valves and fittings, manifolds, automation system and instrumentation;

- watered areas (to remove excess fluid);

- sewage system (for discharge to the surface of sewage);

- oil and gas fields that use special booster pumping stations.

The advantages of Grundfos pumping units include:

- the strength of the system, which is ensured by the quality of the material for the manufacture of pumping equipment;

- high performance;

- a wide range of model range: from the most powerful units that provide water supply for multi-storey buildings, to small pumps, accelerating the circulation of the heat agent and increasing the service life of the equipment;

- no need for constant care and supervision;

- high efficiency;

- lack of noise in models with injectors;

- high lifting capacity and high fluid pressure;

- security;

- convenient installation and disassembly;

- low consumption rates during operation and maintenance;

- long service life;

- simplicity and reliability;

- Corrosion protection.

Any technical equipment has its drawbacks, which should be guided when choosing a device. So, the disadvantages of Grundfos products include:

- for normal operation of the pumping equipment it is necessary to fill it with liquid, and functioning without water often leads to a breakdown of the apparatus or to the failure of the engine;

- the most dangerous part is the electronics of the automated system;

- In some models, the tanks have a small capacity, resulting in the need to install additional capacity.

Kinds

There are several types of Grundfos pumping stations.

JP Series Pumps

Self-priming centrifugal pumping units. The set of the pump station has a capacity, the volume of which depends on the performance of the pump itself (up to 60 liters).The most common irrigation system with an ejector, which provides the flow of liquid from open water systems. The injector is able to lift water from a depth of up to 25 meters, but at the same time the surface electric motor remains on the surface, and the lifting mechanism is lowered into the water. This water supply system operates almost silently.

A popular model of the series is the JP Basic 3PT pumping system (price matches the quality). It has the following characteristics:

- productivity - 3,6 m3 / hour;

- head - 47 m.

This model has found application in the household. Another, no less popular model in this series is the Hydrojet JP. It has enhanced strength characteristics and corrosion protection both outside and inside. Automation done in economy mode.

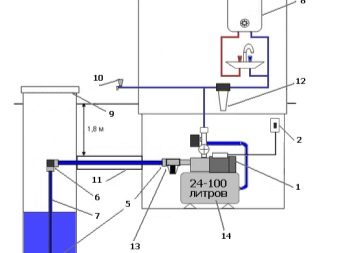

The pump unit during operation creates an overpressure (up to 5-6 atmospheres). It is equipped with a membrane-type battery capacity. For private homes such containers are available with a capacity of 24 liters. The pump has high power (0.75 kW) and pressure (43 meters).

MQ Series Pumps

The battery tank is divided into two parts, one of which is pumped fluid, and the second - the air under pressure. Due to this, the pressure throughout the system will be stable.Included with the pump has a hydraulic tank.

Among the most popular models of the series are the MQ 3-45, which operates with a membrane type storage tank. The system creates increased pressure. The pumping station provides water in the holiday villages. It can also be used as a booster. The pump has a capacity of 3 m3 per hour and self-priming up to 8 meters. Other, no less important features of MQ 3-45 include:

- pumping only clean (not very polluted) fluid, including rainwater;

- pumping extremely warm water (up to +30 degrees);

- dry run protection;

- electrical protection and insulation of electricity.

Pressure drops are very dangerous in these pumping stations. The unit is stably operated only at a voltage of 220 V, otherwise - the device will fail. To avoid damage, voltage stabilizers are often used.

Model MQ 3-35 has such advantages as: ease of installation and minimal user labor - the operation of the pump can be monitored through an electronic scoreboard that visualizes all processes. Also, this model provides minimal energy consumption, does not create noise.

Specifications:

- head - 35 meters;

- performance - 0.85 kW.

Hydro MX Series Pumps

Pumps are represented by 60 models. They are designed for various fire extinguishing systems, have the following characteristics:

- productivity - 55 kW with automatic start;

- head - 150 meters.

The pumping station provides automatic foam supply, as a result of which the price of such systems is very high. Hydro MX equipment is considered a new type of pumping station. The heightening system increases the pressure in the water supply system.

In everyday life, pumps of the model Grundfos Hydro 2000 are used. This compact station with an automatic mode of operation has the following characteristics:

- productivity - 500 m3 / hour;

- pressure -145 meters;

- fluid temperature - up to 70 degrees.

Scala2 Series Pumps

The devices are designed for trunk pipelines cottages, farmers and horticultural farms. In these models there is no increase in pressure, even if water intake occurs simultaneously from different areas. This is due to the presence of several connections at the pumping station. Automation sensors establish the optimum mode of operation of the pump, and cooling is carried out by pumping fluid.

Features of the pumping station:

- water intake - up to 8 meters;

- minimum noise - up to 50 dB;

- constancy of pressure;

- easy operation

Sewage pumping stations PUST

Structures are intended for arrangement of sewage system. These systems are slightly different in management. The user can set the mode of automatic flushing and reversing. At the same time the risk of equipment breakage as a result of clogging with solid components is minimized.

Pumps Series Hydrojet JP-5

The equipment has a small performance. The complete removable receiver allows you to save on energy consumption by reducing the number of motor starts. The device is one of the household booster stations and is designed to collect liquid from wells and boreholes.

Advantages of the station:

- high quality materials;

- efficiency at absorption from a great depth;

- anticorrosive protection of the case, which is provided with a nickel-chromium alloy and an additional protective layer;

- possibility of installation in rooms where the ambient temperature reaches +50 degrees;

- can be used for pumping warm water (up to +50 degrees).

Specifications:

- power - 0, 8 kW;

- head - 40 meters;

- suction capacity - up to 8 meters.

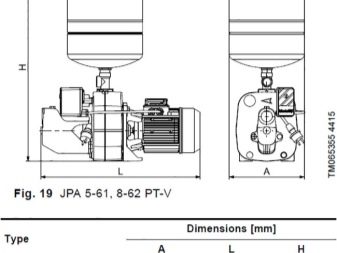

JPA PT models

Models are equipped with single-phase electric motors and are designed for pumping water, as well as non-aggressive non-viscous media (provided that they do not contain solid and abrasive particles, which can lead to mechanical damage to pump components). They are used for water supply of summer cottages, for the recruitment of water in large reservoirs, as well as for water supply to farms.

JPA PT has the following features:

- cumulative capacity (with a capacity of up to 20 liters), which is installed both horizontally and vertically;

- long service life due to the use of wear-resistant materials;

- high performance and low noise due to the presence of the valve, which is responsible for the automatic shutdown of the injector.

Device layout

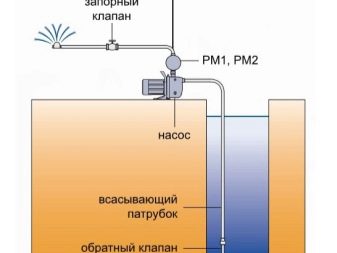

The Grundfos pressure station has the following structure:

- engine;

- receiver;

- curved blade inside the case;

- check valves;

- sensor duct;

- electronic control board.

Before you start the pumping station, you need to read the manufacturer's instructions.

Reviews

Before purchasing pumping equipment, you should read user reviews.

About the MQ 3-35 models, we can say that they are excellent for summer cottages, but have one significant drawback - they do not pump over the polluted liquid. Before installation, the well should be pumped with another unit. A protective grid is installed on the suction port. In the event that small solid particles enter the fan, the entire system will fail.

At Grundfos JP Basic 3pt, users have identified the following benefits:

- high build quality;

- pressure stability;

- no problems with the purchase of spare parts.

But there were some drawbacks to the equipment. So, after idle water gets rusty color.

Tips

When choosing a pumping station, first of all, you need to pay attention to performance and pressure. These two indicators are decisive in meeting the needs.

It is also necessary to take into account that for every 10 meters of the pipeline there is 1 meter of pressure.

Among the most common problems of the pumping station, consumers emit frequent switching on of the pump.

This problem occurs as a result of:

- depressurization of the thread that occurs due to the ingress of solid particles or wear;

- the lack of compressed air in the tank battery and low pressure in it;

- check valve failure;

- manometer breaks.

All the above malfunctions require immediate repair. You can solve the problem yourself, but it is best to trust the professionals.

In the next video you will find an overview of pump stations Grundfos JP.